The building materials market offers a huge number of different insulation materials. The energy consumption of heating systems and the comfort of home and apartment owners depend on their quality. Modern types of thermal insulation differ in a number of parameters, as well as cost. When choosing, they also pay attention to the installation method and features of the use of the finish in the future.

One of the popular varieties is Isobox insulation. It includes a wide range of materials that are used for various construction projects. It will be discussed further below.

Manufacturer

Isobox insulation was introduced to the insulation materials market in 2007. It is produced by a large domestic company. It has been operating since 1992. This brand is a global supplier of various insulation, sound and waterproofing materials, as well as products for highway construction.

When creating its products, TechnoNIKOL uses new scientific developments and improved technologies. Thanks to this, the presented products fully comply with modern construction requirements.

Isobox products are currently manufactured at 14 enterprises in Russia. Product quality is constantly being improved, but experts note that this indicator may differ depending on the manufacturer. The main profile of the presented company is the production of insulation based on mineral wool.

general characteristics

The characteristics of Isobox insulation may vary depending on the purpose of the material. This allows you to select the optimal variety for different operating conditions. There are several main directions when creating thermal insulation.

The presented brand supplies the market with roofing materials, waterproofing, various mastics and primers, and thermal insulation. The last category includes a whole group of insulation materials that are based on mineral wool.

The main parameters by which the presented materials differ include thermal conductivity, density, and resistance to deformation. The cost of mineral wool also differs. The corresponding groups of insulation materials are used for interior and exterior decoration of premises, roofing, flooring, etc.

Geometric parameters

Isobox insulation is available in several standard sizes, but all products are produced in the form of mineral wool slabs and rolls. Depending on the brand and purpose, their thickness can be different: 50, 100, 150, 200 mm. Length and width of slabs: 1200x600 mm, 1200x500 mm, 1000x600 mm, 1000x500 mm. The number of products in a package can vary: from 3 to 12.

The roll version of the brand is represented by the Teploroll brand. This is a non-flammable material intended for the improvement of premises and objects, the structural characteristics of which guarantee the absence of external load on the insulation. The width of the canvases is 500, 600, 1000, 1200 mm. Length – 10-14 meters. Thickness – 40-200 mm.

Raw materials for production

Series that are in high demand are insulation “Isobox Extralight”, “Inside”, “Ruf” and others. In the process of manufacturing thermal insulation, the latest technical developments are used.

Mineral wool is an environmentally friendly material. It retains heat indoors efficiently. At the same time, the presented material has many advantages over other types of thermal insulation.

Isobox brand insulation products are produced in accordance with the terms of the international certificate. Basalt stones, marls or other analogue raw materials are used as the basis for production. During production, coke, feedstock and slag are added to the blast furnace. The process of creating mineral wool takes place at a temperature of 1300-1500ºС.

Creation of stone wool slabs

Insulation “Isobox Inside”, “Vent”, “Extralight” and other modifications are produced in an automatic process. In order for the fiber to take on a uniform structure, it is subjected to special processing. For this purpose, blowing, roller-centrifugal and centrifugal-blowing units are used.

Mineral wool is compacted using special additives (phenol). The slabs are also subjected to pressing and cutting (giving standard dimensions). After finishing, the resulting panels are packaged and stored. For this purpose, vacuum bags made of durable plastic are used. Also an important stage in production is quality control of each batch.

Mineral wool cannot be installed and stored open in conditions of high humidity. In this case, it loses its properties and begins to transmit heat. Therefore, during installation, be sure to take into account the manufacturer’s recommendations.

The best stone wool manufacturers

Stone wool is produced by many manufacturers, but not all of them guarantee quality and durability. In order not to regret your purchase in the future, you should focus on leading manufacturers.

- TechnoNIKOL is a well-known manufacturer. TechnoNIKOL stone wool is released in series. For example, Rocklight slabs cost from $12 per cubic meter. Thermal roll is a roll, priced up to $23 per cubic meter. Technoacoustic – has excellent soundproofing properties. Price from 45 dollars.

- Isover is a French manufacturer. Well-known lines are Isover Classic, Isover KL-37 and Isover KT-37. Prices vary depending on product type and quantity, but on average you can find products for $13 and up.

- Isobox is an inexpensive type of stone wool from a domestic manufacturer. The products are produced in series (“Light”, “Inside”, “Facade”, “RUF”, “Extralight”) in automatic mode.

- Ursa is a well-known company whose material is used for insulation of residential, private houses, apartments, and industrial complexes. This company offers a new version of stone wool - Pure One, characterized by environmental friendliness and high performance. One roll will cost $23 on average. There are also products in slabs at about the same cost.

