Features of the heat insulator

The production of penoplex for wall insulation includes the following technological operations:

- Granules of the material are loaded into an extruder, where they are heated to 130-140°C;

- Foaming agents – porophores – are added to the portion;

- The thickened mass is squeezed out of the extruder onto a conveyor belt, after which it is cut into dimensional slabs;

The mixture of semi-finished penoplex for external wall insulation consists not only of polystyrene foam and foaming agents - it also contains antioxidants designed to prevent thermal oxidation during processing and damage to the integrity of the insulation during operation, fire retardants to increase fire resistance, as well as antistatic, light-stabilizing and modifying additives that protect thermal insulation material from the influence of external factors.

The main positive parameters of the material:

- Low moisture absorption of expanded polystyrene is the main advantage;

- The minimum coefficient of thermal conductivity, which allows, when calculating the thickness, to choose thin slabs;

- High vapor permeability of penoplex: a 20 mm thick slab replaces one layer of roofing material, but at the same time also insulates the working surface;

- High compressive strength and other mechanical loads. The extrusion method in the production of thermal insulation allows the cells of the material to be evenly distributed, improving the quality of density and strength;

- Easy and quick installation of insulation due to its low weight and good density;

- Long service life of extruded foam – up to 50 years;

- Excellent sound insulation and minimal chemical activity.

Features of penoplex

Penoplex size range:

- Slab length – from 120 to 240 cm;

- Slab width – 60 cm;

- Thickness – from 2.0 to 12.0 cm.

Disadvantages of extruded foam:

- Flammability of groups G3-G4, formation of toxic smoke during fire;

- Polymer additives in the composition of the material can evaporate toxic substances when exposed to sunlight. Therefore, the optimal use of penoplex is external, for example, insulation of brickwork;

- Petroleum products and some organic substances can deform penoplex, the thickness of which can be any. These are substances such as: formaldehyde and formalin, acetone and methyl ethyl ketone; liquids containing ethyl, benzene components, polyester resins, synthetic paints and fuels and lubricants.

Performance characteristics of penoplex

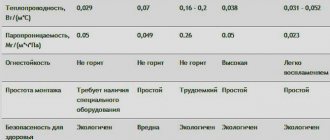

Thermal conductivity properties determine the quality of insulation with penoplex. The higher the thermal conductivity coefficient, the fewer centimeters the layer of insulating material will be. Laying the insulator from the inside or outside depends on the characteristics of vapor permeability and strength (density). You can compare the parameters of popular materials for insulating floors and other surfaces by studying the data in the table:

Comparison of thermal insulators

From the table it is clear that foam plastic thermal insulation has an average thermal conductivity value, which is slightly less than that of polyurethane foam, mastics and roll materials. But you can choose penoplex only because the layer of such liquid insulation does not have joints and seams, like slab insulation, no matter how many layers are applied to the surface.

Energy efficient house - insulation with extruded polystyrene foam. Expert recommendations

This is part of a training course on “Extruded Polystyrene Foam Insulation”. You can complete the course in full at the FORUMHOUSE Academy.

The constant increase in energy prices and the desire to build a comfortable and economical home have led to a surge of interest in the construction of energy-efficient housing. But how to make sense of the sea of insulation materials, since each of them has its own characteristics? Extruded polystyrene foam is a material that is constantly gaining momentum in the insulation market, and in this article, with the help of specialists, we will help you figure out how to make calculations when insulating with this material.

Extruded polystyrene foam (XPS) is an effective polymer thermal insulation material made by extrusion from polystyrene with the addition of a blowing gas and technological additives.

So we'll look at:

- Basic principles of energy-efficient (energy-passive) construction.

- Calculation of the required thickness of extruded polystyrene foam (XPS).

- “Breathing” walls - myth or reality.

- What engineering systems are needed for an energy-efficient house.

Energy efficiency: basic principles

When an ordinary, unprepared developer mentions the phrase “energy-efficient housing,” an image of a premium-class cottage that requires significant investment appears in his head. Hence the reluctance to invest in the construction of a well-insulated and energy-efficient house.

Practice says otherwise. If we summarize our experience, we can say that building an energy-efficient house increases the construction cost by 15-20%. Moreover, the operation of such a home, on average, costs 50-75% less than traditional construction.

Anton BorisovSpecialist of TechnoNIKOL Corporation

If you build an energy-efficient house, then savings on the funds invested in its construction begin already in the first heating season.

The heating season (depending on the climate zone) in our country, on average, lasts from 6 to 8 months. The cost of operating a home in the long term is a key factor influencing the decision to build an energy-efficient, and most importantly, economical home.

To understand the basic principles of building an energy-efficient home, you need to understand how energy is spent in the house.

The main energy consumers are electrical appliances, the hot water supply system and the heating system. Because Since a cold climate prevails in our country, the lion's share of expenses (up to 70%) in a standard house, with large heat losses, goes to heating.

An energy efficient house is a building in which all energy losses and energy consumption levels are reduced by approximately 30-70% of the consumption level in a conventional house.

Anton BorisovSpecialist of TechnoNIKOL Corporation

The main sources of heat loss in a building are the floor, walls, windows, doors, roofing and ventilation system.

The basic principle of constructing an energy efficient building is to minimize all heat loss through the building envelope. To do this, a closed and sealed thermal insulation circuit is erected and all “cold bridges” are eliminated.

A “cold bridge” is a structural part of a building (concrete lintels, joints in walls, etc.) through which, due to the low thermal resistance of this unit or material, heat loss occurs.

For clarity, the percentage of heat loss is presented in the following figure.

The energy efficiency of a house can be judged by the coefficient of seasonal thermal energy use - E.

In European countries, the EP coefficient is used to determine the energy efficiency class of a home. The starting point is EP = 1 and energy class D, i.e. standard.

The main task of additional thermal insulation of a building is to increase energy efficiency and, as a result, reduce heating costs. This results in cost savings and a lower cost of owning a home in the long run.

How to choose insulation and calculate its thickness

Having understood the basic characteristics of an energy-efficient house, you can move on to determining the optimal insulation thickness. Judging by the requests on the portal, this is one of the leading questions among our users when building a warm and comfortable home.

Ivan1985 FORUMHOUSE user

I built a house in Minsk from sand-lime brick. The wall thickness is 0.5 meters. If the temperature outside drops to -25°C, then the house cools down to 14-15°C. The house was built back in the early 90s. Judging by the masonry, the house was built with violations of technology; even the mortar was not installed everywhere. Then I completed the house and plastered it. Now I want to insulate it. I'm thinking of taking 100mm thick insulation. Builders say that 50 mm is enough. How to correctly calculate the thickness of insulation I need?

