Autonomous heating systems are relevant if it is not technically possible to connect an apartment or house to a centralized system. Gas boilers Zhitomir are quite popular among residents of our country. The products have excellent technical characteristics, are of high quality, and adapted to Russian conditions of use. In addition, if you look at reviews on the global network, you can understand that many users are attracted by the reasonable price.

Under the brand in question, heating boilers were born 27 years ago. Since then, the products have undergone many upgrades. In order to meet modern requirements and not lose its leading position, the manufacturer is constantly improving and finalizing its product.

User manual

Before starting to use the Zhytomyr equipment, it is necessary to carry out high-quality installation of the product and check the pipes, especially if the boiler is a double-circuit boiler.

Next, the first launch is made. And after that the boiler enters the standard operating process. According to the standard scheme, you need to turn on the device, light the wick, then adjust the heat supply. After these manipulations, you can change the settings to reduce heating or, conversely, increase it. At the end of the cold season, the boiler must be turned off for the warm period, since it is not needed, which will eliminate unnecessary waste of the device’s potential. In some cases, after a warm period during connection, it is not possible to light the boiler, the igniter goes out. This may be due to weakened draft, weak gas pressure, or a malfunction of the valve responsible for the gas supply.

It is very rare that the gas valve fails to start during use. The reasons for this may be broken contacts, poor quality of the pilot burner, or an incorrectly installed thermocouple. Troubleshooting is simple - you just need to check the contacts

It is necessary to pay attention to the height of the flame. It should be at least 2.5 cm. You can try to reinstall the thermocouple or replace it altogether

Then check and light the boiler the first time

You can try to reinstall the thermocouple or replace it altogether. Then check and light the boiler the first time.

As for the model range of Zhytomyr boilers, in general you can hear only positive reviews. Ideal heating and the ability to regulate the temperature allow you to feel comfortable throughout all the cold weather. A fairly simple mechanism for turning on and setting - just a few knobs and pointers that tell you what needs to be done.

In addition, Zhitomir boilers have a protection system against lack of draft in the chimney system, as well as protection against overheating of the device. In all cases, the gas supply is shut off, which is a big difference in the troubleshooting process. Otherwise, Zhytomyr gas boilers are a shining example of quality and reliability. They are in great demand on the world market. The technical characteristics of Zhitomir boilers allow connection to be made in almost any designated place. Boilers “Zhitomir” are, first of all, a concern with which you can forget about the costs of heating your home using electric radiators, as well as excellent quality at an affordable price.

A review of the Zhitomir gas boiler is in the next video.

Rules for filling the system with water before turning on the gas boiler

In the instructions for the boiler you need to find out where exactly it is located (in the lower part of the boiler body) and what the valve for connecting to the water supply looks like. It needs to be opened slightly so that water slowly begins to flow into the system. Smooth filling reduces the amount of air in the radiators.

You can find out that there is enough water in the pipes by reading the pressure gauge. The instructions for a specific boiler model indicate its operating pressure. You need to stop starting the water when the arrow shows pressure close to the highest limit. For example, if the maximum pressure is 3 Atm., you can stop at 2.5 Atm.

Gas and water supply

Now you need to bleed the air and then pressurize the system.

Work with coolant must be carried out at positive room temperatures, otherwise water may form plugs. If the launch takes place in winter, the rooms are heated with heaters.

The boiler will last longer thanks to Atem Protect

Anti-corrosion coating with liquid aluminum is a proprietary Atem technology, which reliably protects the most vulnerable parts of the boiler - the firebox and the lower part of the heat exchanger. Molten aluminum, upon contact with the heated surface of the boiler, forms a super-strong Interalloy, which in its properties is very close to stainless steel. This reliably protects the boiler from corrosion even in the most unfavorable operating conditions and significantly increases the service life of the boiler. The boiler is supplied with a flue distribution pipe, which ensures compliance with building regulations when installing the boiler.

How effective are gas boilers Zhitomir and their advantages

Autonomous heating systems are relevant if it is not technically possible to connect an apartment or house to a centralized system. Gas boilers Zhitomir are quite popular among residents of our country.

The products have excellent technical characteristics, are of high quality, and adapted to Russian conditions of use.

In addition, if you look at reviews on the global network, you can understand that many users are attracted by the reasonable price.

