One of the most serious problems of living in a country house, especially if it is made of wood, is a cold floor. Insulating the floor in a wooden house from below, which is done using different materials and different technologies, will ensure comfortable and cozy living. More information about insulating a house made of wood will be discussed in this article.

Insulation of the floor from below in a wooden house

A few words about thermal insulation

Drafts in combination with a cool floor do not bring positive emotions, and they also have a bad effect on health. Therefore, there is no point in arguing about the need for thermal insulation in the house. Insulating the floor below is a mandatory and inevitable event, which will pay off all costs over time.

Insulation of a wooden house

The thermal insulation process can be divided into several stages:

- dismantling the floor covering;

- installation of subfloor;

- laying a layer of thermal insulation;

- laying vapor barrier;

- installation of finished floor.

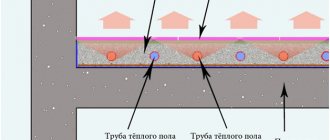

Floor insulation scheme on the first floor

Advantages of a wooden floor

A similar scheme is suitable for cases where a wooden house is being restored during renovation. But if a house is being built from scratch, then all of the above steps are performed during the construction stage.

Thermal insulation of the floor in a wooden house

Types of basements

There are several types of underground: warm and cold. Cold is used for houses that are not heated during cold weather; for this purpose, the floor is additionally insulated.

In such a subfield, the temperature depends on the temperature outside, and not in the house. The ventilation system in the underground of a private building is carried out through the foundation vents of the house; air is not exchanged with the internal home premises.

Floors with a warm underground are used in houses with regular residence and heat supply. Temperature in the underground

depends on the temperature in the house, because it is connected to the interior with vents for ventilation in the floor.

To reduce heat loss, foundation insulation is done.

Very often, the depth of the warm underground floor is 15-25 cm. With a depth of more than 25 cm, heat loss becomes greater, with less, the ventilation system will deteriorate.

When insulation is required from below

There are several main reasons why a wooden house is thermally insulated from below. These include:

When is floor insulation required in a home?

- the need to reduce the height of the room;

- protection of the floor and the entire covering from freezing;

- moving the dew point, thereby avoiding the process of rotting.

Insulation of floors protects the house from freezing

During renovation work in a private house, some difficulties often arise that are directly related to the insulation of the bottom. Let's look at the most common of them:

- more reliable fixation of the heat-insulating material is required;

- the presence of a low subfloor greatly complicates the work;

- insulation of the floor from below contributes to rapid fatigue of workers, which greatly delays the process;

- The variety of types of insulation is not very large.

How and with what you can insulate the floor in a private house

Floor insulation is a rather complex process that requires preparation. First of all, before starting repair work, you need to decide on the choice of insulation.

How can you insulate the floor in a private house and what materials should you use?

Why do you need to insulate a cellar?

Insulating the cellar will help prevent food from freezing in winter.

The storage facility is built at a distance from buildings equipped with heating appliances and communications. This means that the internal space is less influenced from the outside and is relatively stable. However, temperature differences in winter and summer reach serious values, which cannot but affect the microclimate of the underground warehouse. Sometimes construction is done under sheds and garages in co-ops. These buildings do not have any impact on the underground premises, but protect them from precipitation.

Basement insulation is carried out for the following reasons:

- In the summer heat, the earth becomes so hot that the heat penetrates deep underground, heating the walls of the cellar and its contents. This causes vegetables to sprout, preserves to explode, and pickles to become moldy.

- In cold, snowless winters, the soil freezes heavily. This also affects the microclimate in the underground storage facility. Vegetables and fruits spoil, jars crack, and smoked products quickly disappear after thawing.

- When temperature changes, condensation forms. Dampness promotes the development of pathogenic microorganisms, metal corrosion and the destruction of wooden products.

- Contact with the ground causes gradual destruction of the walls of the structure. Insulating the cellar from the outside protects it from the effects of an acidic environment and the depletion of freezing-thawing material.

Material selection

There are several main criteria by which you should choose insulation. These include:

Materials for floor insulation in the house

- resistance to rodents and high humidity;

- durability of the material;

- complexity of installation;

- financial capabilities of the home owner (some materials are not cheap).

Floor insulation with foam plastic

Note! When insulating the floor in a country house, where the owners rarely visit, it is important to choose materials that are resistant to different types of rodents. It is mice, combined with high humidity, that are the main reasons for the destruction of wooden floors.

What is the best way to insulate the floor in a wooden house?