As mentioned above, heat loss through walls accounts for about 20% of all heat loss. Therefore, to insulate a house, you need high-quality and durable insulation that will not lose its properties over time. To choose him, you need to understand what qualities he should have.

Anton Borisov

Effective insulation is a heat-insulating material that, having a small thickness, increases the heat transfer resistance of enclosing structures (denoted R), i.e. prevents the transfer of heat from a room with a higher temperature (from the room) to an external environment with a lower temperature (outside).

The coefficient (R) is measured by the temperature difference in degrees Celsius (or Kelvin) required to transfer 1 W of heat through 1 sq.m. area if the temperature difference on both sides is 1°C. The unit of measurement R is (m²*°С)/W.

Starting from this definition, we move on to thermal conductivity, because This is the main characteristic of insulation. The coefficient of thermal conductivity is expressed in the ability of a material to conduct heat from a more heated part to a less heated part. Let's look at this parameter in more detail.

Any material passes thermal energy through itself. A good example is wood and steel. If you heat these two materials, steel, due to its high thermal conductivity, will heat up quickly, while wood, due to its lower coefficient, will remain warm. To illustrate this process, imagine a frying pan with a wooden handle placed on a gas stove.

Let's move on. The thermal conductivity coefficient is denoted as λ. Each building material has its own thermal conductivity coefficient. This coefficient determines the amount of thermal energy passing through 1 square meter in 1 second. m of material area with a temperature difference of 1°C. λ is measured - W/(m*°С).

Anton Borisov

The lower the thermal conductivity coefficient - (λ), the lower the heat transfer, i.e. higher thermal resistance of the structure - (R). This directly affects the thermal insulation qualities of the building envelope.

Knowing the standards for thermal resistance (R) for different regions of Russia (depending on the climatic zone) and the thermal conductivity coefficient of the material (λ) used in the construction of walls, you can calculate the required thickness of the insulation.

Table. Standardized thermal resistance of walls.

Note: for floors and coatings, the normalized thermal resistance has different values. According to the standards SP 50.13330 “Thermal protection of buildings”, the calculation must be done for a temperature of + 20 °C. (In winter, the temperature in residential premises should be maintained at 18...22 °C).

An example of calculating the insulation of a house using extruded polystyrene foam (XPS)

Due to its characteristics - low thermal conductivity coefficient (0.028-0.034 W/(m*°C), high compressive strength (200-1000 kPa) and minimal water absorption coefficient (0.2-0.4%) - this material is used for insulating the following structures:

- Floor and ceilings.

- Foundations and ground floors.

- Roofs.

Anton Borisov

Knowing what materials are used in the construction of the wall, you can calculate its thermal resistance and compliance with standards.

For example, let’s take a wall made of solid brick 0.3 meters thick. According to the standards, the thermal resistance for walls in the Moscow region should be: R - 3.065 (m²*°C)/W. From here, using the formula, we find the actual heat transfer resistance of the brickwork.

R= d/λ, where:

d—material thickness;

λ is the thermal conductivity coefficient of the material.

Rф = 0.3/0.81= 0.37 (m²*°С)/W

Based on this value, we determine the difference between the standard and actual heat transfer resistance (Rt):

Rt = Rn – Rph = 3.065 – 0.37 = 2.69 (m²*°C)/W

Now we find the thickness of the insulation we need, which compensates for this difference. The calculated thermal conductivity coefficient of extruded polystyrene foam (XPS) is 0.03 W/(m*°C). We put it in the following formula:

d = Rt * λ, where:

d—thickness of insulation;

Rt—heat transfer resistance;

λ is the thermal conductivity coefficient of the insulation.

d = Rt * λ = 2.69 * 0.03 = 0.08 m

Convert to cm, round up (taking into account the multiplicity of the thickness of the produced thermal insulation of 10 mm) and get – 8 cm.

Conclusion: to bring the thermal resistance value of a brick wall to the standardized value, it is necessary to install a layer of extruded polystyrene foam (XPS) 80 mm thick on the outside of the wall.

During the long-term operation of the building, it should be taken into account that XPS does not accumulate moisture, which means it does not lose its thermal insulation characteristics.

Anton Borisov

Using this simplified algorithm, you can independently calculate the required insulation thickness. If the wall structure consists of several layers, for example - plaster - aerated concrete - thermal insulation - facing brick, etc., then to calculate and obtain the total value of the wall's thermal resistance (R), you need to add up the indicators of each layer.

Thus, a thin layer of insulation makes it possible to achieve the required standard for the thermal resistance of enclosing structures (R). And when insulating from the inside, through the use of effective insulation, we can reduce the overall thickness of the wall structure being built up, without “eating up” the internal usable area of the house.

Engineering systems for an energy efficient home

The main principle of building an energy-efficient house is the construction of a sealed (closed), airtight shell inside the building. Those. - construction of a kind of thermos house in which all the heat is retained and is not released outside due to heat transfer, which is possible during the migration of air masses in the so-called “breathing walls.” Thus, anticipating the question from developers, we can immediately say that the so-called. “breathing of walls”, i.e. air exchange between the indoor and outdoor environments, which supposedly provides a healthy microclimate in the house - a myth! Load-bearing structures should not “breathe” and allow air to pass through; they should retain our heat inside. Appropriate systems must be responsible for “breathing the house” (removal of exhaust air and supply of fresh air).

Vinyl wallpaper, a layer of plaster, laminate, clinker brick and other finishing materials, even simple oil paint - in themselves are good layers that ensure the tightness of the system. Ventilation must maintain the microclimate in the house and ensure the flow of fresh air, which, unfortunately, is forgotten in projects. After all, a person’s well-being and the level of comfort in the home depend on the air quality and air exchange rate. In a cottage with properly installed ventilation, it is easy to breathe.

Anton Borisov

Modern standards regulate: the entire volume of air in a living space must be completely renewed once every 60 minutes.

Here lies the pitfall. Heat loss through an inefficient ventilation system can be over 30%. Those. — providing the influx of the volume of air we need in winter, we “throw out” heat outside and spend additional energy on heating the newly received air.

How to proceed? In order not to reduce the volume of incoming air, we are installing a system that will heat the cold street air using exhaust air removed from the premises. This system is called a recuperator, and it is one of the possible options for installing a ventilation system in an energy-efficient house.

A recuperator is a device where, due to heat exchange, heat is transferred from the outgoing heated air to the cold incoming flow. Due to this, heat loss is reduced and heating costs are reduced.

This is part of a training course on “Extruded Polystyrene Foam Insulation”. You can complete the course in full at the FORUMHOUSE Academy.

Calculations

To achieve high-quality and effective heat retention and complete protection from the cold, you need to know how to calculate the thickness of the insulation. Such calculation of insulation thickness is carried out using existing formulas, which take into account:

- thermal conductivity;

- heat transfer resistance of the load-bearing wall;

- coefficient of thermal conductivity;

- coefficient of thermal homogeneity.

