There is probably no person in Russia who has come into close contact with construction and repair work who does not know products under the TechnoNIKOL brand. And this is not surprising. In the building materials market, the company offers the buyer heat and waterproof materials, vapor barrier films and membranes, foams, adhesives, sealants, fire retardants, roofing, etc.

There is a particularly large selection of insulation materials made from different raw materials using different technologies. There are several dozen types of them, for all occasions. In this diversity it is easy to get confused not only for the “home craftsman”, but also for the professional builder. The editors of the StroyGuru portal decided to take their visitors on an excursion into the world of TechnoNIKOL thermal insulation.

A little about the company

The company began its history in 1992. In less than 30 years, the company has grown into a powerful corporation producing building materials for various purposes. Today TechnoNIKOL is a leading European manufacturer of highly efficient and reliable building materials and systems. This result became possible thanks to the symbiosis of world experience with our own scientific developments.

Products are manufactured at 53 factories in 7 countries: Russia, Belarus, Great Britain, Germany, Italy, Lithuania and the Czech Republic. The production company's products are supplied to 95 countries worth about 1.5 billion US dollars per year (103.7 billion rubles in 2022).

The basis for the progressive development of the corporation:

- constant search in scientific centers for new types of materials;

- introduction of advanced technologies;

- training builders in innovative technologies for using cutting-edge materials.

All of the above also applies to the subject of our excursion - TechnoNIKOL brand insulation.

Logistics parameters

| Name of product | Length | Width | Thickness | Quantity per pack | Quantity per pallet | Loading norm in a truck, volume, cubic meters | |||

| mm | mm | mm | Slabs, pcs. | m2 | m3 | Packs, pcs. | m3 | 92 m3 | |

| TECHNOVENT STANDARD | 1200 | 600 | 50 | 6 | 4,3200 | 0,2160 | 32 | 6,9120 | 76,0320 |

| 1200 | 600 | 60 | 5 | 3,6000 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 70 | 4 | 2,8800 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 80 | 5 | 3,6000 | 0,2880 | 24 | 6,9120 | 76,0320 | |

| 1200 | 600 | 90 | 5 | 3,6000 | 0,3240 | 20 | 6,4800 | 71,2800 | |

| 1200 | 600 | 100 | 4 | 2,8800 | 0,2880 | 24 | 6,9120 | 76,0320 | |

| 1200 | 600 | 110 | 3 | 2,1600 | 0,2376 | 28 | 6,6528 | 73,1808 | |

| 1200 | 600 | 120 | 2 | 1,4400 | 0,1728 | 40 | 6,9120 | 76,0320 | |

| 1200 | 600 | 130 | 2 | 1,4400 | 0,1872 | 36 | 6,7392 | 74,1312 | |

| 1200 | 600 | 140 | 2 | 1,4400 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 150 | 2 | 1,4400 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 160 | 2 | 1,4400 | 0,2304 | 28 | 6,4512 | 70,9632 | |

| 1200 | 600 | 170 | 2 | 1,4400 | 0,2448 | 28 | 6,8544 | 75,3984 | |

| 1200 | 600 | 180 | 2 | 1,4400 | 0,2592 | 24 | 6,2208 | 68,4288 | |

| 1200 | 600 | 190 | 2 | 1,4400 | 0,2736 | 24 | 6,5664 | 72,2304 | |

| 1200 | 600 | 200 | 2 | 1,4400 | 0,2880 | 24 | 6,9120 | 76,0320 | |

| TECHNOVENT OPTIMA | 1200 | 600 | 50 | 6 | 4,3200 | 0,2160 | 32 | 6,9120 | 76,0320 |

| 1200 | 600 | 60 | 5 | 3,6000 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 70 | 4 | 2,8800 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 80 | 5 | 3,6000 | 0,2880 | 24 | 6,9120 | 76,0320 | |

