In regions with a harsh climate and frosty winters, there is a need to equip residential buildings, agricultural and industrial buildings, and social facilities with heat supply systems, the key element of which is the heating boiler. The most important criterion for choosing heating equipment is the cost of energy resources on the regional market and, as a consequence, the total cost of heating.

There is no worthy and less expensive alternative to solid fuel (liquefied gas, electricity, fuel oil are much more expensive, and solar systems can be used exclusively as auxiliary). Therefore, a logical question arises: “Which solid fuel boiler to choose for the heating system.” We will try to answer objectively and as completely as possible.

Wood burning boilers Protherm Beaver DLO

Perhaps the most important parameter that you should pay attention to when purchasing a solid fuel boiler is the type of fuel on which it runs.

Main options:

- firewood and various waste from the wood processing industry (bark, wood chips, sawdust, wood briquettes);

- coal (brown, varieties of stone, in particular, coke and anthracite, also keep in mind that this type of fuel differs in fractions, this is very important);

- agricultural waste (for example, grain, oats, straw, sunflower husks, etc.);

- peat;

- granules (pellets that are made by pressing from woodworking and agricultural waste; a pellet boiler operates on this type of fuel).

Before purchasing heating equipment, look at how much each of the above-mentioned types of solid fuel costs in your region and which is cheaper. And in order not to limit yourself in your choice, you should take into account that there are universal, combined solid fuel boilers that operate on several types of fuel.

The second important parameter is the operating principle of the heating device. The battery life of the boiler depends on this. There are only three options:

- manual loading of the fuel chamber and regulation of the combustion process (using a chain);

- manual loading of the fuel chamber and automatic regulation of the combustion process;

- automatic loading and regulation of the combustion process.

Option one - classic boilers

The first option is traditional, classic, which has been used for thousands of years in conventional stoves, put in firewood or coal, and adjusted the air supply with a damper. The main disadvantages are the need for constant supervision and low efficiency, the inability to accurately regulate the combustion process. Advantages - the simplest boiler in technical terms and maintenance, operating on almost any type of solid fuel.

Examples of classic boilers:

- ZOTA Carbon

with a steel heat exchanger, operating on coal with a fraction of

10.00 - 50.00 mm

, power

from 15.00 to 60.00 kW

, with top fuel loading, a movable grate and a design that ensures maximum afterburning of fuel and precise oxygen supply to firebox; - Buderus Logano

with a steel heat exchanger, can work either separately or in combination with a gas or liquid fuel boiler with a capacity of

12, 16, 20, 24, 27, 32, 45 kW

, in systems with natural and forced circulation of coolant, is small in size and heat exchanger protection, large volume of ash pan and loading chamber, works on wood (logs up to 33.00 and 53.00 cm long), coal, coke.

The burning time of such boilers is 3-7 hours.

Natural circulation systems

Systems with natural circulation, due to their characteristics, are more suitable only for houses with a total area of up to 200 square meters. m, or rooms with few thermal circuits. In addition, they will require large diameter pipes (at least 40-50 mm). Moreover, they are laid at an angle to the horizontal plane so that the water flows under the influence of its own weight. Such systems are difficult to regulate, but they are independent of the power supply.

Option two - semi-automatic boilers

A boiler that requires manual loading, but controls combustion using automation, is called semi-automatic, which ensures higher equipment efficiency; it operates on any fuel, like classic boilers. But these boilers are energy dependent.

Let us note the models of the Polish manufacturer Metal-Fach

SDG

line , boilers run on coal and wood, heat exchanger made of

P265GH

6.00 mm

thick , water-type cooling grate, with a vertical chimney system, large loading chamber and

efficiency

up to

81%

, designed for open and closed heating systems with forced and natural circulation of coolant.

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

Features of a water heating system and choice of circulation circuit

The OS, where the coolant circulates naturally, is as simple as possible. In such a circuit, water is heated in the boiler and, according to thermodynamic laws, flows upward along the riser. Having reached the radiator elements, the coolant releases part of the heat energy, and its temperature decreases. Under pressure, the heated, cooled water is released back into the boiler - and the cycle repeats.

High-quality pumping equipment for OS with forced circulation must meet the following criteria:

- energy saving;

- ease of operation;

- durability.

