Surely many residents of high-rise buildings would like to have a private home outside the noisy city. What could be better than your own living space, you think?

This is the absence of noisy neighbors, a large territory belonging only to your family and the opportunity to spend free time with your family and close friends in the fresh air.

But if you think that a country house is pure pleasure, then you are deeply mistaken. In order to live in a mansion in comfortable conditions, you need to make every effort. The house should be cozy at any time of the year.

And since energy prices are currently constantly rising, you have to think about how to best insulate your home and minimize your dependence on the cost of gas and electricity.

IMPORTANT!

Did you know that more than 45% of heat loss occurs through the walls of a house and 20% through the roof.

Every homeowner should strive to reduce heat loss in any way possible. The most effective method of solving this issue is to insulate the walls of a private building from the outside.

Of course, it is better to insulate the house well than to turn on several heating elements simultaneously to heat living rooms every heating season.

As insulation, you can choose one of these materials:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

Insulation with mineral wool under siding

There are two ways to insulate a country cottage - from the inside and the outside. Of course, it would be nice to use both methods at the same time, but this pleasure is quite expensive and not every homeowner can afford it.

Experts with extensive experience in the construction business strongly recommend taking care of external wall insulation. This will be correct and reasonable from an engineering point of view.

On the modern building materials market there is a large number of products for thermal insulation. Mineral wool is very popular among private homeowners.

What is mineral wool

This material has a fibrous structure. This determines its high thermal insulation properties. Mineral wool insulation is characterized by good physical and mechanical characteristics. Mineral wool differs from other heat insulators in its immunity to deforming loads . Thanks to this property, this material is very often used in multilayer thermal insulation systems.

- Mineral wool is considered an environmentally friendly material . Therefore, it can even be used in residential buildings.

- This type of insulation has increased fire resistance and can withstand high temperatures well. The material is destroyed at temperatures above 1000 degrees.

- Insulating walls with stone wool from the outside will help achieve good sound insulation characteristics. This insulation has a long service life - 50 - 70 years .

- Mineral wool is resistant to moisture, aggressive chemical environments and large temperature fluctuations.

Mineral wool consists of rocks in a molten state and various binding components (minerals of clay origin and phenol-based resin). And on top of the material, a small layer of kraft paper is applied.

Comparison of mineral wool with other materials

Penoplex

The material is considered one of the most effective heat insulators. Penoplex is foamed polystyrene produced by extrusion (punching) of general purpose polystyrene. During the solidification process, its sealed air cells form a material with a monolithic structure and excellent characteristics. This insulation has a number of unique properties:

- low thermal conductivity;

- durability;

- strength;

- ease of installation;

- frost resistance;

- lack of moisture absorption;

- low level of vapor permeability.

Insulating a wooden house with penoplex is not a cheap pleasure. In addition, it is loved by rodents, and melts when exposed to high temperatures.

Types of mineral wool

This term means not one material, but five:

- Glass wool. This is the most popular insulating material. When working with such material, you need to wear a special protective suit, goggles and a respirator.

- Slag-like. Numerous disadvantages of this substance do not make it possible to use it as thermal insulation. The material easily absorbs moisture and interacts with metal surfaces, oxidizing them.

- Stone wool. According to its characteristic features, this material resembles slag wool. This type of insulation does not scratch, so it is easier to work with.

- Basalt wool. It does not contain blast furnace slag or various additives. The material is practically not subject to combustion. This variety is most often used as thermal insulation.

Recently, it is often practiced to insulate walls with ecowool. This material is environmentally friendly and has a high degree of sound insulation. It’s up to you to decide which mineral wool is best to use for insulation.