Under the brand in question, heating boilers were born 27 years ago. Since then, the products have undergone many upgrades. In order to meet modern requirements and not lose its leading position, the manufacturer is constantly improving and finalizing its product.

General information

The modern gas heating boiler ATEM Zhytomyr has high performance and compact dimensions. The use of foreign automation allows us to achieve optimal performance.

The user has access to many settings, which allows him to maintain the desired temperature in the room. Sensors will ensure that everything works without interruption. Consumers love Zhytomyr boilers, and reviews emphasize the optimal price-quality ratio.

Advice! The cost of a Zhitomir boiler today is 12-45 thousand rubles. Moreover, products at the upper price range have high performance and are capable of heating large areas of premises, suitable for heating multi-storey private houses. For heating a small house or apartment, a modification in the middle price range, up to 20,000 rubles, is suitable.

Floor standing boilers

In turn, a floor heater is divided into:

- single-circuit,

- double-circuit.

A single-circuit floor-standing gas boiler only powers the heating system. It is extremely economical, thanks to the use of imported automation, which switches the system to energy saving mode as soon as the installation reaches the set temperature.

And at the moment when the temperature drops below a predetermined level, the single-circuit unit lights up at full strength. High-quality components allow you to withstand multiple on/off cycles throughout the heating season.

If you need to not only heat the premises, but also get hot water, you should buy not a single-circuit, but a double-circuit boiler Zhitomir. It has a higher cost, but can perform two options at the same time.

To connect the device, you will need to connect two additional pipes. In the product, the heating circuit operates independently of the hot water preparation circuit.

When choosing a floor-standing boiler in Zhytomyr, you should pay attention to the technical characteristics. So, all floor-standing models have:

- Efficiency 92%,

- maximum coolant temperature 90 °C,

- minimum operating gas pressure 635 Pa.

Moreover, each specific model has:

- power, ranging from 7 to 60 kW.

- the amount of coolant in the boiler ranges from 14 to 70 liters.

- natural gas is consumed in the range of 0.76 - 6.8 cubic meters per hour.

- If we consider a double-circuit floor-standing boiler, then its DHW capacity is in the range of 175 - 1400 l/s.

Wall boilers

Just like a floor-standing boiler, a hanging boiler can have one or two circuits. The entire model range has the same efficiency characteristics, maximum coolant temperature and minimum operating gas pressure - 90%, 90 °C, 635 Pa, respectively:

- The power range of wall-mounted boilers is from 5 to 15 kW.

- The amount of coolant in the boiler is from 5 to 17.5 liters.

- natural gas is consumed in the range of 0.56-1.67 cubic meters per hour, depending on the specific model.

- The suspended double-circuit boiler has a capacity for the hot water preparation circuit ranging from 160 to 345 l/h.

As you can see, the wall-hung and floor-mounted single-circuit boiler Zhitomir can operate in conditions where the gas in the mains has low pressure. The disadvantages of the products of the brand in question include the low permissible coolant pressure in the heat exchanger:

- floor-standing versions have an indicator of up to two kgf/m2,

- wall-mounted – up to zero point seven kgf/m2.

For comparison, foreign boiler models can operate with pressures of up to three kgf/m2. This indicates that Zhitomir gas units are more suitable for independent heating systems of a small house, the number of which is no more than two.

Easy start in any conditions thanks to Atem-Start

Any turbocharged boiler can be difficult to start after a long stop in operation, when the chimney has time to cool down. Start-up is also complicated due to unfavorable weather or simply a poor-quality chimney. The Atem-Start system helps solve this problem. When starting the boiler, the Atem-Start system allows you to increase the temperature of the flue gases in the chimney in order to “break through” the air lock and quickly warm up the chimney to stabilize the draft. Models with power from 7 to 16 kW are equipped with the Atem-Start system.

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical

The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics in more detail:

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

Specifications

Gas boilers Zhitomir are produced in Zhitomir (Ukraine).

They are produced in two versions:

- Floor-standing - installed on the floor or special stands;

- Wall-mounted - placed on the wall using special hangers and brackets.

Both types of boilers, according to their purpose and design, can be:

- single-circuit, intended only for heating premises;

- double-circuit, working for heating and hot water supply to the house.