The listed characteristics are no less important at the moment when the foam thickness is calculated.

When determining the dimensions of the selected slab made from a particular material, it is worth considering that the thickness of each product allows the use of laying in 2 layers. After calculating the thermal insulation, you can be convinced that it is most convenient and profitable to use mineral wool slabs as insulation, and the thickness of such insulation should be from 10 to 14 cm.

Calculations are carried out using a specially created formula, and to obtain accurate data characterizing the heat insulator used, you need to take into account:

thermal conductivity coefficient of the load-bearing wall; if the wall is multi-layered, then it is important to take into account the thickness of its individual layer; thermal homogeneity coefficient; we are talking about the differences between brickwork and plaster; It is important to know the thickness of the load-bearing wall.

By multiplying the sum of all indicators by the thermal conductivity coefficient of the selected insulation, you can calculate the thickness of the heat insulator.

The choice of products sold on the construction market is based on these data.

It is equally important to decide on:

- where exactly the insulation will be placed; it can be the inner surface of the walls or the facade of the building;

- what material will be used as cladding; the façade of the building can be finished with facing bricks or decorative slabs;

- how many layers of thermal insulation will be used in the construction of the structure.

When choosing the thickness of the insulation, it is important to take into account the characteristics of the region in which the building is located. In the coldest regions, you will need material whose thickness reaches 14 cm, and in warm regions it is enough to install slabs 8-10 cm thick

The video shows the procedure for determining the thickness of the insulation:

Based on the results of the calculations, you can easily select the most suitable thermal insulation material, retain heat in the house and protect the walls of the building from destruction under the influence of negative, low temperatures.

Until the second half of the 20th century, few people were interested in environmental problems; only the energy crisis that broke out in the West in the 70s raised the question: how to save heat in the house without heating the street and without overpaying for energy.

There is a solution: insulating the walls, but how to determine what thickness of insulation for the walls should be so that the structure meets modern requirements for heat transfer resistance?

The effectiveness of insulation depends on the characteristics of the insulation and the method of insulation. There are several different methods that have their own advantages:

- Monolithic structure, can be made of wood or aerated concrete.

- A multilayer structure in which the insulation occupies an intermediate position between the outer and inner parts of the wall; in this case, at the construction stage, ring masonry is performed with simultaneous insulation.

- External insulation using a wet (plaster system) or dry (ventilated facade) method.

- Internal insulation, which is performed when it is impossible to insulate the wall from the outside for some reason.

To insulate already constructed and operating buildings, external insulation is used as the most effective way to reduce heat loss.

Technology of facade insulation with foam plastic

Polystyrene foam can be fixed to the wall of a house in two ways: glued and glueless. The use of the first installation option is justified if the load-bearing surface is smooth and does not have significant flaws. This situation often occurs in new buildings. Therefore, if possible, use the PPS gluing technology. It is much simpler and more convenient than the glueless installation method.

Facade insulation, diagram

Step-by-step installation of foam plastic

Stages of façade insulation with polystyrene foam using the adhesive method

Step 1. Dust removal and strengthening of the base.

This is done by applying a deep penetration primer using a brush or roller.

Step 2. Marking and fastening the base profile.

Fastening the plinth profile

Option for fastening profile corners at 45 degrees using a plate and self-tapping screws

The base profile is attached to the bottom of the walls along the entire perimeter of the building. It will act as a support for the foam boards.

Step 3. Preparation of the adhesive composition.

Use dry adhesive mixtures. Experts recommend simultaneously purchasing reinforcing compounds from the same manufacturer. They (compositions) are applied to a mesh reinforced over PPS, which is necessary if plastering of the facade or other type of finishing is planned, the installation of which requires a cement-sand mortar.

The following adhesive mixtures can be used: Cerisit CT83, Kreisel 210, Master Termol, SOUDATHERM, Bitumast.

Cerisit CT83

Kreisel 210 Adhesive for polystyrene foam boards

Foam adhesive for expanded polystyrene and polystyrene foam “Soudal” Soudatherm

Step 4. Applying the solution to EPS boards.

Applying glue to foam plastic

Leveling the glue with a spatula

The solution is applied in two ways: along the perimeter of the canvas and in its middle, at 5 points (in the corners and in the middle). The thickness of the layer depends on the type of glue. On average, it is 0.5-1 cm.

Example of applying adhesive foam

Step 5 . Gluing slabs.

Bonding boards

The PPS sheet is installed on the base profile and pressed against the wall. Hold in this position for several seconds (refer to the adhesive mixture manufacturer's instructions). Excess glue is removed with a spatula.

The sheets are fixed with dowel mushrooms.

Laying foam for insulation

Secure the foam boards with dowel mushrooms

Hammering a nail into a dowel

Seal the seams between the plates with foam

Step 6. Applying adhesive and gluing the reinforcing mesh.

Reinforcing mesh for foam plaster. Photo

Attach the mesh and cut off the excess

Step 7 . Applying a reinforcing solution to the mesh. Leveling the solution.

Applying plaster

Plastering on foam plastic

Plastered surface

Step 8. Applying finishing primer.

Glue-free technology for insulating facades with foam plastic involves fastening PPS boards to dowel-nails with a wide head (umbrella).

The mushrooms should be approximately twice as long as the thickness of the foam.

The work technique is as follows:

- Through the slab laid on the base profile, holes are drilled in the wall. Fasteners are made at 5 points: in the middle and corners of the sheet;

- drive in dowel nails.

Using a hammer drill, we drill a hole a little deeper than the length of the fungus, insert it and hammer in a plastic nail, so that the entire fungus sinks a little into the foam.

Installation of dowel-umbrella for facade insulation

Otherwise, all stages of the foam installation work are similar. If a ventilated facade is being installed, reinforcement of the slabs is not required. In this case, a frame of wooden bars or a metal profile is built on top of the insulation.

Prices for Ceresit glue

Ceresit glue

Video - Fire safety of polystyrene foam

How to insulate aerated concrete, mineral wool or polystyrene foam

Mineral (stone) wool and polystyrene foam are the main insulation materials for aerated concrete houses. Low-density aerated concrete (D200) and sprayed polyurethane foam are used much less frequently.

Insulation should be carried out only from the outside of the building so that the dew point is closer to the outer layer of the wall.

Dew point is a place in the wall with zero temperature. In this zone, a zone of increased condensation (moisture) is formed; the wall in this place constantly freezes and thaws.

