The use of wood stoves for space heating is most often used to heat small spaces. The technology itself is based on the use of traditional cast iron or steel stoves with low efficiency. In addition to high fuel consumption, such stoves also require the constant presence of a person, because if you do not constantly add firewood, it will simply go out. Long-burning stoves are another matter, but alas, today they still have an unreasonably high price, so there is only one option left - to make such a potbelly stove yourself.

A little more about pyrolysis...

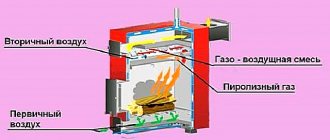

The essence of pyrolysis lies in the process of technological gas-generator combustion.

When solid fuels such as coal, pellets, peat briquettes or firewood are burned, the room warms up. The operating principle is similar to that of a dry distillation boiler. The pyrolysis system is due to its exothermic properties, and can heat the incoming air due to the heat generated. The fuel is ignited and the fan turns on when the door is closed. The high temperature regime (200–800 °C) and low oxygen capacity in the pyrolysis combustion furnace lead to a chemical process - the wood decomposes into coke and pyrolysis gas. Also, when wood burns, it can form methyl alcohol, acetone, vinegar and resin. The released gas combines with oxygen and goes into the combustion process. The smoke generated during combustion does not contain bad carcinogens and other dangerous components. Burnt fuel produces thermal energy, which heats the room. The water contained in the boiler enters the heating structure in a hot state with a simultaneous return supply. The coolant is also used as a coolant. This is how a boiler with a bottom-mounted chamber functions.

Technical nuances

- The oven should not be placed close to walls, objects, etc. Leave enough space around it.

- The oven gets very hot - do not keep flammable materials, fuel, or anything that can catch fire, dry out or melt near it.

- When making a chimney, think about how to clean it in the future. The best option is to make it collapsible.

- If the chimney pipe is prefabricated, install the elements so that the joints are located in the opposite direction in relation to the moving gases.

When cleaning out ash, leave some of it behind each time. If the combustion takes place on an ash bed, the bottom of the stove will not burn out longer.

Large rocket stove with bench

The main advantage of the rocket modification over the Russian stove is its compactness. Even when equipped with a bed, it will please you with its small size. By making it out of brick, you will have at your disposal an effective source of heat with a comfortable bed - household members will fight for the right to occupy this warm place.

The presented procedure allows you to assemble a brick oven without the use of metal. Only the doors will be made of iron. Subsequently, the bricks can be coated with clay, which will make the stove more rounded.

The first row forms the base of our rocket stove. It consists of 62 bricks laid according to the pattern shown in the figure. The second row forms channels for heating the bed - they run along its entire length. Cast iron doors are also installed here, secured with metal wire - it is held between the rows. The number of bricks used is 44 pcs. The same amount will be required for the third row, which completely follows the contour of the second. The fourth row completely covers the channels that heat the bed. But here a vertical smoke channel and a firebox are already beginning to form - the row includes 59 bricks.

Another 60 is needed for the fifth row. The bench has already been formed, all that remains is to finish off the chimney channel and build the hob. The sixth row, which includes 17 bricks, is responsible for this. Another 18 are needed for the seventh row, 14 for the eighth.

The ninth and tenth row will require 14 bricks, the eleventh - 13.

Row No. 12 is our key row - the chimney pipe will begin from here. Also from here begins a hole through which the air rising to the hob will fall down to the stove bench - 11 bricks are required (this is the top of the riser). In row No. 13 this process is completed, 10 bricks are spent on it. Now we lay an asbestos pad, which is covered with a piece of thick sheet steel - this will be the hob.

Rows No. 14 and No. 15 require 5 bricks each; they cover the chimney channel and form a low wall between the hob and the stove bench.

A metal surface is mounted at the back of the rocket stove, under which a small compartment is formed - here you can dry firewood.

Buy or build?

