Materials with low density, excellent thermal insulation characteristics and, at the same time, quite acceptable rigidity and the ability to withstand mechanical loads, open up wide possibilities for floor insulation, including even in apartments of multi-storey buildings. A typical representative of such materials is polystyrene foam. And such floor insulation with polystyrene foam under the screed is especially important on the first floors located above unheated basements or ventilated cold plinths.

Floor insulation with polystyrene foam under screed

As we will see later, you can carry out similar work yourself. The main thing is to purchase high-quality insulation material of the required thickness and strictly follow the technological recommendations for pouring the screed.

What is Penoplex, types, scope of application

Penoplex - under this brand back in 1998, extruded polystyrene foam boards - EPS - began to be produced in the Leningrad region. A little later, factories appeared in Perm and Novosibirsk, then in Taganrog, two factories in Kazakhstan, in the Tula region. So the geography of production sites is wide.

Penoplex insulation boards are orange in color

Brands for private construction

Currently, two types of Penoplex slabs are produced - for private and professional construction. For private there are three types: Comfort, Foundation and Wall. The names reflect the scope of application of the materials. They differ in density and compressive strength.

Penoplex Comfort and foundation are used for walls. What is the difference? Strength and density

The remaining characteristics are the same - they are produced from the same raw materials, using the same equipment. But their purpose is different: Comfort - sound and heat insulation, Foundation and Wall are more aimed specifically at thermal insulation. Although, according to the manufacturer, their noise reduction indices are the same. It’s just that in the Comfort category there is a larger selection of plate thicknesses: 20 mm, 30 mm, 40 mm, 50 mm and 100 mm. The rest have only two thicknesses - 50 mm and 100 mm.

Which Penoplex for flooring under the screed can be placed from this line? Penoplex Foundation. It fits all the criteria. Recommended for laying floors on the ground and on a concrete slab, above a ventilated underground, on a loggia or balcony. The only thing I'm not happy about is the thickness - there are only two options - 50 mm and 100 mm. This is inconvenient since the required/desired thickness is often different. This limits the use of this type of material in screed.

For professionals

Line for professionals - Base, Facade, Roof, Slope, GEO and 45. There are also blocks and shaped products. The blocks are used in heavy construction and private owners have not yet adapted them. Shaped products are a useful thing for insulating wells and solving other similar problems.

Of all the above, it is recommended to use GEO and Slope for floor screeding. The difference between them is in shape: GEO has a standard type of slabs, Slope - slabs with a longitudinal difference in height. They will come in handy if you need to create a floor slope. Their density and strength are higher than those of the materials of the previous category.

Characteristics of PENOPLEX, which can be placed under a screed

Penoplex GEO is convenient to use under screed because there are slabs of this category of different thicknesses - 40 mm, 50 mm, 60 mm, 80 mm and 100 mm. It is easy to dial the desired thickness.

Sometimes they think of using Penoplex 45 for the floor under a screed, but this strength is clearly excessive. This type of material is used in road construction. In any house there will not be even close to such a load. So this type of EPS should not be used.

Structure and main technological and operational characteristics of the material

Materials based on polystyrene have both common properties that are characteristic of all of them, as well as significant differences.

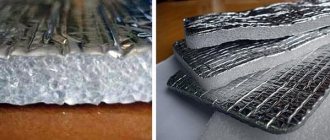

Externally, it is almost completely identical to polystyrene foam. The same ingredients are used for manufacturing - polystyrene granules, to which a foaming agent is added during heat treatment. The result is a cellular structure with isolated chambers. Expanded polystyrene, unlike polystyrene foam, has a more dense structure, reminiscent of a sponge. Therefore, in order to provide a heat-saving effect similar to that obtained from thick foam boards, polystyrene foam boards can have a much smaller thickness. Floor insulation with extracted polystyrene foam has an important advantage compared to polystyrene foam - a higher surface density. This is reflected in mechanical strength. On a note

If we compare the thermal insulation performance of a floor with expanded polystyrene and other materials, it turns out that regardless of the outside temperature, unlike, say, expanded clay, the human body feels heat. The thermal insulation characteristics of such floors are approximately 25 times higher than those of analogues made of expanded clay concrete.

