Despite the huge number of heating devices on the market, a popular option is a long-burning solid fuel boiler.

Homemade TT long-burning boiler

This unit can be used as the main source of heating in remote areas where gasification and electrification are not provided. Reliable, efficient and economical, it is an excellent solution for heating a country house, a cottage in the city or a summer cottage.

Unlike a conventional boiler, where the main heat comes from the flame itself, a long-burning TT boiler works on a completely different principle. This article will talk about how to properly make a long-burning solid fuel boiler with your own hands, and the drawings and installation diagram will help you not make mistakes and do everything technologically correctly!

Operating principle of a long-burning boiler

In conventional solid fuel units, one fill is enough for 6-7 hours of combustion. Accordingly, if the next portion of resources is not added to the firebox, the temperature in the room will immediately begin to decrease. This occurs due to the fact that the main heat circulates throughout the room according to the principle of free gas movement. Heated by the flame, the air rises and goes out.

The thermal resource of a long-burning boiler is enough for about 1-2 days from one load of firewood. Some models can maintain heat for up to 7 days.

How is such economy and efficiency achieved?

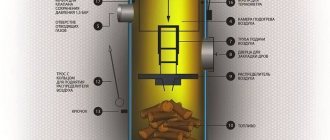

Boiler operation diagram

A long-burning TT boiler differs from a conventional boiler by the presence of two combustion chambers at once. In the first, the fuel itself is burned as standard, and in the second, the gases released during this process are burned.

A major role in this process is played by the timely supply of oxygen, which is provided by the fan.

This principle was implemented relatively recently. In 2000, the Lithuanian company Stropuva first presented this technology, which immediately gained respect and popularity.

Homemade long-burning boiler

Today this is the cheapest and most practical way to heat a country house, where gasification is not provided and there are power outages.

Such units operate on the principle of burning top fuel. As a standard, in all stoves the firebox is located at the bottom, which allows you to take cold air from the floor, heat it and raise it up.

The operating principle of this boiler is somewhat similar to a pyrolysis boiler. The main heat here is released not from the combustion of solid fuel, but from the gases released as a result of this process.

The combustion process itself takes place in a closed space. Through a telescopic pipe, the released gas enters the second chamber, where it is completely burned and mixed with cold air, which is pumped up by a fan.

TT long burning boiler (diagram)

This is a continuous process that continues until the fuel is completely burned out. The temperature during such combustion is very high - about 1200 degrees.

As mentioned above, this boiler has two chambers: a large main one and a small one. The fuel itself is placed in the large chamber. Its volume can reach 500 cubic dm.

The combustion resource can be any solid fuel: sawdust, coal, firewood, pallets.

A constant flow of air is provided by the built-in fan. The advantage of this method is that solid fuel is consumed extremely slowly.

This significantly increases the efficiency of such a heating device. Why does wood burn out so slowly compared to a standard stove?

The bottom line is that only the top layer burns out, since the air is pumped by a fan from above. Moreover, the fan adds air only after the top layer has completely burned out.

There are many models on the market today that work on the same principle, but, depending on the dimensions, material, additional options, they have different efficiency and cost-effectiveness.

Fuel versatility

Universal TT boilers operate on absolutely any fuel, which will greatly simplify their operation for owners. A more budget-friendly option is a long-burning wood-burning TT boiler. It runs exclusively on wood and no other fuel option can be used in it.

What else is worth considering

When assembling a device for your home, you need to consider several important aspects:

- When deciding on the type of design, know in advance what type of fuel it will run on. If it is coal or firewood, then you need to be sure that there are no problems with the availability of these resources in the near future.

- Before starting to manufacture a home-made unit, accurately calculate the required power of the future boiler and include it in the project with a reserve. The higher it is, the larger the firebox and the less often you will have to load fuel.

- Install a pyrolysis boiler when it is possible to use dry firewood and anthracite. This unit produces more power when used. In other cases, heat transfer will be less.

If in the future it is planned to connect the house to household gas, then this option must be foreseen in advance. It will be cheaper and easier to convert the device to a different type of fuel if this option is included in the project right away.