Stage five. Windproof layer

After installing the thermal insulation, it is highly desirable, and when using cotton insulation, it is simply necessary to cover our structure with a vapor-and-wind barrier layer. What is it for? As the name suggests, this protection should prevent moisture and steam from getting between the siding, insulation and the wall. If the mineral wool is wet or damp, consider that you have practically no thermal insulation. It also protects the building from being blown out by strong winds. Although there are skeptics who consider this protective layer optional, citing the fact that almost all moisture-proof materials are flammable

But, in my opinion, you should not pay attention to this, since this protection brings much more benefits

The materials used are polyethylene film, good old roofing felt or modern membrane materials such as isospan or technohaut. I won’t go into too much detail here because you can watch it all in the video. Let me just say that the most budget-friendly film is made of polyethylene, and, accordingly, membrane materials are much more expensive. Windproof material is laid along the wall in a vertical direction, with an overlap of about 10-15 cm. In some developed countries, the joints are glued, but in our country it is customary to use self-adhesive tape for sealing.

If the protective film and insulation were laid according to all the canons of construction art, then you will not be afraid of either Siberian frosts or the southern heat.

Positive and negative sides of mineral wool

Advantages:

- The material has a high level of fire resistance .

- Good resistance to irritants of chemical and biological origin.

- Mineral wool is free from such a disadvantage as deformation.

- The material is not capable of accumulating liquid. It has low hygroscopicity.

- Vapor permeability indicators are at a high level.

- This insulation has high sound insulation .

- This material is safe for human health.

- Easy to install . Even a builder who does not have much experience can cope with the work of insulating walls with mineral wool.

- Long service life - about seventy years.

Negative sides:

- Glass wool fibers are very brittle and if their structure is disrupted, small fragments can painfully injure a person.

- In some cases, mineral wool contains formaldehyde resin . If it is exposed to high temperature for a long period of time, it will oxidize to phenol (which is poison).

- Thermal insulation made using mineral wool is easily blown out . Therefore, the structure must be carefully covered with decorative finishing material.

The above disadvantages are not characteristic of stone and basalt wool.

What insulation materials are suitable for this?

Let's take a closer look at each of the suitable thermal insulation materials. Let's start with the cheapest, that is, glass wool.

Option one. Glass wool

A budget variety of mineral wool, so to speak. The material is quite dangerous, since when working with it, glass dust is released, which is extremely harmful to the respiratory system. When choosing this insulation, be guided by the fact that it will cost several times cheaper than its analogues (more on prices a little later).

Here are the main characteristics of glass wool:

- thermal conductivity index – from 0.029 to 0.041 W/m*K;

- the use of phenol-formaldehyde resin during the joining of fibers, due to which, in fact, toxic substances are released;

- the specific gravity indicator fluctuates between 11 and 25 kilograms per cubic meter;

- high danger to the human body (possible severe irritation of mucous membranes and skin);

- the vapor permeability indicator reaches 0.6 mg/m*h*Pa;

- the material is made from sand, limestone, broken glass, soda and borax;

- glass wool is a non-flammable material;

- high resistance to aggressive chemical environments;

- operating temperature – from minus 60 to plus 250 degrees;

- the fibers of the material do not absorb liquid at all;

- moisture absorption (if glass wool is briefly immersed in water) is approximately 0.8 kilograms per square meter.

From all that has been said above, we can conclude that glass wool would be an ideal insulation material if not for a number of harmful factors; more specifically, he:

- does not burn;

- resistant to high temperatures;

- moisture resistant;

- almost does not allow heat to pass through;

- not afraid of bacteria and fungi.

But health still comes first. That is why in a number of countries glass wool was banned from being used in civil construction. In short, in our case this material is not suitable at all.

Option two. Mineral wool

A common material, including as insulation for siding. It has all the advantages of the previous option, but it does not have its disadvantages. In addition, it is worth noting the long service life of mineral wool, reaching 70 years.

Over the years of operation, this insulation for the walls of a house outside under siding has shown itself only from the best side. You can easily install it yourself, but in the process you must strictly follow all the rules provided for by the installation technology.

In short, if you plan to use mineral wool to insulate walls under siding, you must take care to protect the material from getting wet. This can be achieved with the help of special membranes - moisture, wind and vapor protection (more on this a little later). The heat insulator in this case will be wrapped in a waterproof film. Manufacturers claim that such protection functions like a valve, since it only allows steam to pass out. Steam will not penetrate into the material from inside. What about the “breathing” of the walls, many will ask? The fact is that such “breathing” does not involve the movement of air through the walls; a ventilation system is used to ensure air exchange - even old log houses “breathed” only thanks to the stove draft, and not due to air penetration through the walls.