| 1200 | 600 | 90 | 4 | 2,8800 | 0,2592 | 24 | 6,2208 | 68,4288 | |

| 1200 | 600 | 100 | 4 | 2,8800 | 0,2880 | 24 | 6,9120 | 76,0320 | |

| 1200 | 600 | 110 | 3 | 2,1600 | 0,2376 | 28 | 6,6528 | 73,1808 | |

| 1200 | 600 | 120 | 2 | 1,4400 | 0,1728 | 40 | 6,9120 | 76,0320 | |

| 1200 | 600 | 130 | 2 | 1,4400 | 0,1872 | 36 | 6,7392 | 74,1312 | |

| 1200 | 600 | 140 | 2 | 1,4400 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 150 | 2 | 1,4400 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 160 | 2 | 1,4400 | 0,2304 | 28 | 6,4512 | 70,9632 | |

| 1200 | 600 | 170 | 2 | 1,4400 | 0,2448 | 28 | 6,8544 | 75,3984 | |

| 1200 | 600 | 180 | 2 | 1,4400 | 0,2592 | 24 | 6,2208 | 68,4288 | |

| TECHNOVENT PROF | 1200 | 600 | 50 | 6 | 4,3200 | 0,2160 | 32 | 6,9120 | 76,0320 |

| 1200 | 600 | 60 | 5 | 3,6000 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 70 | 4 | 2,8800 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 80 | 3 | 2,1600 | 0,1728 | 40 | 6,9120 | 76,0320 | |

| 1200 | 600 | 90 | 3 | 2,1600 | 0,1944 | 32 | 6,2208 | 68,4288 | |

| 1200 | 600 | 100 | 3 | 2,1600 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 110 | 3 | 2,1600 | 0,2376 | 28 | 6,6528 | 73,1808 | |

| 1200 | 600 | 120 | 2 | 1,4400 | 0,1728 | 40 | 6,9120 | 76,0320 | |

| 1200 | 600 | 130 | 2 | 1,4400 | 0,1872 | 36 | 6,7392 | 74,1312 | |

| 1200 | 600 | 140 | 2 | 1,4400 | 0,2016 | 32 | 6,4512 | 70,9632 | |

| 1200 | 600 | 150 | 2 | 1,4400 | 0,2160 | 32 | 6,9120 | 76,0320 | |

| 1200 | 600 | 160 | 2 | 1,4400 | 0,2304 | 28 | 6,4512 | 70,9632 | |

| 1200 | 600 | 170 | 2 | 1,4400 | 0,2448 | 28 | 6,8544 | 75,3984 | |

| 1200 | 600 | 180 | 2 | 1,4400 | 0,2592 | 24 | 6,2208 | 68,4288 |

Types of insulation

has mastered the production of 4 types of insulation from different raw materials:

- basalt (mineral wool insulation);

- extruded polystyrene foam;

- semi-rigid polyurethane foam (PPU);

- polyisocyanurate foam (PIR thermal insulation boards, better known among builders as PPU boards).

Basalt wool

Basalt insulation "TechnoNIKOL" is made from rocks of basalt or gabbro (rock wool). The production process begins with crushing the stone. After this, the rock is fed into the furnace, where at high temperatures (up to +1500oC) it melts to a fluid state. The liquid mass is fed into a centrifuge, where very fine fibers are formed with the help of a strong air flow.

The process continues by irrigating the shapeless mass, consisting of stone threads, with plasticizers: formaldehyde or arbolo-urea resin. During the cooling process, at a temperature of 200oC, the resin polymerizes, forming a thin protective layer on the fibers. The production process is completed on a conveyor belt, where the fibers are compressed to a given density and then cut to the required width and length.

Extruded polystyrene foam

Synthetic insulation material made from granulated polystyrene, obtained by foaming the raw material and then pressing it through a special mold (the technology is called extrusion), is called extruded polystyrene foam. Available in sheets with a thickness of 20 to 100 mm. Keeps warm perfectly. Lightweight yet durable.