You might be interested in learning how to make a wood-burning boiler with your own hands.

Design Feature

Any long-burning boiler is equipped with an impressively sized chamber into which fuel is placed. The larger the chamber the boiler is equipped with, the longer the wood will burn.

Today you can find two technologies implemented in long-burning TT boilers, which successfully compete with each other. This is the Buleryan principle and the Stropuv method.

Due to the high price of Stropuv and the complexity of the design, this method is not so popular in Russia. But using the Buleryan method, craftsmen with great dedication construct units for heating dachas and country houses.

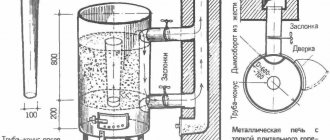

Boiler TT diagram

A boiler using the Buleryan method looks like this: a metal body, inside of which there are two chambers. In the lower chamber, fuel is burned, and in the second, gas flowing through the tube from the first chamber is burned.

The door for loading fuel is located in the upper part of the boiler body, since the entire lower part is reserved for a large storage of resources.

At the top of the boiler there is a smoke pipe, which connects to the chimney. An ash chamber is built into the lower part, through which the boiler is cleaned.

One more nuance should be mentioned. In standard furnaces, the ash pan acts as a blower through which the air necessary for combustion is blown in. Here the ash chamber is absolutely sealed, since air enters through the upper air chamber, which plays the role of a recuperator.

The supply of oxygen to the boiler is regulated by a damper located at the top of the air chamber. As the wood burns, the fuel gradually settles and the distributor lowers. This ensures a continuous supply of oxygen.

When loading fuel again, simply pull it up and return it to its original position. By the position of this lever, you can easily determine how much fuel is left in the boiler and when to load it next.

Separately, it should be said about the environmental friendliness of this heating option. Due to the complete combustion of fuel and gases, virtually no carbon dioxide is released into the atmosphere.

Main elements of long-burning TT boiler

Main elements of the TT boiler:

- Combustion chamber. This is the main element of any boiler and furnace where direct combustion of fuel occurs.

- Gas combustion chamber. Hot gases from smoldering wood enter here.

- Ash pit - ashes are collected here. This unit must be systematically cleaned to maintain the boiler in good technical condition.

- A chimney is a unit through which combustion products are discharged outside.

boiler device

All these components are enclosed in a steel case, which is made of sheet metal 5-6 mm thick.

How to connect heating equipment

The efficiency of homemade wood-burning equipment is ensured by good natural draft from the chimney. In order for the working draft to be sufficient, the pipe must have a height of at least 5 - 6 m, and the diameter of the pipe in the boiler body must be approximately 150 mm in diameter. To simplify ignition in the combustion chamber, bypassing the heat exchanger, a direct draft channel with a handle and a damper is made on the outer side wall.

During operation, an important role is played by the correct piping of the heating device. When operating a gravity heating system, which does not require electricity, there will be no problems. And yet, it is better if, when accelerating the boiler, in order to avoid the formation of condensation on the internal walls of the firebox, cold water from the system does not get into the jacket.

Condensation, mixing with ash, settles on the surface and forms a black coating that is difficult to clean off. Therefore, it will be better if you make a bypass at the coolant outlet from the unit with a three-way thermostatic valve set to 55 or 60 degrees. In this case, the coolant circulates in a small circle, up to a heating temperature of 60⁰. The thermostat will then begin adding cold water from the system.

If the heating system in a private house operates with a pump, then there is a danger that the boiler will boil if the electricity is turned off. To protect it, you need to take a number of measures:

- Install a safety valve into the water jacket, which will release steam when the pressure is exceeded.

- For further operation of the pump, an uninterruptible power supply and a diesel power plant will be required. The battery can only work for a short time, so you can’t do without an electric generator.

- To ensure natural circulation of water from the tank to the boiler and prevent boiling, you will need to install a heat storage tank. It will keep the house warm after the wood burns.