The table shows the main characteristics of single-circuit floor-standing boilers “Zhitomir”

.

| Indicators | Numerical values |

| Thermal power for heating system, kW | 7. 80 |

| Heated area of the building, sq. m | 70. 800 |

| Maximum coolant temperature, °C | 90 |

| Efficiency of the boiler heat exchange device | 0,92 |

| Minimum gas pressure value, Pa | 635 |

| Boiler internal volume, l | 14. 70 |

| Maximum permissible coolant pressure in the heating system, bar | no more than 2 |

| Average hourly consumption of natural gas, cubic m/h | 0,76. 8,72 |

| Only for double-circuit boilers | |

| Hot water capacity, l/h | 175. 1400 |

| Maximum water heating interval, °C | 35 |

| Water heating circuit efficiency | 0,87 |

| Possible additional option | circulation pump |

The principle of operation of the floor-standing gas unit Zhitomir

Wall-mounted boilers have a range of indicators presented in the table

.

| Indicators | Numerical values |

| Thermal power for heating system, kW | 5. 15 |

| Heated area of the building, sq. m | 50. 150 |

| Maximum coolant temperature, °C | 90 |

| Efficiency of the boiler heat exchange device | 0,90 |

| Minimum gas pressure value, Pa | 635 |

| Boiler internal volume, l | 5. 17,5 |

| Maximum permissible coolant pressure in the heating system, bar | no more than 0.7 |

| Average hourly consumption of natural gas, cubic m/h | 0,56. 1,67 |

| Only for double-circuit boilers | |

| Hot water capacity, l/h | 160. 345 |

| Maximum water heating interval, °C | 35 |

| Water heating circuit efficiency | 0,86 |

| Possible additional option | circulation pump |

The information presented indicates that Zhitomir boilers are designed for operation with gas supply at low pressure. This sets these devices apart from the rest. There is also a drawback. The coolant pressure in the heating system is limited to 2 bar for floor-standing boilers, and 0.7 bar for wall-mounted boilers.

Similar imported heat generators allow operation under pressure up to 3 bar. This allows them to be used for heating needs of three or more storey buildings.

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical

The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics in more detail:

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

The lineup

The price range largely characterizes the model range of gas boilers in Zhytomyr. The boiler names contain alphanumeric designations. The letters indicate the main features of the boilers. The numbers give a characteristic of thermal power.

Floor standing boilers

Floor-standing boilers have a wider range of models. Their price depends on the power of the boiler. Thus, the most powerful boiler ZHITOMIR-3 KS-G-080SN has a thermal power of 80 kW. A floor-standing gas boiler is capable of heating a building with a heated area of up to 800 sq.m.

Floor-standing gas unit Zhytomyr

The presence of an additional letter “B” in the name, for example, ZHITOMIR-3 KS-GV-080SN, indicates a double-circuit gas boiler “Atem Zhitomir-3”, which can not only heat the room, but also heat water.

The amount of hot water produced is proportional to the thermal output of the boiler. This dependence is due to the presence of a copper coil inside the heat exchanger. Boilers with a higher heat transfer value also have a larger surface area of the coils. This explains the high hot water output.

Wall boilers

Wall-mounted boilers have a smaller range of sizes. They are less often installed inside private houses. The main purpose of ATEM ZHITOMIR wall-mounted boilers is heating apartments in multi-storey buildings. Wall-mounted boilers are much lighter in weight. They have a lower heat exchanger area. The maximum area of such devices allows heating up to 150 sq.m of housing area.

Gas wall boiler Zhytomyr

Wall-mounted boilers have a peculiarity - they are connected to coaxial chimneys that exit through the wall.

How should preparations be made for the first launch?

Before turning on the gas boiler, it is necessary to carry out preparatory work. For this:

- Completely mount the equipment, complete the wiring, and ensure proper installation.

- Do not neglect fire safety rules. Install all fasteners in accordance with them.

- Leave a small space between the boiler and the wall.

This distance must be indicated in the instructions. It is not recommended to install the equipment near a window. Such equipment should not be placed near a window. - Remove all flammable items away.

- Attach the boiler body evenly, without distortions.

- Connect it to a cold water supply system by removing the plugs on the pipes. At the inlet, mount a filter on which a ball valve is located. This way the system will be protected from contamination, which can lead to breakdowns. A ball valve must be installed on each piping pipe.

- Install gas pipes carefully.