It has a strong resemblance in appearance to polystyrene foam. Therefore, the company paints its products in orange and silver, with the addition of carbon fiber.

Semi-rigid polyurethane foam

The company’s line of thermal insulators also includes sprayed insulation “TechnoNIKOL” - one-component polyurethane foam. Available in tubes. It is sprayed using a special nozzle onto a mounting gun familiar to builders.

PPU forms a seamless, low thermal conductivity, thermal insulation layer with small, open pores. It adheres well to all types of building materials, with the exception of polyethylene.

Thermal insulation PIR

heat-insulating material made of polyol and isocyanate in the form of plates is positioned as an innovative product of a new generation. To enhance the impression of the new product, the insulation was called PIR thermal insulation. This misleads many consumers. Indeed, in reality, this is rigid polyurethane foam in the form of slabs, familiar to many builders. What PU foam sheets are is described in detail in the work “PPU Boards”.

How it is made

When producing TechnoNIKOL mineral wool, the rock is pre-loaded into melting furnaces and heated to a temperature of 1400-1500 degrees.

Next, the molten rock mass is poured into a special centrifuge. Here, spinning tops rotating at speeds of up to 7000 rpm tear it into small fibers. During this procedure, binders are poured into the centrifuge . At the next stage, the fibers already impregnated with phenol-formaldehyde resin enter the lamella machine and are formed into a carpet of a given thickness.

Mineral wool of the TechnoNIKOL brand is manufactured by the domestic company of the same name, founded at the end of the last century. At the moment, it includes more than 20 enterprises and 120 retail outlets operating throughout the country. Mineral wool from this manufacturer is made from high-quality materials using modern equipment, and therefore is extremely popular not only in Russia, but also abroad.

Features of insulation

Thermal insulation "TechnoNikol" is a unique product of its kind. It is distinguished from its competitors (Knauf, Izover, Rockwool, etc.) by its versatility, high quality and reasonable price.

Versatility. It is expressed in the areas of application and the materials used. Thus, the company’s products can be found in almost all areas of the national economy (in truth, it is more difficult to say where they cannot be found), but in construction there is no such structural element of the building and its type (residential buildings, garages, baths, saunas, dachas, etc.) .d.), where it is impossible to use TechnoNikol insulation.

This is evidenced by the extensive range of products. But the versatility is most clearly illustrated by the TechnoNIKOL wedge-shaped insulation, the production of which the company was one of the first.

If we talk about the raw materials used for the production of insulation, the company produces thermal insulation materials from all the most popular materials: basalt wool, polystyrene foam, polyurethane foam.

Quality. A manufacturer can find out most accurately about the quality of its products on various forums. Here the company is in complete order - it’s difficult to find a negative review (it’s still possible if you want). The high level of quality is confirmed by the awards received by the brand at various exhibitions of thermal insulation materials.

Acceptable price. The manufacturer strives to cover all market segments. Therefore, on sale you can find the same type of insulation with a budget price and a cost per 1 m2 of several thousand rubles. Such price variability is achieved by changing the density of the material.

Material calculation

Differences in the dimensions of mineral wool elements can mislead you. Professionals try to save working time. The price of a mistake is the same for everyone - budget overruns and loss of time.

To perform calculations, use an online calculator. It will take into account all the necessary quantities, parameters and conditions. A small reminder on using the calculator:

Please note that not all Russian settlements are represented in the list of cities

Therefore, try to choose options that are minimally distant from the location of your home. This is important because... this parameter determines the average winter temperatures; all numerical values (thickness) are displayed in millimeters

Just in case: 1 m is 100 cm or 1000 mm; We recommend looking at the detailed characteristics of insulation on the manufacturers’ websites. There you will also find recommended prices for this type of product; All calculations are approximate, so it would not be superfluous to add 10% to the results obtained.

Having obtained the thickness of the thermal insulation as a result of calculations and knowing the area of the walls, it is easy to calculate the volume of insulation. We hope this is helpful.