Advantages and disadvantages

Due to its large dimensions and complexity of the design, it is rational to use such a unit for heating a large cottage. But for a small dacha this option is not suitable, as it does not justify the cost-effectiveness.

pros

- high efficiency (about 95%);

- autonomy of the heating system;

- efficiency;

- reliability and durability;

- high efficiency;

- fuel availability;

- an environmentally friendly option for heating your home;

- versatility of fuel (coals, firewood, sawdust, pellets).

Read our material about which long-burning boilers are better.

Minuses

- cumbersome design;

- a special room must be equipped for the device;

- complexity of design and installation;

- the need for constant cleaning.

It is not necessary to buy a long-burning boiler ready-made, because its price is several times higher than conventional stoves. You can make such a design yourself if you have at least a little experience in construction and repair.

Appearance of a homemade structure

A homemade design, compared to a factory-made analogue, has a number of advantages:

- low cost;

- the ability to make the boiler universal for any type of fuel;

- possibility of improving the design and adding power.

The only difficulty is giving the boiler a cylindrical shape. It is very difficult to give metal such a shape without a rolling machine.

But there is a good solution. You can use empty propane tanks or any pipe of suitable diameter. You should choose pipes with a wall thickness of at least 5 mm.

For a village or a small dacha, you can build a small brick stove and enjoy its efficiency. But for a large cottage, this option will be less practical, as it will require a large supply of firewood for the winter. Caring for a conventional stove, compared to a long-burning boiler, is much more difficult, and large temperature changes in rooms remote from the stove do not allow organizing a comfortable microclimate in the house.

If you do not have enough money to create a full-fledged heating system for your home, or the construction of such a system itself is impractical, it would be much more reasonable in this situation to make a long-burning solid fuel boiler with your own hands and not worry about its safety and aesthetic appearance.

Is it worth doing it yourself?

Industrial units are complex devices created using high-precision equipment. It is not easy, and sometimes impossible, to repeat the design in detail and make an identical device with your own hands. But you can assemble a simple, reliable boiler if you have the appropriate professional skills and tools.

pros

Self-assembly of the device will save money. You can use any available materials in your work.

Advantages of homemade assembly:

- saving money;

- the ability to make a design taking into account the characteristics of the room and all possible nuances.

Self-assembly will save you money.

If you have the necessary material, a small workshop of your own and free time, you can assemble a heating system that is not inferior to the factory one in terms of technical characteristics.

Cons of homemade products

Creating devices of this level of complexity at home may end in failure.

Disadvantages of making a boiler yourself:

- a large amount of work associated with metal welding;

- the risk of creating an unfinished or fire-hazardous design.

Before assembly, you need to soberly assess your own strengths and capabilities.

Useful tips for making a TT boiler

- If you want to make a TT boiler universal in terms of the use of raw materials, then use a pipe made of heat-resistant alloy steel for the combustion chamber.

Alloy Steel Pipe for Boiler

You can significantly reduce the cost of building a unit if you take a seamless steel pipe of grade 20.

- Before installing the boiler in the place designated for this unit, carry out the first kindling outside, equipping the boiler with a temporary chimney. This way you will be convinced of the reliability of the design and will see whether the case has been assembled correctly.

- If you use a gas cylinder as the main chamber, then keep in mind that such a unit will provide you with combustion for 10-12 hours due to the small amount of fuel supplied. So, the small volume of the propane tank will decrease after cutting off the lid and ash pan. To increase the volume and ensure longer burning time, it is necessary to use two cylinders. Then the volume of the combustion chamber will definitely be enough to heat a large room, and there will be no need to add firewood every 4-5 hours.

- In order for the ash pan door to close tightly, preventing air from entering, it must be well sealed. To do this, lay an asbestos cord around the perimeter of the door.

Asbestos cordIf you make an additional door in the boiler, which allows you to “reload” fuel without removing the lid, it also needs to be tightly sealed using an asbestos cord.

For the operation of a TT boiler, the diagram of which we attach below, any solid fuel is suitable:

- hard and brown coal;

- anthracite;

- firewood;

- wood pellets;

- briquettes;

- sawdust;

- slates with peat.

There are no specific instructions on the quality of fuel - any will do. But keep in mind that with high fuel moisture, the boiler will not provide a high efficiency.

