08/25/2016 Category: HeatingAuthor: Natalya Ivantsova

The boom in solid fuel stoves that arose in the heating equipment market has several reasons. It is largely due to the massive construction of dachas and country houses in places where there is no possibility of connecting to the main gas. A significant increase in energy prices also played a role, forcing the duplication of installed heating units with boilers running on wood and coal. But the main thing that I would like to note is the emergence of designs that use a completely different approach to burning solid fuel, thanks to which it is possible to increase the time between loads several times. Units using the new principle vary in complexity, size and performance. Today we will talk about a simple long-burning stove that you can build with your own hands in a weekend. Of course, such a unit is not suitable for heating a large house, but it will be indispensable for heating utility rooms, a garage or a greenhouse. Moreover, the materials for the work can be found at any scrap metal collection point.

- Advantages and disadvantages

- Types of long-burning stoves. Choosing a simple and efficient heating unit to make yourself

- Design and principle of operation of a top combustion furnace

- Drawings and diagrams

- Required materials and tools

- Step-by-step instructions for making a long-burning stove with your own hands

- How to load fuel and operate the unit correctly

- Video: Operation of a long-burning stove made from a barrel

Advantages and disadvantages

Modern long-burning stoves have a lot of advantages, which can play a decisive role in the initial selection of heating equipment. However, the disadvantages of existing designs require weighing the pros and cons before deciding to replace an existing heating unit with a newfangled pyrolysis boiler.

The advantages of the structures under consideration include:

- multiple increase in operating time on one fuel load;

- possibility of full autonomy - when entering the main mode, operation of the unit does not require operator intervention;

- the fuel burns with virtually no residue;

- the interval between downloads increases;

- using not only coal and firewood as fuel, but also wood chips, sawdust, dry plant waste, pellets, etc.;

- reduced weight and dimensions;

- possibility of adjusting the combustion process;

- The efficiency of long-burning pyrolysis boilers reaches 90%;

- smoke residues do not contain soot or harmful substances;

- many designs available for DIY.

Be sure to check out the disadvantages of this type of oven:

- increased requirements for the chimney. It must have sufficient height and thermal insulation;

- In long-burning furnaces, only dry fuel can be used. Excess moisture reduces the flame temperature, and water vapor blocks the access of oxygen, which makes it impossible for the unit to operate in gas generator mode;

- the reduced smoke temperature promotes the layering of soot and other combustion products on the walls of the chimney;

- when burning wet fuel, heavy fractions and dangerous chemical compounds appear in the smoke residues;

- higher cost compared to conventional furnaces.

If you weigh all the pros and cons, it is not difficult to understand that the wide popularity of long-burning stoves is not an accident at all, but the result of precise calculations and a carefully designed design.

Features of operation

The duration of combustion is regulated by the supply air valve.

Reduce the volume of supplied air to reduce the rate of firewood burning. You can avoid the appearance of condensation if you make fewer turns of the smoke exhaust manifold channel.

The moisture content of the added fuel should not exceed 25%. During combustion, do not open the door to prevent carbon monoxide from entering the room.

Twice a month you need to heat the unit at maximum mode to burn off slag deposits on the internal walls. The efficiency of the stove will be higher if you use large-sized firewood.

Design and principle of operation of a top combustion furnace

A long-lasting solid fuel unit with an upper burning layer can be made from an iron barrel for fuel and lubricants, a gas cylinder or large-diameter steel pipes. The thickness of the housing walls must be at least 4–5 mm, otherwise they may burn out due to high temperature. The height of the heating device must be at least 1 m, since the duration of its operation depends on the amount of fuel. However, you should not try to build a unit that is too high. Firstly, it will be inconvenient to load it, and secondly, a layer of firewood or sawdust that is too thick can reduce the draft so much that combustion simply stops.