- Make the outlet closer to the heating equipment.

Remember that the boiler must operate from a separate power line. In some cases, it is possible to connect the equipment to a gas generator for the purpose of its autonomous operation. You need to choose reliable pipes for the boiler - Connect the chimney pipe and check its draft.

- Fill the boiler with cold water with the power switched off. The initial set will help eliminate the presence of leaks.

- Turn the thermostat to maximum.

Specifics

The ATEM brand has invested all its efforts in the development and production of a good device for individual heating. For more than 27 years, the company has been providing heat to its own consumers in the form of Zhytomyr gas water heaters. Since the inception of the first boiler, a very large rebranding has been carried out, the device has received changes from the internal base of spare parts to the external design. Nowadays, the Zhitomir

"is a neat, small-sized block with switching instructions that even a child can handle. The main quality characteristic of boilers of this brand is the reliability and quality of the device. The technical properties of products have also changed with the emergence of recent technologies. Not only these components, but also other facts made it possible for the ATEM brand to acquire the “European Quality Level” award.

But the company did not stop there either; Zhitomir boilers received the “Golden Mark” and “Highest Standard” awards, proving to everyone that they occupy first place in the world market.

General information about the manufacturer and products

The manufacturer of this heating equipment is. The brand has been known to consumers for over 27 years. Of course, the product has undergone many changes since its first release. The company is constantly refining and improving gas boilers Zhitomir in order to satisfy all the needs and preferences of customers. Thanks to all this, the company occupies a leading position in the market.

Excellent quality and reliability are the main characteristics that can be attributed to boilers of this brand. The products of this manufacturer have been repeatedly awarded with various awards. For example, “European quality”, “Golden Mark”. They have Zhytomyr gas boilers and the “Highest Standard” quality mark.

Gas boilers Zhitomir are designed for houses that are equipped with chimneys. The range is quite wide, which allows you to choose the most suitable model. Our article “Autonomous heating of a private house: choosing the optimal method” will help you on how to install autonomous heating in a private house.

How to properly turn on and off a heating boiler

Putting the boiler into operation with the EuroSit 630 automation

- make sure that the gas valve on the gas pipeline in front of the boiler is closed,

- make sure that the boiler is turned off - the thermostat knob is in the ignition position,

- open the tap on the gas pipeline supply,

- turn the thermostat knob counterclockwise to align the “star” icons on the panel knobs,

- smoothly press the thermostat knob in the axial direction until it stops and hold it,

- press the piezo lighter button several times (the burner should light up),

- continue to hold the thermostat knob pressed for at least 10 seconds. (until the ignition burner goes out when it is released),

- release the thermostat knob (the ignition burner should be lit),

- turn the thermostat knob counterclockwise towards position “7”, the main burner should light up.

Attention: if the ignition burner goes out, the ignition operation should be repeated again, but not earlier than after 3 minutes. Switching off the boiler with automatic “EuroSit 630”. Switching off the boiler with automatic “EuroSit 630”

Switching off the boiler with automatic “EuroSit 630”

- it is necessary to smoothly turn the temperature setting knob clockwise until the white asterisk aligns with the “asterisk” sign on the panel,

- it is necessary to close the tap on the gas pipeline inlet.

Putting the boiler into operation with the MiniSit 710 automation

- make sure that the gas valve on the gas pipeline in front of the boiler is closed,

- make sure that the boiler is turned off - the thermostat knob is in the ignition position,

- open the tap on the gas pipeline supply,

- press the ignition button and keep it pressed,

- press the piezo lighter button several times (the burner should light up),

- continue to hold the ignition button pressed for at least 10 seconds. (until the ignition burner goes out when it is released),

- release the ignition button (the ignition burner should be lit),

- turn the temperature setting knob counterclockwise towards position “7”, the main burner should light up.

Attention: if the ignition burner goes out, the ignition operation should be repeated again, but not earlier than after 3 minutes. Switching off the boiler with automatic “MiniSit 710”. Turning off the boiler with automatic “MiniSit 710”

Turning off the boiler with automatic “MiniSit 710”

- it is necessary to smoothly turn the temperature setting knob clockwise to the stop and press the switch off button,

- it is necessary to close the tap on the gas pipeline inlet.