The heat transfer coefficient varies from 0.028 to 0.034 W/m*K depending on the density of the structure. According to this indicator, it is better than mineral wool. Therefore, if there is a question of insulating the basement floor - with expanded polystyrene or expanded clay, most often the choice is made on the first.

In addition to this quality, other technical characteristics should be taken into account:

- Waterproof. It is completely sealed, but unlike foam plastic it is hygroscopic. The vapor permeability index is 0.014 (kg*m)/(h*Pa). This is due to the molding process during production;

- Strength. The insulation can withstand significant loads - from 0.4 to 1 kg per 1 cm². Therefore, thermal insulation of a balcony with polystyrene foam can be carried out without installing an additional protective layer;

- Treatment. To form sheets with the required dimensions, you can use a regular drywall knife. Unlike polystyrene foam, this material does not crumble at the ends.

Performance qualities include susceptibility to destruction when exposed to acetone, turpentine, and some brands of paints and varnishes. This possibility most often arises during processing before installation.

Expanded polystyrene for flooring, in addition to the positive properties common to polystyrene foam, also

- durable,

- reliable,

- durable, resistant to mechanical loads (about 400 kg/m²),

- moisture resistant,

- not susceptible to rotting and the influence of harmful microorganisms,

- resistant to deformation, excluding fracture,

- chemically neutral,

- easy to install.

Of course, the material cannot be called ideal. For example, being moisture-resistant, when water leaks, fungus can form on it, and although it generally does not react to acids and alkalis, it melts under the action of resins and mastics containing organic components.

Penoplex thickness for screed

The question often arises not only about the density or brand of Penoplex under the screed, but also about the thickness. To say for sure, it is necessary to carry out thermal calculations. After all, the thickness of the insulation depends on the heat loss that goes through the floor. If it is a floor on the ground, it is one thing; if it is a screed on a concrete slab in a high-rise building, it is quite another, even if they are in the same climatic zone.

And the thickness of Penoplex depends on where you are going to make the screed and how you will use it. In the case of laying a heated floor, the layer is made to the maximum - there will be less heat loss, lower heating costs.

What thickness of Penoplex should be placed under the screed - table of recommendations for the first floor and unheated rooms below

However, calculations are done very rarely; usually the principle “like everyone else” is used. Here are the average thickness values of Penoplex for floor screed:

- Screed on a concrete floor with a heated room from below - 20-40 mm. If you want to achieve a soundproofing effect, it is better to lay 50 mm thick.

- For concrete preparation (on the ground) and a slab with an unheated room below - from 100 mm and more - depends on the region. The table shows the manufacturer's recommendations for the thickness of Penoplex for the first floors or higher, but with an unheated room below.

If you plan to make a heated floor (water or electric), then add another 10-20 mm to the thickness.

Adding polystyrene chips to concrete

To give the concrete layer additional protective characteristics, granules of extruded polystyrene foam can be added to the solution (the latter can be purchased for about 1000-1800 rubles per cubic meter). This is done as follows.

Foam balls for concrete can be purchased pre-packaged

Step 1. A little water is poured into the prepared container, then dry cement is poured into it. All this is mixed with a mixer attachment until the consistency of thick sour cream.

Mixing the solution with polystyrene balls

Step 2. During the mixing process, polystyrene foam granules are added. The proportions of concrete can be very different - both 1:3 and 1:6.

The more granules there are, the more efficiently the floor will retain heat. But there is also a downside to the coin - this will deteriorate the strength, and the surface will begin to crumble under load. In short, the required ratio of polystyrene foam depends directly on how hard the floor covering should be.

Foam chips (expanded polystyrene granules)

Insulating the floor under the screed

Any screed (concrete, CFRP, self-leveling compounds) on top of Penoplex is done in the same way. The presence of reinforcement also does not affect the technology of laying slabs. Let's start with the fact that the slabs have formed projections, that is, a locking connection. This eliminates the appearance of through cold bridges.