In short, mineral wool is a good option for thermal insulation of the outside walls of a house under siding. Go ahead.

Option three. Styrofoam

This material is characterized by a fairly low thermal conductivity (no more than 0.043 W/m*K), and therefore is rightfully considered one of the most effective modern thermal insulators. It is used in many areas, including for insulating the outside walls of a house under siding.

And it’s not surprising, because polystyrene foam has many advantages. So, it is quite easy to install, and it does not need waterproofing. It is also easy to work with polystyrene foam - it weighs little, is easy to cut, and does not emit any harmful dust.

Extruded foam plastic has a minimal thermal conductivity, but it:

- very durable;

- resistant to bacteria, fungi;

- not afraid of high humidity.

Its surface after installation will be protected by siding, and therefore the negative impact of the environment will be minimized. Therefore, extruded foam plastic is one of the best options for insulating the outside walls of a house under siding, especially since its modern varieties are safe both from a fire point of view and from an environmental point of view.

Thickness of mineral wool for wall insulation

The most popular mineral wool product is mineral slabs.

Mineral wool sizes:

- length – 100-600cm

- width – ranges from 20-180cm

- The thickness of mineral wool for wall insulation is usually 10-25 cm.

The interval is quite large, but such indicators were achieved thanks to modern production technology. Mineral wool slabs are easily attached to houses built using frame technology.

Plates with a thickness of 2-25 cm are used for thermal insulation of the facade of a building under plaster . The thickness of mineral wool in mats ranges from 2 to 22 cm (these indicators depend on how the rolls are finished: it can be aluminum foil, fiberglass or wire mesh).

Mats with a density of 150-220 mm can be used for external insulation of walls in central Russia.

wall pie

How to properly install a moisture-and-windproof membrane

In the first part of the article, we already told you why, when installing a ventilated facade, mineral wool insulation must be protected with a wind- and moisture-proof membrane. A film that releases steam (coming from the house) outside, but due to its structure prevents atmospheric moisture from entering the insulation. Because wet insulation completely loses its heat-insulating ability. In addition, the membrane protects thermal insulation from wind, which can “carry out” particles of insulation over time.

We remember that the overlaps of the moisture-and-windproof membrane must be taped with special tape, and not left “just like that”, as “specialists” usually do.

In this regard, the experience of ZlojGenij is interesting. The user first tried to seal the membrane overlaps with ordinary household tape, but after about 2-3 weeks of exposure to the sun, it dried out and fell off.

Gluing overlaps with double-sided tape is an expensive proposition. As a result, ZlojGenij foamed the membrane overlaps with spray foam. Practice has shown that such a connection holds tightly.

It took me 1 day to install the hangers on the second side of the house. It took another 2 days to insulate this side of the facade and cover it with a membrane.

Vapor barrier of walls

When carrying out work on wall insulation, you need to do so as to minimize the penetration of moisture from the interior of a residential building under the insulation.

To do this, you need to provide a layer of vapor barrier; it is laid directly on the wall. To do this, you can use an air-permeable diffuse membrane.

The vapor barrier material is attached using a construction stapler; individual strips must be secured with staples. To preserve the insulating properties of the material, it is best to overlap the fabric by 10 -12 cm.

The seams can be additionally insulated with adhesive tape (stationery tape is suitable for this purpose).

Consequences of high wood moisture

When wood is exposed to a humid environment, it loses its technological properties and advantages. This happens when the material is constantly exposed to precipitation in the form of rain, snow, or fog. Dampness primarily affects wood that has not been treated with special compounds.

Rotting processes cause the formation of mold and fungi, which quickly spread and corrode the logs down to the state of rot. Pests may appear: wood boring beetle, weevil, furniture grinder, bark beetle.