Only metal stoves with a water circuit are available for sale. A foundation and destruction of the house are not needed to install a metal stove, but it does not have the useful qualities of a brick stove. In an energy-efficient house (see below), only a metal stove can be installed. These are produced by many stove companies, incl. foreign ABX (Czech Republic), MBS (Serbia), EdilKamin (Italy). Here, firstly, there is a nuance: do not confuse it with a sauna stove equipped with a hot water heater; Sauna stoves are not suitable for heating. Differences, if the specification does not indicate that the stove is heating - a sauna stove always has a heater. Secondly, the same stove, but with a water circuit, is often sold as a boiler. How to distinguish it from a real boiler? By the presence of a cooking surface and a combustion door with a viewing glass. The boiler is not intended for gatherings by the fire. Third, EdilKamin are built using a water jacket and are not intended for use as main heating devices; this is actually a fireplace stove with a water circuit, see below. And finally, Russian stoves with a Breneran water jacket (the sign is “Aqua” in the name) should be installed in a non-residential building or in a separate boiler room, but for Breneran’s dacha it’s the best: it’s Breneran Aquaten that costs up to 20,000 rubles. (without delivery). For other domestic furnaces with a water circuit, see video reviews:

Video: reviews of furnaces with a water circuit

In addition, if you intend to buy a furnace for water heating, consider:

- For factory furnaces with a water circuit, all of the following operating limitations apply;

- If a heating boiler is often sold with a full set of standard piping, then a stove is always sold without it. Selection and installation of piping is a particularly difficult topic, and its cost can cover the difference in the price of a stove or boiler;

- Fireplace inserts with a water circuit are also available for sale. These are by no means the main heating devices, no matter what they promise in advertising! A fireplace insert with a water jacket (like the EdilKamin stove) is included in the existing local (house) heating system with a boiler to save standard fuel or in the heating system of an energy-efficient house, see below.

Video: about the dangers of a fireplace with a water circuit

In general, if your house has a basement, the first thing you need to consider is purchasing and installing a boiler. The basement will always provide an elevation of the registers above the heating device, necessary for the construction of a simple, inexpensive and non-volatile gravitational CO (see below). The heat from a stove (fireplace) without a water circuit for cooking and/or admiring the fire with cognac and caviar will not be wasted: the boiler automation “senses” it and saves standard fuel.

What is the advantage of a long-burning stove?

Any person who starts assembling a long-burning stove sets himself the main task: to make with his own hands something that will work efficiently with minimal consumption of materials and fuel. It is worth noting that most ready-made stoves of this type have an efficiency much lower than home-made models.

An ordinary factory stove is distinguished by the fact that the fuel in it burns very quickly, so the room quickly heats up and then quickly cools down if more fuel is not added to it. This is extremely inconvenient and irrational.

There is also an alternative on sale: these are stoves that run on solid fuel, which can delay the combustion process and, accordingly, insulate the room for a longer period. Such designs operate on coal, firewood and all kinds of waste. However, such a finished unit is not cheap and has such disadvantages as:

- low efficiency;

- lack of automatic fuel loading;

- the need for regular bookmarking.

All of the above does not apply to long-burning stoves. Thus, one load of fuel can ensure the operation of the structure for approximately 18 hours due to the fact that in the firebox, over time, combustion is replaced by smoldering, and in this case automatic fuel filling is no longer needed. In addition, the design can be thought out in such a way that sawdust or wood chips can be used as fuel, rather than whole firewood.

What to consider before assembling a long-burning stove

Please note that building a long-burning stove with your own hands is a dusty and noisy job, so think carefully about the place where the work will be done. In addition, ensure that there is a source of electricity at this location, since electric welding will be required

The tools for work should be prepared as follows:

- Metal barrel 200 l.

- Two pieces of steel pipe, one larger, the other smaller.

- Metal channel.

- Hacksaw, steel hammer, axe, mallet.

- Tape measure or answer for measurements.

- High quality red brick (about 50 pieces).

- Reflector (if available).

- A set of electrodes and a welding machine.

- Sheet steel.

- Construction mixture or materials for preparing mortar for laying bricks.

Algorithm for assembling a homemade long-burning stove

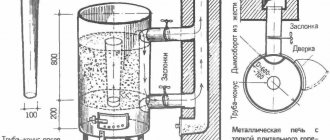

The assembly of this unit consists of the following steps:

- Prepare a metal barrel: cut off its top with a grinder and leave it for later. If there is no barrel, you can take a large diameter pipe section.

- Weld a bottom from a piece of round steel sheet to the section.

- We cut out another circle of steel with a diameter slightly smaller than the barrel or pipe, and in it there is another one for a small pipe of about 12 cm. The pipe section is welded to the steel circle.

- Weld channels to the bottom of the circle, measuring them so that they can fit freely in the pipe. These will then be applied to fuel pressure based on burnout.