Table. Overview of wooden floor insulation.

| Name of material, photo | Description |

| Expanded clay | It is a small granule with a porous structure. Expanded clay retains heat well, and small rodents and harmful insects do not live in it. The optimal thickness of the expanded clay layer is 20-30 cm. |

| Styrofoam | A fairly lightweight and easy-to-install material used for insulating houses and apartments. The foam is moisture resistant, but is afraid of rodents, which quickly destroy it. |

| Wood shavings | One of the cheapest insulation materials, which can be purchased without any problems at your nearest wood processing plant. Wood shavings actively retain heat, but are not moisture resistant. |

| Slag | An excellent material for insulating houses. The slag needs waterproofing, which significantly complicates the installation process. But slag is a durable material. |

| Glass wool | An inexpensive heat-insulating material that not only retains heat in the house, but also muffles sounds. Among the disadvantages of glass wool, it is worth highlighting the material’s tendency to shrink over time. |

| Ecowool | Another type of insulation with low thermal conductivity. To install ecowool, a special installation is required, since it is quite difficult to manually blow it into the underground space. |

Thermal insulation materials for floors

Expanded vermiculite can also be used as crumbly floor insulation. This is a natural material with a granular structure. Vermiculite is lightweight and has high heat and sound insulation properties. In addition to construction, vermiculite is actively used in dacha farming.

Vermiculite expanded

What is the best way to insulate a subfloor?

Insulation is selected depending on the behavior of the basement at different times of the year.

The choice of material is also influenced by the following factors:

- Indoor humidity level;

- Availability of heating;

- Availability of drainage around the building;

- Purpose of the underground.

Construction stores offer thermal and waterproofing materials with various characteristics. The following are popular and available:

- Styrofoam. The cheapest insulation. It is distinguished by its lightness, resistance to rotting, moisture resistance, and low price. The combination of these qualities makes foam plastic the most popular material for insulating wooden houses. The disadvantage of polystyrene foam is that it attracts rodents, is fragile, is highly flammable and releases harmful chemical compounds into the atmosphere.

- Expanded polystyrene. A substitute for polystyrene foam, which is more durable and has a tongue-and-groove system for a seamless connection. The material is often used to insulate basements from the outside and inside.

- Polyurethane foam. A sprayed material that fills all cracks when applied to surfaces. Creates a completely sealed coating, does not burn, does not rot. Disadvantages of the material: high price and the impossibility of self-application without special equipment.

- Penofol. Flexible insulation. Provides decent thermal insulation. Fireproof and waterproof.

- Minvata. Soft insulation, suitable for use only inside absolutely dry rooms. Under the influence of moisture, mineral wool begins to rot and gradually decomposes.

- Expanded clay. The use of this bulk material is only possible for insulating the floor and protecting the foundation from the outside.

TOP 3 mineral wool manufacturers

| Photo | Name | Rating | Price | |

| #1 | Rockwoll | ⭐ 98 / 100 | More details | |

| #2 | Knauf | ⭐ 97 / 100 | More details | |

| #3 | Isover | ⭐ 96 / 100 | More details |

Rockwoll

The company is considered a market leader in the production of mineral wool. The manufacturer has a wide selection of products.

Rockwoll

pros

- environmental friendliness;

- fire safety;

- soundproofing;

- price-quality ratio;

- long service life;

- no shrinkage or shedding;

- Wide selection of sizes and packaging options.

Minuses

- Personal protective equipment is required when working.

Rockwoll mineral wool

Knauf

Knauf insulation products are safe materials produced using innovative technology and from natural ingredients.

Knauf

pros

- excellent heat and sound insulating properties;

- simple installation;

- non-flammable material;

- without smell;

- resistant to insects and rodents.

Minuses

- high price.

mineral wool Knauf

Isover

The material is supplied in rolls and slabs. The products are manufactured using special technology, which allows them to cope with the assigned tasks perfectly.

Roll insulation ISOVER

pros

- simple installation;

- affordable price;

- a wide range of;

- environmentally friendly material;

Minuses

- low resistance to moisture.

Isover mineral wool

Waterproofing paints

Such paints are mixtures of bitumen and polymer components that impart water-repellent properties. Such compositions should be applied with a brush and in several layers. Thus, the wood will receive a high-quality moisture-proof layer. Also, similar paints can be applied to the screed.

You can start painting with a waterproofing compound only after the following procedures:

- Sanding wooden floors.

- Cleaning floors from dust and dirt.

- Drying wooden parts.

- Careful treatment of hard-to-reach areas (joints between joist frames and walls) with waterproofing varnishes.

- Painting the rough base.