Conventionally, a vertical oven can be divided into three working spaces:

- loading chamber - part of the body into which fuel is placed. During operation, the loading height decreases as the briquettes, firewood or shavings burn out;

- the combustion zone or working zone is the highest temperature section. In this layer of combustible material, oxidizing reactions occur, releasing a large amount of heat;

- flammable gas removal zone - a high-temperature space in which heat exchange and afterburning of combustion products occurs.

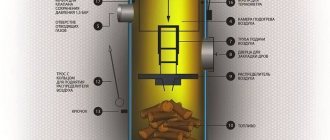

The schematic diagram of a long-burning boiler presented below allows you to get a complete understanding of its design and principle of operation.

Diagram of a long-burning boiler with vertical loading

In order to limit the combustion zone, an air distributor is used. This device is a flat metal circle 5–6 mm thick, in the center of which there is a hole for supplying oxygen to the work area. The air supply is carried out through a long steel pipe brought out through the top cover of the heating unit. The unimpeded movement of the air distribution device is ensured by the difference in the diameter of the metal pancake and the unit body, and the height of the burning layer depends on the width of the impeller. Since the latter determines the air gap between the fuel and the piston, its parameters determine how quickly the fuel will burn.

Homemade boiler air distributor

It has been established experimentally that the height of the air distributor blades should not exceed 50 mm, otherwise the fuel combustion rate will be increased, and this will lead to the need for more frequent refills of combustible material.

The diameter of the air channel must be at least 60 mm, while the size of the distributor opening of more than 20 mm is considered excessive - oxygen supersaturation increases the combustion intensity, which is unacceptable for a unit of this type.

Most often, the distributor pipe is made with an open edge, so that atmospheric air is used as an oxidizer. The place where the air duct enters the upper hatch is not sealed - free access of oxygen to the space above the piston makes it possible for volatile hydrocarbon compounds to burn. There is also an option when air enters the combustion zone from the upper chamber, where it is preheated. This design increases the performance of the heating device and makes its operation more stable. The amount of oxygen is regulated by a special damper installed in the air supply window.

To remove combustion products, the upper part of the boiler is equipped with a smoke channel with a small horizontal section. As a rule, 50–60 cm of straight pipe is enough to relieve the draft. Despite the fact that in furnaces of this type the completeness of fuel combustion reaches 90–95%, it is periodically necessary to remove ash and ash that accumulate at the bottom of the installation. To do this, a window is made in the lower part of the housing and a sealed door is installed.

To connect a long-burning stove to a liquid heating system, the unit is equipped with a heat exchange circuit or a water jacket.

Some tips - what will help improve the operation of the furnace

A long-lasting vertical furnace is heated, adhering to the following rules. Remove the cover and take out the adjusting device - a pipe with a pressure circle. We load the firebox with fuel, the maximum height is to the bottom of the chimney opening. We try to pack any fuel as densely as possible. Place small dry branches on top in the center, then paper or a cloth moistened with kerosene. We install a clamp, a lid, and throw burning paper or a rag into the pipe. It is unlikely that you will be able to set it on fire with a match - it will go out on the fly. When the fuel burns well, close the air damper - work continues in smoldering mode.

Homemade structures use almost any solid fuel: wood, coal, garbage, pellets. But it is still necessary to take into account the features of each model in order to choose the most efficient fuel. As already mentioned, vertical stoves with a conical pipe can work effectively on sawdust. Vertically located devices work well with wood, coal, and briquettes. Long-term burning products with a horizontal firebox are designed for the use of firewood and wood chips. Pellets are used mainly in industrial equipment, where fuel is supplied automatically, but they can also burn in home-made installations.

In horizontal furnaces, heat transfer can be increased by using a combustion bulkhead device. From a thick metal sheet we cut out a blank with a width according to the internal dimensions, and a length - ⅔ of the length of the combustion chamber. We install it at the top under the chimney pipe. Such a simple device slows down the flow of gas and additionally accumulates heat.