Temperature changes in winter have a big impact. It is much warmer and more humid indoors than outside. Wood absorbs more water vapor and releases it more actively through joints and micropores. The escaping moisture must not be obstructed, otherwise the walls will be constantly damp.

How to properly lath under mineral wool on the outside of a wall

The sequence of your actions when insulating walls should be as follows:

- All work surfaces must be thoroughly cleaned and sanitized.

- It is necessary to dismantle various strips, frames, ebbs and other elements.

- Any holes in the wall should be covered with hemp or special mastic.

- The wooden components under the siding are impregnated with a fire-resistant primer, and the walls are coated with an antiseptic.

The sheathing under the mineral wool should be made from wooden blocks (they will later be used to attach the siding). The distance between the beams depends on the width of the slabs being laid.

The sheathing is secured with galvanized nails or dowels. The bars can be placed both horizontally and vertically.

It is necessary to additionally fix the cladding around the perimeter of window and door openings . At the same time, do not forget to check the plane of the frame by level.

The thickness of the wooden beam must correspond to the insulation layer.

NOTE!

The insulating material must fit tightly into its sections . It is best to lay mineral wool slabs in a checkerboard pattern, while covering the joints.

Now let's look at step-by-step instructions for insulating the walls of a private house.

Installation of sheathing

Selection of insulation materials

It is not easy to understand all types of insulation materials. A large range of products and varying prices will take inexperienced consumers by surprise. Insulation materials can be rolled or tile, expensive or cheap. The difference will be the density and thickness of each type. The choice lies in correctly identifying the right product. You need to be guided by the requirements for the quality of the material

You need to pay attention to:

- Thermal conductivity;

- Vapor barrier;

- Fire safety.

The thermal conductivity indicator should be minimal, otherwise the heat will easily escape and in winter the room will cool down in a few hours

In summer, it is important that the building does not heat up quickly, keeping it cool inside. Only properly selected, high-quality thermal insulation will allow you to maintain the optimal temperature in the room, regardless of the time of year.

Vapor barrier is also an important requirement for insulation materials. If the moisture content is high, fungus may appear under the siding in the room.

The insulation must be able to “breathe”, reliably protecting the structure from the cold, but without accumulating moisture. If water accumulates under the sheathing, the material - wood - begins to rot. In this case, the house will quickly collapse.

It is not recommended to insulate a building with flammable materials. Despite the fact that the insulation is located outside the building and has minimal contact with electrical wiring, the risk of fire still exists.

In summer, siding can become very hot from the sun's rays. Toxic elements contained in some insulation materials cause negative reactions in the body.

Technology of insulating walls outside with mineral wool under siding

Do-it-yourself insulation of the walls of a frame house with mineral wool is carried out according to the following scheme:

- First of all, you need to clean the surface of the walls ; if any unevenness is found on it, they should be puttied.

- In order to increase adhesion, apply a primer to the wall surface.

- Next you need to fill the sheathing . The bars can be stuffed both horizontally and vertically.

- We lay overlapping vapor barrier.

- Your next actions, on which the performance of the entire thermal insulation system will be based, is cutting the insulation. For this work you will need a sharp knife and a wooden board that will serve as a press. The dimensions of the mineral wool slabs must match the dimensions of the sheathing plus 5 mm for installation allowances.

- The next stage is laying insulation between the sheathing bars. It is necessary to ensure a tight fit of the mineral wool slabs at all ends . There should be no gaps between adjacent sheets.

- Arrangement of vertical sheathing . Here you need to take into account the type of siding that will be used to cover the house. For ordinary vinyl siding, you need to make the sheathing with a beam pitch of 400mm. If you plan to install metal siding, then there should be a distance of 600-1000mm between the components of the vertical sheathing.

- If your plans are to make a second layer of thermal insulation, then it should be laid in the same way as the first layer, only perpendicularly.

- Installation of waterproofing.

- Fastening siding panels.

