By installing a heated towel rail in the bathroom, consumers begin to enjoy the optimal temperature and dry things using this device. But sometimes it fails, namely, it begins to leak water at the junction. And such a problem requires an urgent solution, because in other situations you can ruin not only expensive repairs in your apartment, but also flood your neighbors below. And that is why we decided to talk about the common causes of the malfunction, as well as ways to eliminate it.

Main leak locations

Many problems require you to contact a specialist. But knowing the locations of leaks and the reasons that led to them will help you repair the device yourself. Most often, a heated towel rail leaks at the junction of the main water supply pipe and the body of the dryer.

- If a leak occurs at the joint points under the union nut , the cause usually lies in the weakening of the mounting sleeve (American). It is appropriate to use a wrench to the size of the section or an adjustable one to tighten it along the thread (without overtightening, which is very harmful).

- The coil in the bathroom is leaking in the same place if the sealing gasket is leaking . Sometimes they install a part made of the wrong type of material, for example, installing rubber for a cold pipe on a hot dryer. The wrong diameter and material are used. Elements made of hard and semi-hard rubber, fluoroplastic, silicone and paronite are suitable.

A leak may appear at the welding points towel rail. In this case, a metal strip clamp will help to temporarily solve the problem. It is welded to the pipe.

Valera

The voice of the construction guru

Ask a Question

For sealing, use FUM tape, flax, tow, or place a professional gasket inside the nut. It is located at the end of the fitting, pressed against this part. When screwing the union nut onto another fitting, the second surface of the seal is also pressed against the other end. Water does not penetrate between the surface of the nut (inner) and the two mating fittings.

If you additionally wind tape or tow, the stainless union nut will not reach the end of the thread. The tightening force will remain the same, but the tightness will suffer, because the seal is not pressed between the ends of the bushings.

Prevention measures

Preventative measures do not require much effort, but can significantly save the dryer owner’s nerves.

- Once a year it is necessary to tighten the nuts at the points of connection to the network.

- Regardless of the presence of a leak, the gaskets need to be changed every 3-4 years. It is better to do this if there is no leak than to drown your neighbors during working hours when no one is in the apartment.

- When installing a heated towel rail, it is advisable to provide a bypass line to avoid problems with disconnecting the riser if a leak occurs.

Among heating engineers, a heated towel rail is considered a consumable item. It is not as expensive as a radiator to require unnecessary efforts to repair it. Therefore, in approximately half of the cases, the leakage problem is solved by simply replacing the device. But there’s no point wasting a day if you can fix the heated towel rail yourself. Therefore, it is better to completely replace the device only after other methods have not worked.

Causes of heated towel rail leaks

Consequences of water hammer

The operating mode of a water dryer is often disrupted. If the device operates from a central heating line, it serves for a certain period, and the rest of the time the surface is cold. The humidity in the bathroom is regularly high and there is a lot of steam in the atmosphere.

Causes of leaks:

- When working according to the standard regulations, there is no problem, because the drops that appear on the surface of the pipe dry out. When cold, condensation . Droplets cause corrosion if this phenomenon is repeated regularly.

- Destruction does not spare the pipes; the joints of the elements also rust . Old coils suffer, but new products can also leak due to rust.

- Damage to the integrity of the pipe and connectors from mechanical impact. For example, an impact when renovating a bathroom.

- The leak problem may be due to wear of elements , for example, rubber gaskets at the joints.

- The device parameters must match the characteristics of the system to which it is connected. This applies to the pressure in the DHW pipe. Sometimes the cause is water hammer if compensators are not installed.

- Installation in violation of technology , non-compliance with the rules of location, connection of the upper and lower pipes. The collectors may not be routed correctly, for example, the ends may be installed crookedly.

- Defect in production . Low-quality equipment is rare, but such models immediately refuse to work and leak water.

There are many reasons why a heated towel rail drips in the bathroom. An internal simple hexagon, poorly tightened, will cause trouble and expose leaks. The water coil may constantly leak, and the cause will be stray currents. Such phenomena occur more often in old high-rise buildings and cause accelerated development of rust.

They respond better to such “ladder” type drying currents. They have a system to prevent electrochemical corrosion and rust. Experts recommend grounding the coil.

Why do leaks occur after turning off the hot water?