Another device for making full use of the long-burning effect is an injector. These are one or two pipes with holes leading into the firebox. We cut holes in the walls of the heating apparatus according to their diameter and weld the injector. It is located at the height of the center of the chimney pipe, but in front of the firebox. The injector serves to feed the combustion process with air, the upper wall warms up better. When the device goes into the smoldering process, it does not work.

There are many design options, we only talked about a few. We hope that using the information received, you will be able to independently make a simple and reliable device that does not require constant maintenance.

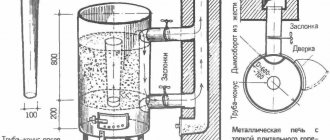

Drawings and diagrams

The undoubted advantage of the long-burning “potbelly stove” design presented above is its undemanding size. As a rule, for the stove to operate correctly, knowledge of the principles of its operation and compliance with the basic proportions is sufficient. However, we present to your attention drawings and diagrams of existing structures, manufactured and tested in real conditions.

Drawing of a vertical loading oven

Drawing of a long-burning boiler

Diagram of a long-burning furnace with an open air channel

Boiler drawing

Technical nuances

- The oven should not be placed close to walls, objects, etc. Leave enough space around it.

- The oven gets very hot - do not keep flammable materials, fuel, or anything that can catch fire, dry out or melt near it.

- When making a chimney, think about how to clean it in the future. The best option is to make it collapsible.

- If the chimney pipe is prefabricated, install the elements so that the joints are located in the opposite direction in relation to the moving gases.

When cleaning out ash, leave some of it behind each time. If the combustion takes place on an ash bed, the bottom of the stove will not burn out longer.

Required materials and tools

Before you start building a long-burning stove, prepare the following materials:

- a two-hundred-liter barrel of fuel and lubricants. It is advisable to choose a container with thick walls, without damage or heavily rusted areas. As a housing, you can use a pipe of a suitable diameter or a propane cylinder (household 50 l or automobile 80–100 l). In addition, the stove can be made from sheet steel with a thickness of at least 3 mm;

- a metal pipe with a diameter of at least 60 mm - for arranging an air channel;

- steel pipe with a diameter of 100 mm - for the manufacture of a chimney;

- steel channel or corner with a shelf 50–60 mm;

- a sheet of metal 5-6 mm thick, slightly larger than the diameter of the body - for the manufacture of an air distributor;

- a steel sheet with a thickness of at least 3 mm, which will be required to make the lid;

- hinges for the bottom door.

As for the tools, any self-respecting home craftsman will have them:

- welding inverter or transformer;

- angle grinder (popularly “grinder”);

- cleaning and cutting wheel for angle grinders;

- electric drill;

- a set of drills for metal work;

- hammer;

- anvil;

- measuring and marking tools.

If the design of the heating unit provides for the arrangement of a water circuit, then it is additionally required to stock up on sheet steel and two threaded pipes for inserting the boiler into the hydraulic heating system.

Let's start making - what you need

To make a homemade stove, you need to choose a convenient place. This must be a room with connected electricity and sufficient area. Now about the materials. It is easier to use a 200 liter steel barrel for a stove with a long burning time. However, the volume is not of fundamental importance; the heat transfer of the device will simply depend on it. They use gas cylinders and even fire extinguishers.

The stove can be made from an old gas cylinder

But, again, the volume of the workpiece: from a 27 liter cylinder you can make a stove for heating a bathhouse, from a smaller one or a fire extinguisher - for a tiny room. The thickness of the metal matters: the thicker it is, the longer the stove will last. If there is nothing suitable, we use a thick-walled pipe or steel sheets. The metal must be free of damage and rust. Other materials you will need:

- material for the legs if the oven is round in shape (pipes, angle, fittings);

- sheet steel 5 mm thick according to the dimensions of the end side of the product;

- sealed door or material for it;

- The 100 mm pipe is 15 cm longer than the device;

- 5 m of 150 mm pipe for smoke removal.

