If the insulation of the floor is carried out from the side of the living room, then it is important to take into account not only the effectiveness of the thermal insulation material, but also its thickness. Often in such situations, ceiling insulation with foil insulation is used. The material has many advantages, but the main advantage is maintaining the usable volume of the room. There are many types of foil insulators on sale; we will look at the two most popular types - penofol and isolon. These materials have similarities and differences, as well as common advantages and disadvantages. Knowledge of the technology for installing foil insulation on the ceiling will help you do all the work yourself.

Pros and cons of using Izolon insulation

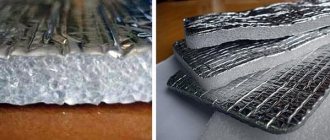

Light-weight plastic insulation Izolon is produced by foaming polyethylene with small cells and closed pores. The structure of the final product allows it to be used for heat, water and noise insulation of various structures. Externally, the material is similar to foam rubber and may have aluminum foil. Supplied in rolls, blocks, sheets.

- Specifics of Izolon

- Technical indicators

- Material Dimensions

- Main varieties

- Izolon PPE

- Izolon NPE

- Foil

- Areas of operation

- Features of loggia insulation

- Creation of wall thermal insulation

- Thermal insulation of floor covering

- Installation features

Mineral wool

Mineral wool is considered an economical insulation material. The main forms of release are mats from 10 cm thick and rolls from 5 cm thick.

It is used for both external and internal insulation, but has significant restrictions on use.

Without additional waterproofing, the use of this material in rooms with high humidity is not recommended. When saturated with water, mineral wool does not perform basic heat-protective functions. Insulation of the ceiling in the bathroom from the inside with mineral wool mats will have to be carried out in several stages, first fixing the base material, and then covering it with film, glassine or foil.

However, waterproofing in such rooms will also be required for other types of materials if the main floor is made of wood. This precaution will prevent condensation from forming directly on supporting structures and wood sheathing.

When working with any type of mineral wool, precautions must be taken.

Toxic and allergic-causing material must be handled using gloves and a tight suit; contact with skin is not allowed. A protective mask or respirator and goggles must be used. The advantage that distinguishes mineral wool from other popular insulation materials is its resistance to fire and rodent activity, which is an important advantage in the private sector.

When working with mineral wool, safety precautions must be observed.

Types of foil insulation

Nowadays, there are several types of this material. They differ from each other not only in the density of the top layer, but also in the type of heat insulator.

The main types of foil-based insulation:

- Polyethylene foam (isolon, penofol, folgoizol) . This type is produced in rolls. The material is distinguished by its low price. Foamed polyethylene is used to create insulation. It can be either stitched or unstitched. The thickness of the canvas ranges from 3-10 mm. A distinctive feature is the presence of a self-adhesive surface. Some types of foil polyethylene foam have a reinforced layer, which is made from fiberglass mesh. As for the foil layer, it can be on one or both sides.

- Mineral wool . The material is distinguished by high levels of moisture resistance. Foil-coated mineral wool is sold not only in rolls, but also in the form of slabs. Basalt is often used for its production. Thanks to it, the service life of the canvas increases significantly. The material is used everywhere. This is due to good thermal conductivity and fire safety.

- Styrofoam . This foil insulation is intended for the “warm floor” system. Its density ranges from 30-50 kg/m. Available in the form of rolls 50 cm wide. The thickness of the canvas ranges from 3-5 mm.

Foil foam with markings

Important! Any type of material acts as an excellent sound insulator.

When used correctly, each type of foil insulation will perform its functions to the maximum. To get what you want, you just need to follow simple rules.

Answers from experts

Grandfather Au:

ordinary food will not work - it is metal and if it can “reflect” some part of the radiation, then part of the convective flow will still heat it up, and since aluminum is an excellent conductor... Insulation is needed under the foil! The walls need to be insulated themselves, for example .termoplex /korund.php?table=korund

*:

Try to stick it with drool...

Marek Black:

You'd be better off insulating it with polystyrene foam from the outside. and the floor can be insulated. You talk to those who do this.

Evil Electrician:

I think you need to consult a construction store at the store or try installation

New:

First, prime it several times with bentonite, and then glue, but it’s better with a heat-insulating layer, even PVA, but there are some that are sold as self-adhesive on a heat-insulating backing.

