Features of boiler operation

The most reliable and innovative types of boilers using solid fuel elements include automatic water heating systems. Their design includes:

- fuel bunker;

- gas generator;

- boiler for heating the coolant (combustion chamber and heat exchange chamber);

- equipment operation monitoring system.

The body consists of the following elements:

- fuel chamber;

- chimney;

- ash pan;

- heat spreader;

- coil;

- blower;

- a set of sensors for monitoring temperature and pressure.

The automatic control system works as follows:

- If necessary, add wood chips to the boiler.

- Controls the oxygen supply taking into account the remaining fuel.

- Regulates temperature changes.

- Extinguishes fires in an emergency.

Features of boilers and furnaces:

- The body and structural elements are made of steel sheets coated on the outside with a heat insulator.

- The inside of the oven is lined with fireclay bricks, which increases the heat level when heated.

- The doors are made airtight, with the addition of concrete.

- With the help of ventilation, primary and secondary oxygen, which is necessary for the combustion process, enters the firebox.

- The drum-type heat exchanger is protected from limescale by circulating water.

Due to the complex heat exchange system, the efficiency of such boilers is quite high. Wood waste up to 4 cm in size is used for kindling.

Principle of operation

On the modern Russian market, heating boilers operating on wood waste are represented by foreign devices. Homemade analogues made in Russia are also found. Their craftsmen adjusted them to certain operating conditions. So these home-made heating units can work not only on sawdust, but also on wood chips.

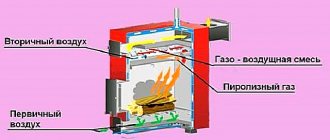

The fuel combustion process is carried out according to the so-called controlled combustion. Firstly, it is a three-stage air supply. Secondly, the use of the pyrolysis process, that is, gas generation of exhaust combustion products occurs. In fact, a sawdust boiler is a long-burning unit.

Sawdust supply and combustion diagram

Foreign boilers are heating devices with automatic loading. That is, their design includes a bunker into which a certain amount of fuel is loaded. There are two modifications:

- The hopper is connected to the boiler.

- A bunker is a separate unit that can be located outside the house (boiler room).

So, sawdust is loaded into a hopper, from which it is fed into the combustion chamber using an auger. Here, using the air supply regulator, the degree of combustion is regulated. At the very beginning, when the boiler is heating up, the fuel burns using conventional technology. When the temperature reaches the required value, the air supply is reduced to a minimum. The process enters the pyrolysis stage.

The carbon monoxide released in this case rises and moves into the second combustion chamber, where it burns when mixed with oxygen. This is where the maximum thermal energy is released.

Pros and cons of a sawdust heating system

To get the most complete picture of the chips, which can act as fuel for modern heating systems, it is very useful to consider the advantages and disadvantages inherent in the method in question.

Advantages

- Among all the advantages that heating with wood waste has, the main one should be low heating costs. Consumers will be able to achieve maximum savings provided that there are wood processing enterprises operating in their area of residence. After all, in this case they will be able to buy sawdust at very low prices.

- When using wood as fuel, it will take a minimum of time to heat the water. In addition, these wastes allow you to obtain the maximum amount of thermal energy. Choosing briquetted chips is even more preferable, since in this case you can provide the house with even more heat.

- When operating a boiler that uses natural raw materials for operation, there is no harm to the environment, since during the combustion of wood waste a very small amount of toxins is released into the atmosphere.

- An additional advantage is that a sawdust-fired boiler is available to everyone. In addition to this, to install this device, there is no need to obtain the same large number of permits that are required when connecting the boiler to the gas main.

Flaws

For all their advantages, installations using sawdust also have a number of disadvantages. These include difficulties arising with fuel storage. Although pressed wood chips and shavings are compact in size, you still need to ensure there is a room large enough to hold a supply of this fuel.

It should be borne in mind that the process of burning wood produces a lot of ash and soot. Many people know that ash can serve as a fertilizer. However, you cannot benefit from soot. For this reason, an operation such as chimney cleaning should be carried out on a regular basis.

Disadvantages of the unit

What can you say about such boilers? Firstly, these are energy-dependent heating systems. Secondly, they have large overall dimensions. So you will have to organize a boiler room or furnace room for them.

Thirdly, in order to achieve a heat release of 25 kW, 40 kg of sawdust must be loaded into this boiler every hour. That is, you will have to provide the home heating system with an uninterrupted supply of fuel.

Fourthly, these heating devices do not work on wood chips. But this, together with sawdust, is one of the most common types of waste from the woodworking industry.

Advantages and disadvantages of boilers of this type

Like any equipment, solid fuel boilers have certain advantages and disadvantages. Almost all the shortcomings of such equipment occur due to the fact that they use wood chips. First of all, wood chips have low free-flowing properties, which makes their transportation more problematic. Sawdust chips have high humidity, and therefore combustion rates are significantly lower compared to wood and coal.

Heating boilers using wood, wood chips and sawdust have many more positive qualities.

- The cost of fuel is low, because it is waste and was previously simply thrown away.

- Full automation of the operation of solid fuel boilers makes it possible to use them even when there are no people in the house.

- Modern automation tools make it possible not only to fine-tune the equipment, but also to automatically monitor its serviceability, thereby preventing the occurrence of malfunctions of certain boiler components.

- All wood fuel is completely clean from an environmental point of view, due to which such devices do not pose any harm to the environment.

(votes: 1, average: 4.00 out of 5)

Advantages of a homemade boiler

Very often, sawdust and wood chips remain as waste on private farms. However, not every heating unit is able to process them. For this reason, and for a number of others, homemade solid fuel boilers have their advantages:

- Low cost. Even if you buy all the materials for manufacturing the unit in a retail chain and adequately pay for the services of a qualified welder, a homemade boiler will cost at least 3 times less . In practice, some of the materials can always be found on your own farm, so the price will be even lower.