If we compare polystyrene foam and mineral wool, then wool is a more expensive and correct solution for aerated concrete walls; it’s all about vapor permeability. Cotton wool has excellent vapor permeability, which ensures that moisture is removed from the wall to the outside of the house. Thus, the interior will be drier and more comfortable. The thickness of mineral wool insulation can be made to any thickness, but it is more economically feasible - from 100 mm.

Polystyrene foam does not allow steam to pass through well, trapping it in the wall and creating increased humidity in the house. Moreover, aerated concrete walls need to be insulated with foam plastic with a thickness of 100 mm or more in order to guarantee that the dew point will shift from the wall to the insulation. Otherwise, at the boundary between the foam plastic and the wall, moisture will constantly freeze and thaw, reducing the service life of the wall.

In general, we recommend using mineral wool or foam plastic with a thickness of 100 mm or more, but it is better to give preference to mineral wool.

Why is it important to choose the right foam thickness?

The choice of foam thickness makes it possible to ensure the required level of surface thermal insulation and sufficient strength properties of the heat-insulating layer. The thicker the material, the stronger it is and it is much easier to work with during installation. On the other hand, thick sheets have significant weight, which can be critical, for example, when insulating a ceiling.

If the thickness was not chosen correctly, then there is a high probability that it may be less than the minimum required, and in such cases the following consequences may arise:

- the house structures will freeze, as a result of which they will lose their strength characteristics and their service life will be reduced;

- the dew point in the load-bearing walls will shift and condensation will form inside the material, which is fraught with the appearance of mold, mildew and harmful microorganisms;

- a reliable basis for applying the finishing coating will not be provided;

- heating equipment will not be able to provide a comfortable indoor temperature or will operate with high fuel or electricity consumption.

If you use polystyrene with excess thickness for insulation, this will be a waste of funds.

TOP 3 best products according to customers

Foam plastic 1000x1000x100 mm (density 25)

270.00 rub.

Product code 2954

Foam plastic Mosstroy-31 1000x1000x100 mm (density 25) - heat-insulating, moisture-resistant boards.....

Foam plastic 1000x1000x50 mm (density 25)

135.00 rub.

Product code 2975

Foam plastic Mosstroy-31 1000x1000x50 mm (density 25) - heat-insulating, moisture-resistant boards for.....

Foam plastic 1000x2000x50 mm (density 25 F)

300.00 rub.

Product code 3008

Foam plastic Mosstroy-31 1000x2000x50 mm (density 25 F) - heat-insulating, moisture-resistant boards.....

Thermal insulation method

The effectiveness of insulation depends on the characteristics of the insulation and the method of insulation. There are several different methods that have their own advantages:

- Monolithic structure, can be made of wood or aerated concrete.

- A multilayer structure in which the insulation occupies an intermediate position between the outer and inner parts of the wall; in this case, at the construction stage, ring masonry is performed with simultaneous insulation.

- External insulation using a wet (plaster system) or dry (ventilated facade) method.

- Internal insulation, which is performed when it is impossible to insulate the wall from the outside for some reason.

To insulate already constructed and operating buildings, external insulation is used as the most effective way to reduce heat loss.

About reviews on forums

In general, reviews of people who have used polystyrene foam to insulate their houses and apartments are divided into 2 categories:

- positive, there are more such reviews. They are left by homeowners who have completed insulation in accordance with the technology;

- negative: there are few openly negative posts criticizing polystyrene foam as insulation. They are associated with errors in the installation of thermal insulation or with violations of technology resulting from various “experienced advisers”.

By the way, there are plenty of advisers on the forums and not all of them know what they are talking about. Therefore, you should not rush to conclusions, get scared and immediately refuse to insulate your house with polystyrene foam. There is a separate category of supporters of “breathing” houses, who claim that polystyrene foam should be mounted on a frame made of wood or galvanized profiles so that “steam can escape from inside the walls.” But this is a completely different technology, called “ventilated facade”, where purely mineral wool is used.

Remember that the use of foam plastic in ventilated facades is a fire hazard. An accidental spark can burn out the entire facade insulation, but according to traditional technology it is hidden behind a layer of plaster.

There are negative reviews associated with natural causes. For example, a stone thrown into a foam-insulated wall will likely leave a dent, and a stronger impact may expose the material itself. We also gave an example with unpruned trees. We can’t discount mice, which really like to make nests out of foam plastic, because they understand that it retains heat. Therefore, in rural areas, where there are a lot of field mice, it is necessary to carry out the technological process especially carefully and apply high-quality glue and plaster to the insulation.

Standard length, width and thickness of bricks

Since bricks have their own standard dimensions (6.5 x 12 x 25), the thickness of the brick wall will have several standard dimensions, taking into account the thickness of the seam between adjacent bricks.

There are other sizes, but they mainly differ in height, and the height of the brick does not affect the thickness of the wall.

Standard dimensions of a brick wall

| Number of bricks, pcs | Wall thickness, cm |

| 0,5 | 12 |

| 1 | 25 |

| 1,5 | 38 |

| 2 | 51 |

| 2,5 | 64 |

In addition to the thickness of 65 mm, there are brick thicknesses of 88 mm - one-and-a-half bricks and 138 mm - double bricks. Those. sizes 8.8x12x25 and 13.8x12x25. In general, the thickness (height) of the brick does not in any way affect the thickness of the brickwork.

The main criterion when choosing the thickness of a brick wall is the purpose and location of the wall itself.

GOST and its size requirements

The symbol for slabs according to GOST consists of letters and numbers, which includes:

- Slab type.

- Brand.

- Sheet sizes.

- Standard designation.

If the sheet has such characteristics as a plate of foamed polystyrene with the addition of fire retardant grade 15, 1200 mm long, 600 mm wide and 40 mm thick, then the entry will look like this: PSB-S-15-1200x600x40 GOST 15588-86.

If the expanded polystyrene board does not contain fire retardant and is grade 15, and its dimensions are the same, then the entry will change and look like this:

- PSB-15-1200x600x40 GOST 15588-86.

Using the technical requirements according to Gosstandart, foaming polystyrene containing a blowing agent: isopentane or pentane is used for the manufacture of foam boards. The residual monomer styrene is added to the total mass.

On the surface of manufactured slabs ready for sale there should be no bulges or depressions more than 3 mm wide and more than 5 mm high. Dullness of the ribs and corners may be observed, but not more than 10 mm from the apex of the right angle.

Calculate the thickness of the insulation

Thermal insulation of the outer wall reduces heat loss by two or more times. For a country, most of whose territory belongs to a continental and sharply continental climate with a long period of low negative temperatures, like Russia, thermal insulation of enclosing structures provides a huge economic effect.

Whether the thickness of the heat insulator for external walls is correctly calculated determines the durability of the structure and the microclimate in the room: if the thickness of the heat insulator is insufficient, the dew point is located inside the wall material or on its inner surface, which causes the formation of condensation, high humidity, and then the formation of mold and fungal infection.