Sergey Burmasov:

think about it, maybe galvanized iron, or better yet stainless steel, because foil is weak

Nina Ilyina:

oh, if the sticker is crooked, get a magnifying glass, with a focus like in ancient Greece they burned the fleet)

Albert Belkov:

I use Termoizol - foil on foam, it’s easy to work with: I insulate steel baths - they turn out no worse than cast iron ones, they are warm. And food grade can be glued onto cardboard with slots for hooks for easy insertion.

Yuri Martysyuk:

Buy penofol, they are sold in different thicknesses. It can be self-adhesive, but if not, try double-sided tape!

Chuck Kazemierczak:

If the foil is glued to the glass with egg yolk, then it will definitely stick to the concrete

Dmitry Nizyaev:

Double-sided tape. He then o? It will hold, but nothing more is required.

egor ag:

Why insulate at all? I've never done this. Insulation only retains heat, but does not generate it. And no insulation will keep the engine warm overnight. Moreover, the hood is not even the surface of the engine itself.

Doctor:

Bolts or rivets

Pavel Voronin:

why attach it at all, just put it in when you need to twist it and put it away

zheka-zloy:

narrow stripes and reinforced adhesive tape around the perimeter, see all this is fair... and the discarded material is used as a reflector for radiators in apartments (it is believed that it increases efficiency when heating in winter)))

kurt:

called FOLGOIZOL

Engineer:

If it’s more durable, then formos /produkciya/klej_adgezivy/klej_sprei-3m/80-scotch-weld/If you stick it and unstick it, then lenta-plus m/catalog/kley/49

kenny unknown:

The material is penofol, the trouble is that it will definitely melt in the collector area. It is glued with liquid nails from the installation company for products made of PVC and polystyrene.

Folgoizolon - foil insulation for the ceiling

Folgoizolon is a fairly new insulation on the market, providing high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, designated PPE and NPE.

- lightness of the material , which makes it possible to finish any base, provided there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the dimensions of the room, maintaining its usable area;

- elasticity - unlike some insulation materials (such as polystyrene foam boards), this foil material allows you to avoid spending time on careful preliminary leveling;

- multifunctionality , or a “3 in 1” combination, contributes to a significant reduction in the costs of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil isolon can be easily cut with a sharp knife, which eliminates the need to use specialized tools;

- the absence of moisture absorption is one of the most important factors that ensures the extension of the service life of not only the foil-isolon itself, but also the structural elements it covers;

- environmental safety - does not emit harmful substances even at temperatures above 100ºС. Among other things, this material will never harbor insects or rodents.

So, is it possible to insulate the ceiling with foil insulation? Taking into account the material above, we can safely give a positive answer.

Useful video

Let's look at the video about the types of foil insulation:

Thus, for internal insulation of the ceiling it is best to use foil insulation. The unique characteristics of this product, elasticity and lightness ensure its demand in the market.

Polyethylene foil insulation has gained such wide popularity that the name of the famous brand – “Penofol” – has become a household name. But often homeowners and would-be craftsmen use the material thoughtlessly, violating the thermal and humidity conditions of the country house. Sellers are also cunning, greatly exaggerating the real performance of this heat insulator. Let’s clarify the situation: we’ll tell you where Penofol insulation is effectively used and describe the technology in detail according to the manufacturer’s instructions.

Insulation technology

It's time to tell how reflective thermal insulation is installed on the ceiling in a private house. To install insulation on a self-adhesive base, you do not need to construct a sheathing on the base. The base needs to be well prepared - cleaned of old finishes, putty on defects and uneven surfaces. The insulation is glued to the primed surface. To do this, remove the protective film from the adhesive layer.

The heat insulator without an adhesive base is mounted between two battens. Moreover, the insulation is laid in two layers - the first is fixed directly to the main ceiling, after which the sheathing is mounted with other heat-insulating material embedded in its cells, and then another layer of penofol or isolon is attached to the sheathing from below. Next comes another lathing to create an air gap between the insulation and the finish. This ventilation gap will prevent condensation from accumulating.

Preparing tools before work

a layer of vapor barrier must be laid between the insulation itself and the wall .

If one-sided foil insulation was chosen, that is, the foil is on only one side, the main layer will come into contact with the wooden wall, and this is unacceptable, especially if the insulation is based on basalt wool. If the choice was made in favor of double-sided foil insulation, then a vapor barrier is not needed.

It is necessary to ensure air flow between the wall and the insulator so that the walls can be ventilated and moisture does not accumulate. To do this, you need to attach 20 mm thick slats to the wall. It would be enough.

Tools for work:

- construction stapler;

- foil adhesive tape;

- dowels and screws;

- screwdriver;

- insulation;

- vapor barrier.

