Aerated concrete (gas silicate) is one of the most popular materials in modern house construction. Houses made of aerated concrete have become a familiar part of the countryside landscape; from 15 to 20% of new buildings built over the past 10 years are houses made of aerated concrete blocks. The porous structure of the material, characteristic of all lightweight concrete, ensures high performance characteristics of the structure. In many cases, owners decide to carry out additional insulation of the house using aerated concrete from the outside. This measure allows you to minimize heat loss and improve the microclimate of your home.

A house made of aerated concrete needs high-quality insulation Source makemone.ru

About the need for insulation

The structure of aerated concrete is a complex system of many open cells (voids) filled with air. This structural feature determines two useful properties of the material:

- Good thermal insulation . The manufacturer claims that the porous structure of aerated concrete brings its thermal insulation properties closer to wood, and is three to four times superior to brick. In the middle zone, according to SNiPs, the thickness of external walls of 400-500 mm will be sufficient without additional insulation if a block of a grade no lower than D500 is used. These calculations are correct, but do not take into account the second property of aerated concrete.

- Gas permeability . Open pores mean that the material is able not only to transmit, but also to accumulate moisture, which is what happens during the operation of the house. Walls that have absorbed a certain amount of moisture become denser (water accumulates in the pores, like in capillaries). The thermal conductivity of such walls increases, and the ability to retain heat decreases, which is especially noticeable in regions with harsh winters. And if in the south (where the winter temperature difference between inside and outside the building is small) country houses do not need insulation, then to the north the walls must be protected.

The properties of aerated concrete are determined by its structure Source pinterest.com

How to insulate a balcony made of aerated concrete

Aerated concrete is used not only for the construction of load-bearing walls of low-rise buildings. In apartments, they fill the spans of frames, make interior partitions, and also build parapets on loggias and balconies. External enclosing structures are designed by the developer, the partitions do not need to be insulated - but what to do with balcony parapets?

- They cannot be insulated from the outside, not only because they are inaccessible, but also so as not to spoil the architectural appearance of the facade. And if you consider that a loggia or balcony is often attached to rooms, or some functional areas are moved there, the need for insulation still arises.

- For insulation to be effective, it must be done from the outside, but in this case, it is done from the inside. And here it is best to use not mineral wool, but polystyrene foam or polyurethane, which will trap vapors and prevent them from being absorbed into the gas-block masonry.

- The insulation process is no different. You can, just like on the facade, stick the slabs and perform surface plastering, or you can put insulation inside the sheathing, on which drywall, boards or some panels will be mounted.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: When installing hanging materials, in addition to slab insulation, you can also use roll insulation - modern and very effective materials based on polyethylene foam.

Alternatively, to finish the parapet, you can use two-in-one materials: textured foam plastic or thermal panels to look like stone or brick.

Principles for choosing insulation

When choosing a suitable material for insulating aerated concrete walls, three factors are taken into account:

- Physical properties of the material . Aerated concrete can regulate the humidity in the room: the walls breathe, allowing water vapor to pass out. The external cladding should not impede this diffusion.

- Properties of insulation . It should not just be vapor permeable; vapor permeability should be higher than that of aerated concrete blocks.

- Insulation rule . It says: the vapor permeability of each subsequent layer of facade insulation should increase. If the selected material cannot easily allow air to pass out, then a ventilated gap must be installed behind it.

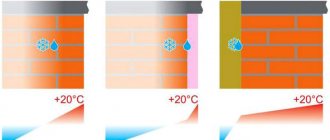

Compliance with these conditions helps to shift the dew point beyond the walls. If the masonry is not protected by anything, the moisture accumulating inside will inevitably freeze in severe frost. This leads to noticeable heat loss; after several cycles of freezing and thawing, the destruction of the surface layer of the blocks may begin.

Good to know! The dew point is a plane in the thickness of the wall where, due to the difference in external and internal temperatures, water vapor condenses into dew. With proper organization of external insulation, the dew point moves outward and cannot harm the walls.

Dew point shift when using insulation Source 1bcm.ru

The energy efficiency of a house is affected not only by correctly selected insulation, but also by the quality of wall masonry. If the interblock seams are made incorrectly (too thick), even high-quality insulation will not give the desired effect. Glue joints with a thickness of 1.5-2 mm are considered optimal. Laying blocks on cement-sand mortar with a seam of 10-12 mm will increase heat loss (and heating bills) by 20-20%.

To insulate or not?