- Rockwool is the most popular brand. Many people have heard about him and this is not surprising. The manufacturer works on quality and durability. Famous lines of stone wool are Roof Butts and Cavity Butts. The average cost of a package or roll is $15-23.

- Knauf produces stone wool in a wide variety of types. Thermo Plate 0.37 is a good choice for floors, facades, and partitions. There are 12-24 slabs in a package. Approximate cost: 15-22 dollars. Tormo Roll is an analogue in the form of a roll. Recommended for insulation of any vertical and horizontal surfaces. The cost of one roll is from 18 dollars. There are also foil-coated products, their prices start at $15 and up.

Photo of wall insulation with stone wool

Specifications

Before purchasing, be sure to consider the technical characteristics of the insulation. “Isobox Extralight”, “Inside”, “Ruf” and other popular series have an acid module that is equal to 1.7. This means that mineral wool is resistant to various chemicals that are present in masonry materials. It does not interact with dry mixes, cement mortars, plaster and other finishes.

The presented insulation is characterized by almost zero thermal conductivity. However, it should not get wet. Otherwise, it loses its original properties. Mineral wool does not absorb water well. It is not subject to various mechanical and physical influences. Aggressive environments have no effect on the presented material. This is a durable, durable insulation.

However, mineral wool is a vapor-permeable material. Therefore, when installing it indoors, it is important to provide a high-quality layer of external insulation. Otherwise, the “dew point”, which has shifted inside the room, will lead to the appearance of condensation on the wall finish.

Properties and characteristics of stone wool

Stone wool is often compared to other types of similar material. Namely with glass wool, slag wool and mineral wool. Below are comparative characteristics that allow you to navigate one or another parameter of all types.

| Parameter | Stone wool | Mineral wool | Glass wool | Slag |

| Average fiber diameter (µm) | 5-15 | 4-12 | 4-12 | 4-12 |

| Fiber length | 20-50 | 16 | 15-50 | 16 |

| Thermal conductivity (W/m2*k) | 0,033-0,046 | 0,077-0,12 | 0,038-0,046 | 0,46-0,48 |

| Use temperature | From -190 to +700°C | -60 to +600°C | from -60 to +450°C | -60 to +250 |

| Sintering temperature | 700-1000 | 600 | 450-500 | 250-300 |

| Heat capacity | 500-800 | 1050 | 1050 | 1000 |

| Compressibility (%) | Up to 40 | 40 | 60 | 60 |

| Elasticity | 71 | 60 | 55 | 50 |

| Flammability class | NG - non-flammable | NG - non-flammable | NG - non-flammable | NG - non-flammable |

| Sound absorption | 0,87-0,95 | 0,75-0,95 | 0,8-0,92 | 0,75-0,82 |

| Vibration resistance | No | No | No | No |

| Binder (%) | From 2.5 to 10 | From 2.5 to 10 | From 2.5 to 10 | From 2.5 to 10 |

| Humidification per day (%) | 0,035 | 0,095 | 1,7 | 1,9 |

| Chemical resistance to water | 1,6 | 4,5 | 6,2 | 7,8 |

| Chem. alkaline resistance | 2,75 | 6,4 | 6 | 7 |

| Chem. resistance to acidic environment | 22 | 24 | 38,9 | 68,7 |

| Release of harmful substances | Yes, if there are harmful binders | Yes | Yes | Yes |

| Need for binders | Yes | Yes | Yes | Yes |

| Taunting | No | No | Yes | Yes |

Advantages

Isobox basalt insulation has a number of advantages over other types of thermal insulation. It belongs to environmentally friendly materials. It does not harm human health and the environment. Although phenol is used in its production, this unsafe substance evaporates even before the slabs are packaged in polyethylene. The end user receives mineral wool that does not emit any harmful substances.

Also, the presented insulation does not release stone dust. It has no odor and does not emit vapors or gases. This is especially important for people with allergies. They can safely be near this material, install it, etc.

The material is not subject to deformation or tearing. It has high thermal insulation rates. Mineral wool is quite dense, which allows it to withstand various loads. Depending on the density, the insulation also has soundproofing qualities.

Tips and tricks

With the help of materials from Isobox, several problems are solved at once: insulation, protection, sound insulation. The plate material does not interact with solvents and alkali, so it is advisable to use it in workshops with environmentally unsafe production. The brand's mineral insulation contains various additives that give it plasticity and fire resistance. They also do not contain toxins and serve as a reliable barrier to cold and moisture, so they are also suitable for residential buildings.

