- How to insulate outside

If you are planning to build or repair a steam room yourself, then most likely you have wondered: what is the best way to insulate the ceiling in a bathhouse from the inside and how to properly cover it with your own hands, and also looked for examples with videos.

Approaches to thermal insulation of the ceiling in a bathhouse

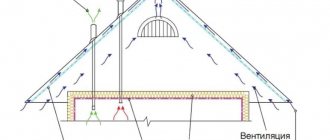

A log bathhouse can be built with or without an attic. In the first case, the ceiling will be much stronger than in the second. As a result, warm air rising to the ceiling inside the bathhouse will encounter a more serious obstacle on its way. The fact is that in such structures, in the process of creating ceilings, a layer of thermal insulation is laid.

In addition, the air gap in the attic also prevents heat from quickly escaping from the room, and an insulated roof traps it even more.

However, there are cases when, even if there is an attic or attic space, it is necessary to insulate the ceiling of the bathhouse.

Conclusion

In order to insulate the ceiling in a bathhouse, you can use different insulation materials and each owner makes their own choice. If you want to save money, you can choose, for example, expanded clay or clay with sawdust, but the installation process is more labor-intensive.

Using materials such as mineral wool or penoizol allows you to complete all the work much easier and faster, but be prepared for more significant costs.

The need for vapor barrier

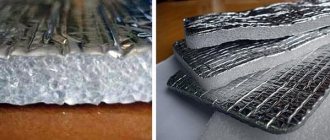

Whatever the structure, laying a layer of vapor barrier for the ceiling in the wooden ceiling of the bathhouse is a mandatory element of insulation. It is laid before installing the insulation layer. As a vapor barrier in bathhouses without an attic, wax paper, aluminum foil or thick cardboard impregnated with drying oil are used.

In buildings with an attic or attic, similar materials are allowed to be used. However, in practice, wooden floors are most often coated with clay, with a layer of 2 cm.

On the building materials market you can find several vapor barrier options:

- Thick polyethylene film is used quite rarely, as it contributes to the greenhouse effect. In this regard, when installing it, it is important to leave technological gaps for condensate evaporation.

- A special polyethylene vapor barrier film with pile to retain condensation.

- All kinds of vapor barrier membranes.

The need for a vapor barrier layer is due to the fact that it allows you to protect the insulation for the bathhouse ceiling from the accumulation of moisture contained in the warm air. This is important, since moisture will gradually lead to a decrease in the thermal insulation qualities of the material, shorten its service life and increase the load on the walls as a result of an increase in the mass of the ceiling.

Clay with sawdust

Proven old-fashioned method. To prepare the mixture, you will need, oddly enough, only clay and sawdust, mixed together in a ratio of 2:3. As soon as the mixture has acquired a stable creamy consistency, it is spread on a pre-installed vapor barrier layer and leveled to an acceptable thickness of 5-10 centimeters.

Eco-friendly. Safely. Cheap. Our grandfathers still knew a lot about life!

Why do you need insulation?

Taking bath procedures in a steam room will be more pleasant the more efficiently the room is heated. You can achieve a quick increase in temperature in the steam room only by laying reliable insulation for the bath on the ceiling.

Thermal insulation of the ceiling performs several tasks at once:

- prevents heat leakage through small cracks in the ceiling;

- prevents the formation of cold bridges, which lead to gradual cooling of the air;

- creates a multi-layered obstacle in the path of heated air.

Thus, if multilayer thermal insulation material is laid in the ceiling, heat loss can be avoided in all three cases. At the same time, it is very important to insulate the ceiling correctly in order to avoid the accumulation of condensation, significant fuel consumption and an increase in the time it takes to warm up the bath.

Types of insulating materials

To decide which insulation to choose for a bathhouse ceiling, it is worth understanding the features and types of thermal insulation materials.

The most popular and widespread material is mineral or basalt wool. It is woven from many basalt fibers, with air in the voids between them. It is this that prevents heat from escaping from the room. True, this insulation is very sensitive to humidity and loses its properties when wet.

It is worth noting that when insulating the ceiling of a bathhouse with mineral wool, it is necessary to lay a layer of waterproofing film on top of the thermal insulation. This will protect the insulation from getting wet if water may leak through the roof. In addition, there must be a gap between the insulating material and the waterproofing.