After turning off the water supply in the pipes, the entire installation cools down. After using a shower or taking a bath, water vapor forms in the air. When heated moist air comes into contact with the cold surface of the coil, condensation appears on the surface.

Single drops of water connect, become heavier, and begin to flow onto the floor. A leak appears. In fact, the coil does not flow, it is drops of condensate falling . It is advisable to prevent this phenomenon, since drops have a harmful effect and violate the integrity of pipes and connecting sleeves.

Combat condensation by organizing effective ventilation . To do this, install a fan in the bathroom hood to increase air exchange. Steam is removed through the vent, and dry air enters through cracks in the doors or windows. If there is no forced ventilation, and the air does not escape naturally through the vent, leave the door open after each use of the shower.

Valera

The voice of the construction guru

Ask a Question

If, after turning off the hot water, the heated towel rail drips, for the summer, wrap the coil pipes with insulation, for example, padding polyester, batting, polystyrene foam, glass wool polyurethane foam. In this case, hot steam does not react with the cold surface, and condensation does not form. The store sells special insulation for pipes; you need to choose the right thickness.

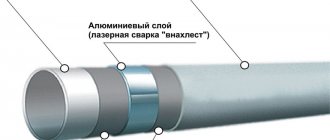

Connection

The most important conditions for the correct connection of this equipment is the correspondence of the diameter of the riser and the device itself, without narrowing and, of course, high-quality fastening.

Let's look at the main and most common mistakes when installing a heated towel rail. First of all, it is not recommended to install shut-off valves, since closing them stops the circulation of water throughout the entire riser, which the neighbors will not be too happy about. That is why shut-off and control valves cannot be installed on risers. You can install a jumper to regulate the operation of the device and run hot water when needed without disturbing your neighbors.

When connecting a heated towel rail, you need to pay attention to the bypass, because a lot depends on it. First of all, it is needed to maintain a certain rate of water circulation. In addition, using a bypass, you can disconnect the towel dryer from the entire system without harming your neighbors

In addition, using a bypass, you can disconnect the towel dryer from the entire system without harming your neighbors.

Repair tools and materials

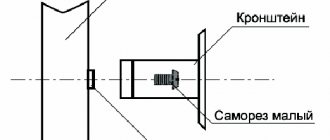

The set of tools depends on the type of dryer and the type of water pipes (metal-plastic, steel). You will need mounting brackets to secure the heated towel rail. Purchase sealing elements made of rubber or other material. If the device is an old type, you will need linen cloth, tow and lubricants for sealing. You need a heat-resistant sealant , sometimes cold welding.

Prepare the tools:

- an adjustable wrench or a set of open-end wrenches to fit the pipe cross-section;

- soldering iron, construction knife for cutting polypropylene pipes (if the line is made of the appropriate material), hammer, pliers.

conclusions

To avoid leaks, as well as frequent breakdowns of the heated towel rail, it is necessary to handle repair work responsibly. If you don’t know how to cope with a particular task, there is no need to improvise; it is better to invite a specialist who will tell you how to cope with this or that task. When a professional does the work, the risk of leakage is significantly reduced, and heated towel rails serve their owners for a very long time.

We wish you that your heated towel rails rarely fail, and that the breakdowns are completely insignificant.

Fixing leaks yourself

The repair method depends on the cause of the leak. Before work, close the shut-off valve at the entrance to the home. You can work with drying from the water supply for a whole year by turning off the tap. Coils that are connected to the heating system are repaired only in the summer after water is drained from the pipes.

Gasket wear

The layer of old paint is removed from the union nuts. To unscrew, use an adjustable wrench. The tool has adjustable jaws, so the cross-section is selected using a screw drive.

Further work order:

- Disassemble the threaded connection and remove the old gasket that has worn out. You cannot trim or straighten an old element with a knife or scissors in order to reuse it.

- An elastic part is placed between the ends of the pipes, and a union nut is screwed on top.

- Turn on the water supply to the heated towel rail and check the tightness of the connection.

If there is no factory element, take a piece of old thick rubber, put the old gasket as a pattern and cut it off after drawing the contours with a ballpoint pen.

The union nut is loose or missing altogether

There are times when the seal has recently been replaced, but the connection is still leaking. In this case, tighten the nut using an adjustable wrench. Make one turn, check for leaks, then add half a turn at a time. If you overtighten, you can damage the seal.