The method for calculating the thickness of insulation is prescribed in the Code of Rules “SP 50. 13330. 2012 SNiP 23–02–2003. Thermal protection of buildings."

Factors influencing the calculation:

- Characteristics of the wall material - thickness, design, thermal conductivity, density.

- Climatic characteristics of the building area - the air temperature of the coldest five-day period.

- Characteristics of materials of additional layers (cladding or plaster of the inner surface of the wall).

The insulation layer that meets regulatory requirements is calculated using the formula:

In the “ventilated facade” insulation system, the thermal resistance of the curtain wall material and the ventilated gap is not taken into account in the calculation.

Installation of insulation

Do-it-yourself insulation of walls with polystyrene foam is carried out in the following order:

- Install platforms or scaffolding, organize free access to the wall throughout the entire area.

- Prepare the wall. Remove loose pieces and, if necessary, repair dents or cracks. Install sheathing bars (if necessary).

- Install the foam sheets one by one using the chosen method. Installation should begin from the bottom up, and if cracks form, fill with foam.

NOTE!

Experts recommend using fungi only as an additional means of strengthening the adhesive bond.

Installation of insulation

Insulation under siding

External wall insulation is a reliable way to retain heat and protect wall material from getting wet and destroyed. The main condition for a successful result is the study of the technology and physical basis of the processes occurring with air moisture. If you have the knowledge and skills, the work will be fast and effective.

Example of calculating wall thickness

The thickness of the insulation of a frame house for permanent residence using the example of the Moscow region (this calculation was given above) was 150 mm when using mineral wool with a density of 50 kg/m3. Since most manufacturers produce this insulation in thicknesses of 50 and 100 mm, you will have to put insulation in either three layers of 50 mm thickness, or two layers of 100 and 50 mm. This will not change the thermal conductivity coefficient.

OSB with a thickness of 12 mm with an air gap of 50 mm and plaster of 5 mm was chosen as the external cladding.

The interior is lined with 13 mm plasterboard.

Total: 150 + 12 + 50 + 5 + 13 = 230 (mm).

Now, based on these data, you can now calculate the foundation, but you need to understand that this is just a mathematical calculation and it does not take into account problems that may arise during installation of the structure.

To make sure that there is no draft anywhere in the house, the structure is checked with a thermal imager

What do you need to know about sizes? What are they?

Foam sheets can be standard or custom sizes.

The length and width of the standard sheet are 1000, 2000 mm. The manufacturer can cut products into other non-standard sizes.

You can often find sheets of 1200x600 that meet the needs of the buyer and are in good demand. This can be a sheet with dimensions of 500x500, 1000x1000, 1000x500 mm.

On order, you can receive a batch of expanded polystyrene with sides of 900x500 or 1200x600 and other sizes, which does not contradict the standards.

GOST allows cutting products 10 mm smaller if its length is over 2000 and its width is 1000 mm. In thickness for slabs up to 50 mm, a difference of ±2 mm is allowed, and over 50, a difference of ±3 is allowed.

If the length is not suitable for the buyer, then companies selling such products offer individual cutting.

Length and width are important only for transporting building materials from the manufacturer to the customer. The main role is given to the thickness of the material.

The length of extruded polystyrene foam (EPS) sheets is 1200-2400 mm, width - 500-600 mm, and thickness 20-150.

To select a specific value, it is recommended to start from the scope of application, for example, for thickness, the following tips:

- for the floor on the first floor - from 50 mm;

- for the second floor and above – 20-30 mm;

- for additional sound insulation on the floor - 40 mm;

- for internal wall cladding – 20-30 mm;

- for external wall cladding – 50-150 mm.

Penoplex thickness for insulation

Penoplex is a derivative of the extrusion of polystyrene foam, a higher quality type of foam, to which improvers are added when pressed through a mold. There are quite a few brands of penoplex, and the choice of a suitable material for insulating a house outside or inside depends not only on the properties of a particular class of penoplex - the functional purpose of the room, the thickness of the penoplex, installation parameters, and many other factors will play a role here. To navigate the properties of this insulation, you should study its characteristics.

Penoplex production

Preparing the sheathing for foam plastic

Sheathing is required if siding is used as the exterior finishing sheathing . It is impossible to attach it directly to the foam, so it is necessary to install a sheathing.

To do this, before installing the foam plastic, wooden blocks of the same thickness as the insulation . They are attached so as to fit exactly between the foam sheets, without gaps, which, if necessary, are filled with polyurethane foam.

After installing the insulation, a counter-lattice is attached to them in the transverse direction, which serves as a direct support for the siding.

CAREFULLY!

The thickness of the counter-lattice strips must meet the requirements for ventilated facades - at least 40 mm.

How to calculate the thickness of insulation

- The required total thermal resistance (R) is 5.28.

- R of aerated concrete wall 400 mm from D500 – 2.6.

- R of the insulation should be: 5.28-2.6 = 2.68

Now you need to use a table that shows the thermal conductivity of insulation materials, in our case mineral wool.

AGB – autoclaved aerated concrete

The thermal conductivity of mineral wool at equilibrium humidity is 0.05.

The thickness of the insulation is determined quite simply: the required thermal resistance of the insulation is multiplied by its thermal conductivity, that is

2.68 x 0.05 = 0.134 meters.

Conclusion: we need mineral wool with a thickness of 134 mm. But mineral wool slabs are sold in multiples of 50 mm, which means the insulation layer will be 150 mm.

Important! The economically justified thickness of mineral wool for wet facades is from 100 mm. Since when installing insulation (wet facade) it is necessary to use several layers of plaster, mesh, facade umbrellas, and other fasteners, there will not be much savings between insulation thicknesses of 50 and 100 mm

And the cost of work and consumables when installing insulation of different thicknesses is almost the same

Since when installing insulation (wet facade) it is necessary to use several layers of plaster, mesh, facade umbrellas, and other fasteners, there will not be much savings between insulation thicknesses of 50 and 100 mm. And the cost of work and consumables when installing insulation of different thicknesses is almost the same.

We also note that 100 mm of insulation, in 90% of cases, shifts the dew point from the wall to the insulation. That is, moisture will never freeze in the wall, therefore, the service life of such a wall will be almost endless.

Preparing external walls for insulation

Construction work related to insulating the facade of a house with foam plastic begins with preparing the walls. They need to be cleaned, leveled, primed, etc. All these steps are described in more detail in the step-by-step instructions below.

Step 1. To work at heights exceeding human height, build scaffolding. You can make them yourself from timber and boards available on the site, but it is safer to use factory-made products.