Installation of metal sheathing

2-layer insulation scheme

3 methods of laying insulation

Peculiarities

Covering a house with siding allows you to solve several problems at once:

- protect the facade of the building from the negative effects of the environment, and therefore extend its integrity and durability;

- increase the thermal efficiency of the building through the installation of siding based on the principle of ventilated technology, as well as through thermal insulation of the facade;

- give the building aesthetic appeal, unify it or, on the contrary, distinguish it from others.

Siding consists of panels that are attached using a “dry” method, that is, they do not require the use of concrete mixtures, but are attached to dowels or nailed.

The panels are usually fastened to a frame, which is placed on top of the facade. Thanks to this, you don’t have to achieve a perfectly smooth wall surface and turn a blind eye to minor defects - they won’t be noticeable under the sheathing. Moreover, by adjusting the thickness of the sheathing and its distance from the wall, it is possible to insert insulation of the required thickness between the facade and the siding.

As you know, external insulation is more effective than internal insulation and does not take up the usable area of the room. By installing a heat insulator together with fastening the siding, it is possible to make this process even more convenient, efficient and less expensive

It is important that all the work can be done with your own hands, without being a professional builder

The ventilated cladding technology itself allows for some thermal efficiency, since an air gap is maintained between the siding and the facade, preventing heat loss. In the Russian climate, one thermal “cushion” 3-5 cm thick, of course, is not enough; installation of insulating material is necessary.

Carrying out waterproofing work

Since mineral wool is a thermal insulation material with high water permeability properties, the façade of the house must be provided with good waterproofing.

In order to ensure the process of removing moisture from mineral wool boards, which is formed as a result of temperature differences indoors and outdoors, it is necessary to install a waterproofing film or diffusion membrane.

To ensure water movement only in the outer direction, it is necessary to fasten the waterproofing with the wide side of the pores to the mineral wool, and the narrow side to the sheathing. Self-tapping screws should be used as fastening elements. The waterproofing is laid overlapping, from top to bottom, the seams are taped with mounting tape.

Waterproofing under siding

Application area

It is not enough to know what materials are used for insulation and cladding of the facade; it is important to combine them correctly. First of all, when choosing, you should take into account the wall material and type of house, its load-bearing capacity

Houses on pile and column foundations are usually built on unstable soils, so heavy fiber cement and sometimes metal siding are unlikely to be used for cladding. The most acceptable option is vinyl or metal (not all houses) panels.

To cover a brick house on stable ground with sufficient load-bearing capacity, you can use all types of finishing; for a cinder block house, it is better to abandon fiber cement siding and increase the thickness of the insulation.

To decorate a country house that provides only seasonal living, there is no point in spending money on more expensive metal siding; vinyl siding will be quite sufficient.

For houses in the construction of which wood is used, that is, timber, panel, frame, it is undesirable to use polystyrene foam and polyurethane foam insulation. The wall under such heat insulators begins to get wet and rot, which is due to their low vapor permeability. The optimal choice for a log house or a timber house is mineral wool, always with a waterproofing system.

How much does it cost to cover a house with siding?

The final cost of insulating and finishing the facade with siding depends on the price of materials and the cost of work.

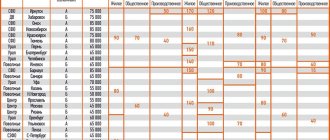

The cheapest insulation material is polystyrene foam. The price of siding depends on the manufacturer and the material from which it is made. We will calculate the approximate cost based on average prices and panel sizes. Let's imagine that you need to sheathe a house with a facade area of 63 sq.m. You will need the following materials:

When turning to the services of professionals, expect an average of 1,500 rubles. per sq. m. Of course, depending on the qualifications of the workers, the price in the price list can vary significantly.

General information

Mineral wool is a fibrous material made from molten slag and rocks.

In particular, mineral wool has the following advantages:

low price; good thermal insulation qualities; combustion resistance - this is especially important if wooden walls are being finished; durability; ease of installation and transportation, due to the fact that it is most often sold in the form of mats. True, if you wish, you can purchase this material in rolls; environmental friendliness and vapor permeability.

Mineral mats

Thus, this heat insulator is one of the best choices for home insulation.