The issue of heat supply to a country house and dacha is always relevant. This is especially true for buildings located in areas remote from the city. As a rule, there is no gas main there. Such buildings are heated either with electricity, which is very expensive, or with a traditional stove. The heating appliance market offers a reasonable alternative to stove heating at home. These are long-burning gas generator furnaces, which have been proving their effectiveness for half a century. Compared to electric boilers, the above equipment is also economical.

Efficiency of long-burning furnaces

- The stove design consists of 2 combustion chambers. In the first chamber, solid fuel burns with a low proportion of oxygen. In the other chamber, gases released during fuel combustion burn.

- But the whole point is that the fuel combustion process is considered low-calorie, since heat is released in small quantities with a sufficient temperature to heat the required room.

Furnace-heater Miracle

Such a heating device provides high-quality heating for premises of any purpose for a long time, while little fuel is wasted.

Device

This device is an all-welded steel structure. The transfer sheet divides the combustion chamber into two compartments. The top contains nozzles and an injector. At the bottom there is smoldering fuel.

The heater is covered with a special steel casing: it reduces the heating temperature of the walls of the device and allows the heat to escape evenly. Thanks to this element, it is impossible to get burned on the stove.

Principle of operation

The process of gas generation is the smoldering of fuel with minimal access to oxygen. Re-burning of the gas occurs using special nozzles.

Such a device can be heated with firewood, garbage, dry manure, and peat. One load of fuel material provides the structure with continuous operation for 6-8 hours.

Application area

The “Miracle” stove-heater can be used for heating summer cottages, large cottages, industrial buildings, outbuildings, garages, and greenhouses.

Advantages

Such a heating device begins heating immediately after kindling. Warmth will come to the house in about 20-30 minutes. In addition, its advantages include independence from gas, oil, electricity, uniform heating of the entire room, work with any type of fuel (with the exception of coal), and high efficiency.

The Miracle oven is an economical and easy-to-use device that does not require special maintenance or care. Its combustion process can be controlled. Installation of such equipment will be inexpensive. You can cook food and heat water on it.

How does the stove work

Now we will explain to you the operating principle of this stove. To begin with, we are interested in the process of fuel combustion in the first chamber of the unit.

Although it would be more correct to call this process “smoldering”, since with a small proportion of oxygen, solid fuel cannot burn fully. Therefore, it will smolder.

Stages of heating a house

Fuel is placed in the stove and ignited, while the ash flap remains completely open. This is necessary so that the fuel heats up and begins to release thermal energy to the maximum level in order to heat the room to the desired temperature.

Interesting fact. Thanks to the use of this stove, the house can be warmed up in about thirty minutes.

After the house has warmed up, we move on to the low-calorie process. The blower damper closes, thereby blocking the entry of oxygen into the combustion chamber.

I would like to add that today there is a huge selection of long-burning stoves. Therefore, the buyer can purchase a stove at his own discretion, based on the technical characteristics of the model: power, external data, frequency of fuel loading.

Operating principle of an air-heating boiler

Air-heating boilers can be made with different design solutions, but their operating principle is the same. In boilers of this type, air is heated from hot surfaces, which ensures continuous circulation of air flows in the room.

External view of the stove.

To effectively heat adjacent rooms, an air duct system is installed. If there are many rooms and the house has a complex, multi-level layout, forced ventilation is used to uniformly distribute the heat flow and overcome friction and length losses.

Modern combustion chambers operate on the principle of pyrolysis - a long process of smoldering firewood with minimal air supply in the combustion chamber, producing both gas and heat. The process takes place in two stages: ignition and gas generation.

When igniting, firewood or briquettes are placed in the firebox on the grate and set on fire, while the gate and ash are left open. After the firewood burns well, they are closed, thereby reducing the amount of air entering the firebox, and it is supplied only through jets.

The efficiency of boilers is ensured by the supply of primary and secondary air. The primary comes from indoors or outdoors. To increase the efficiency of the boiler and reduce heat losses, the air is preheated and only then supplied to the firebox.

Secondary - represents a mixture of air and fuel combustion products. The fuel is not completely burned, so the exhaust gases still contain flammable substances with a high temperature, so their “afterburning” is economically justified and will require additional costs. Secondary air is taken from the top of the flue, and the volume and flow rate are adjusted using a damper manually or automatically, which is impossible to do in the old type of traditional boilers or furnaces.

Pros and cons of long-burning stoves

Unfortunately, the stove has not only advantages, but also disadvantages.

Benefits of use

- Saving fuel consumption. This is the most basic advantage of such stoves and you can’t argue with it.

- High efficiency. This was mentioned in the article above.

- Large model range. Today, manufacturers offer different models of stoves that are perfect for any interior.

- Ease of maintenance. You can bookmark at a high interval: from 5 hours to two days.

- Choice of fuel. It is possible to use any type of fuel.