Characteristics

Each type of insulation has its own technical and operational characteristics.

Basalt wool

TechnoNIKOL basalt insulation has performance indicators that are attractive to consumers:

- thermal conductivity - 0.048-0.077 W/(m K);

- density - 28-210 kg/m3. The value of the indicator depends on the purpose of the insulation. So, for inclined surfaces the most optimal density will be 35-40 kg/m3, for a facade - 80-100 kg/m3, and for a screed on the floor or on a flat roof - 150-210 kg/m3;

- vapor permeability - 0.25-0.35 mg/m2*h*Pa;

- strength:

- for compression - 8-60 kPa;

- separation of horizontal layers from each other - 80 kPa;

- bending - 0.15 MPa.

- durability - more than 50 years;

- operating temperature: from -170oC to +1000oC.

In addition, cotton wool does not burn (flammability class NG) and does not absorb moisture—hygroscopicity is completely absent (water absorption is only 0.095% after 24 hours of soaking). More details about the performance of basalt mats can be found in the work “Basalt Slab”.

Extruded polystyrene foam

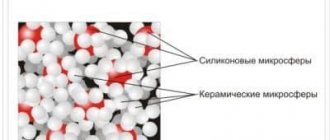

A feature of extruded polystyrene foam produced at the enterprises of the TechnoNIKOL concern is the inclusion of carbon in the form of nanoparticles in the insulation composition. This significantly changed all technical parameters of the material: thermal conductivity, service life and physical and mechanical properties. Therefore, the digital values given below may differ significantly from the generally accepted ones (data taken from the official website of the company www.tn.ru):

- thermal conductivity coefficient - 0.029-0.035 W/(m K);

- density - 26-36 kg/m3;

- bending strength - 0.025-1.0 MPa;

- vapor permeability - 0.005-0.011 mg/m2*h*Pa;

- flammability class - G3-G4 (note that the company honestly indicates the flammability class);

- durability - more than 50 years.

Liquid polyurethane foam

One-component polyurethane foam has open cells, and therefore its technical characteristics differ significantly from those of two-component polyurethane foam:

- thermal conductivity coefficient - 0.025-0.045 W/(m×°K);

- vapor permeability - 0.07-0.17 mg/(m*h*Pa);

- density - 8-18 kg/m3;

- moisture absorption - 10.0-60.0%;

- compressive strength - about 1.02 kgf/cm2;

- bending strength - about 17.0 kgf/cm2.

PIR thermal insulation boards

PPU slabs have the best technical and operational indicators among all insulation products on the market. Among them:

- thermal conductivity - 0.028-0.030 W/(m×°K). The manufacturer indicates a value of 0.021 W/(m×°K), which raises reasonable doubts. The work “PUF Slabs” explains in detail why;

- density - 40-160 kg/m3;

- vapor permeability - 0.02-0.05 mg/(m*h*Pa);

- strength:

- when compressed to failure - 200 kPa or more;

- bending for fracture - not less than 300 kPa.

- water absorption when immersed in water for a day is 1-1.5%.

Release form

The company offers two types of insulation: in rolls and in the form of sheet material. The second type is thermal insulation made from sheets in the shape of rectangles. For ease of transportation, they are sold in packages of several pieces. The number of sheets in a pack may vary. This depends on the thickness of the insulation and its composition.

For the convenience of the buyer, the manufacturer indicates the number of square meters on the label. This allows you to cover rolled or sheet material taking into account the specific parameters of the base.

Advantages and disadvantages

Each type of TechnoNIKOL brand insulation presented on the building materials market has its own strengths and weaknesses.

