Probably every owner of his own house or summer cottage dreams of building a bathhouse. You can entrust this work to specialists, but with all the variety of materials and a sufficient amount of information, it is possible to bring your plans to life on your own. How to insulate the walls in the dressing room with your own hands, as well as the floors - these are questions that you need to think about already in the process of constructing a strip foundation.

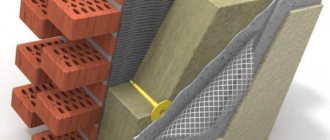

Scheme of wall insulation in the dressing room

Purpose of the room in front of the steam room

In compact baths, the dressing room mainly serves as a changing room, where there is some special furniture. In structures of a substantial size, the dressing room can be:

The process of insulating walls in the dressing room

- a fairly spacious room, equipped at the request of the owners;

- combining a shower and a swimming pool in a bathhouse;

- hydrobox.

When choosing insulation material and floor covering, you need to pay attention to the functions of the dressing room and always remember that this room is exposed to strong moisture.

What it is?

The functions that the waiting room performs are:

- maintaining optimal temperature and humidity, protection both from adverse street influences and from the influence of hot or humid indoor air (a kind of gateway);

- providing rest after and before bath procedures, creating a favorable microclimate (rest area);

- creating conditions for changing clothes and storing them in normal conditions;

- providing opportunities for collective leisure (the leisure area may include a media zone - a stereo system, TV, etc.);

- providing conditions for drinking drinks and food, storing dishes (kitchen unit);

- creating a positive psychological atmosphere and comfort (comfortable design and decoration);

- ensuring the heating of the bathhouse, possibly maintaining a small supply of firewood or other fuel (furnace combustion area);

- storage of accessories (racks, cabinets).

Insulating a dressing room with your own hands is not at all difficult.

An iron door can make this room warmer.

The right choice of insulation

The dressing room must be insulated. When insulating it, you need to take a responsible approach to the choice of insulation, with the help of which the room will maintain a suitable temperature in the winter. The material must have the following properties:

- moisture resistance;

- fire safety;

- environmental friendliness.

Often, when carrying out independent insulation, they give preference to foil-coated polyethylene, the presence of which will help equalize temperature changes.

Finishing the outside of the dressing room with eurolining or other materials will serve as additional thermal insulation.

Outside

It does not allow water to pass through, is resistant to temperature changes, durable and has low thermal conductivity.

Next, about insulating the walls of a bathhouse from the outside with your own hands.

This is why penoplex is considered one of the best synthetic materials.

To insulate walls made of logs and logs, natural materials are most often used; in turn, for a frame or bathhouse made of blocks, penoplex is ideal.

Attention! Penoplex has average fire resistance, and during combustion it releases toxic substances. That is why it is unacceptable to use it for internal insulation of a bathhouse.

Let's look at the process of insulating a bathhouse from the outside step by step:

Let's look at the process of insulating a bathhouse from the outside step by step:

- The first step is to clean the walls of any kind of contamination, such as paint residues, dust or dirt;

- Next, the surface of the wall should be coated with a primer in two layers;

- When the applied layers have dried, the vapor barrier layer can be fixed;

- Next, glue is applied to the foam sheet; the thickness of the insulation layer should be at least 7 cm;

- The sheet is attached to the wall and additionally secured with “fungi”;

- After the wall surface is completely covered with the first layer of insulation, you can proceed to arranging the second layer. To do this, the foam sheets must be placed in such a way as to overlap the seams of the first layer;

- When the glue is completely dry, you can begin sealing the gaps with sealant or foam;

- Next, you should strengthen the structure with a fiberglass mesh attached on top of the second layer with glue;

- The final stage is plastering the walls, as well as further finishing.

Don't forget about wind protection.

To protect the walls and the thermal insulation itself from precipitation, wind and condensation, waterproof, windproof membranes are used.

This protects the wall and thermal insulation.

They are laid on the outside of the insulating layer directly under the building's cladding and secured using a construction stapler.

What materials should be preferred for wall insulation?

Traditionally, the walls in the bathhouse are made of wood. This is an environmentally friendly material that gives the structure a solid appearance and good quality. It is easy to breathe in a wooden room, and the steam becomes richer. But some still prefer to build a bathhouse from brick or foam and cinder blocks, the latter themselves being a heat-insulating material, having a porous structure. However, in severe winters they freeze, making the room cold and causing stains on the walls. Therefore, the walls in the dressing room can be insulated:

- mineral stone wool;

- fiberglass;

- polystyrene foam. The process of insulating a bathhouse with foam plastic

It is best to cover the top of the insulation with polystyrene foam; it is very durable, cannot be compressed, is frost-resistant, durable and does not rot.