- Low requirements for fuel quality. The proposed design is able to burn any type of solid fuel, and even garbage. The humidity of firewood or sawdust can be quite high; coniferous wood or birch wood burns just as successfully as any other. In this case, the released tar and resins do not cause any harm to the unit.

- Sawdust boilers for the home are structurally simple, easy to maintain and clean.

- Ease of use. Depending on the type of biomass, the furnace should be loaded no more than once every 8 hours, this is with the most modest dimensions of the combustion chamber. If you increase it, burning can last a day or more.

- Absolute independence from external energy sources.

Among the shortcomings of the unit, one can highlight such as an unsightly appearance and the lack of any guarantees of the quality and reliability of welded joints, which will be discussed below.

Fuel requirements

The efficiency of boilers directly depends on the moisture content of the sawdust. The use of dry shavings and sawdust from carpentry as fuel does not cause problems. The bulk of sawdust, as noted, is waste from roundwood sawing shops.

Industrial waste from sawing round timber on band sawmills is small (up to 0.3 mm) sawdust with a moisture content of up to 80%. Even with constant forced air supply to the firebox, such sawdust burns very slowly, since it takes time to dry it. An even greater problem when burning is damp, long-stored sawdust, compacted into a damp, dusty mass.

Such fuel should be burned in a certain mode:

- Dry and wet fuel should be supplied to the combustion chamber in a ratio of 3:1.

- The supply of raw fuel can only be started when the boiler reaches full power after ignition.

- Constantly force air into the combustion chamber using a fan.

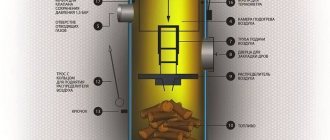

Design features

The specificity of fuel such as sawdust is that its particles are tightly pressed against each other and prevent the penetration of oxygen necessary to maintain the combustion process (those who have had to deal with coal know that for the same reason large stones burn much better than coal crushed into dust).

They are tightly packed into a cylindrical combustion chamber, and a conical rod is inserted in the central part.

During combustion, the rod is removed and a vertical channel is formed - an adit, through which air moves. Sawdust burns layer by layer from the middle.

And this combustion occurs very slowly, in smoldering mode.

There are several modifications of such heating devices:

- One or two holes for the chimney.

- One or two walls.

- Remote or built-in ash drawer.

Note. The stove is made from a two-hundred-liter barrel and can be heated with one load of sawdust for 10 hours.

AC-Burners heat generator design

| Design and principle of operation of the AC-Burners heat generator |

The lineup

The AC-Burners range is represented by 7 models of automatic loading devices and 15 models of heat generators.

| Heat generator HOT 15 | Heat generators HOT 30-55 | Heat generators HOT 120-175 |

| Model | Unit change | HOT 15 | HOT 30/ECO | HOT 55/ECO | HOT 85/ECO | HOT 120/ECO | HOT 175/ECO | HOT 240/ECO | HOT 350/ECO |

| Thermal power | kW | 14,9 | 29,8 | 49,8 | 85,0 | 115,0 | 174,5 | 233,5 | 407,0 |

| kcal/h | 12 800 | 25 700 | 42 900 | 73 000 | 99 000 | 150 000 | 190 000 | 350 000 | |

| Nominal air flow | m3 | 1 000 | 2 200 | 6 000 | 6 400 | 7 200 | 12 800 | 14 400 | 25 500 |

| Chimney | mm | 150 | 200 | 200 | 200 | 200 | 220 | 220 | 250 |

| Air duct diameters | mm | 2 x 150 | 2 x 200 | 2 x 200 | 3 x 180 | 3 x 200 | 3 x 220 | 3 x 220 | 4 x 300 |

| Heated volume | m3 | 800 | 1 500 | 2 000 | 2 350 | 2 700 | 3 000 | 3 500 | 5 200 |

| Electric motor power | kW | 1 | 1/1,2 | 1,5/1,7 | 2,0/2,2 | 2,2/2,4 | 3,0/3,3 | 3,5/3,7 | 6,0/9,0 |

| Mains voltage | V-50Hz | 220 | 220 | 220/380 3N | 380 3N | 380 3N | 380 3N | 380 3N | 380 3N |

| Fuel consumption | kg/h | 3 | 4,8/4,2 | 8,4/7,2 | 12/10 | 16,2/14 | 24/20,6 | 31,6/28 | 54/48 |

| Dimensions, WxHxD | cm | 111x166x70 | 145x160x95 | 155x166x100 | 153x180x105 | 153x180x105 | 162x190x115 | 165x200x117 | 200x250x170 |

| Weight | kg | 300 | 340/360 | 400/420 | 420/450 | 540/570 | 630/650 | 700/720 | 1800/2150 |

Automatic fuel supply systems

AC-Burners solid fuel heat generators can be supplied with automatic ignition and automatic fuel supply systems with different hopper capacities. Thanks to this, the equipment is able to operate autonomously; it only requires regular removal of ash from the pan.

| CP series hopper | P series hopper | SB series bunker |

A significant difference between a heat generator and a furnace is that this device is not intended to heat rooms using radiant energy - its design includes heat exchangers in which the air distributed throughout the room is heated. The efficiency of fuel combustion and the distribution of heated air throughout the room is ensured by a fan that pushes primary air into the fuel combustion chamber.