Basalt slabs are laid in a checkerboard pattern, the joints must overlap. Films and membranes must be used. Thermal slabs are best installed “expanded”; the seams can be sealed with polyurethane foam.

For central Russia, the thickness of the thermal insulation “pie” made from materials from Isobox 20 cm is optimal. In this case, the room is not afraid of any frost. The main thing is to install wind protection and vapor barrier correctly. It is also important that there are no gaps (so-called “cold bridges”) in the area of the joints. Up to 25% of warm air can “leak” through such joints in the cold season.

When laying material between the insulation and the wall of the object, on the contrary, a gap must be maintained, which is a guarantee that the surface of the wall will not become covered with mold. Similar technical gaps should be created when installing any siding or thermal slabs. Rolled insulation “Teplofol” is often laid on top of thermal slabs. The joints are sealed with polyurethane foam. Be sure to leave a gap of about two centimeters on top of Teplofol so that condensation does not accumulate on it.

For pitched roofs, insulating boards with a density of at least 45 kg/m3 are suitable. A flat roof needs materials that can withstand heavy loads (the weight of snow, gusts of wind). Therefore, in this case, the optimal choice would be basalt wool 150 kg/m3.

A comparison of Isobox insulation with its analogues awaits you in the next video.

Insulation "Extralight"

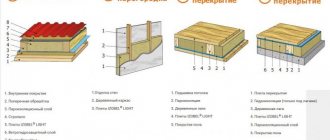

One of the popular materials is the “Extralight” series. It is used to insulate structures that are not subject to loads. These can be pitched roofs, attics, attics, interfloor ceilings, space between joists, frame wall structures, etc.

Several standard sizes of Isobox Extralight insulation are available (1200:600: 50mm, 1200:600:100mm, 1200:600:150mm). The cost of products ranges from 600 to 750 rubles.

The presented wool has a density of 30-38 kg/m³. Moreover, its water absorption is 0.5%. Thermal conductivity is at the level of 0.039 W/(m*K). This is a non-flammable material that is used in various household and industrial facilities. The presented material can be used at temperatures from +400 to -60ºС.

ISOBOX – a comprehensive solution to pressing problems

It should be noted that TechnoNIKOL is the first Russian manufacturer to offer both individual insulating elements and complex thermal insulation systems for structures for various purposes.

ISOBOX is an effective insulation material for horizontal, vertical and inclined surfaces, where the insulation is protected from loads. Pitched roofs, frame walls, ventilated facades, facades with subsequent plastering, interfloor ceilings, floors with a lag system, loggia insulation - these are the areas of application of mineral slabs.

The photo shows an example of using mineral wool to insulate pitched roofs

For your information! Today, materials of this brand are produced at 14 factories: in Ryazan, Uchaly, Nizhny Novgorod, Voskresensk, Mineralnye Vody, Chelyabinsk and others. All ISOBOX products are certified.

Brand assortment

- ISOBOX LIGHT/EXTRALITE. We talked about the areas of application of insulation of this brand a little higher, but now we will consider the main characteristics of this particular modification:

- density – no more than 30-38 kg/m³;

- thermal conductivity – 0.039-0.042 λ25 W/(m K);

- water absorption by mass – no more than 10%;

- water absorption by volume – no more than 1.5-2%;

- steam permeability – not less than 0.3 mg/(m h Pa);

- organic substances included in the slabs - no more than 2.5%.

Attention! All basalt slabs from the manufacturer are packaged in polyethylene shrink films for compact storage and transportation. However, as soon as they are released from the packaging, they will acquire their original volume within 10-15 minutes.

Insulating a pitched roof from the inside

- ISOBOX INSIDE. This modification is designed specifically for insulating well (layered) masonry walls and ventilated facades as a bottom layer. So, technical specifications:

- density – no more than 45 kg/m³;

- thermal conductivity – 0.036 λ25 W/(m K);

- water absorption by volume – no more than 1.5%;

- the presence of organic substances in the composition is no more than 2.5%.

Note! Thermal insulation boards of the presented brand, regardless of modification, are sold in the following sizes: 100x50 and 120x60 cm (the first number is the length, the second is the width). The thickness can vary from 5 to 20 cm.

Layered masonry wall structures

- ISOBOX VENT. These basalt slabs are used to insulate external walls with the “ventilated facade” system. That is, if there is an air gap between the base wall and the decorative cladding that serves as ventilation. Technical characteristics of ISOBOX VENT insulation: density – no more than 80 kg/m³; possible heat conductivity – 0.036 λ25 W/(m K); water absorption by volume – no more than 1.5%; vapor permeability – not less than 0.3 mg/(m h Pa); presence of organic substances in the composition – no more than 3%; The minimum peel strength of layers is 3 kPa.