Basalt wool

Among the advantages of wool made from basalt fibers:

- good thermal insulation properties;

- durability;

- resistance to heat - the material is non-flammable, can withstand temperatures up to +1000oC;

- lack of hygroscopicity;

- vapor permeability;

- good level of airborne noise absorption;

- versatility - you can insulate any structural elements of a building;

- resistance against fungus and mold;

- simple installation - all work can be completed without hiring hired workers;

- convenient delivery to the work site;

- high elasticity, which allows the slabs to be mounted in the sheathing cells in a spacer;

- environmental safety for homeowners.

Among the disadvantages :

- high cost of the product;

- heterogeneous structure of mineral insulation with low density;

- a significant difference, judging by reviews on forums, in the thermal insulation properties and durability of budget line materials and expensive ones;

- dust generated during the work process.

Important: the company was the first in the world to introduce basalt insulation, which does not generate dust.

Extruded polystyrene foam

The main advantages of extruded polystyrene foam (EPS) are low thermal conductivity and low weight. But other strengths are no less significant:

- long service life - the company assures that the EPS durability is 50 years or more;

- ability to maintain original characteristics in the temperature range from -50oC to +75oC;

- high level of water resistance - absorbs no more than 0.2% moisture when completely immersed in water;

- resistance to compression - high-density material can withstand pouring screed up to 10-15 cm thick;

- not subject to rotting and decomposition processes - a synthetic product, so it takes hundreds of years to decompose;

- is not a base for the proliferation of pathogenic microflora (mold and fungi);

- exhibits inertness towards most types of household chemicals and paint solvents;

- frost resistance - there is nothing to freeze due to the complete absence of moisture inside the EPS boards;

- easy to install - you can do the insulation work yourself;

- has good adhesion to building materials: plaster mortars, putty, paint.

disadvantages , but some of them become the main reason for refusing to use XPS in private construction:

- there is no vapor permeability - the walls do not “breathe”, and therefore good ventilation is necessary;

- background noise increases - the plates resonate, amplifying the sounds;

- high sensitivity to ultraviolet rays - under the sun it quickly ages and deteriorates;

- high cost 1 m3;

- incompatibility with rodents - they happily make nests, gnawing out numerous passages;

- flammability, which the manufacturer honestly informs about.

PIR boards

Insulation made from PIR raw materials has many advantages, which should make the material a leader in the market of thermal insulation materials for many years. Among them:

- the lowest thermal conductivity among all types of insulation;

- long service life due to the applied layer of protection made of foil or lavsan - 50-60 years;

- simple fastening to insulated surfaces - all repair and construction work can be done independently;

- environmental cleanliness;

- resistance to household chemicals and colonies of microorganisms (mold and mildew);

- low specific gravity;

- lack of hygroscopicity;

- versatility;

- wide temperature range in which the insulation retains its performance characteristics - from -200oC to +130oC;

- lack of linear expansion during sudden temperature changes;

- low fire hazard class - classified as self-extinguishing (G1);

- can be machined, which allows, if necessary, reuse;

- resistance to decomposition processes: rotting and corrosion.

The manufacturer claims good noise insulation properties and resistance against rodents. In reality, this is just a publicity stunt. Therefore, these two factors can be attributed to the disadvantages of the product. But the most important drawback is the high price. Another drawback of PPU boards is the fear of ultraviolet radiation, which the company perfectly mitigated by protecting the sheets with foil, which at the same time perfectly reflects heat rays back into the room.

Dimensions

In addition to the fact that the dimensions of roll and tile materials are different, the brand provides a flexible approach to each client. Upon individual order, the insulation can be produced in a different format convenient for the customer. The dimensions of standard slabs are 1200x600x100, 1200x600x50 mm. The thickness of the material varies on average from 1 to 15 cm. The sizes of varieties with an edge are 1185x585, 1190x590 mm with a width of 20, 30, 40, 40 mm. The length range is from 600 to 12000 mm, the width ranges from 100 to 1200 mm.