Thermal insulation methods

Insulation of the floor in a wooden house can be done using two methods - using joists and a rough base. The first method is used to insulate wooden or concrete floors. Any of the above materials can be used as insulation. The entire load is evenly distributed on the surface of the logs, so the strength and density of the material used is not important. When insulating the floor using joists, you should take into account the fact that the height of the room will decrease by about 10 cm due to raising the floor.

Floor insulation methods

The second method requires a more durable and rigid material as insulation to eliminate the possibility of it settling under the influence of loads. The role of the rough foundation can be performed by wooden flooring, concrete screed or tightly compacted soil. Installation of the thermal insulation layer can be carried out under the floor covering. The result of the work done will depend on the correctness of the actions performed and the quality of the insulation used.

Floor insulation on a rough base

Ladder and manhole cover

The simplest solution to the question of how to easily build a staircase in a cellar is to use boards and bars of wood. If desired, you can use concrete or even metal. It all depends on personal preferences and capabilities.

It should be noted that wood will require impregnation with special compounds (to prevent rotting), and metal will require painting with a primer.

There are many types of stairs, for example:

- stationary wooden;

- complex concrete staircase;

- retractable.

Don't forget about the hatch The hatch cover can be made hinged (hinged) or completely removable, it depends on how large the hole is inside and where it is located.

Floor insulation

Below are step-by-step instructions for insulating a wooden floor using Tepofol. This is a unique material made of non-crosslinked polyethylene foam. It has noise, moisture and heat insulation properties.

Scheme of thermal insulation of the floor of a wooden house

Step 1 . Unfold the roll of insulation and carefully cut it into equal parts, the length of which should correspond to the length of the house. The material is quite easy to cut, so you can handle it with a regular stationery knife.

Cut the insulation into pieces

Step 2 . Treat the wood used to make various pies and logs using special impregnations. This will increase the fire resistance, moisture resistance and, as a result, the service life of the tree.

Treat the wood surface

Step 3 . Lay a layer of waterproofing around the entire perimeter of the concrete foundation of the building.

Lay a layer of waterproofing

Step 4 . Install the wooden strapping beam on the foundation on top of the previously laid layer of waterproofing material. The beam must be securely fixed.

Install the strapping beam

Step 5 . After fixing the beam, install special fasteners on it for subsequent fixation of wooden logs. The elements must be installed at a distance of 60 cm from each other.

Install joist fastenings

Step 6 . Install the logs onto the ready-made fasteners, securing them using ordinary self-tapping screws. The levels of the strapping beam and joists must match.

Log installation process

Lay the joists flush with the strapping beam

Step 7 . Secure special support boards between the joists, using metal corners as fixing elements. Boards are needed for installing insulation.

Install metal corners

Install the support boards

Step 8 . Lay the previously prepared pieces of insulation across the wooden joists. The material should rest on the sides of the cross boards and on the strapping beam. Lay the material over the entire area of the house, tightly joining the pieces of insulation together.

Start laying insulation

The process of laying insulation

Step 9 . Use special dowels to fix the insulation, attaching the material to the surface of the log.

Use special dowels with a plastic insert

Step 10 . Now secure the laid layer of insulation around the perimeter of the strapping beam. For fixation, use self-tapping screws and a special block no more than 5 cm thick.

Secure the insulation with a wooden block

The beam is attached along the entire perimeter of the floor

Step 11 . Treat the joints of the insulation sheets using a hair dryer. This will eliminate any existing cracks through which cold air could enter the house.

Treat the joints with a hair dryer

Step 12 . Perform the lathing on top of the thermal insulation layer. To do this, fix small bars along the logs, fixing them every 50-55 cm. To do this, it is advisable to use long screws and screw them in in pairs.

Install the sheathing

Self-tapping screws should be screwed in at an angle of 45 degrees

Scheme for screwing in self-tapping screws

Step 13 . Secure the floor boards by nailing them to the surface of the previously made sheathing bars. The next stage of work is finishing.

Install floor boards

Step 14 . The floor insulation work can now be considered complete. Enjoy the results.

The result of floor insulation work

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

When choosing insulation for a country wooden house, it is necessary to rely not only on the technical indicators of a particular material. The conditions under which the selected insulation will be used should also be taken into account. This is the only way to choose the most optimal option. But if your choice is two options that are almost the same in price and quality, you should give preference to a more well-known brand.

Insulation of a wooden floor in a private house

On a note! If the insulation was made by a well-known manufacturer, then the chances that it will last for many years without any complaints will be much greater.