Dismantled scaffolding

Assembly of factory scaffolding

Scaffolding prices

Scaffolding

The distance from the walls to the scaffolding should be equal to the thickness of the insulation layer (in this case it is 20 cm) plus another 30-40 cm for the working space

When erecting scaffolding, be sure to check its correct position vertically and horizontally using a level

Step 2. Inspect the walls for various defects. Fill cracks and holes, chip off mortar build-up. Prepare openings for water and gas pipelines and other utilities.

Removing solution build-up

Step 3. Treat the walls with a deep penetration primer. Since the house in the example is made of aerated concrete blocks, two layers will be required. For the first time, the primer must be diluted by adding water from a third to half of the total volume.

First, the primer must be diluted with water.

Treating walls with deep penetration primer

Important! Primer treatment in two layers is necessary not only for aerated concrete, but also for other porous materials, such as foam blocks and sand-lime brick.

Step 4. Apply a second coat of primer, but not diluted with water.

Applying a second coat of primer

Characteristics of various materials

Table 1

The value of the standardized heat transfer resistance of an external wall depends on the region of the Russian Federation in which the building is located.

table 2

The required layer of thermal insulation material is determined based on the following conditions:

- the external enclosing structure of the building is solid ceramic brick of plastic pressing with a thickness of 380 mm;

- interior finishing – plaster with cement-lime composition 20 mm thick;

- external finishing – a layer of polymer-cement plaster, layer thickness 0.8 cm;

- the coefficient of thermal homogeneity of the structure is 0.9;

- thermal conductivity coefficient of insulation - λA=0.040; λB=0.042.

How to determine thickness

The thermal resistance of the material (R) plays a significant role in calculating the thickness of polystyrene foam. The quality of the building’s thermal insulation depends on it. This value is individual for each region. Some of them can be viewed in the table presented.

If the walls consist of several layers, then it is necessary to summarize the thermal resistance indicators for each material.

The thickness of the foam is calculated by multiplying the thermal resistance and thermal conductivity, which can be found in the table.

What is penoplex

Heat loss through the walls of a building can range from ¼ to 1/3 of the total. Increasing thermal resistance due to the inclusion of special coatings in the design of external walls makes it possible to reduce its thickness and reduce the consumption of other building materials.

Wall insulation is necessary not only to prevent heat from escaping from the house in the cold season, but also to excessive heating of the room in the summer, so the correct choice of a heat insulator determines the financial costs not only during construction, but also during operation (heating, air conditioning).

Differences from other options

In the name of this insulation, you should pay attention to the word “extruded”, since a different production technology distinguishes it from ordinary polystyrene. The molten polymer is passed under high pressure through small nozzles, resulting in a dense foam board with a thickness of 20 to 100 mm as a result of solidification.

The molten polymer is passed under high pressure through small nozzles, resulting in a dense foam board with a thickness of 20 to 100 mm as a result of solidification.

The technical characteristics of various brands of penoplex are presented in the summary table:

Of the presented types, only 45 are used for making road surfaces, the rest are used for insulating residential buildings.

Meaning of indicators

The fine-porous structure of penoplex (100 - 200 microns) makes it a fairly light but durable material. Its characteristic qualities are:

- resistance to mechanical loads (when laid on a flat surface);

- low vapor permeability (thickness 20 mm is comparable to 1 layer of roofing felt);

- moisture resistance allows use on the outside of walls, in bathhouses, bathrooms, basement levels without heating;

- the insignificant coefficient of thermal conductivity expands the possibilities of use in thin partitions created with your own hands: balcony railings, veranda walls, extensions or garages;

- low weight does not lead to a significant increase in the load on the base when covering already designed structures (insulation of individual apartments in a multi-storey building);

- the density of the polymer allows the use of conventional cutting tools to adjust sheets to size when performing work;

- chemical resistance to most compounds used in construction (exceptions: gasoline, diesel fuel, acetone, enamels, oil paints, formaldehyde, acetate-based solvents). For more information about the qualities of the material, watch this video:

What to compare with

The listed characteristics classify penoplex among modern achievements in the line of traditional insulation and polymer counterparts.

The ratio of technical characteristics can be seen in the reference tables of materials:

Where is it used depending on the size?

This durable, moisture-resistant insulation is used for outdoor work. To insulate a wall with polystyrene foam, you first need to determine what density, size, and type of polystyrene foam you will need for the job.

The choice depends on the expected loads that this material will bear during operation.

When insulating a vertical wall, the loads will be minimal; sheets of any brand will do.

Even PSB-S 15 will give the same result as PSB-S 25 when it comes to wall insulation in areas with mild winters.

This is due to the fact that the principle of operation of the foam is based on gluing polystyrene balls, between which and inside there are multiple air chambers.

It is known that the less mass and more air, the better the thermal insulation effect.

It is inconvenient to work with low-density sheets, which are more fragile and break. PSB-S 25 has a higher density, making finishing easier.

Expanded polystyrene 25 is often used for external insulation of walls of non-residential premises. They are used to decorate balconies, loggias, garages, shopping centers, and various institutions.

For northern regions with cold winters, it is believed that a sheet thickness of 5 cm is enough to keep the room warm on the coldest nights.

Polystyrene foam grade 100 is used for thermal insulation of industrial freezers , as well as for insulation of houses in the harsh climate of the Far North.

A sheet size of 10 cm will ensure maximum thermal protection. When choosing a brand of expanded polystyrene, you can choose a sheet that has various parameters.

A non-standard sheet 500x500 is sometimes much more convenient to work with than a standard long one with dimensions of 2000x1000 mm.

For insulating the walls of a house, sheets measuring 1000x1000 and 1000x500 mm are suitable. They are convenient to work with and result in fewer joints that will have to be sealed hermetically.

To fill smaller areas, existing sheets are cut into suitable pieces. In all non-standard situations in finishing, it is better to use a sheet of large sizes to make it easier to cut configurations.

During the installation process, such sheets are adjusted to the required parameters by cutting polystyrene foam into pieces. This material is easy to cut.

Expanded polystyrene, having dimensions of 2000x1000 mm, is more difficult to install. When working alone, it is easier to lay two sheets of 1000x1000 each than one sheet measuring 2000x1000 mm.

Variety and features of insulation

Modern manufacturers offer a wide range of materials used as insulation and meeting all existing requirements and standards:

- Styrofoam;

- basalt or stone mineral wool;

- penoplex;

Before making your final choice, you need to familiarize yourself in detail with the features and advantages of each of them. Having studied the technical characteristics of various materials, we can safely say that the leaders in their main qualities are slabs of mineral wool or basalt insulation, as well as slabs for wall insulation.

The basis for the choice is data on the thermal conductivity, thickness and density of each material:

- stone wool - from 130 to 145 kg/m³;

- expanded polystyrene - from 15 to 25 kg/m³;

- penoplex - from 25 to 35 kg/m³.