Measuring instruments are required: tape measure, plumb line, level, as well as a hammer, mallet, trowel.

Step-by-step instructions for making a long-burning stove with your own hands

1. To make the stove body, use a grinder, which is used to carefully cut off the top of the metal barrel. Of course, in the case of using a container with a thickness of more than 3 mm, the use of a gas cutter will be more justified. We remind you once again that the work must be done carefully - the furnace lid will be made from the cut part in the future. If a pipe is used as a body, then it is necessary to weld a bottom cut from sheet metal 5–6 mm thick to it.

When cutting off the cover, remember that this element will be needed later

2. In the lower part, four legs from a channel or angle are mounted to the body using a welding machine. Note that if the body is made of metal and has a rectangular shape, then you can do without additional supports.

One of the options for arranging support legs

3. Using the same grinder or autogen, an air distributor is cut out of sheet steel 5-6 mm thick - a circle that can fit into the barrel with a small gap. The edges of the metal pancake must be thoroughly cleaned to prevent the possibility of touching the walls of the oven.

4. A hole with a diameter of 20 mm is cut in the center of the air distribution device and a pipe is welded to supply air to the combustion zone.

The blades of the air distribution device are mounted at the same distance

5. On the back side of the flat piston, four sections of a channel or angle are welded, evenly positioning them in a circle. Note that the blades should not protrude beyond the air distributor. In the future, thanks to these elements, there will be an air gap between the metal pancake and the firewood, which is necessary for fuel combustion.

As a result, the air distribution device should look like this

6. A lid is made from the previously cut off top of the barrel. To do this, a metal strip is welded from the outside along the entire contour so that its diameter allows the top of the stove to be freely installed on the body.

Making the lid

7. A hole is cut in the lid, 3–5 mm larger than the diameter of the air duct pipe. In addition, two handles made of strips of metal are welded onto its top. With their help, it will be easier to open the hatch for loading fuel.

8. A hatch for cleaning the oven is cut out in the lower part of the body. Try to do this part of the work using a grinder with a thin circle installed. This will ensure a more precise fit of the door to the body. A thin metal strip is welded along the perimeter of the hatch to eliminate the resulting gap. Then the hinges are welded, the structure is installed on the body and the valve is mounted.

9. On the other side of the stove, at a distance of 50–100 mm from its upper cut, a smoke exhaust pipe is cut in. It is used as a piece of steel pipe, into which the chimney will fit with a slight interference.

Installation of a smoke exhaust pipe

It is better to use a chimney of a collapsible design, consisting of several sections - it will be easier to clean during operation.

At this point, the production of a vertical-type solid fuel unit can be considered complete. All that remains is to install the stove in place and connect the chimney.

Long burning stove: final version

Installing a heating device - important rules

For the installation to operate safely, certain rules must be followed:

- It is prohibited to place combustible and flammable objects within the warming-up distance;

- we make the chimney dismountable for cleaning;

- Before use, we carry out a test to select the optimal mode.

The diameter of the chimney exhaust pipe is about 15 cm.

For the chimney exhaust we use a pipe with a diameter of 150 mm and a length of 5 m. With a smaller cross-section, smoke will not be removed well; with a larger cross-section, excess draft will appear. We install an adjustable damper on the chimney. Accumulated condensate must be removed periodically. If the chimney is not dismountable, doors are made in it for cleaning. Excessive formation of condensation can be prevented by constructing a chimney using the sandwich principle. Between two pipes of different diameters we place a layer of glass wool for insulation. We cover the top of the chimney pipe with a deflector to prevent rain, snow, and wind from blowing in.

In a house where there are children, we line the stove with bricks. The masonry around plays the role of a protective screen, so as not to get burned if you accidentally touch it, and protects objects and walls from overheating. It also serves as a good heat accumulator. The brick will accumulate heat and release it much more slowly than the iron body. We arrange the foundation if the floor under the stove is made of flammable materials. It is not necessary to deepen it too much; the weight of the heating device is light.