Heating the drying and heating agent in the heat exchanger prevents the ingress of fuel combustion products into it and allows dry and heated air to be removed into the room, and gases and waste from the process to be released into the atmosphere through the chimney. The design of the generators allows you to take full advantage of a number of advantages:

- the use of biomass as fuel, which makes it possible to significantly reduce the cost of purchased fuel and turn the waste accumulated in production to benefit;

- high-strength design that tolerates heat well and practically does not emit radiant thermal energy through the body;

- maximum direction of fuel combustion energy to heat the air supplied to the room;

- almost complete and controlled combustion of fuel due to effective fan injection and the design of the combustion part of the generator.

Water boiler

Heating of the room can be done using water or air. If there is a water supply in the house, you can assemble a system with your own hands with circulating water between the heating boiler and radiators or a “warm floor” system.

In the body of the boiler itself for water heating, the pipes are in water, which will be heated by the action of hot air passing inside them. This system is similar to a gas water heater

Rice. 2 Water double-circuit heating boiler system

The circulation of water through the system begins even before it enters the boiler.

For optimal system operation you need:

- controller for water level in the tank;

- overflow so that the water does not exceed the permissible level;

- a pump that lifts water from the radiator circuit;

- lower outlet for water intended for floor heating.

It is difficult to make such a sawdust boiler with your own hands, but a house equipped with such equipment will be very comfortable to live in all year round.

Boiler power calculation

One of the problems with homemade heating equipment is determining power. You can do the calculations for a sawdust boiler yourself. To do this, you need to know the basic characteristics of the fuel.

Calculation order.

- Bulk density. On average, this parameter varies from 180 to 230 kg/m?. With a fuel chamber volume of 0.07 m? it will hold about 15 kg of crushed material.

- Calorific value of fuel. The average value for 1 kg of fuel is 2.3 kW.

- Power calculation. The maximum value for this example will be 15 * 2.3 = 34.5 kW.

This simplified method does not take into account fuel moisture and air supply intensity. It is recommended to subtract 10-15% from the obtained value. The actual maximum power will be 29 kW.

The best known manufacturers and models: characteristics and prices

When choosing a boiler for sawdust and wood chips, in addition to technical characteristics, you should pay attention to the country and brand of the manufacturer. Northern European countries have learned to squeeze the highest economic performance out of fuel

To this end, they have been working for a long time on improving automation specifically for private homes, and given their desire for comfort and environmental requirements, you should pay attention to the products of the companies Hargassner, Froling, ETA. Of course, if the budget allows.

Russian-made boilers, especially if the developer is a well-known European brand on the market, may well be competitive. At a significantly lower price, they are quite capable of providing both the reliability and comfort of a private home. In addition, they are unpretentious in raw materials and maintenance, and the automation even in European solid fuel boilers is often from China.

Specialized

These are boilers designed primarily for the use of bulk solid fuels.

Pyrolysis Master BIO-15

One of the best sawdust boilers for heating a private home. It also works on wood chips, peat, and sunflower husks. With the use of replaceable burners it can burn straw. Thanks to a five-pass heat exchanger, it has a high efficiency of 91% and has a hopper capacity of 200 liters. The only drawback is its considerable dimensions.

Cost: 185,000-240,000 rubles.

FACI FSS 115

It is produced in Russia, but the developer is Italy. This is an automatic industrial boiler for burning wood waste. Power adjustable within 25-115 kW, efficiency 92%. As additional options, it is equipped with auto-ignition, burner self-cleaning, and remote control. Hopper capacity is 810 liters, fuel is supplied by two augers. Can burn any biomass with a fraction not exceeding 40 mm. The 115 kW model has a huge weight of 1150 kg, which increases the flooring and transport requirements.

Cost: 450,000-477,000 rubles.

Universal models

Boilers using any solid fuel: all types of coal, peat, firewood, wood waste, seed husks, briquettes with varying efficiency, but structurally designed for long-term combustion. They are much cheaper than specialized ones, but also much less effective and practical when working with sawdust.

Tis Pro DR

Excellent inexpensive universal boiler. Furnace steel 5 mm thick is used as a heat exchanger, which is a very good indicator in terms of reliability and durability. It also features a huge firebox; depending on the power, the volume of the combustion chamber can be 80-116 liters. Does not use fan pressure and is non-volatile. Available in 17, 22 and 27 kW versions, efficiency reaches 82%.

Owners often note that the design of the grate is extremely practical: they are separate, cast iron (reliable and easily replaceable). No deficiencies were found due to operating practices.

Cost: 58,500-72,000 rubles.

PEREKO KSP Duo

High-tech Polish universal TT boiler of the highest price category. The innovative burner allows high-quality combustion of fine-grained fuel from eco-peas to oats as efficiently as possible. A water-filled grate in the combustion chamber makes it possible to burn wood and its waste.

Equipped with automation controlled by the ST-480 controller, which, in addition to controlling the central heating and hot water pumps, the boost fan, can also control the operation of the mixing valve and take into account signals from room and street temperature sensors. Available in power variations: 12, 18, 26, 36, 52 kW. In addition to the price, the disadvantages are large dimensions, weight and low permissible operating pressure - only 1.5 bar.

Cost: 283,000-498,000 rubles.

LIEPSNELĖ L20U

Universal Lithuanian long-burning shaft-type boiler with a power of 20 kW. The fuel is coal, pressed briquettes from coal, peat, wood waste, sawdust and other raw materials. The efficiency reaches 91%, but this is only when heating with low-ash coal; when using sawdust and wood chips, the efficiency will be lower. The heat exchanger is cast iron, in a steel casing. The boiler is known for its reliability, quality of alloys used and assembly. Even when using sawdust and wood chips, the burning time of one load can be achieved in 2-3 days.

The only drawbacks, as in the previous case, are the low operating pressure of 1.5 bar and heavy weight.

