It happens that a consumer buys mineral wool, insulates the walls with his own hands and hopes for a long service life of the product, but in reality the opposite happens. The material fails very quickly, the premises begin to freeze, and the user develops a negative attitude towards the product, which he expresses on forums on the Internet.

Alas, such situations are not uncommon, but the main reason is not a violation of installation technology, operating rules or incorrect preparation of the walls, but incorrectly selected dimensions or physical characteristics. In particular, the density and thickness of the slabs. To ensure that insulating walls outside with mineral wool does not become a waste of money, a potential buyer should familiarize themselves with the recommendations regarding the parameters of the material.

About the use of insulation

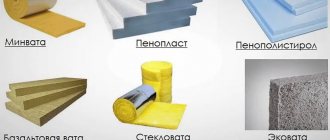

The general category of insulation, obtained by dividing the raw material into fibers, is usually called mineral wool.

The widespread use of inorganic insulators is associated with high heat and sound insulation properties:

- construction of engineering communications;

- to protect industrial equipment;

- in the field of construction.

Insulation of the roof of a building

The main advantages of mineral wool:

- There are completely no organic elements in the structure of the product, which allows the service life to be unlimited;

- does not burn - class NG, NPB 244-97;

- the material belongs to breathable insulation - the fibrous structure allows excess moisture vapor to pass through, air circulation is maintained;

- does not decompose or mold;

- does not attract insects and rodents;

- tolerates temperature fluctuations and exposure to aggressive environments.

Mineral wool is used in interior decoration in accordance with building codes (SNiP) and codes of practice. The vapor permeability of the material is especially important for insulation and sound insulation of wooden and stone structures. High performance properties of the best types of mineral wool and reasonable price are the main factors for consumer choice. v

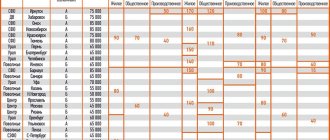

Recommendations for thickness and density of mineral wool

Taking into account the climatic characteristics of the region is crucial when choosing the size of insulation. For the external walls of houses located in areas of temperate continental climate (Moscow, Leningrad, Volgograd and other regions), it is recommended to choose slabs with a thickness of 80-100 mm. As the region moves away from a given area (continental, sharply continental, monsoon, maritime climate; subarctic, arctic zones), the thickness increases by about 10%. For example, for the Murmansk region it is advisable to take mineral wool with a thickness of 150 mm for external walls, and for Tobolsk the correct range will be from 90 to 110 mm.

Insulation with a density of up to 40 kg/cu.m. m is used only in unloaded horizontal surfaces, so it is better to ignore them. This type of wool is produced in rolls, rolled onto sheathed interfloor partitions, floors, etc. For insulation of external walls of non-residential or industrial premises, the figure varies from 50 to 75 kg/cu.m. m. If the user makes a ventilated facade, the slabs should be even denser - up to 110 kg/cu.m. m. Otherwise, the figure can reach 130-140 kg/cubic meter. m, but on the condition that the walls will be plastered later. The first option involves subsequent finishing with siding or a similar method of finishing work in order to extend the service life.

Main types

The source material and manufacturing technology determine the future characteristics of the product and the type of mineral wool. Main groups by type of raw material:

- stone (basalt);

- slag (slag wool);

- fiberglass (glass wool).

Basalt mineral wool

The raw material for the manufacture of insulation is volcanic rock (basalt) or dolomite. The hardness and fine-grained nature of the material make it possible to produce super-thin (1-3 microns) fibers up to 5 cm long in the mineral wool structure. Due to the small number of ingredients, simple manufacturing technologies are used. The thermal conductivity of stone wool is the lowest among the main types of insulation.

Basalt fiber insulation

Article on the topic - which is better, polystyrene foam or mineral wool?