- The length of the welded pipe must exceed the height of the main part by 10 cm.

- Let's start with the upper part of the structure: take the part of the barrel that was initially cut off and cut a hole in it for a small diameter pipe.

- Cut out the hatch for storing fuel; then a door will be welded to it, which can be purchased ready-made or made yourself. A handle needs to be welded to the door so that it can be opened comfortably.

- Install another smaller door below to make it possible to dispose of fuel waste.

Preparing the foundation and constructing a chimney for the stove

To install a furnace, a solid foundation is required, since the furnace metal will become very hot during operation. It is strictly forbidden to install it on fragile or insufficiently fire-resistant material.

It is not worth doing deepening, since the specific gravity of the structure is not very large. You need to fill the slab, laid next to one brick, with a special solution or mixture.

Now let's move on to the issue of installing a chimney. It is needed so that combustion products quickly evaporate from the room into the atmosphere. To construct it, you can take a metal pipe with a 15-centimeter diameter. It should be welded to the top or sides of the stove structure.

Then it is bent, but not more than 40 degrees. In general, you need to make sure that there are as few knees as possible before leaving the room.

Sometimes it is necessary to install a reflector, especially for small rooms. Thanks to them, heat flows will be redistributed and regulate uniform heating of the entire room.

There is no need to cover the stove with bricks if it is located in a boiler room or other utility room where children do not have access. If it is installed in full view of everyone, then it is better to do the cladding for safety reasons.

Making a potbelly stove

Long-burning potbelly stoves are good because they are made from any available materials - these are various barrels, old capacious cans, pieces of large-diameter pipes or simply sheet metal. We chose sheet steel as the starting material - it is a more convenient material to process. You can adapt a barrel for this, but doing work in its internal volume is not very convenient.

All sizes are presented rather as guidelines, a kind of averaged best option. You, in turn, can deviate from the dimensions of the parts to create a stove that satisfies your specific wishes.

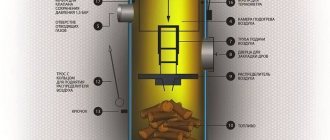

The design of a long-burning furnace is quite clear from the drawing presented above. Here are its main components:

- Combustion chamber - wood burns in it with the formation of pyrolysis gas;

- Afterburner – combustion of pyrolysis products occurs in it;

- Doors of the combustion chamber and ash pan - they are purchased in the store, but you can make them yourself;

- Chimney - in most cases it is a pipe with a diameter of 100-150 mm.

You can deviate from the drawing in one direction or another. But remember that as the size decreases, the burning time decreases and the power of the long-burning stove decreases.

The lower the power, the smaller the heated area. Therefore, it is best to provide a small reserve.

To make a long-burning stove like a potbelly stove, we need sheet steel with a thickness of at least 3 mm - this will ensure a long service life of the heating equipment. If the steel is thin, it will begin to burn through - after a couple of seasons, holes will form in it

Therefore, special attention is paid to the thickness of the steel. The optimal thickness is 3-5 mm

For our example, we will take the classic scheme of a potbelly stove, modify it and get at our disposal an effective wood-burning stove for a home. At the initial stage, we prepare the side sheets - in our drawing they have dimensions of 450x450 mm. Next, we make the lower walls, front and rear walls - their dimensions are 200x450 mm. As a result, we should get a rectangular box. But don’t rush to weld it together - there is a lot of work ahead.

First you need to make a base - this is the bottom wall and two side ones. We weld them together, weld the grate at a height of 80 mm from the bottom. Now we need to prepare the front wall of the long-term heating oven - we weld both doors into it, and then weld it to our structure.

We prepare two metal sheets measuring 200x370 mm. We weld the first of them to the front and side walls at a height of 160 mm from the top. Next, we prepare the back wall - we weld small metal tubes into it, which should fit into the space between the two inner sheets that form the afterburning chamber - secondary air will be supplied through them. Then we weld the back wall and a second metal sheet at a height of 80 from the top (welded to the side and rear walls).

The damper is used to regulate air flow. It is this that improves the efficiency and quality of traction.

Our DIY long-burning stove is almost ready - all that remains is to figure out the top cover. We make a hole in it with a diameter of 100 mm and weld a piece of pipe for the future chimney. Now it remains to find out whether you need a hob or not - it is also welded into the top cover. At the last stage, we install the lid in place and weld it - the stove is ready, now it can be installed on a non-combustible base, attached to the chimney and started.