Putting the boiler into operation with the Kare automatic system

- make sure that the gas valve on the gas pipeline in front of the boiler is closed,

- turn the temperature sensor adjustment knob counterclockwise until it stops,

- open the tap on the gas pipeline supply,

- press and hold the solenoid valve trigger button,

- press and release the piezo lighter button (you may have to press several times until the igniter starts to burn),

- When the ignition burner starts to burn, continue to hold the solenoid valve start button for at least 30 seconds. (until the ignition burner goes out when it is released),

- by turning the nut on the ignition burner, you need to achieve a blue flame on the burner,

- turn (smoothly, effortlessly) the thermostat knob to the right until the main burner lights up,

- set the desired temperature.

Attention: if the ignition burner goes out, the ignition operation should be repeated again, but not earlier than after 30 seconds

Boiler features

Looking at the reviews of owners on gas boilers in Zhitomir, it becomes clear why this manufacturer’s equipment stands out so much, why it is so popular and relevant.

The equipment is characterized by many distinctive positive features in comparison with competitors' analogues. Yes, like any other devices, boilers of this brand also have disadvantages, but in comparison with the many advantages, any inaccuracies are insignificant.

Let us highlight the main advantages that Atem gas boilers have:

- A steel heat exchanger that allows you to transfer maximum heat energy to water, which is generated when burning fuel.

- Full compliance with all international standards.

- High-quality and reliable design of the burner device. Thanks to it, the heating unit is considered highly efficient and emits a minimum of harmful substances during gas combustion.

- Use of high-quality automation from a foreign manufacturer. This allows you to achieve better technical parameters.

- Simple and comfortable control and operation.

- Attractive design.

- Small design dimensions.

The unit has various settings that make it possible to adjust the desired temperature level. There are built-in sensors that monitor the stable operation of the heating structure.

About the boiler

Chimney boilers that are characterized by very high operating efficiency combined with time-tested design reliability and an attractive price. Thanks to successful design solutions and many years of experience of engineers, Zhytomyr-3 boilers have long been the most popular series of boilers among buyers. During the production of the series, these boilers have already been chosen by more than 1,000,000 customers.

Organizing a home heating system without gas or electricity

To select alternative heating options for a non-gasified electrified home, with a low power consumption limit of up to 5 kW, several effective heating sources can be offered. To heat a house, you will need to choose one of the heat supply schemes using the following modern technologies:

- Long-burning boiler, with two heating circuits for heating and domestic hot water and a tank for indirect heating of hot water. Available and cheap solid fuel can be used as fuel for such a design: firewood and its waste, coal or anthracite and any other fuel product in the form of briquettes/pellets.

- The boiler is a double-circuit boiler, powered by liquefied gas obtained from a cylinder or gas holder installation.

- Gas convectors running on liquefied gas.

- Double-circuit liquid fuel boiler: heating oil, diesel fuel or oil processing.

- Renewable natural sources: wind power plants, solar collectors and various heat pumps.

Once a heating source has been selected, the home owner will need to carry out organizational measures to ensure that the circuit becomes operational.

The stages of organizing a heating system in a simplified form can be represented as follows:

- Before heating a house without gas, they carry out a heating project and develop diagrams of in-house heating systems.

- Obtaining approval from regulatory authorities to begin operating boiler equipment. In this case, these are approvals from the gas service for connecting to a gas tank or installing liquefied gas cylinders, distribution systems and water utilities.

- Invitation to a specialized organization for installation and commissioning of the boiler and other boiler equipment.

Combination boiler ATEM Zhitomir-9 KS-GV-020SN/AOTV-15 - 20/15 kW

Combination boiler ATEM Zhitomir-9 DHW 20/15 kW

Manufacturer

A country

Find out about payment and delivery

ATEM Zhytomyr 9 is a high-quality factory-made combined boiler running on natural gas and solid fuel for systems with natural and forced coolant circulation. Separate combustion chambers, high-quality steel heat exchanger, spacious firebox for wood and coal, hot water production, non-volatile automation.

Attention! Free delivery means payment of the cost of transporting the product to the Nova Poshta warehouse chosen by the customer at the expense of the Thermocouple store, subject to partial prepayment! Check with the managers of our online store for details.

Attention! The cost of cash on delivery, as a separate service of Nova Poshta, is not included in the delivery amount and is paid by the buyer in full.