How to load fuel and operate the unit correctly

A long-burning unit differs from a traditional furnace by an increased loading volume and limited access of oxygen to the working area. The operating time of the boiler depends on the amount of fuel loaded, so the firewood is stacked as tightly as possible, without leaving large gaps between the logs. If materials such as peat, fine coal, shavings, sawdust or pallets are used as fuel, then they are poured to the level of the smoke channel without compacting. The necessary compaction of the fuel will be provided by a heavy metal piston.

Fuel loading is performed in the following order:

- remove the top cover from the unit;

- remove the air distribution device;

- load the stove to the level of the chimney;

- spray the top layer of flammable material with lighter fluid;

- install an air regulator;

- return the cover to its place;

- A piece of rags soaked in a flammable liquid is thrown inside the air channel.

Steady combustion is accompanied by smoke coming out of the chimney evenly. As the wood burns, the duct pipe moves down. It can be used to judge the remaining operating time of the solid fuel unit.

It is best to light the stove using a rag moistened with a flammable liquid.

During operation, ash and ash accumulate at the bottom of the barrel. It must be said that their quantity does not have any effect on the combustion process. However, fuel combustion products must be periodically removed, since they reduce the thickness of the filling layer. To do this, open the bottom door and scoop out the ash using a regular metal scoop.

When removing ash, leave a layer 10–20 mm thick on the bottom of the oven. This will not have a particular effect on the amount of firewood; however, it will create an excellent heat-insulating cushion that will protect the bottom of the unit from burning out.

A little more about pyrolysis...

The essence of pyrolysis lies in the process of technological gas-generator combustion.

When solid fuels such as coal, pellets, peat briquettes or firewood are burned, the room warms up. The operating principle is similar to that of a dry distillation boiler. The pyrolysis system is due to its exothermic properties, and can heat the incoming air due to the heat generated. The fuel is ignited and the fan turns on when the door is closed. The high temperature regime (200–800 °C) and low oxygen capacity in the pyrolysis combustion furnace lead to a chemical process - the wood decomposes into coke and pyrolysis gas. Also, when wood burns, it can form methyl alcohol, acetone, vinegar and resin. The released gas combines with oxygen and goes into the combustion process. The smoke generated during combustion does not contain bad carcinogens and other dangerous components. Burnt fuel produces thermal energy, which heats the room. The water contained in the boiler enters the heating structure in a hot state with a simultaneous return supply. The coolant is also used as a coolant. This is how a boiler with a bottom-mounted chamber functions.

Varieties

If you are going to purchase a wood-burning stove, then you will need information about the types of these units. Here's what we can find on sale:

- Steel and cast iron models;

- Units with and without a hob;

- Fireplace and conventional stoves;

- Conventional combustion furnaces and pyrolysis modifications.

The differences between steel and cast iron units are quite obvious - the former are lighter, less reliable and cheaper, while the latter are gigantic in weight, but are distinguished by their durability and long service life.

Such units not only look great in the interior of a country house, but will also allow you to cook directly on them.

An economical wood-burning stove, which includes a hob, is an excellent find for a cozy country house, small cottage or technical room where people constantly work. Here you can cook soup, fry meat, heat a kettle to enjoy a hearty lunch or dinner. In general, a worthy addition for small-sized housing and technical premises.

Long-burning fireplace stoves combine the practicality of heating units and the beauty of classic fireplaces. Such wood-burning units will create a cozy atmosphere in your home with a beautifully burning flame. Relaxing in a house with a fireplace is a pleasure that will be available for minimal money.

Such devices can burn wood in the usual way or by pyrolysis. In the first case, combustion is carried out in a standard mode, with combustion products being removed through the chimney. Pyrolysis furnaces have a fuel afterburning chamber - the pyrolysis products formed during heating and combustion of wood in the main chamber are burned in it. Such furnaces have higher efficiency.