No less often, the choice of insulating the ceiling of a bathhouse from the outside falls on foamed polypropylene, or penotherm. This is a lightweight foil material that was specially created for insulating saunas and baths. Penotherm not only prevents the leakage of warm air from the room, but also reflects it back into the bathhouse, that is, it works like a mirror. Thanks to the use of this material for the ceiling in the bathhouse, you can speed up the heating of the steam room by two to three times.

If you plan to build a large bathhouse, expanded clay can be used as insulation. To ensure high-quality thermal insulation, you will need a layer 30 cm thick. Expanded clay is a fairly light material, but a large amount of it makes the ceiling heavier. In addition, it is necessary to lay a layer of waterproofing on top of expanded clay, since it is sensitive to moisture.

Some consumers, when choosing which insulation is best for a bathhouse on the ceiling, settle on the so-called folk method of thermal insulation. It involves the presence of several layers. The first component is crumpled clay - the layer thickness is 2 cm. If there is no clay, you can use a mixture of peat with chernozem, a combination of sawdust, sand and clay, or wood shavings covered with a cement solution on top. Next, a layer of oak leaves or dry sawdust is laid. The last layer is 15 cm of dry soil.

As one of the options for insulating the ceiling in a bathhouse with an attic, you can use growing aerated concrete. Before pouring it, a simple formwork is required.

It is difficult to say definitely which insulation for the ceiling in a bathhouse is better, as well as to accurately indicate the thickness of the insulating layer. It all depends on the technical parameters of a particular room, its size, materials used, climate zone and a number of other factors. Therefore, if, when using one or another type of insulation, condensation accumulates on the ceiling, then the thickness of the layer is not enough for high-quality thermal insulation of the room. The solution in this situation is to increase the layer of insulating material.

Installation of floors in different rooms

From the above, you could already come to the conclusion that different rooms dictate their own rules in the design of ceilings, despite the fact that the type of construction itself is chosen at the design stage. Therefore, the whole difference comes down not to the device, but only to the external design.

In the steam room

There is no point in spreading too much here. Firstly, several features of this particular room were listed above. Secondly, the site has ready-made, extensive and high-quality material dedicated specifically to the ceiling in the steam room.

In the car wash

There is a lot of water in the washing room. That is, this must be understood in two ways: there is high humidity, and water is sprayed in different directions. These are different things, but interconnected. The materials that are best used in this room should be either moisture and water resistant, or have artificial protection.

It was said above that plastic lining has the necessary properties regarding water. But wood is not prohibited from washing, because you have enough options at your disposal to protect it from water.

Firstly, these are impregnations. Of course, they require updating over time, and the time frame is not very long - about two years. But impregnations have an undoubted advantage over coatings that form a thicker film - impregnations do not peel off. And this guarantees a decent appearance at all times.

Secondly, varnishes. There are special types of varnishes that are designed to cover wood in water. A typical example is yacht varnish. If you buy a product from a reputable manufacturer, you can expect it to perform as advertised.

Thirdly, paints. We have not yet reached the European latitude in our views, which allows us to easily paint over wood texture that is valuable from our point of view. And the same Finns easily say goodbye to it, covering it with any color they like. If the washing room has a separate shower stall, the walls can also be painted. We wrote about different bath compositions in some detail here.

ADVICE! For those considering paints, it's best to look at those marketed as bathroom paints. This guarantees their suitability for the washing room. In addition to wood, the ceiling in the washing room can also be lined with mosaics, but this is a rare solution, more often found in hammams

In addition to wood, the ceiling in the washing room can also be covered with mosaics, but this is a rare solution, more often found in hammams.

In the dressing room and rest room

But these two rooms, despite all the difference in “showiness,” depend more on the style chosen by the owner or designer than on the temperature and humidity characteristics of the environment.

That is, here you need to focus exclusively on the harmonious combination of the ceiling in the dressing room or rest room with all other design elements.

If this is an ethnic style, then it is better to choose wood. If something is technologically advanced, choose a material taking into account the fact that the bathhouse as a whole has high humidity. Therefore, there is no need to use any drywall here.

Antique finishing of baths and steam rooms

Most baths are built with a wooden ceiling base, and this directs the thought towards, say, tongue and groove boards - make sure the seams are invisible and paint them in any color according to the design. It will look good even where the high-tech style is chosen. But high-tech, fortunately, has been and will remain an exception to the rules in the bathhouse.