Interesting fact! Today there are long-burning combination boilers on sale.

Wood-burning heat guns ITProm

Wood stoves

use one of the cheapest types of fuel - wood - and heat the air quickly and with maximum safety. Fast and efficient heating of the air supplied by the fan is achieved thanks to the presence of a heat exchanger, in which the heated air is clean, and all gases resulting from the combustion of wood are discharged through the chimney. The efficiency of the device depends on the type of fuel used, so to achieve the best results we recommend wood from oak, birch, beech, alder, hornbeam, etc., with a moisture content below 20%.

Wood burning air heaters

is a profitable investment and an effective solution for heating workshops, warehouses, agricultural facilities, production workshops, greenhouses and other similar facilities. Since wood heating systems have lower costs, the operation of such air heaters becomes profitable in the long term, regardless of the heated room.

Advantages

Easy to use:

- most users prefer mobile heaters so that they can be moved if necessary without much physical effort;

High power:

- the required power is calculated depending on the volume/area of the room you want to heat;

- installations with a thermal power of 50 and 100 kW are offered for sale, allowing to heat rooms up to 1000 m2;

Operational reliability:

- The device is designed for long-term operation, thanks to its durable design and high-quality materials;

- the device can be used in open space;

Reliable design:

- durable steel body;

- the firebox is lined with refractory fireclay bricks;

- the body is painted on the outside with heat-resistant paint;

- tubular heat exchanger made of heat-resistant steel;

- cast iron grates;

- drawer for ash;

- axial fan for installation on any side of the heater;

- protective thermostat against heat exchanger overheating;

- manual fan speed control;

- connection of air ducts for air distribution is provided.

- There is a terminal on the housing for connecting protective grounding.

How to choose a stove

Before purchasing a stove, you need to determine at least two important points.

First, what will be the area of the heated room? Since heating equipment manufacturers offer stoves that can heat houses with an area of 80 to 250 square meters.

Second, how long will the fuel smolder? In this case, the stove can be divided into 3 groups:

- Minimum time: from 5 to 8 hours;

- Average time: from 8 to 10 hours;

- Maximum time: more than 10 hours

Model range of boilers by Professor Butakov

- Gymnasium student, heating and cooking model, weight 49 kg, heat load 8 W, heating area up to 60 m2, cost up to 6800 rubles.

- Student, for private housing construction, weight 57 kg, heat load 9 kW, heating area up to 150 m2, cost up to 13,900 rubles.

- Engineer, for one-story houses and small household premises, weight 75 kg, heat load 15 kW, heating area up to 250 m2, cost up to 17,700 rubles.

- Associate Professor, for non-residential industrial premises, weight 143 kg, heat load 25 kW, allows you to heat an area of up to 500 m2, cost up to 28,000 rubles.

- Professor, for large residential and non-residential buildings, weight 57 kg, heat load 40 kW, heating area up to 1000 m2, cost up to 32,000 rubles.

What is a stove made of?

Many private homeowners have a question: is it possible to make a long-burning stove yourself? The answer is obvious: of course yes! The main thing is suitable material and certain skills. If these conditions are met, then there should be no problems.

- Then the question arises: what can a stove be made from?

- The answer is: it can be made from cast iron, brick and steel.

- Then the next question arises: what material can it be made from?

It is better not to mess with cast iron due to the fact that the technology for casting all the necessary parts is quite complex and energy-consuming. All that remains is brick and steel.

Disadvantages of modern devices

Please note that all the excitement around the new cooking device is gradually subsiding and the new product, at best, quietly and silently serves its owners. More often than not, the culprits will have to sink into oblivion, as a certain disappointment ensues. The housewife in the kitchen needs an assistant for convenient, quick preparation of delicious food that is also healthy.

With the advent of microwave ovens on sale, all manufacturers, suppliers and sellers unanimously insisted that this was the oven of the future. Cooking food using high frequency waves is a guarantee of a healthy lifestyle.

A new round of development of devices with intelligent cooking was marked by the appearance of the multicooker. This story looks simply funny, the housewives were promised a super device that is capable of preparing any dish from the ingredients, but in the end they received the same pan in which they need to put cooked, peeled, chopped vegetables. Naturally, no one expected a miracle.

A modern variation on an old friend

We must pay tribute to the developers, the lack of contact of food with the heating element could not fail to impress housewives, but the accompanying work on caring for the device becomes the reason that for many it is easier to cook dinner in the traditional way than to then clean, wash and dry the elements of the multicooker.

Good to know: What is an electric mini oven, how does it work

What can you say about brick?

Brick is a good and reliable material for making a stove. But it has a significant disadvantage - it takes a long time to warm up the house in order to achieve a comfortable temperature, since brick has inertial properties.

Therefore, in order to warm up the house well, you will need to consume a large amount of fuel.

From all this, only steel remains. In the next chapter, we will tell you how to make a long-term storage oven with your own hands using a metal barrel.