What to burn, from sawdust to anthracite

Firewood

Firewood is a classic solid fuel; its use dates back as many years as people have been familiar with fire. Firewood from various types of wood is used for boilers; the efficiency of the heating system and its uninterrupted operation largely depend on the type of wood and humidity. As for humidity, it is clear that the lower it is, the higher the heat transfer, since energy is not spent on moisture evaporation, and the properties of various types of wood when used as fuel deserve more careful consideration.

The most suitable option is considered to be deciduous trees, among which the record holders for heat transfer are: oak, beech, hornbeam and ash; birch is not far behind, but if there is insufficient air supply to the combustion site, birch begins to release tar, which is deposited on the walls of the smoke removal system.

Hazel, ash, yew, pear and apple have proven themselves well; they split easily and burn hot, but elm and cherry emit a lot of smoke when burning. Poplar and linden, familiar to city dwellers, are not the most suitable option for a firebox; they burn well, but quickly burn out and spark strongly during the combustion process; aspen and alder are a completely different matter, which not only do not emit soot, but contribute to its burning on the walls of the chimney .

Coniferous trees are characterized by the presence of resins in the composition of the wood, which is ultimately deposited on the inner surface of the pipe; the process of deposition of resin and soot is especially relevant for boilers in which the combustion process occurs at a not very high temperature. The heat transfer of conifers is noticeably lower than that of deciduous trees.

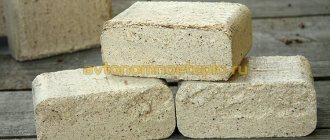

Briquettes

Briquettes are produced in the form of a cylinder or parallelepiped; cylindrical products from some manufacturers have an internal hole along the entire length. Briquettes are not susceptible to fungal attack, have a high calorific value and are very convenient to use, as they have a low ash content of no more than 3%.

Pellets

Pellets are a granular type of fuel that greatly facilitates the task of automating solid fuel heating devices. The material for production is waste from woodworking and agricultural production - sawdust, bark, wood chips, shavings, flax waste, sunflower husks, etc. The material is processed into flour and pressed into cylinders under high pressure, the diameter of the pellets is 5–8 mm, and the length is not exceeds 40 mm. As in the case of briquettes, the binding material is a natural component – ligin.

The advantages of pellets include: low ash content, environmental friendliness, ease of transportation in bags or packages, and the ability to automate feeding into the combustion chamber. The disadvantage is the additional costs of special equipment for burning pellets.

Coal

The quality of coal depends on age, mining conditions and chemical composition. Based on age, all coal is divided into three main groups: brown (the youngest), hard coal and anthracite. The older the fossil, the lower the moisture and volatile components content; anthracite has the lowest values

It is important for the consumer to know the labeling, which indicates the grade and size class; brown coal is designated by the letter B, anthracite - A, and stone coal has seven grades from long-flame - D, to skinny - T. The size of individual pieces determines the name of the class:

- ordinary (P) – no size limitation;

- piece (W) – less than 6 mm;

- seed (C) from 6 to 13 mm;

- small (M) 13–25 mm;

- nut (O) 26–50 mm;

- large (K) 50–100 mm.

Read in detail about all types of fuel, their calorific value, advantages and disadvantages here.

Security measures!

In order for such a boiler to truly be an effective and economical heating option, to serve for a long time and not cause burns or accidents in the house, take into account the main points of fire safety.

TT boiler

- It is necessary to monitor the temperature in the system and prevent it from overheating.

- Do not install a shut-off valve on the pipeline.

- Do not keep flammable objects near the boiler.

- It is necessary to monitor the ventilation in the room.

- A separate room must be equipped for the boiler.

At the preparatory stage, consider the place where the boiler will be installed.

Ideally, of course, to equip a separate boiler room, because the operation of a long-burning TT boiler is somewhat different from the usual wood-burning brick stove. And externally, this unit will not be pleasing to the eye or serve as a decoration for the house.

Considering that solid fuel does create a certain amount of dirt, it is better to install a long-burning TT boiler in a non-residential area.