If a product with a self-adhesive side is chosen as insulation, then a stapler will not be needed. The adhesive side adheres well to slats and other surfaces. In this case, you will need a degreaser, such as a solvent.

Features of thermal insulation with penofol ceiling

Penofol is a multilayer synthetic material, the basis of which is a sheet of foamed polyethylene foam. It is considered an unusual insulator due to its specific operating principle. The outside of the sheet is covered with aluminum foil up to 10 microns thick to reflect heat in the direction where it is most needed. The presence of a mirror surface retains 97% of heat.

There are several modifications of the product, which differ in the placement of a metallized shell on one or two sides and the presence of an adhesive layer.

The insulation has unique properties that prevent heat loss through convection, conduction and infrared radiation. Other modifications do not have such a wide range of protection. It is capable of replacing several different insulators or one, but of great thickness. For reference, the standard material thickness is 2-10 mm. There are more massive samples, but they are inconvenient to work with.

Penofol is used in domestic and industrial premises as primary and additional insulation. In addition to the main function, it solves the issue of vapor barrier. It is often used in baths, saunas, and steam rooms.

The material cannot be secured with nails or screws due to a significant loss of reflectivity if the foil is damaged. Therefore, manufacturers recommend fixing it with an adhesive solution. The result improves if there is a gap of 15-20 mm between the ceiling and the panel. Usually, after installation, a decorative ceiling is made under the panel, but in basements, garages and industrial buildings it is left “bare”.

Often used with other insulators such as foam. In such structures, foam plastic is attached first, then insulation is glued to it, and the entire “pie” is covered with sheets of drywall. The room will maintain its temperature perfectly: cold does not penetrate from the inside, and heat does not escape outside.

Scope of application

With the help of Penofol, you can significantly increase the energy efficiency of any home - a private house or apartment. Where the material is used:

- thermal insulation of the roof of an attic or cold attic;

- covering ceilings and walls from the inside - as an addition to the “pie” of basic insulation;

- under the finished floor covering laid along the joists;

- strengthening the outer thermal insulation layer;

- internal insulation of balconies and loggias;

- coating of heating pipes and ventilation ducts.

Addition. Many drivers use “penofol” type C (adhesive surface) to insulate the car body – interior floors, doors and roof. The cut blanks are glued to the metal on top of the bitumen vibration insulation.

It is not advisable to use the material as an independent insulation of external fences - you will not achieve the desired effect, only protect the building from wind blowing. An exception is products of large thickness from 20 to 150 mm of the Tepofol brand, suitable for complete insulation of a house.

Features of installation of foil insulation

If work is carried out in a log house, then, as a rule, foil insulation is used. The material can be attached directly to logs (beams) using a stapler with the aluminum side facing the inside of the room. Depending on the thickness of the cladding, butt or overlap joints are used. The joints are taped with metallized tape.

Air gap between foil and lining

To drain condensate, it is planned to release foil material from the ceiling to the wall, and from the wall to the floor. Slats with a thickness of at least 3 cm are attached on top of the foil insulation. They perform two functions: they serve as a lathing for the finishing cladding and form an air gap between the foil and the lining. The gap is important in order to exclude direct heat transfer from the lining through the aluminum layer.

The arrangement of baths in rooms with brick or concrete walls has a single, but very significant difference from work in log houses: contact of foil material with the load-bearing wall is strictly unacceptable. First, the main insulation is carried out with heat insulators of sufficient thickness. Then the foil material is installed. The gap between the foil plane and the finishing lining must be observed.

How to attach penofol

Attach penofol with the foil side facing the inside of the room. A greater thermal insulation effect is created by an additional air layer 1-2 cm thick (using a backing - sheathing).

By watching the video you will learn more:

https://youtube.com/watch?v=zx8WiU-qxvI

Glue of different compositions for polyethylene foam can be ready-made or requires preparation on site. You must carefully read the instructions for the selected mixture:

The glue is applied in an even layer, paying special attention to the edges. Before sticking, you need to wait up to 1 minute so that the composition has time to be slightly absorbed

This ensures better adhesive properties. Attach the treated penofol to the insulated surface. The plates are fastened joint to joint, but not overlapping; setting time varies depending on the characteristics of the glue (at least 15 seconds); smooth the surface of the polyethylene foam, removing folds. Tape the seams, you can use foil tape; glued insulation in residential premises requires additional decorative finishing. The last layer of the structure (plasterboard or lining) is installed on the sheathing.

Nothing brings satisfaction more than a job done correctly and skillfully. If you follow all the recommendations, attaching the insulation will not cause much trouble.