Stove for a cauldron

This version of the garden stove is designed for cooking in a cauldron or on a built-in stove. It has a simple masonry scheme, and can be done independently if you have certain skills.

Stove with built-in cauldron

You can, of course, just hang a cauldron over a fire and cook food, but such a stove, designed for a cauldron, will help distribute the fire evenly under it, and the dish will turn out exactly as it should be according to the recipe, and not with a burnt taste. In addition, a carefully constructed and decorated building will add a special warm note to the landscape of the site and become a decorative element.

The first thing to start working on a stove is site planning. To do this, you need to know the dimensions of the building - in this case they are 1010 × 1114 × 800 millimeters.

Schematic diagram of a stove with a cauldron

- Next, based on the diagram, the necessary materials are purchased: brick (preferably fireproof); mortar of fireclay dry mixture and sand for masonry; doors for the blower, firebox and cleaning chamber, grate and hob made of steel with a thickness of at least 3 mm.

- A well-designed site is a reliable basis for such a stove. Since it does not have the same weight as heating and cooking buildings, it is not necessary to make a capital foundation for it. The area under the stove should be raised above the soil surface by 10-15 centimeters. The base is made using formwork, and it is advisable to reinforce the structure with five-millimeter metal wire.

- The main feature of the internal design of a cauldron stove is its shape - it resembles a truncated cone. This is done to ensure that the surface of the cauldron is heated evenly.

An important feature of the stove is the channels for uniform heating of the cauldron

- On a prepared and fully set site, you can begin laying the masonry. In this case, the bricks are bandaged in the corners, so that even rows begin with half a brick, and odd rows with a whole brick. The firebox is laid out from halves of bricks, which are cut at an angle - this is done in order to achieve a semicircular shape.

- The diagram above clearly shows that starting from the first row, a hole for the blower chamber is marked, and a door is installed on it, which is secured with metal wire.

- A grate is installed on the third row, and the laying of the walls continues.

- On the fourth row, at the back of the building, a hole is left to remove smoke and a firebox door is installed, securing it in the same way as the blower.

- Fifth row - external and internal walls are laid.

- Sixth row - the masonry around the fire door is completed.

- From the seventh to the eleventh row, work proceeds according to the scheme and the inside of the firebox is laid out.

- On the twelfth row, the structure is strengthened with a metal corner, a plate is installed on top of it, in which a round hole is made in advance the size of the cauldron.

The hole can be made with a grinder, short cuts, or using a gas cutter. Then the hole needs to be leveled, since the cauldron must fit tightly into it at two-thirds of its height.

Such a stove will help you cook not only in a cauldron, but also use the stove for boiling water or frying vegetables or meat products in a frying pan. To do this, you need to provide a lid to cover the hole for the cauldron.

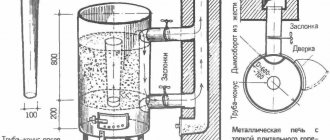

Do-it-yourself long-burning stove

In this chapter we will look at a homemade version of a long-burning stove. It's called Bubafonya. This stove does not require any special financial costs and is quite easy to make.

Of course, without having basic skills in working with electric welding and a grinder (popularly called a “grinder”), it is better not to make it, in order to avoid injuries and mutilations.

What components do we need?

- Iron sheets (thickness approximately 5 mm.)

- Pipe (diameter 100 mm.)

- Grate.

- Asbestos cord.

Next, we move on to the main stages of creating a long-term storage stove:

- The lid of the barrel is cut out.

- A hole is cut at the bottom of the barrel to fill the fuel.

- A hole for the blower is created even lower.

- 4.Wire guides are welded inside the barrel.

- 5. A hole for the chimney is cut at the top of the barrel on the side.

- 6.Then a pancake is cut out of a metal sheet with a diameter almost like a barrel, a hole is cut in the middle and a pipe is attached.

- 7.Next, we assemble the unit.

Well, everything is done. All that remains is to install the stove at its destination and attach the chimney to it.

To summarize, we can say that today such stoves are becoming more and more popular, since they have more advantages compared to traditional stoves. The main advantages of such a stove are economical fuel consumption and high efficiency.

Features of air-heating boilers

Air-heating boilers have become popular among owners of country houses. This simple and easy-to-use equipment makes it possible to heat your home, workshop, workshop, or production premises without unnecessary worries and difficulties.

Air heating boiler with burner

Heating systems that operate an air-heating boiler or furnace are characterized by a simple design and high efficiency. Comfortable heating units have the following functional areas:

- hot air boiler;

- heating stove;

- heating stove with hob.

All models of boilers under consideration with the possibility of heating with air are different and can be equipped with:

- Multi-burner cooking panel.

- Door with window made of fire-resistant glass.

- Door with self-cooling function.

- A separate glass door for observing the flame, like in a fireplace.

- Special installation of the chimney pipe and so on.