Judging by customer reviews, insulating a house made of aerated concrete is not mandatory, but in some cases it cannot be avoided. The following reasons speak in favor of insulating an aerated concrete building:

- High density of the material used. Houses made from D500 aerated concrete blocks have low thermal insulation properties. Blocks D300, 350 and 400 retain heat much better.

- Porosity of aerated concrete. This material absorbs moisture well and allows steam to pass outside and inside the room. Absorbed moisture over time exposes the outer layer of the aerated block to slow destruction.

After insulating the walls of a building, the service life of aerated concrete blocks increases significantly.

Types and advantages of facade insulation

There is an alternative possibility - insulating the building from the inside. This option is less preferable for several reasons:

- Living space will decrease.

- effective ventilation system will need to be installed .

- There will be a high risk of mold formation , as the dew point will shift inside the home. Moisture and heat are optimal conditions for unpretentious microorganisms and fungi.

Video description

About mistakes when insulating aerated concrete in the following video:

Internal insulation reduces the usable area of housing Source makemone.ru

Considering different options for how to insulate a house made of aerated concrete from the outside, many opt for ordinary or mineral plaster; the latter is specifically designed for aerated concrete walls. The insulation layer can be sheathed with several finishing materials:

- Siding or clapboard .

- Face brick or decorative stone .

- Plaster.

- Grouting the joints followed by the use of vapor-permeable facade paint .

Installation of an insulating layer on the outside has the following positive aspects:

- The energy efficiency of the building increases and heating bills decrease.

- Load-bearing walls are not exposed to natural forces, which increases the service life of a country house.

- Along with improved sound insulation of walls, living comfort increases .

- The appearance of facade walls improves .

Scheme of a ventilated facade with finishing Source gettarget.ru

See also: Catalog of companies that specialize in insulating country houses.

Why do disputes arise about fasteners and the ability of an aerated block to support weight?

Aerated concrete is a porous and relatively lightweight material. That is why it is so warm and easy to process, and houses made from it have an excellent microclimate in winter and summer. At the same time, due to the peculiarities of the structure of this material, conventional fasteners hold in aerated concrete worse than in “classical” concrete or brick.

Therefore, people who have built houses from aerated concrete may encounter the following:

These problems are not made up. However, they can be avoided, and it is not difficult to do so. Taking into account the characteristics of this material, special fastening methods and fastening elements were developed - nails, dowels, anchors specifically for aerated concrete .

Let’s figure out how and what kind of fasteners should be used in a Twinblock house so that the curtain does not “slant” and a family portrait or, more critically, a cabinet with dishes does not fall.

To do this, it is enough to hammer a nail into a wall made of aerated concrete or tighten a self-tapping screw, just like in ordinary wood.

What's the best way to secure a wall light, coat hooks, or a heavy picture?

For these purposes, it is better to use a “pair of nails” - a fastening method in which two nails or self-tapping screws are driven into the wall or twisted at an angle of 45° to each other. Such fasteners work like an “anchor”, securely fixing your equipment.

Fig.1 Attaching to the Twin Block “Nail Pair”

Using the same method, you can attach structural elements to the external walls of a house made of aerated concrete - various canopies, gutters, awnings, etc. Two holes are drilled in the wall at an angle and reinforcement is hammered into them. Next, the structural elements of the structure are welded to the reinforcement.

How to securely secure a mirror, shelf or small cabinet?

In this case, you can use a dowel for aerated concrete “Turbinka” with longitudinal ribs (it is also called a driven one). This dowel is driven into a pre-drilled hole in the wall. Scrolling, the dowel for the gas block forms a thread. The “turbine” holds weight better than a nail or self-tapping screw, and is quickly installed, but is not suitable for mounting massive equipment.

Fig.2 Dowel “Turbine” for aerated concrete

To solve this problem, a screw dowel for aerated concrete (with transverse turns) is suitable. Unlike the “Turbinka”, it is screwed into a pre-made hole using a special key or screwdriver. Next, a self-tapping screw is screwed into the screw dowel.

Fig.3 Screw dowel for aerated concrete

Have you decided to install a water heater in a house made of aerated concrete?

Most likely, a water heater (boiler) filled with water will be the heaviest attachment in the house. Electric boiler 100 l. on average weighs 25-30 kg, gas - 35-40 kg. The weight of 100 liters of water is approximately 100 kg. Thus, the weight of the water boiler is about 140 kg. - a serious load both for the Twin Block wall and for the fasteners, no matter what the design.

To make the water heater mounting as reliable and safe as possible, anchors for aerated concrete were invented; they can be mechanical or chemical.

