Thermal insulation of a home needs to start from the foundation, and the best material for this is polystyrene foam. Insulating the foundation with polystyrene foam is a 100% proven option, + the video will help you master the technology. And although this method is not the cheapest, it is very effective, and also quite simple to implement.

Foundation insulation with polystyrene foam

Is it necessary to insulate the foundation?

In addition to the weight of the house, the buried part of the building is subject to horizontal and vertical loads during soil movements that occur due to seasonal freezing of the soil. With the onset of cold weather, when water turns into ice, the soil swells, affecting the foundation from below and from the sides. Therefore, the building rises, and in the spring, when the ice melts, it lowers. As a result, cracks form on the foundation and, as a result, on the walls of the house.

Thermal insulation of the foundation with expanded polystyrene in combination with an insulated blind area eliminates heaving, since the soil near the house is protected from freezing. Therefore, for low-rise buildings without a basement, shallow strip and slab foundations can be laid above the freezing point of the soil. This reduces construction costs by 30%.

Insulation is also necessary to:

- protect concrete from destruction due to temperature changes;

- keep warm in the basement and first floor rooms;

- protect utility lines from the cold;

- prevent the appearance of dampness, which is formed when moisture vapor condenses on the walls.

When the soil freezes, external factors affect the foundation, as a result of which cracks and dampness may appear in the basement

Bridge of Cold

A cold thermal bridge is a structural element of a building with low thermal resistance.

Masonry elements and monolithic structures are conductors of cold into the building, as they contain concrete, mortar and metal in their composition. These materials cool much faster than others, and along them, like bridges, heat leaves the building. The more such bridges are in direct contact with the external environment, the lower the thermal protection efficiency of the building.

The lower the energy efficiency of the structure, the greater the energy consumption will be. Heating costs will increase. At the same time, cold bridges contribute to the formation and accumulation of water condensate. This affects the appearance of mold and various fungi. Condensation also gradually leads to corrosion and destruction of building elements.

What is expanded polystyrene

Expanded polystyrene is a heat-insulating material based on styrene, which is produced in three types:

- Unpressed polystyrene foam with a density of 15 - 50 kg/mᶾ called polystyrene foam. Due to the low price it is very popular. The structure of high-quality material consists of granules of the same size.

- Pressed insulation is obtained after hot pressing of polystyrene with the addition of gas-forming agents. Due to the cellular structure, heat and sound insulation characteristics are improved.

- Extruded polystyrene foam (EPS) is made from molten polystyrene, which is foamed with a mixture of freon and carbon dioxide. Then it is pressed through the nozzle of an extrusion unit. After cooling, the material acquires a monolithic fine-porous structure with cells measuring 0.1 - 0.2 mm. Expanded polystyrene slabs for foundation insulation are produced in sizes 120x60 cm with a thickness of 2 to 15 cm. To simplify joining, tongue-and-groove fasteners are made on the edges.

The tongue-and-groove system simplifies the installation of polystyrene foam and also minimizes cold bridges

Cost of work per m² and material

Installation of expanded polystyrene by professional builders will cost 250–700 rubles/m² (depending on the type of fastening, brand and thickness of the EPS).

If you need to apply a reinforcing or waterproofing layer, apply decorative plaster or paint surfaces, the cost of the work will increase (from 400 rubles per 1 m² and more).

In addition to paying for the services of the craftsmen, you need to take into account the price of the material. Penoplex and TechnoNIKOL (10 cm) cost 1300-1700 rubles per package (4 slabs, 2.7 m²) or 450-600 rubles. for 1 m². There are cheaper options - from 250 rubles. Together with all materials, installation of 1 m² can cost 1,800 rubles or more.

What is the advantage of extruded polystyrene foam

In order to save money, you should not choose the method of insulating the foundation with foam plastic for several reasons. If moisture gets into the gaps between the cells, the insulation will begin to crumble at the first frost. The foam will crumple under soil pressure, as it can withstand a compressive load of only 100 - 200 kg/m². Mice love to make their burrows in this kind of insulation. The only way to eliminate the shortcomings is to protect the foam with brickwork. But then the price of insulation will be several times higher than the option with EPS for the foundation.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

Insulation calculation

You can determine the thickness of extruded polystyrene foam for the foundation to buy using an online calculator or calculate it using a simplified formula:

H = (R – h/K1)K2.

Where:

- h is the thickness of the insulation;

- R - heat transfer resistance (average value for Russia 3.5 m²k/W);

- H - foundation thickness;

- K1 - concrete heat transfer coefficient (average value 1.5 W/mk);

- K2 - the heat transfer coefficient of polystyrene foam is indicated on the packaging.

To obtain a more accurate result, instead of averaged data, substitute values for a specific region into the formula, which are easy to find on the Internet. The required number of slabs is determined by dividing the insulation area by the area of one slab. To the result obtained, add 10 - 15% for waste during fitting. For two-layer insulation of the foundation with extruded polystyrene foam, the number of slabs is doubled with a corresponding decrease in thickness. For example, you need 100 slabs 10 cm thick, which means you buy 200 pieces 5 cm thick.

Final stage

*

If part of the insulation protrudes from the trench, damage can be prevented by using a reinforced mesh. It is installed on the top insulation ball using the gluing method.

Next, you should treat the insulating layer with any finishing material. If the base structure is located flush with the soil, installation of the mesh and final finishing work will not be required. All that remains is to close the trench space with sand, earth or expanded clay, which also has thermal insulation properties.