It is cut, like any EPS, with a fine-tooth hacksaw (for plastic or metal). A more serious tool is not required. You can straighten the cut or trim it a little with a sharp knife (regular or construction knife). The rules for laying on the floor are very simple:

- For better heat retention, it is better to lay two layers. Their total thickness should match or be slightly larger than the selected one.

- Before laying Penoplex on the floor under the screed, roll out the damper tape around the perimeter.

- We lay the first layer so that the seams in the rows shift and there are no intersections in the form of a cross. That is, we start the first row, for example, with a whole slab. The second is from the segment that remained after trimming the last one in the first row. If it is too narrow, it is better to cut the new one in half.

- You can glue the joints of the first layer slabs with tape, but this is not necessary, since the edges in the form of locks are sufficient fixation. But for those who like it “more reliable”, you can glue it.

It is necessary to lay penoplex under the screed with the seams offset so that they do not coincide - The slabs of the second layer are laid so that the seams do not coincide. That is, to lay the first row in the second layer, halves are needed. To do this, the slab is cut lengthwise. That is, the junction of two rows will be above the middle of the bottom sheet. And so that it does not completely coincide, you need to start the first row in the second with a quarter. In the second row it is very advisable to glue the joints. Firstly, because they will be walked on - there is no escape from this. Secondly, because it is necessary to protect the joints from leakage of the solution.

Should polystyrene foam be attached to the base? For what? Loaded with a screed and everything on it, it won't go anywhere. If this installation method seems very unreliable to you (but this is what the manufacturer recommends), you can fasten it. The first layer is a dowel-nail with a large plastic head. The second one is usually not attached, but you can attach it with glue (PVA, for example). You can secure the first one with glue or some kind of mastic, but you will have to wait until the adhesive composition dries.

Ecowool

This material is very similar in characteristics to mineral wool, but is made from cellulose fibers, therefore it is absolutely safe for health. Just like mineral wool, ecowool is afraid of water and is easily deformed. Therefore, in most cases it is used to insulate wooden floors between floors.

The big advantage of ecowool is that it is installed by spraying under pressure from a special pipe. Thus, the insulation can be “blown out” under the already assembled floor; for this you only need to make several small technological holes.

The required thickness of the ecowool layer corresponds to the thickness of the mineral wool layer, all other things being equal.

Characteristics of basalt and ecowool

Penoplex screed: technology

Let's consider the simplest case - Penoplex for a floor under a screed on a concrete base. This can be concrete preparation in a floor structure on the ground, or a concrete floor in a high-rise building or private house. The procedure is as follows:

- Local irregularities larger than 5 mm are leveled. The manufacturer does not specify the alignment principle. That is, it can be a leveling screed (if there are too many irregularities) or local filling of potholes and cracks with a solution. In the second option, it is necessary to trim/cut/knock down the strongly protruding fragments. Sometimes they even level it with sand. This method is also not excluded.

Standard scheme for using Penoplex under screed - Seal all cracks and crevices. Along the perimeter of the premises, around pipes and risers, communication inputs.

- Roll out the edge or damper tape.

- Lay Penoplex in one or two layers. Tape the joints with tape.

- Spread the film (another waterproofing material) with an overlap of 15-20 cm, the joints taped. We place the edges on the walls and secure them with strips higher than the planned thickness of the screed.

- The beacons are set, the screed is poured and leveled.

You can level the base with sand, but do you really have a lot of unevenness

? Actually, the whole technology. All clear. Only questions may arise regarding the minimum thickness of the Penoplex screed. The manufacturer recommends at least 40 mm. When laying floors in wet rooms, it is advisable to cover the slab with waterproofing. Choose the type of waterproofing material yourself. The rest of the technology is the same.

Protection against heat loss of concrete floors located above a high subfloor

Insulation of a concrete floor with polystyrene foam can be effectively done from the side of an unheated room. This thermal insulation will help maintain the ceiling height in rooms located above the basement. The underground floor is a room with high humidity, so insulation work should be carried out with extruded polystyrene foam. This building material retains heat-saving properties in a humid environment. When installing an insulating pie on the basement side, you should:

- Clean the concrete base from dirt and wash it.