When starting the long-burning stove presented above, let it burn, then cover the ash pit so that the wood barely smolders and the generation of pyrolysis gas begins.

Another interesting long-burning pyrolysis furnace is shown in the following figure. It is made from a barrel or a piece of large diameter pipe and is equipped with a suitable lid. In the lower part, at a distance of 80-100 mm from the bottom, a metal disk with a hole in the middle is welded. A door is welded between the disk and the bottom, on the side wall. The resulting space forms our firebox. We weld a chimney with a diameter of 70-100 mm in the upper part.

In terms of low cost of use, such a stove is a real gift, since there is no shortage of sawdust in a private home.

The resulting long-burning furnace receives heat by burning pyrolysis gases generated when heating sawdust. The sawdust itself is poured into the main volume, and to prevent it from spilling into the firebox, it is compacted using a wooden cone. When the stove starts, a fire is lit in the firebox, the cone is removed - after a while the unit will begin to produce heat.

Water heating circuit - an option for heating a house

A potbelly stove can be easily converted into a slow-burning boiler for water heating. Instead of a screen, we install a U-shaped metal water heater, which will also reflect IR rays. We install it at the same distance as the screen. The installation cools the furnace too much, reducing its efficiency. A potbelly stove, as in the drawing, produces 15 kW, so it can heat 25 m2 of space. If there is no need for water heating, you can use a water heater for domestic needs.

The intention to make a potbelly stove with a long burning time to heat a larger area is futile. Increasing the size will lead to a deterioration in quality indicators. In a large firebox, there is sluggish circulation, insufficient gas emission, and the room does not warm up well. If you fill the firebox to the top with wood, there is simply no room left for a convection vortex to form. The conclusion is clear: the size of the potbelly stove determines the properties of the pyrolysis gas.

But still, a more powerful long-burning boiler for water heating has been developed. It is difficult to replicate industrial designs, but the design shown in the drawing can be assembled at home.

Unit B with a telescopic rod to regulate the flow of oxygen deserves special attention. The unit develops a power of 35 kW when operating on coal and pellets, combustion lasts 12 hours. Firewood is less efficient; it burns out in 8 hours.

Features of a pyrolysis furnace and its application

Pyrolysis furnaces are called long-burning furnaces. Combustion of solid fuel in them occurs without access to oxygen: volatile gases are first saturated with the fine fraction of wood, and then burned at a high temperature (from 450 °C), mixing with residual air in the second chamber. Fuel and gas burn almost completely, providing high efficiency (up to 85-95%).

The simple design of the stove allows you to build it yourself and makes the device convenient to use

A stove of this type is installed in a garage, in a country house, in your home, and in any small room where long-term heating is needed. The devices are easy to operate and provide maximum heat output with significant fuel savings. In this case, the solid material is processed almost completely: gas and coal are burned, so smoke, soot and ash are almost never formed. This principle of operation is relevant for all models of pyrolysis furnaces, but different designs may differ in characteristics, appearance and internal structure.

Advantages and disadvantages

The heating device is efficient and economical, but also has a number of features. Knowing the pros and cons of pyrolysis furnaces allows you to make the right choice. The positive features of these devices are expressed as follows:

- Efficiency up to 95%, fast heating;

- minimal percentage of smoke and soot, environmental friendliness;

- no need for constant monitoring (fuel is loaded once a day);

- use of different types of fuel;

- accessibility of assembling and installing the stove yourself.

The simple operating principle ensures the practicality of the unit

The main disadvantage of using such a stove is the need to properly store firewood, selecting the optimal level of humidity. Otherwise, the material will not burn efficiently, because wet vapors will not allow the gas to be processed.

When burning waste (raw wood, car tires, industrial waste), there is an unpleasant odor, so it is recommended to use only clean and high-quality fuel, or additionally install a ventilation system in the room. It is also worth considering that condensation forms in the chimney, for which a special storage tank is provided. The outlet pipe and chimney have a larger diameter than the storage tank, so proper installation of the stove is important.

Chimney

The variability of this design lies both in the type of construction and in the materials used. Suitable for a chimney under Buleryan:

• 12 cm bricks;

• concrete (6 cm wall);

• metal.