How to insulate the foundation from the outside with polystyrene foam

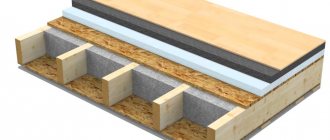

Work on insulating the foundation of a house from the outside with extruded polystyrene foam is easier to carry out during construction. However, all stages can be performed on an old building if you dig a trench around the perimeter. The bottom of the shallow slab and strip foundation is insulated with polystyrene foam with a density of 45 kg/mᶾ, and the walls - 35 kg/mᶾ.

Waterproofing

The old foundation is cleaned with a stiff brush to remove adhering soil and loose pieces of concrete. Then rinse with water from a hose. After drying, a layer of bitumen mastic 4 mm thick is applied to the foundation walls with a roller or brush, carefully filling the cracks and irregularities.

The second layer of waterproofing can be made from roofing felt, but it will be more reliable from rolled material of the Technonikol brand. The sheets are overlapped vertically. The rolls are cut into sheets and rolled into tubes. The end of the tape is heated from the back with a gas burner or blowtorch and glued to the bottom of the foundation. Then the tape is rolled out to the top while simultaneously heating. Each heated part is carefully smoothed so that no air bubbles remain under the canvas.

Proper waterproofing will protect the foundation from groundwater

If your budget allows, you can invite specialists with special equipment to apply a waterproofing coating made of liquid rubber. The work will be completed in 1 shift. Self-application of liquid rubber with a spatula will take a long time.

Basement insulation with penoplex

Technology for insulating the base in the same plane as the walls of the house:

- Marking. Since the insulation boards should be several centimeters higher than the waterproofing layer, horizontal markings should be made with a pencil along the entire surface of the wall.

- Cleaning the outside of the wall. The wall surface is pre-prepared for gluing with polystyrene foam. To do this, it is thoroughly cleaned from the outside of dust and dirt. After this, the surface is primed. After the primer has dried, you can proceed to the next step.

- Connecting slabs. Pasting the walls of a house with polystyrene foam is done using special glue, starting from the corner. The slabs are marked and cut with a sharp wallpaper knife.

- Applying glue to the wall and slabs. Using a special notched trowel, the adhesive is applied to the surface of the base. Pre-prepared fragments of slabs are smeared with glue and attached to the wall, the joints between the slabs and the ends outside the house are carefully sealed.

- Next, using a hammer drill, dowels are drilled and inserted, followed by driving in nails. After covering the entire surface of the outside of the house with slabs, a special primer layer is applied to provide the basis for all subsequent layers.

- Strengthening the slope angle. A metal corner is attached around the entire perimeter of the wall. For installation, the same adhesive is used as for the slabs.

- Installation of reinforcing mesh. The reinforcing mesh is pre-cut to the size of the slabs, lubricated with adhesive and glued on top of the polystyrene foam. The technology for strengthening the reinforcing mesh is the same as for installing the corner.

- Finishing work and installation of drip linings. Materials for external work are used to putty the base area. It is left to dry and primed again followed by painting. To prevent moisture penetration, flashings are installed.

Technology for insulating the base with polystyrene foam

If coating defects occur, they can be easily eliminated by re-priming and painting. The technology of thermal insulation with foam plastic is the same as that of penoplex.

Does it make sense to insulate from the inside?

Internal foundation insulation is justified in cases where external insulation is ineffective or impossible. It is carried out during finishing or major repairs of the basement and ground floor, to increase the temperature in recessed rooms and insulate the floor of the first floor. However, the foundation will not be protected from damage due to freezing, which will lead to a reduction in service life.

The insulation is glued directly onto the concrete and additionally secured with mushroom dowels. After completing the installation of all the plates, the insulation surface is covered with a layer of glue 2 - 3 mm thick. Without waiting for complete drying, a fiberglass mesh is pressed into it with a spatula. Then holes are drilled for the dowels and the slabs are secured. After drying, the surface is treated with coarse sandpaper and a layer of cement putty is applied.

In basements, not only the walls, but also the ceiling are insulated.

To insulate the foundation with extruded polystyrene foam, builder qualifications and special tools are not required. Therefore, all work can be done independently. The result in the form of warm floors and reduced fuel costs will please you in the first winter.

Features of foam

Polystyrene foam or expanded polystyrene is a slab of small balls. This structure allows you to retain a large amount of air inside the material. It is this that has the best insulating properties (except for inert gases). Air is used in all heat insulators, in the manufacture of windows, etc.

The thermal conductivity of polystyrene foam is comparable to that of mineral wool and extruded polystyrene foam. The thickness is assumed to be almost the same.

But when choosing the material in question, it is worth knowing that it is afraid of the simultaneous action of moisture and cold. Manufacturers may be silent about this point, but when the liquid between the balls freezes, the foam crumbles into separate particles. Without proper waterproofing, such insulation will not last long.

The advantages of polystyrene foam include:

- accessibility and affordable cost;

- ease of cutting and installation;

- good thermal insulation performance;

- safety for humans (except in cases of fire, therefore it is applied only outside the building).

Expanded polystyrene is not recommended for use if there is a risk of flooding. The reason is poor resistance to moisture. At the same time, the balls themselves do not absorb liquid and are not afraid of it, as many manufacturers indicate. But the connections between them are easily destroyed by the action of water and sub-zero temperatures.