The power is determined by the size of the home that needs to be heated.

On a note!

For example, to heat 250 m², a circulation pump with an indicator of 3.5 m³/h and a pressure of 0.4 atm is required.

In addition, the choice of pump is influenced by calculations from the heating circuit design. This:

- pipeline system material used for installation;

- pipe diameter;

- total length of the system;

- number of heaters;

- type of coolant.

Selecting pumping equipment on your own can be difficult, so it is recommended to consult an expert.

When installing an OS with forced circulation of the coolant, it is not necessary to comply with the requirements for the slope of the pipes. Heat lines are installed in a straight line or with a slight slope relative to the drain. This will make it easier to release water before carrying out repairs or, for example, in a situation where the OS faces a long downtime.

The third option is automatic boilers

Fuel loading into the chamber and combustion control are carried out automatically. The advantage is autonomy (5-9 days on one load), the disadvantage is the high cost.

Such boilers are equipped with a loading hopper for supplying solid fuel and automation. The operating principle is quite simple. Fuel of a certain fraction is loaded into a bunker, from which it is supplied to the loading chamber as it burns.

Let us note the automatic boilers of the Polish manufacturer Metal-Fach

with a steel heat exchanger (P265GH steel with a thickness of up to 6.00 mm is used),

efficiency

over 90

%

, a modern, innovative type controller

FL 310LGRTC

, which allows servicing one mixer and up to four circulation pumps with continuous logic and PID control functions, an upper combustion chamber, retort burner of the following lines:

- SEG (work on coal of various fractions)/SEG BIO (pellets, oats, grape and olive seeds, other agricultural solid waste and coal are used as fuel). These are devices with automatic fuel supply, the ability to connect room (internal) and weather (external) sensors, a lambda probe and the STRAŻAK (FIREMAN) protective system, which prevents the ignition of granules;

- SD DUO

, coal is used as solid fuel, including sunflower seeds, coal dust, and any hardwood (in manual mode). The boilers are equipped with a fuel dispenser, two loading chambers, an automatic device responsible for supplying fuel; if necessary, a lambda probe can be connected; - SD DUO BIO

, configured for burning pellets, agricultural waste, grain crops (wheat, oats), as well as coal, hardwood and coal. The devices are equipped with an automatic tray loading device with a feed screw, an ignition device, a lambda probe (if necessary), and the STRAŻAK (FIREMAN) protection system, which prevents fuel from igniting outside the firebox. - SMART

and

SMART EKO

, running on pea fraction coal, pellets, with a unique Ekoenergia burner. These boilers can operate in both manual and automatic modes, which guarantees stability in the heat supply to the premises. The MASTER 500 controller allows you to control two pumps and a room thermostat.

Separately, we note the automatic boilers of the Russian company Vulkan

, developed on the basis of proven European manufacturers of heating equipment.

They are unpretentious in operation and fully adapted to Russian operating conditions. They work on coal of various fractions ( up to 40.00 mm

), including pellets, pellets (fraction

from 6.00 to 8.00 mm

), heat exchangers are made of boiler steel 6-8 mm thick, have a screw supply of solid fuel from a bunker.

These automatic coal boilers are capable of operating autonomously from five to ten days, and are equipped with electronics from various European manufacturers, which allows you to control two circuits of the heating system and the hot water supply system (DHW) simultaneously.

Anyone can understand the controls thanks to a simple and intuitive menu (interface). Additionally, a GSM module

for remote monitoring and control using mobile communications, an automatic ash removal system and automatic ignition.

, Vulkan automatic boilers

one of the best offers on the Russian market.

What material are boiler heat exchangers made of?

Once you have decided on the type of fuel and type of boiler, you need to pay attention to the design features and operational characteristics.

An important parameter is the type of material from which the heat exchanger is made. There are only two basic and widespread options :

- cast iron;

- steel.

Cast iron heat exchangers are more durable, their useful life is more than twenty years, and they are resistant to corrosion. But this material is quite sensitive to mechanical stress and temperature changes, which can lead to deformation of the structure. Cast iron boilers consist of modules and sections, which facilitates transportation and installation.

This is an excellent solution for solid fuel wood boilers. But this is not a very good solution for automatic solid fuel boilers, since these boilers operate in start-stop mode, which leads to frequent temperature changes, and this adversely affects cast iron. In addition, a cast iron heat exchanger requires frequent cleaning, and it is not very convenient to clean, unlike a steel one.