Thermal insulation device in the case of a ventilated facade

- ISOBOX FACADE. A modification designed for insulating facades for wet plastering, as well as for insulating floors on the ground and floating floors. Characteristics:

- maximum density – 131-159 kg/m³;

- thermal conductivity – 0.038-0.046 λ25 W/(m K);

- water absorption by volume (subject to complete immersion) – no more than 1%;

- steam permeability – not less than 0.3 mg/(m h Pa);

- organic substances included in the slabs - no more than 4.5%;

- The minimum peel strength of layers is 15 kPa.

The principle of laying mineral wool

The sequence of facade insulation with the final layer of plaster

- ISOBOX RUF, RUF Hi B. What is the difference? All three modifications are used to insulate flat roofs. However, RUF slabs are intended for single-layer insulation, but RUF Hi and B are for two-layer insulation (RUF H as the bottom layer, and RUF B as the top layer). Naturally, their technical characteristics will vary. For example, the density of RUF B slabs is higher than that of RUF H slabs, which is due to the higher load.

Double-layer flat roof insulation

Single-layer roof insulation

Positive qualities of ISOBOX

Insulation materials of this brand, due to their responsible purpose, are distinguished by irreplaceable performance properties:

- Low heat conductivity (we have already discussed the possible coefficients of this parameter in the technical characteristics of each modification).

- Low water absorption . In the production process of mineral slabs, special impregnations are successfully used, which significantly reduce the absorption of moisture by the insulation.

- Excellent vapor permeability , which allows insulated structures to “breathe”, thereby maintaining a favorable indoor microclimate.

- Excellent sound insulation ability . ISOBOX mineral wool with a density of 30-80 kg/m³ is perhaps the best solution for getting rid of external noise, since it has a sound absorption coefficient of 0.8-0.9 (and this despite the fact that the ideal value is 1.0).

- NG (non-flammability of the material) . Mineral plates can be used at maximum temperatures up to 400º. Melting of the fibers begins only at temperatures above 1000º.

The thickness of the slabs can be from 5 to 20 centimeters

- Environmental Safety . If you follow the installation technology (by the way, instructions for working with mineral wool are also available on our construction portal), then the material does not have a harmful effect on human health. In addition, due to colossal energy savings, such stoves reduce their impact on the environment.

- Durability . With proper installation of basalt insulation and windproof film, the service life of the slabs approaches half a century (50 years!). And, it should be noted, throughout the entire period of operation, mineral wool retains its basic qualities.

- Impeccable chemical and biological stability . The insulation does not come into contact with acids and alkalis, and is also not afraid of fungi, mold and rodents.

- Easy installation . Unlike many analogues, ISOBOX brand boards are easy to cut with your own hands, without crumbling or breaking. And all thanks to the low percentage of impurities and homogeneity of the material.

The method of installing the slabs is quite simple and can be done by anyone. When thermally insulating inclined and horizontal surfaces, the insulation is simply placed tightly into the cavities of the frames (in the case of floors, between the joists).

As for vertical surfaces, here the slabs are also laid in the frame, and then additionally pressed with counter-battens, onto which at the final stage decorative facade material (siding, lining, etc.) is attached.

Technology of laying mineral wool on logs

- Economical . Not only is the price of mineral slabs quite low (when compared with other thermal insulation materials), but the money spent pays off instantly due to a significant reduction in heating costs.

Insulation "Inside"

When considering the technical characteristics of Isobox insulation, you should pay attention to such a popular series as Inside. This is a hydrophobic material that is non-flammable. It is used when arranging thermal insulation in a well, when creating ventilated facades using two-layer technology. It is also often used for insulating frame structures.

The presented material is produced in slabs measuring 1200:600 mm. In this case, the thickness is 50, 80 and 100 mm. The cost of the presented series is 700-900 rubles.

The density of this material is 40-50 kg/m³. Water absorption is 1%. In this case, the thermal conductivity is 0.037 W/(m*K). When exposed to load, the presented stone wool is deformed by no more than 10%. This is a durable, high-quality material that is in demand today in various areas of construction.

Characteristics of Isobox Light and Extra Light boards

Thermal insulation Isobox “Light” and “Extralight” are universal materials recommended for use in private low-rise housing construction. These mineral wool sheets are optimal for laying in openings between posts in frames.

Both modifications of the boards do not shrink, are non-flammable, and have a low degree of moisture absorption. These materials have the same geometric parameters: length - 1000-1200 mm, width - 500-600 mm, thickness - 40-200 mm in increments of 10 mm. “Light” has a higher density compared to “Extralight”: 34-42 kg/m³ versus 30-38 kg/m³ .

