Often, autonomous heating equipment is used to heat a private home, and a boiler is used for hot water supply. The only way in this case to minimize the time it takes to move heated water, thereby increasing the efficiency of the systems and avoiding heat loss, is a recirculation pump, correctly installed in the pipeline. Let's look at what it is, what its structure is, its operating principle and purpose, what control options there are, what types it is divided into, as well as how to select and install it correctly.

Recirculation pump in the hot water supply system of a house Source masteravannoy.ru

Device, principle of operation, purpose

Pumping equipment for pumping heated water through a closed pipeline loop in a private house is small in size and consists of the following main elements:

- Housing made of stainless steel, cast iron or bronze and brass.

- A stator that can withstand heating of the pumped medium up to 60-700C.

- A rotor shaft with an impeller, the rotation of the blades of which ensures the injection of water into the pipeline.

- Thermoplastic impeller.

- Squirrel cage steel rotor.

At the same time, the pump is able to exhibit the characteristics laid down in it by the manufacturer, provided that the pumped liquid is technically clean - with a viscosity characteristic of water without the inclusion of mechanical impurities. The device is installed quite simply - without removal from the system, but by inserting it into a pipeline section. Therefore, the use of a bypass is not necessarily necessary.

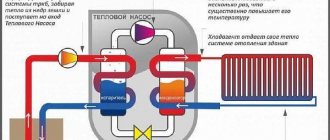

The principle of operation of a recirculation pump for domestic hot water or heating boils down to the following mechanism:

- Water from the pipeline enters the device into the central part of the impeller.

- An electric drive rotates the blades.

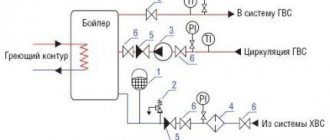

Design of a circulation pump for hot water Source eurosantehnik.ru

- As a result, the resulting centrifugal force pushes water to the outlet pipe, giving the flow a given pressure.

- In this case, an increased injection of incoming water occurs at the entrance to the pump - due to the vacuum created on the back side of the blades.

The use of such equipment is not necessary for the operation of an autonomous water heating system, but it can significantly increase the efficiency and cost-effectiveness of energy consumption. If under normal conditions it takes time for hot water to come out of the tap when opening (since with a slow flow it cools quickly), then when using a pump it flows almost instantly.

This is especially true when the consumer is located at a relatively large distance from the water heater. Another useful function for which this type of recirculator is intended is the return of unused heated water to the heater via the return line. In addition, with a gravity-flow system, the farther the consumer is located, the more noticeable the initial pressure drops.

Option for placing a circulation pump in a heating and hot water system for a private home Source s-proms.ru

The use of a recirculation pump allows you to get rid of this significant drawback. This ensures constant water temperature and pressure at any point in the heating system or DHW circuit - regardless of the distance to the unit.

Important! Only a specially designed pump can be installed in a domestic hot water or heating system. A conventional centrifugal model for pumping water is not suitable, since it is not designed to work in an environment with elevated temperatures and will quickly deteriorate.

How to choose equipment?

Before purchasing equipment, it is necessary to take into account a set of technical characteristics of circulation pumps. These include:

- Performance. To do this, it is necessary to make an accurate calculation, which ensures uniform heating of the living space.

- Calculation of head height. For example, if the pipeline length is more than 15 m, then the pressure pressure will be up to 0.6 mm.

- Regulation of fluid supply speed.

- Installation power. The higher the electrical power of the equipment, the higher the price of the circulation pump

Control options

Hot water in a private house is used periodically - for washing, washing, cleaning, showering, etc. There is no need to constantly maintain it in the DHW circuit. In addition, such an approach would lead to extremely wasteful consumption of energy resources and equipment.

Circulation pump with temperature sensor Source prom.st

See also: Catalog of companies that specialize in water supply, sewerage and related work

Therefore, in order for the heated water to reach the tap at the right time, 2 special pump control options are used - these are:

- Thermal sensor.

The principle of operation is based on maintaining a given water temperature in the circuit and boils down to the following algorithm:

- The temperature-sensitive element is immersed inside the pipe and is in direct contact with the water.

- As soon as the temperature inside drops below the set value, the sensor instantly sends a signal to the control module.

- The recirculation pump starts and begins to supply hot water to the DHW circuit.

- As soon as the heating level reaches the required value, the pump turns off.

To reduce energy consumption and equipment resources, the pipeline is specially thermally insulated.

- Timer.

Timer operation differs from the above option in that hot water is pumped into the pipes according to a specific schedule. This approach is convenient when it is known exactly during what specific period of time the hot water supply will be used. For example, on weekdays these are the morning and evening hours, when household members get ready for work and come back from it.

Circulation pump with timer Source cok.ru

Modern smart timer models allow you to set up a schedule several days in advance, as well as independently monitor the water consumption schedule and then automatically set the operation of the equipment. In addition, they are able to take into account the parameters of the hot water circuit - the length of the pipes, their capacity, the percentage of heat loss, the cooling time of the water - and, based on this, adjust the time the device is turned on/off.

Advantages and disadvantages

Like any other device, circulation pumps have their pros and cons.

- Ignoring small flaws in the heating system, such as narrowed areas or the presence of counter-slopes.

- Higher heating speed: the system accelerates within a few minutes and constantly circulates the coolant, due to which the room warms up much faster.

- Reliability and stable operation - the working life of such water pumps is enough for many years.

- Easy to use.

- Increased heating system performance.

- Increased energy consumption.

- The device may stop working due to a power outage. In particular, in severe frosts, such a malfunction can lead to serious consequences. Therefore, we strongly recommend purchasing a generator as well.