Cost: 110,000-125,000 rubles.

Model series tables

So, here are tables of models, main characteristics and prices at which you can buy a boiler model that suits you.

Industrial boilers for woodchips and sawdust of the BIO VULKAN PRO series 100-1000 kW.

| Model | power, kWt | Area, up to m² | price, rub. |

| BIO VULKAN PRO-100 | 100 | 1000 | 662 600 |

| BIO VULKAN PRO-160 | 160 | 1600 | 696 200 |

| BIO VULKAN PRO-200 | 200 | 2000 | 722 900 |

| BIO VULKAN PRO-250 | 250 | 2500 | 865 600 |

| BIO VULKAN PRO-320 | 320 | 3200 | 1 083 600 |

| BIO VULKAN PRO-400 | 400 | 4000 | 1 143 600 |

| BIO VULKAN PRO-500 | 500 | 5000 | 1 219 600 |

| BIO VULKAN PRO-600 | 600 | 6000 | 1 488 600 |

| BIO VULKAN PRO-750 | 750 | 7500 | 1 595 600 |

| BIO VULKAN PRO-850 | 850 | 8500 | 1 780 600 |

| BIO VULKAN PRO-1000 | 1000 | 1000 | 1 990 600 |

Among the manufacturers of industrial boilers using woodchips and sawdust, it is worth noting the domestic company Pyrolysis Master and its BIO VULKAN PRO 100-1000 kW series.

Industrial boiler using wood chips and sawdust Pyrolysis Master BIO VULKAN PRO

With their help, you can heat domestic, industrial and other premises, and prepare heat for technical needs.

The boilers are equipped with a system for mechanical supply of wood chips and sawdust into the combustion chamber.

Fuel fraction – 40 mm, humidity – up to 50%.

The maximum hot water temperature is 110 ºC.

If necessary, manually loaded firewood, coal, briquettes can be used as fuel, but the power will decrease by 15 - 20%.

Boiler design Pyrolysis Master BIO VULKAN PRO

Among the features of solid fuel boilers BIO VULKAN PRO we note the following:

- The body is welded from steel sheets and pipes, and the outside is covered with shields with thermal insulation material.

- The firebox is lined with fireclay bricks, which increases the combustion temperature.

- They are equipped with large, tightly closing firebox doors, and their body is filled with heat-resistant concrete. They are produced in a right-handed version, but at the customer’s request they can also be left-handed.

- An explosion valve is installed in the doors of the heat exchanger. As a result, when a mixture of flammable gases explodes in the boiler furnace, the blast wave ruptures the valve membrane and goes up the channel.

- The boiler heat exchanger is drum type, fire tube. In order to effectively extract heat, removable turbulators are installed in the pipes. The bottom of the drum is protected from limestone deposits by providing two layers of efficient water circulation.

- The primary and secondary air necessary for combustion is supplied to the furnace by fans. It passes through the gap between the heated walls of the boiler and, having warmed up, through the holes of the grate, and between the fireclay bricks in the walls of the furnace, it enters the combustion zone.

- The amount of air supplied is adjusted using dampers.

- To protect the boiler from excess pressure, two pipes for installing safety valves are welded into the outlet water pipe.

BIO VULKAN PRO

In the ash pan of the Pyrolysis Master BIO VULKAN PRO, under the grates, there is a fuel supply chute; a boiler screw conveyor is mounted into it, with the help of which, along the “volcano”, between the grates and a frame of heat-resistant concrete slabs, reinforced with a supporting structure, the boiler furnace is mechanized bulk fuel is supplied.

The flame of burning fuel heats the fireclay slabs of the firebox, its internal walls and the bottom of the drum, and the resulting hot combustion products pass through the heating pipes of the heat exchanger so, giving off heat to the circulating water, cool and are removed from the boiler through the chimney.

Boilers for sawdust, husks, wood chips, peat, pellets of the BIO series 15-500 kW.

| Model | power, kWt | Area, up to m² | price, rub. |

| BIO-15 | 15 | 150 | 185 000 |

| BIO-20 | 20 | 200 | 190 000 |

| BIO-30 | 30 | 300 | 210 000 |

| BIO-40 | 40 | 400 | 225 000 |

| BIO-50 | 50 | 50 | 265 000 |

| BIO-60 | 60 | 600 | 294 000 |

| BIO-80 | 80 | 800 | 357 000 |

| BIO-100 | 100 | 1000 | 420 000 |

| BIO-120 | 120 | 1200 | 483 000 |

| BIO-160 | 16 | 1600 | 555 000 |

| BIO-200 | 200 | 2000 | 621 000 |

| BIO-250 | 250 | 2500 | 667 000 |

| BIO-320 | 320 | 3200 | 930 000 |

| BIO-400 | 400 | 4000 | 1 380 000 |

| BIO-500 | 500 | 500 | 1 610 000 |

Pyrolysis master BIO

The basic package of the BIO boiler includes:

- biomass heating boiler housing;

- basic fuel bunker for biomass;

- screw conveyor;

- burner;

- fan;

- automatic control unit.

If desired, the bunker can be enlarged, the boiler can be equipped with automatic burner cleaning, GSM and WiFi modules.

Pyrolysis Master boilers of the BIO series are distinguished by the presence of a 5-pass heat exchanger. As a result, the boilers have the highest efficiency when compared with boilers that have 2-3 strokes in the convective channels of the firebox.

Biomass is burned using a horizontal retort burner. This allows you to burn pellets of any quality, sawdust, wood chips with a fraction of up to 4 cm, oilseed husks, and peat.

Automation, electronics and fans are presented by the best European manufacturers.