You can only stick it with double-sided tape

it has been proven that it holds tightly if you glue it along the joints and put one strip of tape in the middle of the strip. If this doesn’t appeal, you can try titanium glue for foam false ceilings (it’s sold everywhere and is inexpensive). again, it has been proven that it does not dissolve penofol and holds well. It’s just more hassle - you have to press the penophone until it sets

It is no longer possible to know who first came up with the idea of using expanded polystyrene instead of a building material for thermal insulation of buildings - initially its area of use was limited to the transportation of furniture and equipment, where it acted as a sealant. In this article we will try to figure out how to properly glue polystyrene foam to metal and concrete.

The most popular type of insulation with foil for interior finishing is aluform

Bestizol or alufom is a bubble base consisting of aluminum foil (outer layer) and polyethylene (inner layer) on one side. The foil acts as a reflector of solar and heat rays. The polyethylene layer has a cellular structure and neutralizes sound waves and shocks. The advantage of this material is low thermal conductivity.

Bestizol can be used in both cold and hot weather. Due to its small thickness (1 cm), the material is used for hard-to-reach places:

- for winding ventilation pipes;

- air duct coverings;

- insulation of pipelines and other outlet communications.

Is it worth insulating a house with foil insulation?

This also helps to reduce external noise levels and get rid of drafts. The anti-corrosion properties of aluminum foil are useful in rooms with high humidity (baths, saunas) or when condensation occurs. Insulating the chimney, in particular with stone wool insulation, will help avoid unnecessary heat loss into the air.

Important positive qualities include low cost with a long service life - up to 50 years. The ability to install the insulator yourself without involving specialists is also appreciated.

The disadvantages of this material stem from its advantages: insulation with foil retains not only heat, but also moisture and odors. These side effects are most noticeable when you want to wrap the entire house in foil: floor, walls, ceiling. In this case, regular ventilation of the premises is recommended.

With maximum use of foil insulation, especially in rural areas, the cellular signal strength is likely to decrease, which can lead to frequent disconnections while talking or using the Internet. Placing the PC or the subscriber itself closer to the window will solve this problem.

What is Folgoizolon and its varieties

There are about a dozen brands of insulation materials based on polyethylene foam with a foil layer on the domestic market; consumers are well aware of such brands of roll and sheet insulation as Penofol, Stizol, Polifom, Tepofol, Isoflex, Izolaym, Stenofon, pipe insulation Energoflex, Jermaflex.

Folgoizolon, as the name implies, is a multilayer material, the main components of which are foamed polyethylene and a foil backing. Thus, the insulation provides double protection against heat loss - it insulates the insulated object from contact with cold air and reflects the infrared spectrum of thermal radiation.

In the production of polyethylene, its structure is often modified by linking molecular links into a three-dimensional network with the formation of cross-links (cross-linking); the technology consists of removing atomic hydrogen from chains of molecules and using the vacant spaces in the lattice to connect them. If cross-linking is carried out in foam material, it allows you to increase its density and strength, reduce thermal conductivity and moisture absorption, increase chemical resistance, noise absorption, and increase service life.

During the production process, foaming and cross-linking of polyethylene is carried out using various technologies using physical and chemical processes; on this basis, waterproof Folgoizolon is divided into the following groups:

- NPE is polyethylene foam produced using conventional technology without cross-linking the molecular structure.

- PPE is ordinary polyethylene foam, foamed in a vertical oven using the physical cross-linking method.

- PPE-NR is polyethylene foam made using physical cross-linking technology in a horizontal oven.

- PPE-NH is chemically cross-linked polyethylene foam in a horizontal oven.

- PSEV - penosevilene cross-linked by physical method.

Based on the technology and method of applying the foil layer, Izolon is divided into the following classes, the designation of which is indicated in the marking together with the letter F (designation of Folgoizolon):

- A - aluminum foil is applied on one side, sometimes the designation (LA) is found.

- B - double-sided layer of foil around the polyethylene base.

- C - a foil film is applied on one side, and an adhesive composition is applied on the other, the resulting self-adhesive sheet is convenient for mounting on ceilings and vertical surfaces.

- CP is a designation for corrugated (corrugated) material consisting of layers of fiberglass, polyethylene and aluminum foil.

- ALP is a type of foil self-adhesive Izolon with a dense polyethylene film with a cross-section of up to 3 mm.