Application area

The Russian corporation supplies the building materials market with a wide range of its products, which allows it to meet any buyer’s needs. A combination of 4 types of thermal insulation "TechnoNikol" allows for insulation:

- a pitched roof from the inside (about the inappropriateness of thermal insulation of the roof from the outside with extruded polystyrene foam boards and PIR materials can be found in the article “How to insulate the roof of a private house”) and a flat roof from the outside;

- facade, in two ways:

- wet method for decorative plaster or painting;

- ventilated facade for finishing with siding, PVC panels, porcelain stoneware, block house, imitation timber, etc.

- walls using the “well method”, when the insulation is attached between the load-bearing and decorative walls;

- walls from the inside of the room, as well as the facade, using two methods;

- gender, with all possible options:

- from below, from the basement side;

- under the screed (“floating screed”);

- directly under the finishing floor covering (“floating floor”);

- by lags;

- under "warm floor".

- ceiling - underneath for painting, wallpaper, suspended and suspended ceilings and outside, in the attic.

If you depend on the type of building, the company’s product can be used for thermal insulation of a private house, apartment, cottage, garage, bathhouse and sauna.

In addition, insulation is used to insulate metal entrance doors and utility networks (pipes with cold and hot water).

TechnoNikol insulation materials have also found their application in technical insulation: agriculture (greenhouses, incubators, storage of vegetables and fruits), automotive industry (insulation of refrigerators and sound insulation of individual vehicle components), marine and railway transport (refrigerators), etc.

Scope of use

Thermal insulation of walls

Thermal insulator Rocklight has a wide range of uses. Basalt slabs can be laid on concrete screeds and between joists. The installation technology is to eliminate gaps. A final coating is made on top of the heat insulator. The coating can be absolutely anything (laminate, parquet, etc.).

This insulating material is used for thermal insulation and sound insulation of partitions. The thermal insulator is installed in a frame made of both wood and metal. Sheets of plasterboard are placed on top of the Rocklight, and then the final coating is installed. An additional area of use for this thermal insulation product is ventilated facades.

Rocklight is actively used during the construction of frame houses. The inside of the material is covered with a vapor barrier. This eliminates the possibility of moisture entering from the room. After installing the vapor barrier membrane, the final finishing is done. The wind protection is mounted on the outside of the heat insulator. As a wind barrier, you can install a specially designed film or OSB boards. The choice of wind protection depends on the type of coating. A pitched roof is insulated using a similar method.

Range of insulation materials and prices

The company produces insulation with dimensions and technical characteristics for specific building structures. To make it easy for the consumer to navigate the variety of products presented, each type is given its own name.

Basalt wool

The most widely represented line of basalt mats. The manufacturer offers slabs and rolls:

- "Rocklight";

- "Technoruf";

- "Technovent";

- "Technolight";

- "Technoflor";

- "Technofas";

- "Technoblock";

- "Technoroll".

"Rocklight." Lightweight basalt fiber slabs (density 35 kg/m3) for external and internal thermal insulation of horizontal and vertical structures in private homes: attic walls and frame buildings, floors, internal partitions; ceiling from the attic, pitched roofs.

Available in two sizes:

- 120x60x5 cm at a price of 170 rubles/m2;

- 120x60x10 cm costing about 250 rubles/m2.

"Technoruf". The main purpose is to insulate facades using the “wet” method under decorative plaster or painting and flat roofs under screed. For this purpose, the company produces Tekhnoruf slabs with a density of 140 kg/m3 and high delamination strength (at least 15 kPa). In addition, we have mastered the production of wedge-shaped insulation (Tekhnoruf n prof).

The length and width dimensions are standard: 120x60 cm. The thickness can be any in the range of 20-100 mm. A slab with a thickness of 120 mm can be produced upon request. The price is high, starting from 7,000 rubles/m3.

"Technovent". Specialized insulation for walls with ventilated facades. The manufacturer also allows for use as a middle layer in the “wet” method of insulation for painting and decorative plaster with a thin solution thickness. You can buy it for 2.8-3.2 thousand rubles/m3.