Steel heat exchangers are more resistant to temperature changes and mechanical damage, but their useful life is slightly shorter.

This solution is perfect for appliances operating on hard and brown coal. Steel boilers are welded from fragments of sheet steel; this is a non-demountable structure.

Much less common materials for heat exchangers are copper, ceramic-coated steel, or combined solutions.

Do-it-yourself water heating installation for a private house

It is easy to independently install any type of water heating in a wood-burning house. But the heating scheme requires high-quality calculations; the plan is drawn up in detail. And it’s better when a pro does it.

On a note!

The installation process begins with selecting a location for the boiler equipment to be installed before wiring. It’s clear that professionals know very well how to properly plan a network, so it’s wise to invite a specialist at the initial stage.

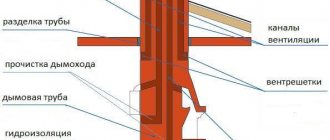

Having figured out the place for the boiler unit, you need to make a concrete base for it. The equipment is installed on it and combined with the chimney, and all connecting parts are sealed with clay or other non-flammable material.

Then you need to draw what the piping layout will be like in the heating circuit of the house. Consider in detail where radiator elements, risers and other composite structures will be installed. This is why it is important to invite a master.

As you know, it is recommended to install radiators under window openings. This is required so that the hot air from them warms the incoming cold currents. The number of sections and their type should be determined not only by financial capabilities, but also by the length of the circuit. The more of them there are in the OS, the faster the water will warm up the room.

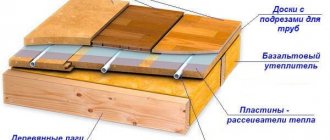

Next, pipes are laid and radiator elements are installed. Nothing complicated: the pipeline is led to the location where the battery is installed, all the required inputs/outputs are connected, then the pipe is led to the next radiator element.

On a note!

It would be good if a special tap was installed on each battery. It will allow you to remove air from the heating network automatically.

The circuit closes at the inlet of the boiler unit. A filter device and (if required) pumping circulation equipment are also installed here. The very bottom of the OS should be equipped with a flood-drain unit. It is necessary for removing/refilling coolant in a repair situation.

Combustion technology

The next stage of selection is very important. You need to decide on the boiler operation scheme. All solid fuel boilers according to fuel combustion technology can be divided into three large groups:

- the first one uses the classical principle of burning coal and wood, which is that combustion occurs from the bottom up, that is, first the lower layer burns, and then the upper one, this is a classical scheme, such heating equipment is the cheapest;

- the second, more advanced, is the combustion of fuel from top to bottom, combustion occurs like a regular paraffin candle, which allows for the longest burning on one tab, this is the so-called long-burning solid fuel boiler, the most common design is called Stropuva;

- the third, the most complex and expensive technology, is to use two chambers, the first loading chamber, solid fuel is supplied into it, where it smolders due to the low oxygen content, which prevents combustion, as a result, pyrolysis gas is released, fed into the second chamber, where it is produced its afterburning is the optimal scheme; such boilers are usually called gas generator or pyrolysis boilers, but they are more expensive and the requirements for fuel quality are high.

Pumps

Additionally, when laying heating pipelines for a country house, circulation pumps are installed - they do an excellent job of circulating water in large houses with a long length of pipes, save fuel consumption, and also heat the room faster due to the rapid movement of water.

Experts recommend that for one-story houses with a steep roof and a basement, make a scheme with vertical risers and two-pipe wiring. When installing water heating with your own hands, it is important to think about where the exhaust gases will go. To ensure their exit, you need to install a special pipe.

Functional purpose

After you have decided on the technical and structural features of the boiler, you need to answer the question: “What is the boiler for?” . Naturally, the first answer will be: “For heating.” And that's true. Such heating devices are called single-circuit.

But the functionality of the equipment can be significantly expanded; for this, a second circuit and storage tanks for hot water are used. Such boilers are called double-circuit and are used simultaneously in heating and hot water supply systems, that is, two in one, they are more expensive, but the functionality is higher and these are very compact solutions. There is no need for additional purchase and installation of water heating equipment.