The structure of one of the brands and the scheme for using Folgoizolon in the home

How to glue isolon to concrete

how to glue isolon to concrete

During the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important construction requirements for heat and sound insulation. Such material, for example, is isolon or polyethylene foam. The use of isolon allows you to reduce construction time and heating costs due to the excellent thermal insulation properties of this material.

Isolon has the following characteristics: 1. Low density (light weight) and at the same time good thermal insulation properties. A 10 mm layer of isolon can replace a 15 mm layer of mineral wool, 45 mm of wood or 150 mm of brickwork.

This reduces the weight of structures and helps save usable space. 2. Freons and other substances hazardous to humans are not used in the production of isolon. Izolon is non-toxic, does not affect the skin, and does not emit harmful substances when used. Has a hygiene certificate, 3.

Isolon is a chemically inert material and is not affected by organic solvents. It is possible to combine isolon with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to rotting, mold and aging, 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Isolon is used as a backing for carpet, laminate, linoleum or parquet. Izolon sheets are used to separate adjacent walls if the adjacent walls are subject to movement or vibration, 5. The operating temperature range is from -60`C to +75`C, and if there are no mechanical loads, the operating temperature increases to +100`C. With the exception of special isolons with fire-extinguishing additives, isolon is a flammable material. But at temperatures less than +140`С no harmful substances are released from isolon, 6.

Izolon is produced in different thicknesses and densities (with different foaming coefficients) and is supplied in the form of rolls, sheets, tape or blocks. This significantly increases the possibilities of using isolon in construction. Depending on the production method, isolon is divided into cross-linked (when molecules are cross-linked, a network molecular model is formed) and non-cross-linked (there are no chemical bonds between the polymer molecules).

Cross-linked isolon, compared to non-cross-linked, has improved characteristics: 1. Heat resistance increases (the operating temperature range increases by 20°C), 2. The service life of the material increases due to increased resistance to ultraviolet radiation and organic solvents: oil, gasoline, diesel fuel, Izolon can be used 1.

For sound, steam, heat, waterproofing of walls, foundations, floors and roofs for country houses, cottages, garages, 2. As a sealant under slate, ribbed metal roofs or tiles, 3. Isolon tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect from dust, moisture and noise, 4. Izolon strips can be used to insulate cold and hot heating pipes, as well as ventilation pipes, 5. Izolon with a polymer metallized film is used as a heat-reflecting screen to protect against heat loss through the areas behind the radiators of the walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other heating devices is reflected back into the room. The big advantage of isolon is its ease of use and installation. It is easy to cut and can be glued to the surface with adhesives (pre-glued surfaces should be cleaned of dust and degreased).

To attach to a smooth surface, use screws, slats, and furniture staplers. To connect the joints, use a hair dryer. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, it is possible to significantly reduce construction time and heating costs.

How to glue isolon to concrete

How to glue Izolon to concrete How to glue Izolon to concrete During the construction of industrial facilities and residential buildings to ensure the most important construction requirements for heat and sound insulation

Description of material

Isolon thermal insulation consists of artificially foamed polyethylene, which has the form of small cells or pores. Increased thermal insulation characteristics are achieved thanks to the porous structure. Using it, various surfaces and entire structures are insulated and waterproofed. The finished material can be in the form of a sheet, tape, block or roll.

The main scope of application is hydro, sound and thermal insulation. It is also used in household tasks, as it has better characteristics compared to similar products. The special structure makes isolon a durable and wear-resistant material.

It is often used in conjunction with other insulators. For example, if the task is thermal insulation of the surface, it is combined with polystyrene foam or expanded polystyrene. This “pie” allows for high-quality insulation of walls, interfloor ceilings and loggias. It also serves as an insulating coating when screeding floors. It is also used in car production - it insulates bodies and protects metal parts from corrosion.

What glue to use for gluing polyethylene composition

The easiest way is to purchase structural adhesive in the store, which contains methyl acrylate. Its properties ensure rapid softening of polyethylene and its further gluing. The glue also contains inorganic and organic acids and xylene, chromic anhydride and various additives.

The advantage of using the mixture is that no additional processing of the material is required. However, polyethylene glue is quite toxic, so it is recommended to carry out work outdoors. The glue acquires its best properties at a temperature of +35C; it is not afraid of moisture, but is flammable. It is better to buy it in specialized stores so as not to run into a fake.

This technique allows you to obtain a strong, unbreakable seam. Among the disadvantages of the method, it is worth noting the deformation of the edges of the product.

Mixtures for combining polymers are available for sale, with a consistency similar to a thick paste. An activator is included in the kit. After adding it to polyethylene glue, it acquires the necessary consistency and can be used for the near future.