"Technolight". "Technolight" is another specialized type of basalt wool - insulation for pitched roofs. According to its characteristics, it can also be used for internal insulation of balcony walls along the frame, ceilings and walls from inside the apartment along the sheathing, and wooden floors along the joists - it can only be fastened by surprise.

But when used for other purposes than its intended purpose, you need to look at how much 1 m2 of this type of mat costs, because... for profile heat insulators it may be lower. The cost of 1 m3 is about 1800 rubles.

"Technoflor". Thermal insulator with high compressive strength, withstands up to 50 kPa and a density of about 170 kg/m3 is intended for insulation of floors with increased load: sports facilities, warehouses and industrial premises. Therefore, it is practically not used in private construction (it is used for insulating flat roofs of residential buildings). It is expensive - 4,960 rubles/m3 or more.

"Technofas". The entire line of this brand of basalt mats belongs to the best facade insulation materials from TechnoNIKOL. It is used for insulation of buildings made of brick and concrete with subsequent finishing with building mixtures. The price ranges from 3,300 to 5,500 rubles/m3, which is a bit expensive for the middle class.

"Technoblock". The material was created for insulating walls using the “well” method, when the insulating layer is placed between two walls: load-bearing and decorative. It has a high density, which allows it to withstand significant loads on the edge when the mats are supported on each other. But it does not always have the same compressive strength along the plane. Therefore, it is not used for horizontal insulation. The price fluctuates around 2,180-2,470 rubles/m3.

"Technoroll". The only type of basalt insulation that is sold not in sheets in packs, but in rolls. Mat length is 4,000 mm, width - 1,000 mm, standard thickness: 50 and 100 mm. Lightweight (density 30 kg/m3), and therefore its use is possible where there are no static loads on the surface of the heat insulator: when insulating floors along joists, attics and ceilings. The price is budget.

For information: At the time of writing, the company has temporarily suspended the production of rolled material. Therefore, it is not possible to indicate a more accurate price.

Extruded polystyrene foam

For private construction, according to technical indicators, the most optimal option is extruded polystyrene foam, produced under the general name “Carbon”. The following types of insulation can be found on sale:

- XPS CARBON ECO;

- XPS CARBON ECO DRAIN;

- XPS CARBON ECO FAS;

- CARBON ECO SP;

- CARBON PROF;

- CARBON PROF SLOPE;

- CARBON SOLID;

- XPS CARBON SAND;

- C-XPS CARBON.

XPS CARBON ECO. The slabs of this series are the basic ones in the Eco line. They are used in low-rise construction to insulate foundations, floors, roofs and facades. They burn well, so they are not recommended for use for insulating walls and ceilings from the inside of rooms. A pack of 8 slabs measuring 1180x580x50 mm can be purchased for 1230-1252 rubles.

XPS CARBON ECO DRAIN. They have a distinctive feature - drainage grooves, which allows the following functions to be performed when insulating the foundation and flat roof:

- drain rain and groundwater;

- organize microventilation of the roof.

1 m3 of such a slab costs from 17,590 rubles.

XPS CARBON ECO FAS. Specialized insulation for facades under plaster. Technical characteristics allow it to be used when insulating walls using the “well” method, pitched roofs, ceilings from the attic side and floors under screed. A distinctive feature is that it has excellent adhesion to mortars and all kinds of adhesives based on cement and gypsum. Price from 215 rub./m2.

CARBON ECO SP. Rigid and very durable insulation is used for thermal insulation of shallow foundations using the “insulated Swedish slab” type. It has no analogues of Russian origin. A package of 4 slabs measuring 2360x580x100 costs RUB 2,670-2,780.

CARBON PROF. CARBON PROF slabs are the basic version of insulation for multi-storey construction. The Prof line from Eco is distinguished by:

- reduced flammability class due to the addition of fire retardants;

- the presence of a special edge to speed up installation (some Eco series also have it);

- ability to withstand significant loads during operation.