From the tables above, you can see that this is the richest range of boilers using wood chips and sawdust among all manufacturers represented on the Russian market. This set of power options will allow you to solve the problem of heating with wood chips and sawdust at any facility and for any area.

Separately, we would like to note that the industrial line of boilers of the BIO VULKAN PRO series allows you to build a boiler house using wood chips and sawdust at minimal costs, thanks to the lowest dimensional requirements of this equipment, which reduces the costs not only of transporting boilers to the customer’s site, but also the costs of constructing boiler rooms. For those who want to study the characteristics of these boilers in more detail, we suggest that you familiarize yourself with them on the manufacturer’s official website.

Pros and cons of the technique

The main advantages of using burning sawdust and wood chips as an energy source for the heating system are:

- High efficiency of heating the coolant (usually water, although antifreeze can also be used in a water system), with the help of which the house is kept warm, and sometimes also provides hot water supply.

- Low cost of raw materials. A system based on the use of a sawdust boiler will be especially advantageous if there are one or more woodworking enterprises (for example, furniture factories or sawmills) near the heated premises.

- Ecological purity of sawdust as fuel. Their combustion practically does not release toxic substances into the atmosphere, unlike a number of liquid and gaseous energy carriers.

- Easy to operate and maintain. Almost everyone can use equipment that runs on sawdust and wood chips. And its installation does not require permission from regulatory authorities, as when connecting a gas appliance.

Naturally, such a system also has disadvantages. Among them, it is worth noting the difficulty of storing material that is highly flammable.

This problem is partially eliminated by pressing the fuel, however, sawdust still needs to be stored in a fairly spacious room.

Another disadvantage is the need for periodic cleaning of chimneys, which is due to the large amount of soot and ash generated during operation.

In general, the positive effect that the method of heating rooms with long-term burning of sawdust gives is much greater compared to some of its disadvantages. This means that such systems have a right to exist. And, moreover, over time they can supplant traditional heating options.

Heating unit design

The boiler design also includes a heat exchanger for the home heating system. It is located at the back wall for two combustion chambers at once. In some models of long-burning boilers, the heat exchanger is a water jacket located over the entire area of two combustion chambers. This boiler works more efficiently.

Screw

The screw for automatically feeding sawdust is an important component that ensures the correct operation of the entire installation. If the loading hopper is located outside the walls of the boiler room, then the supply is carried out in two links: the first - from the hopper to the boiler, the second - from the loading chamber to the firebox.

Fans and automation

Fans provide the necessary supply of fresh air to the two combustion chambers. In this case, two goals are pursued: the first is to create conditions for proper combustion of sawdust, the second is to create a certain swirl of the flame.

The exhaust fan provides draft in the boiler and effective removal of carbon monoxide. The thing is that the process of pyrolysis is a decrease in the temperature of fuel combustion products. This means that, according to the laws of physics, there is a slight upward movement of smoke. To increase the lifting speed, an exhaust fan is installed.

Of course, all modern heating and long-burning boilers are equipped with an automation system that controls all thermal processes inside the installation.

The principle of operation of a sawdust-wood boiler

Pyrolysis combi boilers using wood and sawdust have an internal structure and a modified design that ensures maximum heat transfer and efficiency when burning fuel. The operating principle of heating equipment is as follows:

- During the combustion of solid fuel, a large amount of carbon dioxide is released. The CO produced is sent to the afterburner. During transportation, an air-gas mixture is formed, burned at high temperatures. To maintain the required temperature conditions, the afterburning chamber is made of fireclay bricks.

The heated gases are not immediately discharged into the chimney, but are directed into a broken chimney channel located inside the boiler, surrounded by a coolant liquid medium. The pyrolysis process and changes in the boiler design increased the efficiency from 70% (in standard models) to 92% (in gas generating equipment).

Modulation operating mode – long-burning solid fuel boilers for firewood and sawdust use sensitive automation connected to room thermostats. Depending on the heating needs of the room, performance varies from 30 to 100%.

The use of two types of fuel - you can independently choose as the main source of heat: firewood or sawdust. The second type of fuel will be used as a reserve. After the firewood has burned out and the coolant has begun to cool, the burning of sawdust or wood chips will start automatically.

Bifuel boilers use sawdust and firewood as fuel. Working on each of these types of fuel has its own characteristics.

Wood burning

Universal long-burning solid fuel boilers can operate on wood and sawdust. But, in the case of using firewood, the thermal efficiency of the equipment increases. This is explained simply. Firewood, when burned, releases the maximum amount of carbon dioxide, which is used to generate additional heat.

Wood burning has the following features:

- Fuel filling and ignition are carried out manually.

The intensity of air supply to the firebox is controlled using a damper either manually or automatically.

The autonomous operation of the boiler from one load varies, depending on the quality of the firewood and the model of the heating unit, from 6 to 24 hours.

If you compare the technical data of boilers using wood and sawdust, it is more profitable to burn with logs. The main disadvantage of using firewood is the need for constant maintenance of the hot water boiler. It is necessary to add fuel 2-3 times a day, clean out the ash and clean the combustion chamber. All work is done manually.

Burning sawdust

Sawdust combustion is carried out with maximum automation of the process. Combustion and fuel supply proceed as follows:

- Sawdust enters the combustion chamber via a screw transmission. The intensity of movement of the fuel conveyor is monitored by the boiler automation. In the event of an emergency, a signal is given to turn off the supply of sawdust. If necessary, a mechanized fuel storage facility is organized. After connecting the bunker, the boiler is able to operate throughout the entire heating season without stopping.

Electric ignition – sawdust is ignited using a plasma arc. An optical sensor is installed in the combustion chamber to monitor the presence of flame. When it fades, the sawdust is ignited again.