Peculiarities

The features of Isobox insulation should be known to every builder who chooses insulation for various objects. This stone wool can be used at all facilities in our country, regardless of the climate zone. In this case, the type of insulating material should be selected correctly in accordance with the operating conditions.

The material does not burn, does not smolder, and does not emit smoke at elevated temperatures. When the plate is immersed in water, it will absorb no more than 1% of the liquid. At the same time, the indicator is not affected by the length of time the cotton wool stays in the liquid.

Thanks to good vapor permeability, the façade of the building is well ventilated. This avoids the appearance of condensation on various surfaces. Mineral wool has a long service life. It does not require replacement for 50 years. This is a material that is resistant to various adverse influences.

Features of the material

Isobox thermal insulation from TechnoNIKOL is chosen not only by ordinary consumers, but also by builders who have extensive experience in carrying out insulation work.

Isobox insulation gained its championship thanks to a unique technology that preserves the thermal conductivity properties of the material. This is due to the fact that the wool fibers are arranged in an anarchic order, due to which there are strips of oxygen between them, which provide excellent thermal insulation.

In this video you will learn how insulation actually behaves

Isobox insulation material is used for insulation of various parts of construction projects:

- roof;

- attic;

- loggias and balconies;

- floors;

- facades.

Isobox insulation can be used in several layers, while leaving a gap for its ventilation.

Thermal insulation Isobox is a leader in the building materials market. This is confirmed by reviews not only of ordinary citizens, but also of professional builders.

The company makes sure that the product is not damaged during transportation and that moisture does not get into it, which has a very detrimental effect on the insulation , so all insulating material is vacuum packed.

If you follow the instructions and installation rules, the material will last a long time.

Reviews from professional builders

Reviews about Isobox insulation are left by professional builders. They claim that domestically produced mineral wool is of high quality. It is lightweight but durable. At the same time, installation of thermal insulation is simple. Cotton wool adds little weight to the structure of buildings.

Before installation, the vacuum packaging is opened. The material is left for 5 minutes. During this time, the panels acquire their natural appearance. After this, you can mount them on the prepared surface.

The quality of finishing when using basalt wool remains consistently high. Cotton wool does not collapse under the influence of various temperatures, does not burn or smolder. Condensation does not appear on interior finishing surfaces. With the correct selection and installation of slabs, it is possible to create a reliable, durable insulating layer.

Reviews

Russian consumers note in their reviews the ease of installation of the brand’s materials and their resistance to temperature changes. They also talk about the high strength and durability of insulation. At the same time, the price of basalt slabs is low, so many consider Isobox products to be among the best on the market.

Customer Reviews

Considering customer reviews about the presented insulation, one can note the predominance of positive statements. Many private property owners who have used Isobox for insulation note the reasonable cost of the material.

Thanks to an extensive dealer network, you can purchase the necessary thermal insulation in almost any city in our country. It has shown its high efficiency during operation. Insulation can significantly reduce energy bills. This is a durable, strong and reliable material. It is chosen by many domestic homeowners for various buildings, structures and premises.

Having examined the features of Isobox insulation, we can note its high quality. This is an environmentally friendly, reliable material that has been in use for several decades.

Reviews of stone wool

It cannot be said that any stone wool is good in use and durable. There are both positive and negative customer reviews.

- Mikhail Pavlov : “To insulate the house last year, we needed stone wool. The choice fell on TechnoNIKOL. This is a relatively inexpensive type, so in total we can say that we saved money. The cotton wool was used quickly, without problems. Among the shortcomings, I can note that it is very loose, although I took medium density. So you should be more careful when choosing. As for the qualities, the house became warmer, this was noted already in the first year after insulation.”

- Dmitry Zaitsev : “Rockwool is a well-known brand that produces stone wool. And the material is really high quality, very good. After insulation, the house is warm, cozy, there are no drafts, and even the dampness has disappeared. However, anyone who plans to buy this product should also purchase a pair of protective suits for work. This is truly dangerous insulation. On the skin it caused irritation, redness, itching, constant sneezing, and difficulty breathing. In general, nothing good - you can’t work with him without protection!”

- Elena Alexandrova : “Isobox stone wool is our choice for home insulation. Throughout the summer I was engaged in insulating the house both inside and outside. This insulation has both advantages and disadvantages. It insulates sound really well, retains heat, and the price is affordable. As for problems, a lot of dust flies from the stoves, which causes irritation, so it is better to use a respirator. The downside is that the insulation has uneven density over the entire surface. It crumbles and breaks a lot, and I’m sure this will affect its service life.”