The exact dimensions of the chimney are determined by the size of the buleryan:

• models 00 and 01 – height 4 m and cross-section 12 cm;

• products of type 02 – 04 – 5 m and 15 cm, respectively.

The tightness of the chimney is largely determined by the use of a special heat-resistant sealant.

Technically, it is allowed to exhaust the chimney in residential buildings for permanent or seasonal residence, both through the ceiling and through the wall. The second option is easier to implement with your own hands. The passage through the ceiling and roof will require knowledge of fire safety fundamentals. But the height of the pipe above the ridge in both cases is at least 50 cm.

Cleaning and repair

Over time, the partitions in the furnace will burn out and will need to be replaced. In the described case, this can be done by removing the fuel door and cutting off the side strips in the central part of the stove. Having replaced the partitions, we weld the steel strips back. These inconveniences can be easily avoided by making the fuel door wider so that the partitions can freely pass diagonally.

The firebox is cleaned from carbon deposits with a stiff metal brush. If you use only firewood or waste from wood production as fuel, and do not burn various plastic waste in it, then you will not have to clean the stove often, maximum once every 5 years.

Modern model - hermetically sealed, easy to move to another place

The process of assembling a long-burning potbelly stove is not complicated, so its assembly is feasible for anyone with welding skills. If you follow the manufacturing instructions, such a stove will last a long time, warming you in the country, in the garage and at home.

Furnace models and manufacturers

Before you buy an inexpensive wood-burning stove for your home, you should get acquainted with the features of products from well-known manufacturers. In this case, it will be easier to navigate the assortment offered in the store, the advantages and disadvantages of individual models.

Buleryan

A stove with a similar design was first developed in Canada. It is characterized by simplicity of design and high performance characteristics.

The cylindrical firebox is made of steel having a thickness of 5 – 6 mm. The combustion door is located on the front side. Hollow pipes having a round or rectangular cross-section are welded to the body. After heating the firebox, the air in the pipes heats up, providing an active convection process.

The grate is located inside the chamber at the bottom of the cylinder. There is a partition in the upper part, dividing the firebox into two parts. The first is intended for storing firewood, the second is for afterburning pyrolysis gas. The chimney is located on the side opposite the door and goes inside the combustion chamber. This ensures that the combustion products formed in the depths of the main chamber return to the front wall, and then rise to the top and enter the chimney.

Buleryan - time-tested quality

Butakov furnaces

The patented model has demonstrated good results in harsh climatic conditions. Several models are produced under this trademark, with different technical characteristics:

| Model | power, kWt | Weight, kg | Volume of internal space, cubes |

| Student | 9 | 70 | 150 |

| Engineer | 15 | 113 | 250 |

| Assistant professor | 25 | 164 | 500 |

| Professor | 40 | 235 | 1000 |

| Academician | 55 | 300 | 1200 |

Butakova - reliability and durability

Breneran

Russian analogue of the Canadian model, manufactured using European technology. Available in several models:

| Model | power, kWt | Heated area, squares | Weight, kg |

| AOT-6 | 6 | 40 | 56 |

| AOT-11 | 11 | 80 | 105 |

| AOT-14 | 14 | 160 | 145 |

| AOT-16 | 27 | 240 | 205 |

| AOT-19 | 35 | 400 | 260 |

Continuous ovens can be equipped with glass doors. Connection to a water circuit is acceptable. However, unlike its foreign counterpart, such equipment has insufficient sealing of the smoke fitting, which can cause condensation to enter the room.

Breneran - Russian analogue of Buleryan

Teplodar

Products of a famous Russian manufacturer. It features high efficiency thanks to a carefully thought-out design. Compact size and light weight. You can choose a long-burning stove for a garage or home with suitable characteristics.

Teplodar Matrix-200 is relevant for rooms with an area of up to 200 square meters. Siberia provides quick heating of the room. T series models will be the best choice for the garage. For the kitchen it is better to purchase a vertical heating and cooking stove-fireplace

Teplodar Matrix-200 is a good choice

Vesuvius

Russian development. Such long-burning wood-burning stoves for a bathhouse, cottage or country house can be the best solution. Often used to heat outbuildings. The choice of model is influenced by the purpose of the room for which it is purchased. They provide uniform heating thanks to a special design: pipes are welded into the firebox through which heated air passes.