Sawdust is burned with artificial air injection. A stable flame is created, heating the coolant as quickly as possible.

Along with sawdust and firewood, in dual-fuel units it is allowed to use wood chips made from hard wood with a moisture content of no more than 20%.

Sawdust boiler

Sawdust boiler: operating principle and technical features

Solid fuel boilers have long been seriously competing with traditional gas equipment.

The efficiency of solid fuel devices, as well as their efficiency, has recently increased particularly rapidly. This is facilitated not only by the use of modern technologies, but also by the use of fuel, which was not even paid attention to before. Sawdust boilers have become especially popular, although they are rare in our country. Therefore, few people have any idea about the principle of their functioning. Nevertheless, such boilers are truly worthy of yours, since they have many advantages - among them, environmental friendliness and the ability to save money. And if we add to this the fact that the cost of traditional types of fuel is growing every day, it turns out that soon these devices will become simply irreplaceable. Using a sawdust boiler, you can heat greenhouses and workshops, as well as private houses, completely.

How does this type of boiler work?

The main part of any heating device that runs on sawdust is the combustion chamber. This is where the heat exchanger is located, which heats up when sawdust is burned. When burning, the fuel is located on a special grate, due to which all residual waste falls into the ash pan - a special container that should be cleaned periodically. On average, cleaning the ash pit occurs about once every three months, but, of course, this period is relative, since much depends on the heating intensity.

Sawdust is essentially a waste product from the woodworking industry, and, as you know, it cannot produce a strong flame. For this reason, heated gases pass through the heat exchanger, further heating its surface. To enhance the effect, heat exchangers are predominantly made in a spiral shape, but there may also be several tubes that are connected to each other. The material from which the heat exchangers are made must be resistant to rust formation, as well as high temperatures; Moreover, it must conduct heat well. The heated gases, having transferred thermal energy to the exchanger, go into the chimney, being completely cooled.

In order to obtain high efficiency, sawdust boilers use not only the thermal energy that is generated during the combustion of wood, but also a by-product of this process - pyrolysis gas. But you must adhere to specific conditions in order to receive this gas. Thus, the amount of oxygen in the combustion chamber must be minimized, which is why the device is equipped with an artificial ventilation system - it will not only remove air from the firebox, but also bring it in if necessary. In order for the pyrolysis gas to also burn, the firebox must be divided into several separate parts:

- In one of them the sawdust itself will burn.

- The other contains gas transferred from the first chamber using a special burner.

Boilers operating on sawdust, as well as other heating equipment, can be of two types.

- Single-circuit, capable of heating only.

- Double-circuit, which both heat the room and supply hot water.

How fuel is supplied

In general, such boilers can operate on any wood fuel, from biological briquettes to ordinary firewood.

Note! In order to operate fully automatically, sawdust boilers must only use wood chips and sawdust!

In order for the device to be able to “feed” on wood, its combustion chamber must be redone. But most modern models already include everything needed for conversion.

Regardless of what type of fuel is used, pyrolysis boilers need it to be dry. If it is wet, steam will be generated during combustion. And if steam mixes with gas, the latter will become heavier, and the combustion process itself will deteriorate significantly. Therefore, it is not strange that every solid fuel device spends up to 1/3 of its power precisely on drying the fuel.

You should pay due attention to the fuel supply, which consists of two elements:

- agitator - it permanently mixes sawdust, which ensures their constant supply to the auger;

- auger - a device designed to transport sawdust from a special bunker to the combustion chamber.

Note! Automatic boilers are characterized by the fact that they supply fuel continuously! This will allow you to make a bunker for it, located underground.

An underground bunker is good because it not only stores fuel, but it saves free space in the house. Often it is installed in such a way that its highest point is located at the same level as the foundation itself. In the same place there should be a hatch through which fuel will be poured immediately from the transport that delivered it. We also note that the bunker should be located in the room adjacent to the one where the boiler is located in order to easily set up a fuel conveyor.

Pros and cons of this material as a fuel

First, let's look at the advantages of this material as a fuel, because there are many more of them than disadvantages.

- Any fuel made from wood is an environmentally friendly product that, even when burned, will not harm the environment.

- Such fuel is inexpensive, because it is, in essence, ordinary waste.

- Today sawdust boilers are fully automated, thanks to which all work processes are controlled.

- Sawdust generates more heat than, for example, firewood, and can burn twice as long.

- Sawdust can be used at any time, as it is always dry and ignites very easily.

- During operation, virtually no soot is emitted.

- The maintenance costs of such a boiler are significantly lower than those of its analogues.

- Today, special pressed sawdust is even sold, sealed in convenient packaging.

- The fuel is compact, which makes it very convenient to store.

- Finally, sawdust does not release any toxins when burned.

And now about the shortcomings, which, as we promised, are not so many.

- Sawdust is loose, which makes transporting it not very convenient.

- The combustion parameters of this type of fuel are relatively low.

Features of choosing boilers operating on sawdust

In order to choose the right boiler that uses sawdust as fuel, it is necessary to pay special attention to a number of aspects. First of all, objectively assess the size of the house that will need to be heated. Based on the data obtained, you can determine what power device you need. To correctly calculate this power, use a simple, well-known formula.

For 10 square meters of room, 1 kilowatt of device power is required

It is important that when making these calculations you take into account the following parameters of your home.

- Thermal insulation.

- Number of windows and doors.

- Ceiling height.

In addition, pay attention to whether the model you like is capable of automatically supplying fuel to the combustion furnace. If this procedure is automated, then further operation of the boiler will be easy and relaxed. As a result, you will spend less time monitoring all the operating processes of the device.