Insulation of the ceiling in a steam bath room

The work on creating thermal protection in the bathhouse is completed by insulating the ceiling.

The complexity and order of work depends on the design of the ceiling itself. It can be with or without an attic. If the bathhouse has an attic or attic, the insulation process should proceed as follows: the board is coated with a 20 cm layer of clay. This material copes well with the task of retaining moisture. Wooden chips must be poured into the cracks between the boards. If they are not available, then you can use any other material that provides good thermal insulation. For example, you can backfill with expanded clay. But the thickness of the layer of this material must be at least 200 mm.

Insulating a bathhouse without an attic

A bathhouse without an attic, made of logs or a panel building, must be insulated inside in a completely different way:

first, vapor barrier material is laid, then insulation is attached, onto which the beams are sewn. Then the shelf boards are nailed.

When insulating the ceiling of a bathhouse, special attention must be paid to the junction of the pipe and the insulation. To ensure that fire safety standards are not violated, it is necessary to make an indent of 200 mm between the pipe and the heat-insulating material.

This problem is easily solved by creating a box from rafter legs. It will be a barrier separating the pipe and the insulation. The space inside the box can be filled with fire-resistant insulation, such as stone wool.

It is optimal if the roof of the bathhouse is designed in such a way that there are no places through which warm air can escape from the room and cold air can enter from outside. Insulating the ceiling has another goal - to avoid the formation of condensation. Condensation is converted into moisture, which, in turn, is the main enemy for most building materials.

Please note that not all materials are suitable for ceiling insulation work. It is worth refusing to use materials such as chipboard, plywood, and fiberboard for thermal insulation. They can not only become deformed during operation, but also release substances harmful to human health when exposed to high temperatures.

How to get the job done

A frame made of timber is installed on the walls, maintaining a certain distance and location depending on the material. Insulation is laid between the slats, then a layer of foil polystyrene foam is attached on top of it, which should face the inside of the dressing room. Then everything is covered with finishing lining, which is sewn onto the sheathing. The variety of existing finishing materials allows you to decorate the interior of the bathhouse to the taste of the owners. Wooden components can be treated with bath varnish or special impregnation. Video instructions for insulating walls and floors in a bathhouse.

Ventilation

The ventilation system allows you to maintain the quality of the air in the bathhouse, the correct thermal conditions, drying, and ventilation. Ventilation provides air exchange. It is carried out through ventilation ducts. Ventilation can also be provided by opening windows.

The size of the ventilation ducts is about 15x20 cm. The first duct is the supply duct, located next to the firebox, at a height of less than half a meter from the floor. Another channel, an exhaust channel, is made on the opposite wall at a distance of about two meters from the floor. A fan can be installed in this channel to speed up ventilation. The channels are closed most of the time with valves of the appropriate size.

Warm water floor

Traditionally, wooden floors are built in the bathhouse. They retain heat well and are pleasant to step on with wet feet. But if a concrete slab foundation is chosen, then installing a warm water floor is suitable.

Scheme for installing a warm water floor in a dressing room

This is a completely rational and significant option, because the use of such a system is completely safe. However, you need to know that in this case it will be necessary to install the boiler and all the structures due to it.

Expert advice

For bath structures, the criterion of environmental friendliness of the insulation is important, so it is better to choose natural heat insulators that meet fire safety standards. Expanded clay, prepared sawdust-cement backfills, and vermiculite are well suited for thermal insulation. They can be installed independently, following installation technology.

When installing insulation, you need to build a protective steel box for the chimney pipe. Expanded clay can be poured into the box. It is necessary to ensure that wooden structures do not touch the chimney.

When insulating with mineral wool, it is better to choose multi-layer installation with overlapping of previous joints. This method will avoid heat leakage through the seams of the insulation. This will not affect the cost of the heat insulator, since it is sold in cubic meters. There is no need to exceed the thickness of the planned layer, but choose a thinner roll of cotton wool.