The procedure for installing a union nut if couplings are used and there is none:

- The depressions between the threaded turns are filled as much as possible with FUM tape or tow is placed on solid oil. It is not easy to determine the required volume of tape, so it is better to take flax or tow. If you wind a little, the liquid will flow out through the pipe, a large layer will lead to cutting when screwing, so it will flow again, it is better to wind in 1 - 2 layers.

- A part of the strand, thick according to the depth of the thread, is separated from the skein and twisted.

- Stepping back 5–6 cm from the edge, wind it clockwise around the edge, unroll it near the end and make a second winding counterclockwise.

- The remainder is wound from the center to the end at the end.

- The top of the tow is coated with sealant until completely saturated.

First, screw the coupling with your fingers, then tighten it with a wrench.

A rusty area or leak under a weld

Sometimes a through hole is found under the coupling due to corrosion. In this case, it is necessary to dismantle the coil and restore the damaged area by welding . It will be necessary to replace the damaged section or the entire dryer (depending on the size of the damage).

Under the influence of stray currents, pinpoint damage to the walls appears on heated towel rails that are not connected to the ground. If the leak is detected by small drops, deal with it yourself.

Operating procedure:

- Take wire to seal fistulas.

- Turn off the water in the dryer, sand the surface, and degrease it with an acetone solvent.

- Use a gas torch to heat the damaged area, press a wire against it, which melts and seals the hole.

- Excess material is immediately removed from the pipe without waiting for it to harden.

Valera

The voice of the construction guru

Ask a Question

If there is a leak at the welding site of the coil, you can install a clamp or use cold welding before the mechanic arrives. The temporary measure cannot be repeated indefinitely, so the heated towel rail is replaced with a new product.

Prevention measures

Preventative measures do not require much effort, but can significantly save the dryer owner’s nerves.

- Once a year it is necessary to tighten the nuts at the points of connection to the network.

- Regardless of the presence of a leak, the gaskets need to be changed every 3-4 years. It is better to do this if there is no leak than to drown your neighbors during working hours when no one is in the apartment.

- When installing a heated towel rail, it is advisable to provide a bypass line to avoid problems with disconnecting the riser if a leak occurs.

Among heating engineers, a heated towel rail is considered a consumable item. It is not as expensive as a radiator to require unnecessary efforts to repair it. Therefore, in approximately half of the cases, the leakage problem is solved by simply replacing the device. But there’s no point wasting a day if you can fix the heated towel rail yourself. Therefore, it is better to completely replace the device only after other methods have not worked.

Preventive measures

If the device is hung with an incorrect slope, it is leveled so as not to disturb the direction of the coolant flow. To improve water quality and reduce hardness, install a filter at the entrance to the bathroom . Be sure to arrange effective ventilation.

Electric heated towel rails are the best option, especially those running on oil. In principle, there cannot be any water leakage in them. They buy coils of any type only in trusted construction stores, choosing well-known brands.

Getting rid of corrosive changes

Long-term use of towel dryers is accompanied by the natural formation of rust. Corrosive changes affect not only the pipe elements of the device itself, but also their connections, which is caused by temperature changes and high humidity levels.

For the purpose of prevention, periodic checking of the device for the presence of rusty spots is used, which, under the influence of water hammer or increased pressure inside the water supply system, cause a strong breakthrough and an emergency situation. In this case, you will need to replace all rusted elements or install a new device

Of no small importance is the installation of hydraulic protection at the inlet group of the coil

It's leaking from under the American gasket, there is no new gasket, what should I do?

The American has leaked, it is leaking from under the gasket, there is no new gasket, what can be done in this situation, how can we stop the leak, at least according to a temporary scheme?

American women made in the basement are in demand, and since they are naturally cheaper, no one is protected from such a purchase.

It’s good when the ring is too much and protrudes from the groove; there’s simply no way to overtighten it; It’s worse when it’s “recessed” - it ends up leaking.

According to the “Need for invention is cunning” system, there is a way out. You just need to enlarge the ring = reduce the depth (volume) of the groove.

It’s not bad when you have a thin ring of a suitable diameter, just put it on the bottom, and then your own, but this is ideal. You can cut a ring out of cardboard and place it under the original one; being in a dry place (under the ring), it will serve until the next disassembly. Sometimes even the thickness of a notebook sheet is enough to eliminate a leak.