Attention! According to the terms of the promotion, the ATEM Zhitomir-9 combination boiler is equipped with a mechanical thermostat for the Regulus RT4 solid fuel boiler!

Purpose:

The KS-GV-020SN/AOTV-15 double-circuit boiler is designed for heating residential, utility or industrial premises - up to 200 m2 - with an autonomous open or closed heating system and the production of hot water for domestic needs. This device can work either independently or in combination with other heating devices that use other types of fuel. The heating device ATEM Zhytomyr-9 fully complies with the requirements of DSTU EN 297:2005, DSTU EN 265:2002 and DSTU 3075-95.

Certificates, awards, documentation:

The universal gas/wood boiler Zhytomyr-9 with two circuits is equipped with:

- durable fire-tube heat exchanger made of steel up to 4 mm thick, coated with special heat-resistant paint;

- separate combustion chambers for solid fuel and natural gas with one common wall;

- turbulators in the natural gas combustion chamber;

- gas burner device with Polidoro microflare burners controlled by a Sitgroup Eurosit 630 gas valve;

- spacious loading chamber for solid fuel;

- a copper DHW coil located in the water jacket of the unit, with connections to the water supply system;

- two doors for the solid fuel part of the boiler, which are lined with a non-flammable seal up to 2 cm thick;

- two outlets for a round chimney for separate removal of combustion products of different fuels;

- a damper on the chimney of the solid fuel part of the device;

- removable top cover for cleaning the heat exchanger;

- non-burnable cast iron grate with a special thickening in the center;

- coolant supply and return pipes;

- a bonnet for connecting a chain thermostat;

- dial thermometer on the front panel of the device;

- ash chamber;

- a layer of high-quality thermal insulation;

- boiler cleaning accessories;

- aesthetically pleasing casing made of 1.5 mm steel, painted with heat-resistant ivory enamel, with two reinforced doors.

Design of the KS-GV-020SN/AOTV-15 boiler:

The Zhytomyr-9 model compares favorably:

- relatively small dimensions;

- low price with impeccable workmanship;

- full adaptation to domestic operating conditions;

- the presence of separate chambers for solid fuel and a gas burner;

- long-term operation and corrosion resistance of the heat exchanger;

- the ability to work on the main types of solid fuel and natural gas, both alternately and simultaneously;

- high efficiency: on solid fuel - up to 78%, on gas - up to 92%;

- burning duration on one tab is from 4 to 8 hours, depending on the calorie content of solid fuel;

- the presence of a circuit that heats water for household needs;

- the presence of a removable cover for high-quality cleaning of the heat exchanger;

- round section of chimneys;

- the presence of a door for servicing the grate and bottom ignition of the boiler;

- availability of reliable non-volatile gas automatic equipment Eurosit 630 (Italy);

- the presence of a dial indicator for visual control of the coolant temperature;

- possibility of connecting a mechanical thermostat;

- saving space and consumables, which are usually used when installing two separate heating devices in parallel;

- a three-year quality guarantee for the boiler from the manufacturer from the date of commissioning of the device;

- ease of transportation and installation.

Connection diagrams:

Features of operation of the ATEM KS-GV-020SN/AOTV-15 boiler:

Attention! In order to avoid irreversible damage to the thermal bellows of gas automation, we strongly recommend that you do not allow the coolant in the solid fuel part of the device to overheat above 90° C!

A number of typical problems with the device can be resolved independently, without contacting a service center.

- If combustion is normal, but the water in the system does not warm up well, bleed off excess air. If the amount of coolant is not enough, add it to the system. In the event of a coolant leak, find the problem area and eliminate the leak, then refuel the heating system.

- If excessive fuel consumption is observed, check the heat exchanger for excess soot and clean it. Perhaps the heating system needs to be cleaned of scale deposits, or the amount of coolant is significantly higher than recommended.

- In case of condensation on the heat exchanger, the temperature of the coolant should be increased.

- The reason for the attenuation of the main and pilot burners, as well as unstable combustion of solid fuel, may be poor draft or insufficient ventilation of the room.

Attention! In case of more serious malfunctions, especially those related to the gas part of the heating device, we strongly recommend that you seek help from specialists from the service center.

Latest design changes:

In May 2016, the manufacturer made several changes in order to increase the structural strength of the heating device.