We insulate the ceiling in the bathhouse: sequence of work

Regardless of the material from which the bathhouse itself is built, the upper floor for it is constructed in the same way. The basis of the ceiling will be load-bearing beams, which are laid on the mauerlat in the case of brick or panel buildings, or on the upper rims of a log frame.

Please note that all wooden elements must be treated with an antiseptic compound. If this procedure was not performed before laying the wood, it must be carried out before insulating the ceiling in the bathhouse with mineral wool or any other selected heat insulator. Joints between dissimilar materials should be treated especially carefully - in combinations of wood with brick, foam concrete or metal.

From the inside, the ceiling in the bathhouse must be hemmed with a board, nailing it to the supporting beams from below.

At the next stage, they move on to assembling the rolling boards, that is, grade 2 boards arranged in two rows perpendicular to each other.

Please note that when installing rolling shields on the skull boards, there should be a gap of 5 cm or a little more between them and the beams. There must be a gap of at least 25 cm from the wooden elements to the chimney.

To simplify your work, you can first draw a diagram from which to calculate the size and shape of the roll-up shields. Then they should be numbered so as not to confuse anything.

It is advisable to also treat finished panels with an antibacterial agent to avoid fungus and rot.

It is necessary to attach a layer of vapor barrier to the bottom and inner walls of the boards, for which a construction stapler is used.

Before insulating the bathhouse ceiling from the inside, wooden structures must be raised into the attic. First of all, they bring in the protection, which will be installed at the very end.

When all the wooden structures are brought up, they need to be laid in accordance with the diagram so that the lower edge of the beam is level with the bottom of the boards.

After this, you can proceed to insulating the bathhouse ceiling with basalt wool or any other material. The selected insulation is used to fill the roll-up panels and all the gaps between them and the beams.

Everything is covered with a board on top, laying it perpendicular to the beams.

In addition to boards, for the top cladding of the insulation, you can use fiberboard or even slabs made independently from sawdust and cement mortar. Upon completion of the work, asbestos sheets are sewn onto the surface, as well as near the chimney.

Design from Sosnin Yu.P. and Buharkina E.N.

Sosnin Yu.P. and Buharkin E.N., the authors of the book “Household Stoves, Fireplaces and Water Heaters,” offer the following option on how to insulate the ceiling in a bathhouse in a steam room:

- Tongue and groove boards 25 mm thick are taken and attached to the beams. The boards must be coated with drying oil in two layers, which should make them moisture resistant.

- Low quality boards are fastened across the beams on top. There should be a distance of 3 cm between them. In this way, a moisture gap is created.

- Next, roofing material or plastic film is spread over the boards. Reinforced foil is best.

- Slag or sand is poured. The layer should be 20 cm.

How else can you insulate a steam room?

You can hem the ceiling with a 50 mm unedged board. Narrow boards are attached to it from the outside for support, which are fixed to the wood grouse. For further cladding, tongue-and-groove aspen boards are used. It is attached with some gaps to narrow support boards.

In the attic, a vapor barrier membrane is first laid, on top of which sawdust mixed with clay is poured in a layer of 3 cm. Next, a 15 cm layer of basalt wool, density 125, is laid, and then a polyethylene film for protection from the wind. After this, the entire surface is covered with subfloor boards.

For bathhouses with log floors, a slightly different approach is used. To line the ceiling, a special sheathing is placed on the inside of the bathhouse. From the attic side, glassine is first laid and 20 cm of sand is poured. The owners add additional layers at their own discretion.

A detailed study of the insulation features of the steam room and other rooms in the bathhouse will help the owners of such structures to do everything right. Then a bathhouse built with your own hands will delight you with warmth, comfort and good steam. The options we have described can be modified and added at your discretion. We hope everything works out for the best for you.

Expanded clay

Ceiling insulation with expanded clay is used in bathhouses that have under-roof spaces (attics, attics). The properties of expanded clay are in many ways similar to those of mineral wool. The same advantages: environmental friendliness, resistance to high temperatures... and the same disadvantage: the material absorbs moisture too well. From below it must be protected from the penetration of steam, and from above - from the effects of atmospheric and condensation moisture.

In addition, the fired granules of this heat insulator have much lower resistance to heat transfer than mineral wool. For this reason, the required thickness of the effective embankment is at least 30 cm.

This option is suitable for large steam rooms. Since the floor beams above spacious rooms have a significant vertical section, deep natural niches are formed for filling the required amount of expanded clay.