For bath buildings, foil materials are more relevant , since foil reflects infrared heat rays from the ceiling, improving the heating rate of the steam room. This reduces heating costs. The vapor barrier with foil is laid with the reflective side down. To fix the joints of vapor barrier films, foil tape is used. To form a sealed vapor barrier, the seams are overlapped by 10 cm and then secured.

The thickness of the installed layer of a specific heat insulator is calculated based on climatic conditions and the thermal conductivity coefficient of the material.

The average thickness of the thermal insulation layer for natural insulation materials is 25-35 cm, for artificial materials - 15-20 cm.

The greater the temperature difference between the environment and the heated steam room, the faster the hot air tends to leave the room. Proper sealing of all cracks, gaps and technological openings will prevent rapid heat loss. A monolithic thermal insulation layer with a sealed reflective vapor barrier will significantly reduce heat loss.

Cable floor

Cable floors come with a power of 250 watts per 1 sq. m. A single-core or two-core cable is laid in mat slabs. It is better to give preference to the second option.

Diagram of a cable field for a bathhouse

The energy consumption of such a floor is higher than that of a film floor, but the system is very reliable, well adjustable and suitable for all types of coverings.

Lighting and furniture

There should be no bright light in the waiting room; the light bulbs should be covered. The light should be dim, promote relaxation and create comfort. Therefore, the lighting is preferably dim and unobtrusive. At the same time, of course, the level of illumination must remain sufficient. Modern lighting technology widely uses LED lamps. This type of device allows you to create very flexible and original solutions for lighting design of rooms.

Chandeliers with different types of lampshades are suitable for the dressing room; it is also possible to install wall lamps. If there are places in the dressing room where increased illumination is required, for example, a mini-kitchen unit, a table for making tea, it is worth highlighting local lamps to illuminate such an area.

In addition to lamps, it is worth paying attention to the placement of sockets and switches, since they are not installed in the washing room and steam room. Since the dressing room is also a relaxation room, this factor should be taken into account when furnishing

Of course, the size of the room determines a lot. If the dressing room is small, the set of furniture there is small: a table, stools or chairs, a hanger, a cabinet. If there is more space, then it is desirable to have a sofa, a comfortable wardrobe, a shoe closet, and a mirror. In addition to furniture, it is not prohibited to install a TV or stereo in the dressing room. The main thing is that these devices do not interfere with the rest and recovery of the body after bath procedures

Since the dressing room is also a relaxation room, this factor should be taken into account in the furniture. Of course, the size of the room determines a lot. If the dressing room is small, the set of furniture there is small: a table, stools or chairs, a hanger, a cabinet. If there is more space, then it is desirable to have a sofa, a comfortable wardrobe, a shoe closet, and a mirror. In addition to furniture, it is not prohibited to install a TV or stereo in the dressing room. The main thing is that these devices do not interfere with the rest and recovery of the body after bath procedures.

If the layout is done correctly, then the room must have a bench and a table.

How to insulate concrete structures

Scheme for insulating a concrete floor in a dressing room

To insulate a concrete floor, you need to select a material that allows air to pass through well to avoid the accumulation of condensation. This can be prepared by foaming, polystyrene foam, polystyrene foam or natural expanded perlite. Expanded polystyrene and polystyrene tiles are laid in layers on the subfloor, and perlite is mixed with water and cement, placed on the floor, it must dry for at least 2 weeks.

There are other types of materials for insulating a concrete floor in a dressing room:

- glass wool or felt;

- expanded clay sand;

- gravel;

- boiler slag, etc.

A concrete floor will undoubtedly last a long time, but many still prefer wooden structures. And insulating them will not be difficult.

Subtleties of the procedure: from A to Z

It doesn’t matter exactly when you decided to insulate the steam room - at the stage of building the bathhouse itself or after completion of construction. The main thing is to strictly follow the sequence of insulation measures and do not forget about the basic rules of insulation:

- Waterproofing is an essential part of the insulation process. Even if the material does not absorb moisture or form condensation, take full care of the waterproofing layer. Over time, pores may form in the insulation, and water risks “reaching” the outer coating of the bathhouse and accelerating its destruction.

- It is better not to skimp on material for insulating the steam room. The service life depends on this. Basalt will last 30 years, and foam plastic will last only 5-7.

- It is better to secure the insulation with screws or nails. Today there is a large selection of special adhesives, some of them are designed for very high temperatures, but, as practice shows, nothing more reliable and cheaper than a simple nail has yet been invented.