Mechanical anchor for aerated concrete

Fig.4 Mechanical anchor for aerated concrete

During installation, the mechanical anchor is wedged or cut into the wall, thereby being securely held in the wall. Sometimes it is not possible to remove such an anchor without damaging the wall.

Chemical anchor for aerated concrete

Chemical or adhesive anchors are called anchors, for the fixation of which compositions based on various resins are used. The choice of composition depends on the conditions of use - low temperature, high humidity of the wall, etc.

Fig.5 Chemical anchor for aerated concrete

How is a chemical anchor installed?

A capsule with an adhesive composition is inserted into a pre-drilled and cleaned (this is important) hole, or the composition is simply squeezed out inside. Next, screw the fastener into the hole and leave it to dry (up to 48 hours). The adhesive “tightly” binds the aerated concrete to the anchor. It can only be removed together with a piece of the wall.

We also recommend using a chemical anchor, but to increase the area of interaction of the adhesive composition with the wall, a conical hole is formed in the ceiling or partition of the aerated block, which is filled with the adhesive composition.

Fig.6 Installation of a chemical anchor for aerated concrete

Chemical anchor is an excellent solution for fastening in aerated block houses. But it also has disadvantages: it takes a long time, is expensive and impossible to remove without damaging the wall.

As you can see, reliable and easy-to-implement solutions have long been invented for attaching household items to aerated concrete walls. To make sure that they work, read the reviews of people who have long and happily lived in houses made of aerated concrete (Twin Block):

Vladimir, built a cottage from Twinblock in the village. Kosulino - Boiler, all kitchen furniture hang on ordinary anchors and self-tapping screws.

Want to know more about Twinblock? Read our publications and articles:

Source

Video description

We will dwell in more detail on insulating a house with polystyrene foam. Find out how safe polystyrene foam is in our video:

Foam insulation Source beton-house.com

- Installation of foam plastic . It is placed in the spaces between the frame elements, additionally secured with foam or glue.

- Fixing the slabs . The foam sheathing is additionally reinforced with plastic dowels (metal dowels are not suitable, as they create cold bridges).

- Decorative finishing . A primer is applied to the foam layer, a fiberglass mesh is fixed on top, then reinforcing glue is applied. After the glue has dried, finishing is done with decorative or warm plaster.

See also: Catalog of projects of houses made of aerated concrete blocks presented at the exhibition “Low-Rise Country”.

Insulation with mineral wool

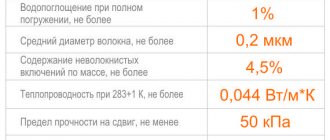

Mineral wool is presented on the market in the form of slabs and rolls. It is actively used for insulating facade walls; basalt slabs are a special case of mineral wool, with similar qualities and performance characteristics. The widespread use of mineral wool is due to its many positive qualities:

- Good vapor permeable properties .

- High strength and immunity to biohazards. Materials are available in different hardness categories.

- Fire resistance (in case of fire it does not burn, but melts).

- Environmental friendliness . The basis of mineral wool is natural components that are not hazardous to human health.

Insulation with mineral wool Source no.decorexpro.com

Installation of mineral wool on the facade is carried out in the following order.

- Facade preparation . The wall is cleaned and leveled using cement mortar. Then the surface is primed and, if necessary, additionally leveled with vapor-permeable plaster.

- Frame installation . The guides of the frame structure are fixed taking into account the size of the material used (roll or rectangular mats). Thanks to the frame, a ventilation gap is formed, sufficient for air circulation along the wall and steam removal.

- Fastening mineral wool . It is carried out using glue applied to the slab material. Additional fixation is provided by plastic umbrella dowels.

- Preparing for finishing . The mineral wool layer is reinforced with mesh and glue.

- Finishing . The walls are coated with primer and plastered; The second common option is to cover it with putty and paint it. When finishing, do not use acrylic plaster, which has moisture-proof properties; such a coating will cause condensation to form.

Expanded polystyrene

Extruded polystyrene foam (EPS) is one of the types of foam plastic. Expanded polystyrene is produced by foaming the starting ingredients at high temperature and pressure. The production method determines the physical properties of the material - it is mechanically strong, frost-resistant and can have different densities. The higher the density (and strength) of EPS, the higher the thermal conductivity. Vapor and air permeability are always at the same (low) level, and water absorption is minimal. The combination of qualities makes it possible to widely use EPS as an insulating facade material.