The density of basalt wool reaches 100 kg/m³, which makes basalt insulation one of the most popular and popular. This does not mean that consumers should abandon the use of mineral wool as an insulating material used during finishing work before facing the façade walls of a building made of brick.

Thermal insulation material is selected based on the most significant characteristics of each. Having decided to choose polystyrene foam as a reliable and effective heat insulator, it is necessary to clarify the dimensions of the slab, its density, weight, vapor permeability, and resistance to moisture. Despite many positive qualities, this wall insulation also has some negative features:

- susceptible to destruction by rodents;

- high degree of flammability.

This forces consumers to select other materials, among which mineral wool is the most popular for wall insulation. It is characterized by high density, low weight, and low thermal conductivity. Its vapor permeability allows you to ensure a normal level of humidity. In addition, mineral wool is one of the fire-resistant materials.

Extruded polystyrene foam is in demand among consumers. These plates are characterized by a high degree of resistance to mechanical damage. EPS is not susceptible to rotting, the formation of fungus and mold, and is resistant to moisture. It is used to insulate the basement and load-bearing walls. In the latter case, slabs are installed whose density is 35 kg/m³.

Foam plastic - advantages and disadvantages

Polystyrene foam is a leader among insulating materials, combining the most successful qualities:

- Low thermal conductivity . Polystyrene foam consists of 98% air and only 2% polystyrene, so its heat-saving qualities are very high.

- Light weight . Among all materials, foam is the lightest; it does not create unnecessary loads on the walls.

- No consequences from the action of water . The material consists of many sealed granules filled with gas bubbles into which water simply cannot penetrate.

- Sufficient rigidity . The foam sheet is convenient for installation, it does not bend and holds its shape well, and is easy to cut.

- Convenient format and sheet thickness . Standard sheet sizes have convenient linear dimensions and thickness, allowing you to use the optimal option.

- Good adhesion - adhesion of the foam surface to primers or compositions for plastering walls.

- Fire safety . Manufacturers claim that ball foam does not burn at all. This is not entirely true, it burns, but its ignition temperature is twice as high as, for example, that of wood. Therefore, it cannot be a source of danger.

- The price of polystyrene foam is the lowest of all types of insulation.

Difference in thickness with the same thermal insulation

Such properties characterize the material from a very positive side.

However, there are also disadvantages:

- Polystyrene foam does not tolerate contact with solvents such as acetone or gasoline.

- The fragility of the material is quite high; it crumbles when cut and does not allow bending.

- Foam boards are impermeable to air, unlike mineral wool.

- There is a possibility of rodents living in the thickness of the material.

All shortcomings can be compensated in a certain way if you know about their existence and take the necessary measures.

Frame house projects

- 1 room

- 1 bathroom

- 42² Total area

- 6 x 7m Construction area

- 1 room

- 1 bathroom

- 28² Total area

- 5 x 4m Building area

- 4 rooms

- 2 bathrooms

- 170² Total area

- 11 x 8m Construction area

- 3 rooms

- 2 bathrooms

- 127² Total area

- 10 x 7m Construction area

- 4 rooms

- 2 bathrooms

- 200² Total area

- 9 x 13m Construction area

- 4 rooms

- 2 bathrooms

- 140² Total area

- 12 x 9m Construction area

- 3 rooms

- 2 bathrooms

- 127² Total area

- 9 x 8m Construction area

- 4 rooms

- 2 bathrooms

- 130² Total area

- 10 x 10m Construction area

- 3 rooms

- 1 bathroom

- 83² Total area

- 10 x 9m Construction area

- 1 room

- 1 bathroom

- 30² Total area

- 7 x 6m Building area

- 3 rooms

- 2 bathrooms

- 156² Total area

- 11 x 9m Construction area

- 4 rooms

- 2 bathrooms

- 140² Total area

- 8 x 9m Construction area

- 4 rooms

- 2 bathrooms

- 120² Total area

- 8 x 10m Construction area

- 1 room

- 1 bathroom

- 35² Total area

- 5 x 9m Construction area

- 2 rooms

- 1 bathroom

- 42² Total area

- 6 x 9m Construction area

- 2 rooms

- 1 bathroom

- 72² Total area

- 12 x 6m Construction area

- 2 rooms

- 1 bathroom

- 74² Total area

- 7 x 6m Building area

- 3 rooms

- 1 bathroom

- 110² Total area

- 13 x 9m Construction area

- 3 rooms

- 1 bathroom

- 75² Total area

- 9 x 7m Construction area

- 1 room

- 1 bathroom

- 45² Total area

- 6 x 9m Construction area

At a fairly low price, the quality of materials used in frame housing construction is growing every year. It is not surprising that this type of building is becoming increasingly widespread in all regions of Russia. And depending on the climate zone, the same project will have different requirements for heat conservation, therefore, what the thickness of the walls of a frame house should be must be determined in each case separately.

There are several subtypes of frame technology - if the general principle of building houses is the same, then the nuances, including the thickness of the walls, may differ

Features of foam insulation

Material selection

The photo shows expanded polystyrene slabs, which are successfully used for insulation.

Polystyrene foam, which is used for construction purposes, is most often expanded polystyrene. There are other types of foam, but I'll talk about the white cellular material.

Construction foam plastic has a cellular structure and is white in color.

The material is called expanded polystyrene (PPS, EPS, PSB, PSB-S) and is made from molten polystyrene by adding foaming agents. The resulting foam is then sintered and polymerized, resulting in a relatively strong and lightweight substance.

Polystyrene foam exhibits unexpectedly high strength.

Depending on the formulation and production method, PPS may have different properties. For example, if the material was made by extrusion, then it will have increased strength and lower thermal conductivity. And if PPS is treated with fire retardants, it will not support combustion.

Extruded polystyrene foam or EPS.

Obviously, foam plastic can be different, and our goal is to choose from this variety the type that will most fully satisfy the tasks assigned to it. Our task is to insulate housing.

The insulation layer should be on the outside. This is a requirement of SNiP 3.03.01-87 (PZ 2000). The easiest way is to buy polystyrene foam for outdoor use without delving into the nuances and characteristics. But this approach can play a cruel joke, and an unscrupulous seller will sell you an unsuitable cheap product at the price of expensive façade polystyrene foam.

According to building regulations, the walls are insulated from the outside.

How to choose facade foam? It is important to consider several characteristics here:

- Density _ The density of foam plastic for facade insulation must be at least 25 kg/m³. But practice shows that it is better to overpay and take material with a density of 35 kg/m³;

- Flammability group . The legislation of the Russian Federation prohibits the use in construction of materials not treated with fire retardants. This is especially true for ventilated facades. I would advise using polystyrene foam of the G1-G2 group for “wet” facades and strictly G1 for ventilated structures;

- Thickness _ This indicator depends on the climatic characteristics of your region, as well as on the thickness and material of the external walls of the house.