- It is imperative to insulate the floor. If there is no concrete screed, one is made. Top filling with cement or concrete will help extend the service life of the entire steam room and its base, in particular.

- The materials used for working in the bath should be marked that they can be used at elevated temperatures. When heated, some products emit substances that are caustic and dangerous to people. To avoid putting yourself and your loved ones at risk, always read the information on the packaging of the products you purchase.

- The interior lining of the steam room is not painted or varnished. Heating will contribute to the release of toxic fumes, and constant changes in temperature inside the room will lead to the layer becoming externally unattractive and will have to be renewed regularly.

How to insulate a wooden floor in a dressing room

A waterproofing material, for example, roofing felt, is laid on the subfloor, and insulation is placed on it. Then another layer of waterproofing is laid, and then the plank floor is laid. All wooden structures must be treated with special agents against fungus and mold. The following materials will be suitable for insulating a wooden floor:

- glass wool or stone wool;

- Styrofoam;

- expanded polystyrene.

The option with a wooden floor in the dressing room is relevant. Proper insulation will significantly reduce body losses. And in the steam room, for long-term use, the floor can be made of concrete. It has high strength and is not subject to chemical reactions. A well-decorated room in front of the steam room will allow family or friends to comfortably spend time in the bathhouse, cheer up and improve their health.

We insulate the steam room

The steam room in the bathhouse requires special attention. After all, it is here that the highest level of moisture and elevated temperature are observed during operation. Therefore, insulation, waterproofing and finishing of this room must be done with special materials.

The ceiling of the steam room is subject to maximum heating during operation (up to 150 °C). Therefore, the question of how to insulate the ceiling of a bathhouse is solved by using materials with high heat resistance.

If there is no attic or attic, insulation is installed in the following order:

- wooden lattice made of timber on the ceiling boards;

- sheathing elements;

- thermal insulation;

- vapor barrier.

If there is an upper room - an attic, an attic - the insulation scheme looks slightly different. A layer of clay at least 2 cm thick is applied to the ceiling boards. This will ensure moisture retention. All small holes, joints between boards, etc. are filled with bulk material. Typically, expanded clay or wood chips are used for this. The thickness of this layer is at least 20 cm.

https://youtube.com/watch?v=1BMehi4cwNU

A box-shaped base of rafter supports is mounted on the ceiling around the chimney. This will provide a gap of 20 cm between the pipe and the heat insulator, required by fire safety. A non-flammable heat insulator such as glass wool or mineral wool is placed inside the box. The main surface of the ceiling is covered with a layer of mineral heat insulator.

More about vapor barriers

The most successful vapor barrier option for all sauna rooms is aluminum foil. It is fire-resistant, durable, non-hygroscopic. The main advantage of aluminum foil is its ability to reflect heat. By using such a vapor barrier in a bathhouse, you can significantly reduce the consumption of fuel material.

Glassine and roofing felt cannot be used in the steam room, since these materials, when heated, emit volatile toxic substances. In some cases, glassine can be used as insulation. It is better not to use roofing material for this purpose at all.

Manufacturing Features

Since the bathhouse is a room whose working environment is high temperature and humidity, the materials must easily withstand exposure to water and be resistant to rotting. This coating will be the right choice, especially if you are going to install a heated floor.

Often, various types of tiles, porcelain stoneware, and in some cases even natural stone are used for such purposes. All these materials perfectly transfer the received heat and are not at all affected by water. Laying is carried out strictly using tile adhesive with waterproofing properties, such as ceresite.

Many people want their floor to be made of natural wood, which is of course tactilely more pleasant than stone, but requires much more effort for installation and subsequent operation. The nuance of such a coating is that wood absorbs moisture, expands under the influence of water, and at joints promotes the formation of mold. Therefore, professionals recommend using only coniferous trees, because their body contains a huge amount of oils that increase resistance to water and prevent the wood from rotting.

But, if you are looking for the best option, then I recommend choosing regular floor tiles. Despite the fact that the material is inexpensive, it is many times more efficient than wood. Wood cannot fully transfer thermal energy to the floor covering, because it itself is an insulating material.

Also, you can opt for natural stone. Looks great on the floor and conveys an atmosphere of warmth and naturalness. Well, in terms of thermal properties, it transfers heat from heating pipes in full size no worse than tiles. The only disadvantage of this coating is the difficulty of cleaning. But everything will depend on what stone you choose.