- additional costs for installation and upgrading of the device.

Varieties

Hot water recirculation pumps are classified according to several criteria. First of all, they are divided according to their purpose in a closed loop circuit into 2 types:

- The servers. Mounted on a direct line for supplying water from the heater.

- Reverse. Installed on the return branch to return cooled water to the heating circuit.

Based on the type of design, pumps are divided into 2 types:

- With wet rotor.

The working part of the device is located directly in the pumped medium. Therefore, both cooling and lubrication of the device is carried out by the pumped liquid, in this case water.

Recirculation pump with a wet rotor Source teploufa.ru

Installation

It is better not to install the circulation pump yourself if you do not know all the nuances of the installation process. But you need to familiarize yourself with the technology and the sequence.

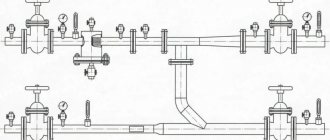

Installation location

The pump is installed on the return line next to the heating boiler. This is done with one single purpose - to reduce the temperature load on the seals, cuffs and gaskets that are used in the design of the unit itself. When exposed to high temperatures, they quickly fail.

Selection rules

In order to choose the right circulation pump for domestic hot water, it is necessary to take into account the following number of criteria:

- Performance. The value is determined by the amount of water pumped per unit of time. For example, for a private house with an area of 100 m2, a model of 80-110 liters/min is optimal.

- Pressure The indicator depends on the location of the water heating installation and the height of the consumer relative to it. So, if the boiler is located in the basement, then a tap on the 2nd floor will require a value of this characteristic of 6-8 m.

- Power consumption. The stronger the motor, the more productive the device will be, but also the more expensive it will cost to operate.

- Control method. By timer or temperature sensor.

- Manufacturer's brand.

- Price.

A circulation pump for a home is selected based on several parameters at once Source byreniepro.ru

Important! Pump selection should be carried out by an experienced designer based on specific application conditions. This takes into account the number of intake points, the minimum and maximum volume of water used, the supply height, and the length of the pipeline.

Rating of the best circulation pumps

| Nomination | place | Name of product | price |

| The best inexpensive pumps for the heating system | 1 | VORTEX TsN-32-6 | 2 070 ₽ |

| 2 | Leberg GRS 25/4 (180 mm) | 2 350 ₽ | |

| 3 | Grundfos UPS 25-40 180 | 4 800 ₽ | |

| 4 | VORTEX CN-25-6 | 2 020 ₽ | |

| The best circulation pumps for heating in terms of price-quality ratio | 1 | GILEKS Compasses 32-80 | 5 852 ₽ |

| 2 | WCP 25-80G (180 mm) | 4 590 ₽ | |

| 3 | Wilo Star-RS 25/4-180 | 4 800 ₽ | |

| 4 | DAB EVOTRON 40/180 | 10 108 ₽ | |

| The best circulation pumps for high-performance heating | 1 | DAB A 110/180XT | 20 600 ₽ |

| 2 | Grundfos UPS 32-80 180 | 12 250 ₽ | |

| 3 | Wilo Star-Z 20/7 CircoStar | 12 876 ₽ |

Video description

Video review of what a DHW recirculation system is and the rules for choosing a pump for it:

In this case, the standard installation procedure in the DHW circuit of a private house is carried out according to the following algorithm:

- Assembling the device in accordance with the technical documentation.

- Determining the installation location in the circuit.

- Shutting off the feed.

- Cutting out part of the pipeline at the installation site.

- Connecting the device.

- Sealing and checking joints for leaks.

- Turning on the water supply, connecting equipment.

- Configuration and performance testing.

Advice! To facilitate equipment maintenance and maintain maximum system functionality, it is best to install the device in a so-called pocket. This is a special outlet separated from the pipeline by shut-off valves. If necessary, the pump can be quickly turned off and dismantled, replaced with a new one or repaired - without stopping the coolant.

Selection of device

The crucial point is to correctly calculate the power of the installed pump. Two indicators are taken into account here:

- volume of distilled water mass, m³/h;

- pressure measured in meters.

It is very difficult to make the correct calculation if you are not a specialist in this matter. Here we have to take into account the complexity of the pipe line layout, the number of radiators and shut-off valves, the power of the heating boiler, the materials from which the pipes and other heating devices are made. Therefore, this stage is best left to a professional.

If you nevertheless decide to take responsibility, then it is best to purchase a pump in which you can switch the speed of movement of the coolant.

The ideal option is with automatic adjustment. Such a device costs several times more than a conventional model, but you have peace of mind that you can adjust it yourself to the necessary parameters of the heating system at home.

Briefly about the main thing

A hot water circulation pump consists of a housing, a rotor, a shaft with blades, a stator and an impeller. The principle of its operation is that water flows through the inlet pipe to an impeller rotated by a drive. As a result of the resulting centrifugal force, the flow is injected and exits with a given pressure into the system. Thanks to the pump, the water does not have time to cool down in the pipeline and does not lose pressure, regardless of the distance of the tap from the water heater.

Such a pump can be controlled in two ways - by a temperature sensor and by a timer. In the first case, the supply is resumed when the water in the circuit cools, in the second - according to a schedule. Pumping equipment is classified according to several criteria:

- Installation location in the diagram - supply and return.

- Design type - with wet and dry rotor.

- Number of drive speeds.

When choosing a pump, you need to take into account performance, pressure, power consumption, control option, brand, cost. Installation into the pipeline diagram is carried out depending on the purpose and strictly according to a given algorithm.