The slab is used to insulate foundations, flat roofs and floors along the ground and under the screed. Insulation costs from RUB 4,090/m3.

CARBON PROF SLOPE. The original form of insulation, patented by the company, for a pitched roof. Consists of 5 wedges of different sizes. When assembled, a slope is created to remove water from wet areas of the rafter system. 1 m3 costs more than 6,000 rubles.

CARBON SOLID. EPPS CARBON SOLID is an ideal insulation material for floors. It can also be used when laying highways and railway tracks - it does not deform under loads and does not swell in a humid environment. The price starts from 6,490 rubles/m3.

XPS CARBON SAND. The slabs are produced for companies producing sandwich panels.

C-XPS CARBON. The main purpose is laying on top of a “dry” floor screed. Can be used for thermal insulation of other building structures during renovation. Cost of 1 m2 - from 865 rubles.

Where is it used?

Builders use the material to perform thermal insulation and sound insulation work. This substance minimizes the penetration of cold and heat loss. Experts prefer to use stone wool in frame buildings and for insulating residential buildings.

In what works are they used:

- KV processes metal, concrete, stone and wooden walls from the outside and inside.

- For insulation of small architectural forms (balconies, loggia) and small extensions.

- For floor insulation.

- On floors, ceilings and walls.

- For the purpose of insulation of pipelines, chimneys, stoves and ventilated facades.

Installation of insulation

Each type of insulation has its own installation technology. At the same time, it can vary depending on what kind of building structure is insulated. The standard insulation scheme looks like this:

- calculation of the necessary materials is carried out (insulation, vapor barrier film, timber for sheathing, fasteners, etc.);

- a set of tools and devices is prepared, materials are purchased;

- preparatory work is being carried out;

- insulation is attached;

- if necessary, vapor barrier work is carried out;

- The finishing of the walls is carried out outside and inside, and the ceiling from the inside.

A detailed description of each type of thermal insulation work using TechnoNIKOL insulation can be found on our website Stroy.Guru.Com:

- insulation of roof structures:

- “Is it possible to insulate a roof with foam plastic and how?” – the instructions for insulation are the same for EPS and PIR boards;

- “Insulation of a polyurethane foam roof with your own hands”;

- “Insulating the roof of a private house with mineral wool.”

- ceiling:

- "Ceiling insulation with mineral wool."

- facade:

- “Do-it-yourself insulation of walls with mineral wool”;

- “Do-it-yourself insulation of polyurethane foam walls”;

- “Technology for insulating walls with basalt wool”;

- “How to insulate internal and external walls with foam plastic” - the technology is suitable for extruded polystyrene foam and PIR boards.

- gender:

- “Insulation of polyurethane foam floors with your own hands”;

- “Floor insulation with mineral wool”;

- “How to insulate a floor with foam plastic.”

Calculation

Every master and even the customer should know the rules for calculating insulation. Sometimes repair crews deliberately inflate the indicator. To avoid becoming a victim of deception, you can use an online calculator. However, you can do some simple calculations yourself. The fundamental factors are density and approximate area covered.

To make it clearer, we can take a clear example as a basis. It is planned to use 5 cm thick insulation. In this case, the size of the material is not yet taken into account. We need to find its total quantity. The planned height of the facade is 3 m, its perimeter is 24 m.

Calculate the area: 3*24=72 m2.

The thickness of the insulation is converted into meters: 50 mm = 0.05 m.

Multiply the resulting quadrature by the thickness: 72 * 0.05 = 3.6 m3.

After this, all you have to do is look at the packaging labeling. Usually the volume is written on it in cubic meters. All that remains is to divide the resulting indicator by this mark. For example, it is equal to the standard value of 0.36 m3. Then the number of packs is: 3.6: 0.36=10.

Thus, for 72 m2 with a material thickness of 5 cm, 3.6 cubic meters will be needed. m or 10 packs of insulation. The same method is used to calculate the consumption for multi-layer insulation.