Vesuvius for uniform heating of the house

Termofor

Domestic development for any home. Several models are produced under this trademark:

- Germa;

- Cinderella;

- Indigirka;

- Normal;

- Fire-battery.

The stoves can be used to heat various rooms with an internal volume of 50-250 m³. Their power varies from 4 to 13 kW.

Termofor in brown color

Ermak

Heating equipment that is small in size and has a classic design. The reliable casing protects from harmful infrared rays. This is the optimal solution for a small country house.

Operating principle of the Ermak stove

Power selection

The description of a metal fireplace stove must indicate the heating area it is designed for. When choosing power, it is better to take a margin of about 15-20%. This is to prevent the body from overheating even on the coldest days. It quickly burns out in this mode.

The power of the fireplace stove is selected with a small reserve - for the coldest days

On the other hand, you shouldn't take too much stock. Solid fuel stoves and fireplaces are difficult to regulate in temperature. And, if the power of the heating equipment is many times greater than necessary, the room will be too hot when firing. Nothing can be done about it. If the power is too high, even in smoldering mode there may be too much heat.

So, when choosing the power of a long-burning fireplace stove for a summer house or home, we take it with a margin of 15-25%. For example, the heated area is 100 sq.m. A suitable metal fireplace should have the ability to heat 115-125 square meters.

Video review of the Kratki Koza K9 stove-fireplace.

Do-it-yourself long-burning stove

Everyone wants to ensure that the boiler produces a lot of heat, but does not require a large amount of fuel. Current heating structures have low efficiency or require constant and expensive maintenance.

Scheme of a waste pyrolysis furnace.

If you are not satisfied with the samples offered in stores, you can build a long-burning stove yourself. But you will have to study useful information and instructions for creating a heating device.

The most popular in our time are boilers that are powered by solid fuel. Such structures make it possible to lengthen the combustion process, and firewood, coal, sawdust and other waste that are at hand may well be suitable as fuel.

Slobozhanka

The stove was named after the historical area where it was “born.” It is a full-fledged heating device with a hob.

According to the principle of operation, the Slobozhanka is similar to the Bubafone, but the air flow here is from the side. Next, it is pulled into the perforated casing located inside the housing and rises up. In this case, the fuel takes in as much air as is required for smoldering, and the excess moves on.

00f39f8c5e29ae86bb91a48939ae3381.jpe

e784a30a9894a5da8662a5fa6f14c5a5.jpeThe air in the slobozhanka enters all the fuel layers, so the pyrolysis process occurs more actively, and the furnace operates more efficiently.

What types of fuel can be used

When it comes to the heating system for a temporary premises, such as a workshop or garage, two aspects are usually taken into account - economic feasibility and safety. In terms of economic feasibility, the most affordable type of fuel today is wood.

Liquid fuel, such as diesel fuel or used engine oil, is used for heating mainly utility rooms; in residential areas, the use of this fuel is limited because it has a specific odor. Coal is usually not used for long-burning furnaces of handicraft production; it is intended for heating boilers and stationary brick furnaces.

Thus, the most acceptable type of fuel is firewood or pallets - fuel from wood processing waste. And here lies the whole secret of long-burning furnaces. The fact is that to get maximum effect you need to use only dry firewood. In ordinary, freshly cut firewood, the wood contains a large amount of moisture; during combustion, it turns out that two processes occur in parallel - burning of wood fibers and drying, releasing a large amount of water vapor. The result is a large amount of unburned fuel and combustion at a low temperature. These processes do not allow obtaining the maximum amount of heat.

It's a different matter with dry firewood. The moisture content in them is minimal, which means that when the temperature rises to 300 degrees, the process of decomposition of wood into simple substances begins. This allows you to significantly increase heat transfer, as a result of which the firewood burns completely with minimal formation of soot and ash.

Principle of operation

The design of such furnaces is based on pyrolysis - this is the process of fuel decomposition under the influence of high temperatures in a practically oxygen-free environment. To create these conditions, the oxygen supply in the primary combustion zone is shut off immediately after ignition of the fuel.

With a small amount of oxygen, wood begins to smolder, releasing flammable gas, which consists of a mixture of carbon monoxide and methane. After formation, the gas enters the afterburning chamber, where, under the influence of a secondary supply of oxygen, it ignites, releasing a large amount of heat. This two-stage combustion of a combustible substance allows for maximum heat transfer.