- the front doors of the boiler received additional stiffening ribs;

- The wires of the front part of the device were equipped with a reinforcing coating.

Recommended articles from the Thermocouple store blog:

termopara.net.ua

Circulation pump

The boiler circulation pump requires special attention during startup.

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

It is recommended to rotate the shaft manually before starting.

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid and let the air escape.

Read about the installation features of combined heating boilers in the following material.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range. Temperature adjustment and other boiler settings are described in the instructions for each model.

Turning on the boiler

- The gas boiler is plugged into an outlet.

- The switch must be set to zero.

- The gas supply is turned on (the tap on the gas pipe is opened).

Further actions may differ for different models of gas boilers.

For example, the switch for Aton or Danko boilers needs to be set to the “star” icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located nearby.

The unit will respond with a characteristic click and hum. After which the regulator is released and the required power is set.

To turn on the Baxi boiler, you also need to turn on the gas, plug in the plug and press the “Start” button. The operating sound will appear. You need to give the device a little time, and it will automatically ignite the flame. After that, you need to press the power button again and connect the heating circuit (the corresponding icon will appear on the display). Finally, using the buttons, the desired temperature is set.

Heating appliances of the Buderus brand are characterized by high reliability. Buderus gas boiler - a brief overview of popular models and their cost.

We will look at the types of generators for gas boilers here.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vybrat-dlya-chastnogo-doma.html discusses the main criteria for choosing heating equipment.

Why Zhytomyr boilers?

The Zhytomyr boiler has been known among consumers for more than twenty years. The choice of these products is often due to several reasons

:

- the design of the products uses EUROSIT automation devices made in Italy, which has long been known as a supplier of the most reliable equipment for boiler houses;

- these devices for automatic combustion mode control can turn the gas supply on and off at a certain coolant temperature within 0.08 s;

- when the enhanced gas supply is turned off, the control equipment leaves the pilot burner on, its combustion is always stable, which is a guarantee of successful operation;

- POLIDORO burners are of high quality, they almost never break down;

- The stable flame never breaks away from the edges, which does not lead to malfunction of the combustion process of gaseous fuel.

The company has service centers that always stock spare parts and components for heating equipment produced by it. Representatives ensure that point-of-sale sales managers can provide clear product information.

The media conducts regular surveys of the population about the quality of operation of equipment produced by Atem-Frank. Constant modernization of manufactured products is carried out in order to improve their quality and attractiveness for the population.

Video on the topic:

The article is smart and sensible. In fact, they are not bad boilers. But if you have money, then it’s better to take Italian.

Design Features

The main elements of the Zhitomir boiler are

:

- a housing in which the main components and equipment are installed;

- gas burner unit located in the firebox. Here gas combustion occurs and heat flow is released;

- recuperative heat exchanger, in which heat exchange occurs between combustion products and coolant;

- gas exhaust system, its responsibilities include removing combustion products outside the boiler and releasing them into the chimney.

Construction of the Zhitomir boiler

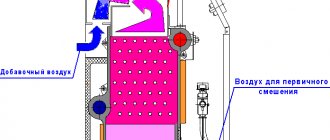

In order to increase the efficiency of heat transfer, the gas boiler Atem Zhitomir 3 has the following design features.

- The heat exchanger pipes made of heat-resistant steel have a rectangular cross-section; this device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchange device to 92%;

- To increase the area of interaction between combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the lower surface of the turbolizers, while the pipe walls remain clean. To remove soot, you need to periodically remove the turbolizers and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhitomir have a coil of copper pipelines around the heat exchange heating pipes.

Double-circuit gas unit Zhytomyr Atem

To organize a stable gas combustion process, a POLIDORO gas burner device is used. Its distinctive feature is a single-stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows you to maintain the combustion mode at different gas supplies to the firebox. Even at low gas consumption, the heating of the edges is sufficient to maintain stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. As the ambient temperature decreases, the temperature of the coolant increases.

Flue with floating damper retains heat

Unlike simple “open” draft compensators, which are still used in boilers of many brands, Atem boilers are equipped with a floating flue damper, which, on the one hand, prevents the loss of warm air from the premises, and on the other, ensures stable operation of the boiler safety sensors. This design solution made it possible to reduce gas consumption, especially at low external temperatures, when the draft increases and the air flow speed increases.