Finally, most modern sawdust boilers can be operated in combination with additional devices. This could be, for example, a household drying chamber. That is why, when purchasing a boiler, pay special attention to the additional options available in it.

As a conclusion

So we found out that sawdust boilers are an ideal option for a country house. Judge for yourself: the fuel for it is cheap, because it is ordinary waste from the woodworking industry, when the fuel burns, no substances harmful to health are released, and the operation of such boilers is a fairly simple procedure. In general, if you chose sawdust as fuel, then you made the right choice!

Heating boilers using sawdust - significant savings

A sawdust heat generator is currently rare, although it can be used to effectively heat a private home. Basically, sawdust heating boilers are produced by foreign companies.

Heating boilers using sawdust - operating principle

Sawdust heating boilers have a simple design, but despite this, they are able to effectively heat a house thanks to controlled combustion, three-stage air supply and gas generation of combustion products. The sawdust is placed in a special hopper where the auger is located. The receiving tank can also be placed outside the house. Using a worm gear, sawdust is transferred from it to the room intended for its storage. Another auger takes fuel and sends it to a tank connected to the combustion chamber. Thus, the sawdust heating system is fully automated.

The process of converting fuel into thermal energy occurs in several stages:

- Entering the combustion chamber, sawdust is automatically ignited and burned using a three-stage air supply system that provides swirling flames.

- Under the influence of combustion, the heat exchanger heats up.

- The gas formed during the combustion of fuel is sent to a special chamber where it is burned. Usually this compartment is installed additionally. Combustion products are removed through the smoke exhaust system.

Thus, the sawdust boiler is a large-scale installation - this can be seen by looking at the photo. Installation of this heating system is justified only if it is possible to allocate a large room for fuel storage and ensure constant replenishment of resources. For one hour of operation of a 25 kW boiler, about 40 kilograms of sawdust will be required.

Sawdust boiler design

For efficient and automatic operation of the boiler, a set of devices is required. There are also models on the market into which you can add fuel yourself, but they are extremely inconvenient to use - sawdust will have to be loaded every 1-2 hours.

It is more correct to call the boiler a whole station consisting of several elements:

- Screw system

. It provides an automated process for sawdust entering the hopper and combustion chamber. - Air pump

. Such heating boilers are not able to operate without forced air injection into the firebox. An air pump is also present in devices that require manual insertion of sawdust. Air is forced into the firebox by fans in such a way that the necessary pressure and flame swirl are generated. - Gas generation chamber

. It is not present in all models; sometimes it has to be installed additionally. Heating with sawdust is possible without this structural element. The heating efficiency in the presence of a gas generator compartment increases by 30-40%, and almost completely cooled air goes into the chimney. As a result, all the heat obtained from burning sawdust is accumulated and transferred to the coolant. - Exhaust fan

. It is necessary if there is a gas generation chamber. Since cooled gas causes a decrease in thrust, its removal is only possible through the use of an exhaust device. - Automation

. It serves to control the temperature and the rate of sawdust entering the combustion chamber. If necessary, you can buy equipment that allows you to control it remotely. If unexpected situations arise, the owner of the house will receive an alert on his mobile phone.

It is worth considering that sawdust boilers may have different configurations depending on the type of equipment and manufacturer. Installations are also created to order.

Types of sawdust boilers

Heating systems operating on sawdust are divided into two types:

- conventional - heat is generated only as a result of fuel combustion, such boilers are less profitable than those that have a gas generator chamber;

- with a gas generator element - more efficient units, may have different designs.

Some manufacturers offer condensing-type models, as well as long-burning boilers.

You can assemble a homemade sawdust boiler if you wish, but it will be the simplest design. As for automated heating systems, even domestic manufacturers cannot offer high-quality and economical equipment.

The German Hargassner models are considered the best - they are highly effective, but at the same time expensive. Some other foreign companies also produce high-quality boilers.

Cost-effectiveness of heating with sawdust

Heating a house with sawdust is considered the most profitable, but this opinion is wrong. Indeed, fuel is cheap, but as for whether it is really the cheapest heating method, this is not entirely true.

For a house with an area of about 200 square meters, you will need a boiler with a capacity of about 25 kW. One hour of operation will require 40 kilograms of sawdust, so the fuel storage tank must be large enough. They are inexpensive, and if you buy them at woodworking enterprises, they will cost even less. Pressed sawdust for heating is also very profitable.

For comparison: gas equipment of the same power consumes about 3 cubic meters per hour. meters. The cost of such a volume of gas is almost equal to 40 kilograms of sawdust. Thus, heating with a gas boiler costs the same amount as with sawdust-fired equipment. At the same time, gas boilers are much cheaper and do not take up so much space (about

Making a potbelly stove

Long-burning potbelly stoves are good because they are made from any available materials - these are various barrels, old capacious cans, pieces of large-diameter pipes or simply sheet metal. We chose sheet steel as the starting material - it is a more convenient material to process. You can adapt a barrel for this, but doing work in its internal volume is not very convenient.

All sizes are presented rather as guidelines, a kind of averaged best option. You, in turn, can deviate from the dimensions of the parts to create a stove that satisfies your specific wishes.

The design of a long-burning furnace is quite clear from the drawing presented above. Here are its main components:

- Combustion chamber - wood burns in it with the formation of pyrolysis gas;

- Afterburner – combustion of pyrolysis products occurs in it;

- Doors of the combustion chamber and ash pan - they are purchased in the store, but you can make them yourself;

- Chimney - in most cases it is a pipe with a diameter of 100-150 mm.

You can deviate from the drawing in one direction or another. But remember that as the size decreases, the burning time decreases and the power of the long-burning stove decreases.

The lower the power, the smaller the heated area. Therefore, it is best to provide a small reserve.