What materials are used for insulation?

Mineral wool is one of the most common insulation materials, which is characterized by good thermal insulation, but has a significant drawback: high moisture absorption. In this case, it is recommended to protect the wool with hydro- and vapor barrier.

Fiberglass is a good heat insulator. The material is resistant to high temperatures and does not rot. Mineral wool can be used not only for insulating the external walls of a brick house, but also for thermal insulation of a chimney in a boiler room or bathhouse.

Cellulose wool is used mostly for interior work. The material has good characteristics, with the exception of a high degree of moisture absorption and low resistance to mechanical loads. Note that this heat insulator is environmentally friendly.

A good option for insulating brick walls from the outside or inside is polyurethane foam, which is characterized by resistance to mold and is not susceptible to rotting. The material can be used without any problems when insulating a brick house with your own hands.

Insulation such as expanded polystyrene (foam plastic), which is characterized by low cost and high thermal insulation, is also widely used. It is necessary to take into account that the material does not absorb moisture, but is also highly flammable. It is not recommended to use it in residential buildings; however, internal insulation of brick walls is often carried out using polystyrene foam.

Extruded polystyrene foam has similar characteristics. Among the positive features, it is worth highlighting the low vapor permeability and high strength index. The characteristics of the material are maintained even at high humidity levels. It can be used not only for insulating a brick house from the inside or outside, but also in the construction of an insulated blind area, since this design has a longer service life.

Which polystyrene foam should I choose for external thermal insulation?

types of foam are currently produced :

- PBS-S-15. It has the lowest density and is used on secondary objects.

- PBS-S-25. The most used material has optimal characteristics and price.

- PBS-S-35. Material used for insulation and waterproofing of underground structures - foundations, plinths.

- PBS-S-50. The densest type used at critical facilities with difficult operating conditions.

IMPORTANT!

The declared density of the material often does not correspond to the actual one , therefore, when purchasing material, it is better to play it safe and buy a denser one.

In addition, there are modified foam samples - for example, extruded polystyrene foam (EPS). It has higher strength and does not crumble. At the same time, it is flammable and has lower vapor permeability than conventional foam. In addition, it is more expensive, which somewhat limits its scope of application.

Why is it necessary to calculate the thickness of insulation?

Comfortable living in the house involves maintaining optimal indoor temperature, especially in winter. When constructing a building, you should remember about thermal insulation; you should correctly select and calculate the thickness of insulation for the walls, roof, floor and attic. Any material - brick, wood, foam block or mineral wool - has its own value of thermal conductivity and thermal resistance.

A warm home is every owner’s dream

Thermal conductivity is the ability of a material to conduct heat. This value is determined in laboratory conditions, and the obtained data is provided by the manufacturer on the packaging or. Thermal resistance of a material is the reciprocal value of thermal conductivity. A material that conducts heat well has low heat resistance and requires insulation.

When constructing a building, you should remember about high-quality thermal insulation. If mistakes were made in the walls of the house or in other structures during construction, then cold bridges may appear - areas through which heat quickly escapes from the house. In these places, condensation may appear, and subsequently the formation of mold, if insulation measures are not taken during the process.

Technology of thermal insulation of external walls with polystyrene foam

There are several ways to install polystyrene foam on the facade:

- On glue.

- Mechanical fastening using dowels.

- Combining method. Both glue and fasteners are used. It's more reliable.

Everyone can choose the appropriate option for themselves, but professionals recommend using the latter method. In order for the entire structure to remain securely adhere to this plan.

Preparatory work

It all starts with preparing the foundation. This stage is as important as fixing the insulation or finishing it. Here they do the following:

- If the building was previously covered with finishing, it is removed.

- Remove fasteners and hanging structures.

- The wall is cleaned of dirt, grease stains, solution build-up, and dust.

- Prime the surface. For porous materials, such as foam or gas block, choose a deep penetration primer and apply it in 2 layers. It is also desirable that the composition be antibacterial. Then the main structure will be protected from harmful microorganisms. The soil allows you to increase the adhesion of the material from which the load-bearing walls are made, and therefore securely fix the insulation to the base.

- Next, install the starting profile at the border of the base and the beginning of the wall. It will serve as a support for the foam. The profile is fixed immediately along the perimeter of the entire building. Be sure to check the horizontal position using a building level.

- Now we begin to prepare the adhesive solution. The glue should only be suitable for polystyrene foam; other brands will not work. Cooking instructions are on the package. Be sure to adhere to the proportions, otherwise the material will not stick to the wall.

Bonding boards

The finished solution must stand for some time so that all components react with each other. Next, proceed to gluing the insulation boards:

- A thin layer of the solution is applied around the perimeter of the foam board. In these places, the mixture must be rubbed into the material - this increases adhesion.

- Make 2-3 small blots in the center.

- The slabs are installed in the starting profile from the lower left corner of the house.

- The foam is pressed tightly against the wall so that the solution is evenly distributed under the sheet. If excess adhesive solution is visible, remove it with a spatula. The evenness of the installation is checked using a building level.

- Glue is also applied to the next plate and pressed tightly against both the wall and the previous sheet.

- In the second row, the vertical joints should not coincide. To do this, the foam is shifted 15–20 cm to one side.

- After all the walls are completely covered with insulation and the adhesive solution has set, begin mechanical fixation. Make holes using a hammer drill and install disc-shaped dowels.

Installation of the reinforcing layer

When the glue is completely dry, begin reinforcing the surface of the foam. For this use:

- An adhesive solution, perhaps the same one that was used to fix the slabs to the wall.

- Fiberglass mesh.

There is also a special technique for gluing the mesh:

- First of all, apply a thin layer of glue using a spatula.

- Pieces of mesh 15–20 cm wide are glued to the corners. The mesh element is laid in such a way that the two walls have identical segments. Using a clean spatula, press the fiber into the adhesive solution.

- If it doesn’t work out, add glue on top and smooth it out.

- Next, we begin to reinforce the wall.

- A mesh is placed on the corner element with an overlap of 10 cm. It is also pressed into the solution with a spatula.

- When this layer has dried, apply the finishing layer to completely hide the mesh under the glue.

Applying a decorative layer

After applying the last layer of glue, wait until it dries completely. Next, it is customary to cover the foam insulation with plaster. This may be a decorative option with an original pattern or a regular, even layer painted in a suitable color.

After all the work is completed, the house will be warm and updated at the same time. And this is a solution to two problems at once. Of course, whether to choose polystyrene foam for insulating a house or not is everyone’s business. The nuances of choice and technical characteristics listed above are quite enough to make the right choice.