Gluing polyethylene - step-by-step instructions

To glue polyethylene, you do not need special knowledge and skills. Even beginners can cope with the task at home.

The operating procedure is as follows:

- Clean the surface and degrease it. Some manufacturers claim that this step is not mandatory, but experts still recommend spending a few minutes and under no circumstances skipping it.

- Apply glue to the treated material. It will only take a few minutes for it to harden, so the parts need to be attached to each other without delay.

- Leave the glued polyethylene elements for several hours until the glue completely sets.

In general, this algorithm is similar to working with any glue. However, you should take care to use protective gloves, since the glue can cause allergic reactions and is quite toxic.

It is more convenient to apply the adhesive using a glue gun, which can be loaded with ready-made cartridges. The mixture of them is distributed evenly, so it is easy to achieve the desired dosage. If you are planning a large amount of work, this device is worth investing in.

VIDEO ON THE TOPIC

How to glue foamed polyethylene

Foamed polyethylene has a porous structure, therefore it provides high-quality heat, steam and waterproofing.

Due to its low price, ease of operation and installation, it is actively used in construction. The most popular brands are Izolon, Vilaterm, Energoflex, Polyfom, Temaflex.

If there is a need to glue foam insulation, experts recommend two-component adhesives based on methyl acrylate. Such compositions are characterized by high adhesion and are suitable for working with polyvinyl chloride, polyethylene, and polypropylene. An example is the well-known adhesive composition “Easy-Mix PE-PP” from WEICON.

Typically, in order to achieve high results in gluing polyethylene foam, the following procedures are additionally required:

- surface treatment by sandblasting or grinding,

- physical treatment, for example, thermal fire,

- chemical treatment (usually the fluoridation method is used).

But when using “Easy-Mix PE-PP” you can do without additional preparation and treatment of surfaces due to the “primer” included in the composition, which changes the structure of the materials being glued, after which they easily adhere.

The use of “Easy-Mix PE-PP” adhesive for working with polyethylene foam both on an industrial scale and at home allows you to reliably and quickly fasten materials, while it is ready for use immediately after opening the package, it is easy to dose and mix, and apply.

The glue has a soft paste-like consistency, is not afraid of conditional “aging” and retains its properties for a long time even in open areas.

Varieties

Despite its apparent simplicity, it has several varieties that differ greatly in their characteristics:

- Type "A". This is the most common species. It is covered with a foil layer on only one side.

- Type "B". The foil coating is already on both sides of the material.

- Variety marked “C”. It will differ from the others by the presence of a self-adhesive coating on one side. This is a very useful feature during installation.

- The type of polyethylene foam, marked with the letters “ALP,” has a foil layer on both sides, but at the same time, one of the foil-covered sides is also protected by a film coating.

- Penofol types “R” and “M” have foil only on one side, but have a relief structure.

- Products marked “AIR” are used to create air ducts.

- Another type, marked with the word “NET”, is used for thermal insulation of heating mains, air ducts and pipelines.

The last four types are not used very often, but rather on a specialized basis. Therefore, you are unlikely to encounter them in everyday use. But polyethylene foam, designated by the letters “A”, “B” and “C”, can be found much more often, and is actively used for domestic purposes, among which the main thing will be the insulation of all kinds of surfaces.

The first type of this heat insulator is mainly used as an auxiliary material when creating a thermal cushion. It works well as a vapor barrier.

For complete heat conservation, a material with more significant characteristics is needed. It is best to create an independent layer of thermal insulation, use either polyethylene foam, marked with the letter “B”, or, a variety, marked “C”.

Price

in the production of foil insulation on the Russian market :

- Jermaflex;

- Izolon;

- Penofol;

- Tepofol;

- Folgoizol;

- Ecofol.

| Firm | Characteristics | Price |

| Jermaflex | 1.2 m x 8 mm | 80 RUR/m² |

| Izolon | Type A, thickness from 2 to 10 mm, length 1 m | 140-260 RUR/m² |

| Penofol | Type A, thickness from 3 to 20 mm, length 36-12 m (the thicker, the shorter the meter) | 53-278 RUR/roll |

| Tepofol | Type A, thickness from 2 to 10 mm, length 2.5 m | 40-1200 RUR/roll |

| Folgoizol | Type A, thickness 10 mm, length 15 m | 1650 RUR/roll |

| Ecofol | Type A, thickness from 2 to 15 mm, length 25-10 m | 780-1030 RUR/roll |