To make a long-burning stove like a potbelly stove, we need sheet steel with a thickness of at least 3 mm - this will ensure a long service life of the heating equipment. If the steel is thin, it will begin to burn through - after a couple of seasons, holes will form in it

Therefore, special attention is paid to the thickness of the steel. The optimal thickness is 3-5 mm

For our example, we will take the classic scheme of a potbelly stove, modify it and get at our disposal an effective wood-burning stove for a home. At the initial stage, we prepare the side sheets - in our drawing they have dimensions of 450x450 mm. Next, we make the lower walls, front and rear walls - their dimensions are 200x450 mm. As a result, we should get a rectangular box. But don’t rush to weld it together - there is a lot of work ahead.

First you need to make a base - this is the bottom wall and two side ones. We weld them together, weld the grate at a height of 80 mm from the bottom. Now we need to prepare the front wall of the long-term heating oven - we weld both doors into it, and then weld it to our structure.

We prepare two metal sheets measuring 200x370 mm. We weld the first of them to the front and side walls at a height of 160 mm from the top. Next, we prepare the back wall - we weld small metal tubes into it, which should fit into the space between the two inner sheets that form the afterburning chamber - secondary air will be supplied through them. Then we weld the back wall and a second metal sheet at a height of 80 from the top (welded to the side and rear walls).

The damper is used to regulate air flow. It is this that improves the efficiency and quality of traction.

Our DIY long-burning stove is almost ready - all that remains is to figure out the top cover. We make a hole in it with a diameter of 100 mm and weld a piece of pipe for the future chimney. Now it remains to find out whether you need a hob or not - it is also welded into the top cover. At the last stage, we install the lid in place and weld it - the stove is ready, now it can be installed on a non-combustible base, attached to the chimney and started.

When starting the long-burning stove presented above, let it burn, then cover the ash pit so that the wood barely smolders and the generation of pyrolysis gas begins.

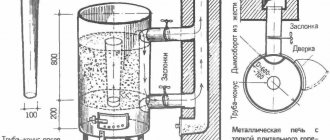

Another interesting long-burning pyrolysis furnace is shown in the following figure. It is made from a barrel or a piece of large diameter pipe and is equipped with a suitable lid. In the lower part, at a distance of 80-100 mm from the bottom, a metal disk with a hole in the middle is welded. A door is welded between the disk and the bottom, on the side wall. The resulting space forms our firebox. We weld a chimney with a diameter of 70-100 mm in the upper part.

In terms of low cost of use, such a stove is a real gift, since there is no shortage of sawdust in a private home.

The resulting long-burning furnace receives heat by burning pyrolysis gases generated when heating sawdust. The sawdust itself is poured into the main volume, and to prevent it from spilling into the firebox, it is compacted using a wooden cone. When the stove starts, a fire is lit in the firebox, the cone is removed - after a while the unit will begin to produce heat.

Homemade design: materials and assembly procedure

So, when we have figured out the structure and operating principle of the industrial design, we can begin to make a mini household unit similar in operation. First, you should stock up on the necessary tools and materials from which the stove will be assembled, namely we will need:

- welding machine;

- pipe of existing diameter (32 - 56 mm);

- gas exhaust pipe (100 mm);

- a set of adjustable and gas wrenches;

- Bulgarian;

- roulette;

- clock relay;

- temperature sensor;

- anti-explosion valve;

- water pump;

- ball valves (3 pcs) and couplings with screw threads;

- feed auger;

- ash removal auger (optional);

- metal corner 45 – 50 mm;

- hydraulic cylinder;

- 200 liter barrels for ash pan and sawdust (2 pcs);

- electric fan;

- sheet metal (4 mm);

- tow or fum tape.

The working process

The assembly of homemade sawdust boilers begins with the manufacture of the body and bottom of the unit. Everyone chooses the dimensions of the structure individually for themselves. Using a welding machine, a boiler body is formed without a bottom and covered with a water jacket . Homemade boilers can consist of empty gas cylinders, but we will focus on the welded version, which will allow you to vary the dimensions and power of the installation.

Next, it is necessary to make stiffening ribs between the water jacket, and also to provide technological openings through which air will be supplied from the fan to the combustion chamber. A “living” bottom is mounted from a metal corner, if provided, for which it is cut to dimensions of 50x25 mm and the output rod is attached to the cylinder. When the sawdust stove body is ready, it is mounted on the seat, an auger is installed to remove ash and a container is secured under it . Now you can install a fan, a screw that supplies wood chips, as well as a container for fuel, and you can say that the sawdust burner has been assembled with your own hands.

How to light a stove

In order for homemade sawdust stoves to operate as efficiently as possible, it is necessary to burn the fuel correctly. Initially, the crushed wood is placed in a barrel (or in a “live” bottom bunker) to the extent of 75% of its volume, after which the clock relay is activated and the auger feeds sawdust into the firebox, where it is ignited with special care with gasoline or diesel fuel. Next you need to turn on the fan.

There is another scheme for heating with wood chips, which differs slightly from the previous option, as it fits a simpler sawdust boiler, created by yourself (see photo).

To implement this, you need to fill the fuel chamber with sawdust to three-quarters of its volume, while it is recommended to press the crushed wood around a cone-shaped pipe. After compaction, the pipe is removed, the sawdust heating boiler is closed with a lid and the damper on the chimney is opened. Firewood is placed and lit in the lower part of the stove, the heat of which causes the sawdust to slowly smolder .

Now you know how to assemble a sawdust stove with your own hands, how it should work and how to fire it correctly. A well-made unit can provide economical heating of a small living space or any other outbuilding, and you can learn more about the operation of a potbelly stove from the video attached below.