The advantages of this type are manifested in the following characteristics:

- compressive rigidity of the material - installation of vertical insulation sheets does not require supporting supports;

- chemical resistance;

- durability (service life up to 50 years);

- low hygroscopicity – optimal air humidity is maintained;

- high strength, elasticity;

- good sound absorption – high degree of sound insulation;

- fire resistance – up to 1000°C;

- environmental friendliness

v

Basalt wool can withstand loads when reinforcing and plastering the surface. Insulation sheets are placed inside the wall, as part of fire protection structures.

High performance qualities ensure the versatility of using basalt insulation.

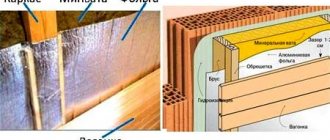

Foiling stone wool enhances the thermal insulation properties of the product. When arranging the sheets, it is important to point the shiny surface towards the room.

Foil insulation

In operation, basalt mineral wool is more convenient in comparison with other types of insulation due to the fact that during production the fibers do not take on pointed shapes.

The disadvantages of the material include:

- dust formation during work - a mask or respirator is required;

- relatively high cost.

In practice, high demand in private construction for stone mineral wool remains due to the fact that:

- the quality of the slabs fully complies with the requirements for internal and external wall insulation;

- The labor intensity of the process is lower than when working with other types of mineral wool.

Slag wool

The raw material for the production of mineral wool is waste from the metallurgical industry - blast furnace slag. The cotton wool fibers obtained through processing are up to 16 mm in length, with a diameter of 4-12 microns - the smallest size due to the chemical composition and processing technology of raw materials.

Slag

The special properties of the material limit its use in private construction; insulation is more often used for thermal insulation of non-residential premises.

The advantages of slag wool include:

- Possibility of installation on round, shaped surfaces;

- high-quality sound insulation;

- fire resistance;

- durable operation - up to 50 years;

- high chemical and biological stability;

- low cost.

Disadvantages:

- low sintering and application temperatures;

- hygroscopicity – cannot be used for insulation of facades or water pipelines;

- exposure to temperature fluctuations - the quality of thermal insulation decreases;

- barbs during installation;

- the presence of phenol-formaldehyde resins, which are harmful to health;

- low vibration resistance - loads lead to subsidence of the material, increasing thermal conductivity;

- slag acidity – incompatibility with metals at high humidity.

v

The safe use of slag wool is recommended for insulating attics, basements, and non-residential buildings, since the material is inferior in quality and inconvenience to work to other types of insulation. Its use is wider at industrial facilities.

The products are characterized by the lowest rigidity (compression). The level of good thermal insulation is comparable to other types of mineral wool.

Glass wool

The production of fiberglass material is based on the use of up to 80% cullet and silicon rock as raw materials. The addition of sand, soda, limestone and other ingredients does not exceed 20%. The mixtures are melted and blown with centrifuges to obtain thin fibers approximately 5 cm long. The performance properties of the product are of a good level, but working with fiberglass material requires the use of protective equipment.

Installation of glass wool

The widespread use of glass wool, despite the large selection of alternative insulation materials, is based on certain advantages of the material:

- chemical resistance;

- insulation of uneven surface shapes;

- good sound absorption;

- vibration resistance;

- low thermal conductivity;

- fire safety;

- low price.

Significant disadvantages of the material are:

- high water absorption - vapor protection is needed;

- causticity;

- low heat resistance;

- the need for reliable insulation;

- service life up to 10 years, significantly shorter compared to other insulation materials.

Working with glass wool requires special care: enhanced protection of the organs of vision, respiratory tract, and skin.

The high fragility of the fibers carries the risk of particles getting into the lungs and mucous membranes, which causes severe irritation, swelling, and allergic reactions.

Working with glass wool

Insulation technology

Insulation work on the outside and inside of the building is carried out using different technologies.

Outside

There are several ways to insulate a façade:

- "well" system;

- "wet" method;

- ventilated facade.