Features of installation on logs

Insulation with stone wool on joists

When a strip foundation is used as a base, a structure consisting of joists, rough and finishing flooring is used. Flooring material is selected based on the type of interior and the maximum values of ground temperature in summer and winter.

In such cases, beams are used as a frame for placing thermal insulation

In this case, special attention is paid to the processing of the lower boards, which are exposed to dampness coming from the ground. The best option is to cover them with waterproofing, but this is not always possible, especially when a shallow tape is made

When insulation is laid between the joists, polyethylene or other similar material is first placed there. And only then the insulation is installed. After this, a membrane film is applied, then a final or pre-coat. To ensure high-quality ventilation, grilles with mesh are installed in the corners of the room.

Insulating a house from the basement

If you have a basement in a private house, you must devote time to insulating it. This will not only avoid heat loss, but also prevent the destruction of the house from prolonged exposure to dampness. To perform thermal insulation work, different materials can be used, for example, foam plastic or penoizol. Many craftsmen use mineral wool to seal the ceiling of a house.

Insulating the basement ceiling with foam plastic from the inside

Before starting repair work, it is necessary to prepare the surface by clearing it of all kinds of debris and dust. After cleaning, it is advisable to treat the surface with an antiseptic and then with a primer. This sequence will help ensure reliable adhesion of the insulation to the surface, as well as protect it from the process of rotting. The process of attaching thermal insulation material cannot be called complicated, so even a beginner can cope with this task.

Scheme of floor insulation in the basement on the ground

You just need to apply a little adhesive to the surface of the insulation, and then press the material against the ceiling for a while. After a few seconds (the exact time is indicated on the glue packaging), the insulation can be released - it is securely attached. Repeat the procedure with each sheet of thermal insulation material.

How to insulate the floor on the first floor

Insulating the floor in a country house made of wood is an important measure that allows you to create optimal living conditions. Only with the use of high-quality thermal insulation material can a warm environment in the house be ensured, so you need to choose it correctly. Fortunately, the modern market offers a wide selection of insulation materials, which differ not only in price or thermal insulation properties, but also in the installation method. Therefore, in order not to encounter troubles in the future, when choosing insulation, you must definitely consult with specialists.

Insulation of a wooden floor

Ventilation device

The first stage of insulation is the installation of a ventilation system in the underground, which will ensure air circulation inside the room and prevent the formation of condensation on surfaces.

Underfloor ventilation consists of installing two pipes on different sides of the room. The optimal location of pipes is on the south and north sides of the house. The installation of pipes is carried out in accordance with the laws of physics, cold air tends downward, and after warming up it rises.

The supply pipe is located at a height of 20-30 centimeters from the basement floor, and the inlet pipe - 40 cm from the ground. The outer opening of the pipe is covered with a fine mesh - protection against rodents entering the basement.

The outlet pipe is placed 30 centimeters below the basement ceiling. And its upper end is brought out onto the roof of the house. The top of the pipe is covered with a protective cap. This arrangement of pipes will ensure optimal air movement in the underground and protect the room from mold.

Setting up a glacier to preserve food

On the site, in addition to stationary basements, you can build a storage facility that is a little simpler, for example, a pit, a pile or a glacier. Let's take a closer look at how to properly build a glacier.

The glacier serves to preserve food and is a room buried in the ground, which has an ice chamber, a compartment for storing food and a vestibule. Glaciers can be divided into three types, which are determined by the method of filling the ice: bottom, side, top filling. The simplest option is a glacier with a top filling of ice, but at the same time, the arrangement of a water drainage system becomes more complicated. The glacier is loaded once a year.

The location of the glacier on the site should be selected taking into account its distance from the garbage pit, yard latrine and other sanitary facilities. A pit for arranging a glacier is dug in a rectangular shape with the most acceptable dimensions: length - from 1.5 m to 2.2 m, width - 2 m, and depth of the pit - from 2.2 m to 2.5 m. Wall cladding should be done with brickwork , which must be treated in advance with an antiseptic or rubble stone. The floor is laid with bricks or cobblestones.

Above the ground, the glacier is erected up to 3 m high and covered with a continuous plank sheathing. On the outside, the covering and walls should be covered with a layer of a mixture of crumpled clay and straw, and then covered with a layer of dry earth at least 30 cm thick. The outer layer of earth should again be coated with clay up to 3 cm thick and the entire surface should be covered with turf.

To increase the shelf life of ice in the glacier, it can be covered with matting, a layer of shavings or sawdust. To enter the glacier, you need to equip a vestibule with good wall insulation.