But if its power is small (does not exceed 30-35 kW), then you can simply separate (zone) the main room from the “boiler room” using a brick wall.

Be sure to provide a ventilation system in the room where this boiler will be used. Oxygen must be supplied from the street on a constant basis.

Step-by-step instructions for creating a long-burning solid fuel boiler with your own hands

The project of a solid fuel boiler is not an easy task and it will not be easy for a beginner to cope with it. Before starting construction, prepare drawings and sketches.

Drawing of a homemade solid fuel boiler

Also prepare the following tools:

- Welding machine.

- Tools for working with metal: pliers, grinding wheel.

- Electric drill.

- Construction level and tape measure.

- Marker.

- Bulgarian.

- Gloves and eye protection.

Attention! When performing work on the manufacture of a homemade TT boiler for long burning, you should be very careful and have at least basic practice with a welding machine. Be sure to use protection when welding.

Materials you will need:

- Empty gas cylinder.

- Sheet metal.

- Asbestos cord.

- Steel pipe with a cross section of 60 mm.

- Metal hinges and handles.

- Metal corner or blades.

- Metal hood.

- Basalt fiber for the passage of the smoke exhaust pipe.

Before starting production, we suggest you read the video instructions on how to properly cut an empty gas cylinder, watch carefully and do not neglect safety measures!

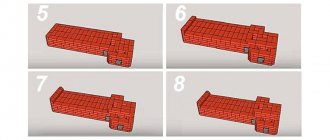

Step 1. Marking the body and making the body

Using a marker, mark the propane tank according to the dimensions of the drawing.

We make a small rectangular hole for the ash pan door, through which the boiler will be cleaned.

On the top of the balloon (along the entire perimeter) we draw a straight line to cut off the top.

Using a grinder, cut off the top along the line.

The cut off top of the cylinder

Now we make markings in the center for the hole through which the pipe will pass. The hole, accordingly, must be larger than the diameter of the pipe.

We cut a hole in the lid and weld a metal ring that will tightly fit around the pipe inserted into the cylinder.

Weld the ring in a circle

We weld a small ring of sheet metal (4-5 mm) from the outside and inside of the cylinder itself, on which the lid will be placed.

Step 2. Making the pipe

We take a metal pipe with a length of 80 to 100 cm. If you are not using a standard propane cylinder, but are welding the body for the boiler yourself, keep in mind that the height of the pipe should be 20-25 cm higher. After all, the essence of the work is that as the fuel burns out, the pipe inside the housing will go down.

We weld a metal circle – an air distributor – to the pipe in its lower part.

The cut off top of the cylinder

We cut out fasteners from sheet metal, which we weld securely along the cut line of the cylinder, after laying an asbestos cord.

Weld the handles to the lid

We fasten the cut top so that it can be easily removed and put back. Make handles from metal and, for ease of removal, also weld them to the body.

Step 3. Making a pipe to the chimney

We make markings on the cylinder in its upper part for the opening of the pipe.

We weld the pipe

Using a grinder, we cut out and weld a pipe to remove combustion products.

Then a steel smoke exhaust pipe is connected to this pipe.

Step 4. Making an ash pan

Using the previously made markings, we cut out a hole for the ash chamber using a grinder.

Cutting out the ash pan

We make a door separately from sheet metal, which will then need to be screwed onto brackets to the boiler body.

Hole for ash pan door

For convenience, you can make a small loop of thick wire or reinforcing rod and screw it on as a handle.

Step 5. Prepare the air supply system

Measure the inner diameter of the cylinder body. Now draw a circle on the sheet metal, the diameter of which will be 5 mm less than the inner diameter of the cylinder.

Using a grinder, cut out this circle.

This is what the air supply system looks like

Take a metal corner and cut it into 6 equal parts. The size of each part is equal to ½ the diameter of the metal circle. An impeller with old blades is still good for these purposes.

Making an air supply system

We weld the metal circles in the same direction counterclockwise.

Step 6. Making a heat exchanger

We will make a heat exchanger designed on the principle of a water circuit.