- Fill voids, chips and potholes with cement mortar.

- Coat with deep penetration primer.

- Place extruded polystyrene foam slabs on special glue and additionally secure them to the base with wide-headed dowels.

- Place a layer of waterproofing building material on top. A profiled membrane or foil can be used as waterproofing. The film sheets should be laid overlapping, the seams and edges should be sealed with armored tape.

- Lay metal mesh and plaster.

Laying heated floors on Penoplex

There are differences, but they only concern the laying of pipes or heating cables/mats. Preparation of the base, the first layers, including the waterproofing layer on Penoplex, were described above. A steel mesh is laid on the waterproofing film. It is needed to fix the cable or pipes in a given position. When using heating mats, they can be placed in a layer of tile adhesive - this is simpler and more effective, so this type of heating elements for the floor is rarely used at this stage (although no one prohibits it).

Which mesh should I use? Depends on the step at which you need to lay the pipe or cable. You can lay 50*50 mm, 100*100 mm or 150*150 mm. It is important that the chosen scheme can be implemented. What is the thickness of the wire in the mesh? Not less than 3 mm. In the case of a cable, perhaps 2 mm is possible. And before pouring the screed, the pipes will be filled with coolant and need to be held in place, so a mesh made of 3-4 mm wire is needed.

You can use Penoplex under a warm water floor without any problems

To prevent the mesh with coolant from moving when filled, it must be attached to the Penoplex. There are several options:

- Plastic clips that are driven into the insulation. But the thickness of the mesh rods is at least 4 mm.

- The metal tie is aimed at the insulation on both sides of the mesh cell.

- Special harpoon clamps.

- Special tires, but they are expensive.

- A mat with bosses is laid on top of the Penoplex. Then the grid is not needed. But these mats are also expensive.

After the mesh is secured, we attach the pipes or cable. The easiest way is with plastic ties, or knitting wire. But the wire can theoretically fray a pipe or cable as it increases or decreases in size (from heating and cooling) during operation. Therefore, if knitted with wire, it is in a plastic sheath. Manufacturers of pipes for heated floors have it.

Actually, that's all. Then they pour the screed, level it, and wait until the concrete gains strength.

Penoizol

This is a liquid version of polystyrene foam, which has the same pros and cons as the solid version. Its advantage is that it can be poured into hard-to-reach places and, after hardening, forms a monolithic coating without seams.

The disadvantages include the fact that you need to think about the method of supplying penoizol for pouring; on high floors this can be a problem. In most cases, penoizol is used during the construction of private houses; when insulating floors in apartment buildings, it is more convenient to use polystyrene foam and penoplex.

The required thickness of the penoizol layer is the same as that of solid foam.

Dry screed on Penoplex

Cement-sand or concrete screed is, of course, good. And it is the best solution if you want to make a warm floor from heating. But the mass of materials amounts to tons. Raising this to any level is already a problem. You also need to wait at least 28 days for the concrete to gain strength. It's faster and easier to make a dry screed. Not in the sense that from a solution that is called dry. And using sheet materials - plywood, OSB, gypsum board. This base will be suitable for any finishing coating. Even under tiles, but with certain reservations - glue is needed for complex unstable bases.

You can make a flat floor without concrete and mortar: lay Penoplex for the floor under a screed made of gypsum plasterboard, plywood or other sheet materials

How to make a dry floor screed using Penoplex? Just:

- Level the base.

- If necessary, we lay or apply waterproofing.

- We lay out Penoplex slabs, preferably in two layers with bandaging of the seams.

- We lay one layer of sheet material. Again, we move the seams.

- The second layer of sheet material is also staggered.

- We fasten through with suitable fasteners. It depends on the material that was laid on the insulation.

- Further on the technology of laying the flooring.