An undesirable property of polystyrene foam for aerated concrete walls - low vapor permeability, leading to the appearance of a thermos effect and a shift in the dew point - is avoided by installing a ventilation gap. As in the case of using polystyrene foam, the second option is possible - installing powerful supply and exhaust ventilation. Installation of the insulating layer and decorative finishing is carried out according to the same scheme as for foam plastic.

Expanded polystyrene boards Source ko.decorexpro.com

Polyurethane foam (PPU)

The material refers to sprayed substances; its application requires special equipment, which makes it not the most popular choice in private housing construction. After spraying, a homogeneous sealed layer with the following properties is formed on the wall:

- PPU penetrates the porous surface layer of the aerated concrete facade and forms a strong bond with it that does not collapse over time.

- The thermal conductivity of polyurethane foam, depending on density, is intermediate between polystyrene foam (minimum thermal conductivity coefficient) and mineral wool.

- The required thickness of polyurethane foam is determined by the type of material and ranges from 5 to 10 cm (in the middle band). The service life of such coating is at least 25 years.

- The vapor permeability of polyurethane foam after hardening is comparable to that of reinforced concrete; the filtration of air and water vapor completely stops. To remove water vapor accumulating in the premises, an effective ventilation system is organized.

The principle of creating a polyurethane foam layer Source stroyfora.ru

- If polyurethane foam (as well as polystyrene foam or EPS) is chosen as the external insulating layer, a finish is selected for the premises that does not allow steam to penetrate into the aerated concrete . Cement plaster and alkyd paints are suitable for this role; ceramic tiles and vinyl wallpaper are often used.

Calculation of the “Dew Point” for the walls of your cottage

On the Internet you can find corresponding online calculators for heating engineering of enclosing structures. We recommend the following:

www.smartcalc.ru/thermocalc

Calculation example at the link: Region: Ekaterinburg, Sverdlovsk region; Premises: Residential; Construction type: Wall; Construction layers: Autoclaved aerated concrete D400, 400 mm thick (one layer, without finishing and insulation)

It is enough to select a region and enter information about the construction of the walls (layer by layer). Next, open the “Moisture Accumulation” tab. If the conclusion appears that “The enclosing structure satisfies the standards for waterlogging” - that’s it, the calculation is completed!

Please note: when calculating the “dew point”, the average temperature during the heating period is considered. In the Sverdlovsk region it is about -7°C. If within a few days the temperature drops to -35°C, the amount of steam that will fill all the pores will not have time to pass through the wall, the moisture will turn into ice, and the ice will “tear” the material. Especially if the walls are made of Twin Block - its frost resistance (F) is 100 cycles.

The lower the temperature, the lower the air humidity both outdoors and indoors. Thus, the probability of steam turning into water is low.

Summary: the “dew point” in the wall itself is not as dangerous as we are often afraid of. Risks arise only due to the accumulation of moisture in the walls during the heating period as a whole.

Methods of attaching insulation to the facade

In practice, three technologies are used to insulate external gas-block walls.

- Curtain façade . It is a wooden or metal frame structure, the pitch of which is equal to the width of the heat-insulating material. The insulation is placed in the cells of the frame, and a decorative layer is mounted on top.

- Wet facade . The aerated concrete surface is cleaned. The selected thermal insulation material is attached to the adhesive and additionally secured with dowels. Then the wall is plastered in 2 layers using a reinforcing mesh.

- Wet façade with reinforcement . If brick or natural stone is chosen as the finishing facing material, hooks are used to fix the insulation. Then the surface is reinforced with mesh and plastered. After the plaster has dried, cladding is carried out; The method allows you to do without strengthening the walls and foundation and in many cases is preferable.

Cost of work on insulating the facade of an aerated concrete house

Construction organizations offer services for insulation and plastering of the facade of aerated concrete houses, the price of which is determined by several factors. The exact estimated cost of the work is determined during a direct inspection of the house. The cost of work is affected by the following parameters:

- Home inspection (the service is free in most cases if a contract is signed).

- Geometric features of walls, number of storeys and surface area.

- Consultation with a specialist on choosing optimal thermal insulation.

- Drawing up an .

- Purchase and delivery of materials.

- Carrying out work on insulation and finishing of the facade.

- Removal of construction waste .

Do you need waterproofing and vapor barrier for aerated concrete façade?

Aerated concrete blocks are endowed with such qualities as good vapor permeability and excellent thermal insulation.

At the same time, this building material has one negative characteristic - it strongly absorbs moisture.

It is for this reason that it is imperative to carry out work on hydro- and vapor barrier of the blocks.

wall pie