Making a heat exchanger

The size of this heat exchanger depends on your personal preference. The larger it is, the more firewood you can put in it, which means the longer burning time your boiler will have.

From sheet metal 5-6 mm thick, we cut out sheets according to the diagram and weld them into a reliable housing, inside which our gas cylinder will be located.

In the upper and lower parts of the housing we make pipes for connecting the supply and return lines.

In the central part it is necessary to provide a hole through which fuel will be inserted. We mark using a marker and cut out with a grinder.

Step 7. General assembly and installation of the boiler

We attach the ash pan door to the firebox.

We mark on the heat exchanger body the place where access to the ash pan will be made and cut it out using a grinder. We also equip this opening with a door, which should close very tightly, blocking the access of oxygen to the housing.

Assembling the boiler

We insert the cylinder inside the heat exchanger.

Using a welding machine, we weld the tank on top, resulting in an absolutely sealed housing, inside of which there is a round firebox.

The essence of a long-burning TT boiler is a limited air supply from above, the function of which is performed by an oxygen supply system.

Fuel (firewood, coal, briquettes) should be loaded very tightly so that there is as little space as possible between the layers. If the firewood is different in size and it is not possible to pack it tightly, then between the layers you can fill it with wood chips and paper. The denser this solid fuel mixture is, the longer the wood will burn.

The boiler load must be dense

How will such a boiler be loaded?

- we take out the air supply restrictor from the housing;

- We load fuel through a special door. It is better to spray the fuel with a special ignition fluid beforehand;

- put back the restrictor pipe;

- throw a lit match inside the cauldron;

- After you are sure that the fuel gradually begins to smolder, close the door tightly.

As the wood burns, the pipe inside the cylinder will gradually lower. By its height you can always find out how much firewood you currently have inside.

Step 8. Lighting the boiler

You can build such a simple boiler right outside in the warm season and test it outdoors, equipping it with a temporary chimney.

Fire up the boiler

If the area of the room exceeds 30-40 square meters, then you can weld two cylinders vertically, thus increasing the amount of firewood.

Step 9. Installing the boiler indoors

Take the issue of boiler fire safety very seriously.

It is better to allocate a separate room for it or make a small fence from residents to prevent burns. After all, the boiler body is metal and, unlike a stone stove, there is a high probability of getting burned.

Install in a place where there is a possibility of chimney outlets. There are two ways to remove the chimney: through the roof or through the wall.

Keep in mind that you must have direct access to the boiler, so nothing should stand at a distance of 50 cm next to it.

- Make a brick base for the boiler, laying solid brick in 2 rows. Check the slope of the base with a building level.

- Maintain distance from walls (regulated by SNiP). The distance from the combustion door to the wall must be at least 125 cm. The distance between the side parts and the back of the boiler and the wall must be at least 700 mm.

- If the walls in the house are made of wood or any other flammable material, it is necessary to protect the junction of the boiler with the ceilings with sheet metal or basalt. You can use ordinary brick as thermal insulation, which should be used to line the perimeter of the junction of the boiler with the wall.

Where the chimney exits through a wall or roof, it is also necessary to ensure proper thermal insulation. Basalt fiber is suitable for this, which should be laid tightly between the chimney pipe and the ceiling.

- Place the boiler on the prepared foundation and again check with a level how level the device is. Please note that the gas outlet pipe must be at the same level as the chimney pipe. If the line is not horizontal, traction may be disrupted during operation.

Step 10. Connect the boiler to the chimney.

Attention! It is necessary to lubricate the joints of all parts of the chimney with sealant.

We connect the chimney pipe to the TT pipe of the boiler. The diameter of the chimney must be no less than the TT pipe of the boiler. If these parameters are not met, the gas outlet capacity will decrease.

Chimney connection

As you can see, by doing everything with your own hands you can get excellent results; everything is not as complicated as it seemed at first glance! If you strictly followed the instructions, you will quickly appreciate the high performance and efficiency of a long-burning solid fuel boiler, which is many times superior to its competitors with an open flame principle. This will allow you to maintain a comfortable microclimate in your home with minimal maintenance.