The thickness of gypsum boards for laying on Penoplex on the floor is 20 mm, plywood is better to take 10-12 mm, OSB can be smaller. You can also put GVL on Penoplex. The slabs lie flat, without differences, so the base is suitable for this material. But it does not have the disadvantages of gypsum plasterboard and OSB, and the cost is approximately the same as them.

Review of manufacturers

When choosing a model for insulating a garage floor with polystyrene foam, we pay attention to the manufacturer of this material. The main guarantee of a long service life is compliance with technology during manufacturing. Currently, there are a number of companies whose products meet quality standards. Among the foreign ones the following can be distinguished:

- Basf;

- Polimeri Europa;

- Nova Chemicals.

Products from Russian manufacturers are no less quality:

- TechnoNIKOL;

- Penoplex.

To create a heat-insulating layer, it is best to use materials of the same brand. Even a slight difference in manufacturing technology can affect their compatibility.

© 2022 prestigpol.ru

Features of expanded polystyrene

Modern polystyrene foam is a cheap material widely used in both country houses and city apartments. It is made by thermal expansion of polystyrene granules. As a result, the granules sinter, forming a white material.

Section of a floor insulated with polystyrene foam

Each of the polystyrene foam granules consists of many microscopic cells filled with air. This is what can explain the extraordinary lightness of the material, because 97% of its composition is air voids.

General information

Conditions for isolation

In order for foam insulation to work most effectively, and for the floor screed on foam to be as strong as possible, several conditions will need to be met:

Insulation density

The most significant issue when using polystyrene foam is related to the strength of the foam insulation. According to GOST, foam rubber corresponds to its maximum density, for example, for grade 25, the density of foam board can vary from 16 to 25 kg/m3. This means that the strength of a slab from one manufacturer may be satisfactory if the specific gravity exceeds 20 kg/m3, or may be insufficient if the value varies from 16 to 20 kg/m3.

If you don’t bother and take ordinary foam plastic at hand, then there is a high probability of finding yourself in a situation where, when you try to lay the screed, the foam will simply choke.

It is well known that polystyrene foam is a compressed mass of polystyrene in the form of balls. With prolonged exposure to the sun, the material quickly ages and breaks up into many tiny balls. Therefore, before using foam under the screed, you should clarify how and where it was stored. If the material has been stored outdoors for a couple of months, it cannot be laid under a screed; alternatively, you can insulate the floor in the barn.

There is an opinion that polystyrene foam is not a hygroscopic material, but this is not the case. The lightest brands of polystyrene foam, which have the best thermal insulation, are able to absorb some moisture from the soil and air. After this, the water foam can come off the screed, partially losing its insulating properties, and collapse even when frozen. Foam polymer can last up to 50 years without deteriorating in its properties.

How to choose the right insulation?

If you choose polystyrene foam as insulation, you should take into account such indicators as the quality and type of material. First of all, you can evaluate the quality of the material by looking at the appearance, you should evaluate the following points:

- Initially you need to look at the color, it should be bright and uniform, since this is what indicates the manufacturing process. As a rule, you can find blue or orange slabs on the construction market;

- you need to determine the smell; if the material smells sharp, then you should refuse to buy it, because this should not happen;

- the slabs must have clear geometric shapes, the edges must be smooth and not crumble;

- all granules must be the same size, without voids;

- The surface of the plates must be distinguished by its evenness, otherwise the thermal insulation qualities will be reduced.

When purchasing a heated polystyrene foam floor, experts recommend paying attention to the cut location; if the granules remain intact when broken, this indicates poor quality of the slab

Recommendations and common mistakes

Often, owners try to save on auxiliary materials, such as polyurethane foam, tile adhesive or plastic film. Any attempts to lay polystyrene foam even on the smoothest concrete, without fixing it with glue, are doomed in advance to further destruction of the insulation at the joints and seams.

The second mistake is related to improper arrangement of vapor barrier. A membrane with one-way water vapor conductivity should always be used. Moreover, the insulation system must have vents that ensure normal ventilation and removal of steam from the warm side of the concrete towards the colder surface.