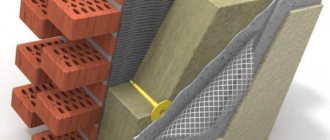

In the first method, insulation boards are placed inside the wall. In this case, the structure of the latter looks like this: a base wall made of brick or foam blocks (internal part) - fiberglass or basalt wool - sand-lime brick (external cladding).

The “wet” method involves attaching insulation mats to glue with additional fixation with 5 special dowels and applying decorative plaster over stone wool in a layer 2-3 cm thick.

The ventilated facade method is used for insulating wooden houses made of timber and high-rise buildings when facing walls with slabs. Its essence is to stuff sheathing over the entire area of the walls and place insulation sheets in the formed cells. The mats are fixed either with glue or with plastic dowels with a wide head. PVC panels (siding) are attached to the sheathing. The good thing about this method is that the dew point remains inside the wall, as a result of which there will be no condensation moisture either on the surface of the facade or inside the insulation.

From the inside

To insulate the walls from the inside of the apartment, a frame is made from a metal profile or wooden slats. Mineral wool slabs are tightly driven between the ribs of the sheathing and covered with plasterboard or plywood. Sometimes decorative plaster is applied, but in this case the insulation is additionally attached to the wall with glue and plastic dowels.

The best manufacturers

v

The comfort and safety of people in the room depends on the use of proper insulation. Leaders in the production of mineral wool strive to achieve a product combination of construction advantages, environmental friendliness of the product while maintaining an acceptable price for the product.

According to consumer reviews, the ranking of the best brands is as follows.

Rockwool

Danish company with factories in Russia. They produce stone wool with enhanced properties:

- fire safety - fibers can withstand temperatures up to 1000°C (standard 600°C);

- sound absorption – products are chosen for acoustic comfort;

- environmental friendliness;

- durability - maintains quality indicators during operation;

- thermal insulation.

Read more about Rockwool.

Paroc

In the production of basalt wool, the company identifies priority quality areas, which are:

- saving energy, including heat;

- environmental friendliness;

- soundproofing;

- fire safety.

The manufacturer does not allow counterfeits and realizes the advantages of stone wool in full.

The downside is the high price.

Facade insulation

Isover

The manufacturer produces two types of insulation: stone wool and fiberglass wool. This suits builders who need different materials according to the conditions of the objects being built. The best side of the product is the reduction in the “prickliness” of products while maintaining high characteristics of the main indicators.

The price-quality ratio of this company is one of the best on the mineral wool market.

Izover insulation

Knauf

The products are represented by basalt mineral wool and fiberglass-based insulation.

An important factor was the specialized purpose of the products, reflected in the names:

- Acoustic partition;

- HEATWALL;

- WARM roofing, etc.

The environmentally friendly material is intended for construction work on the construction of residential buildings. The high price is the only drawback.

IZOVOL

The low price of basalt products used for insulation of walls, facades, and roofs is attractive. Quality indicators meet standards. The disadvantage is a slight shedding of the material during work. A particularly popular area is finishing attics and pitched roofs with Izovol mineral wool. Mineral wool is fire resistant, environmentally friendly, and has good thermal insulation properties.

Examples of our work on finishing wet facades made of mineral wool

Finishing of the facade in the Gar-Pokrovskoye community center

Finishing of the facade in KP Babenki

Finishing of the facade in the village of Firsanovka, Moscow region

Facade finishing in Antonovka

Consumer choice

In private construction, approximately 80% of the purchased insulation is basalt and stone mineral wool, which have universal quality characteristics. Slag and fiberglass wool are used more often in enterprises for thermal insulation of specific objects.

Reliable thermal insulation

In practice, which mineral wool is best for insulation needs to be decided taking into account a specific building, room, structure. When making design decisions, specialists calculate in advance what density of mineral wool is best to choose and how to use the material correctly.

Errors most often occur not because of the quality of the insulation, but because of its improper use. It is recommended to carefully study information from the manufacturer about the characteristics and properties of mineral wool, and features of use.