Home / Boilers

Back

Published: 12/03/2019

Reading time: 5 min

3

1432

Water heaters are used both in apartments and in private houses. Their use allows for uninterrupted supply of hot water regardless of the presence of a centralized network.

One type of water heater is an indirect heating boiler. The boiler device includes a heat exchanger that is connected to an external heat source. This allows you to heat a large volume of water in a short time.

- 1 Types of boilers for heating water

- 2 Design of water heaters 2.1 Electric storage

- 2.2 Electric flow

- 2.3 Gas water heaters

How does a storage water heater work?

A storage water heater in its simplest form is a metal tank of a certain capacity, a heat source, a control unit and several pipes through which cold water flows in and hot water comes out.

If the heat source is a gas, solid fuel, electric or other boiler, as well as a solar collector, heat pump, etc., use a water heater with a tubular heat exchanger inside. The coolant moves through the tubular heat exchanger, mostly water. The coolant transfers heat to the heated water, cools and is removed from the tank for heating.

A tank is a container strong enough to withstand the pressure of the heated water it contains. Also, the tank is usually protected from corrosion in various ways if it is made of steel sheet. In order to save heat, storage water heater tanks are made as thermally insulated as possible.

The control and monitoring unit provides a set of sensors and devices that allow you to select and control the temperature of the heated water, the temperature of the supplied coolant, as well as the flow of cold and hot water. Using special devices, the fullness of the tank with water is monitored. If the tank is empty or not filled enough, the water heater stops working.

Types of electric storage water heaters

Boilers are divided into those made of stainless steel or steel. The last option is covered from the inside with glass fiber and enamel. Such an electric storage water heater is more expensive than its stainless steel counterpart, but its service life is longer. According to the method of arrangement, devices are divided into:

- horizontal;

- vertical.

There are three types of boilers:

- cylindrical;

- flat;

- rectangular.

Due to their height, narrow electric storage water heaters can provide consumers with a large volume of hot water. In addition, the flat shape saves space. By type of internal element there are:

- Long-lasting storage electric water heaters with dry heating elements. Then it is placed in a special sealed box and is considered the most practical.

- A device with a wet sample heating element. Then such a heating element is in direct contact with the aqueous environment. Because of this, the device does not last long because it is susceptible to corrosion.

Pros and cons of boiler-based heating

Heating obtained from a water heating tank has its advantages and disadvantages.

| pros | Minuses |

| No special tools, skills or engineering education required for installation | The installation process, in terms of labor resources, is quite expensive |

| Boilers are much cheaper than heating boilers | The unit is constantly in operating mode |

| Thanks to the thermal insulation layer, water heaters spend less derived heat than space heaters | The water supply must be constant, which can cause corrosion to occur prematurely. |

| It is possible to use wall or ceiling mounting type, so they take up little space | There is no required power to heat a large area |

| The amount of resources consumed is scanty, electrical energy consumption is minimal | |

| Allows you to independently regulate the temperature |

Heat accumulator for heating boilers: design features and connections

The purpose of using this unit is to collect and store coolant heated to a certain temperature for its further transfer to the system when the need arises. Being connected to the water circuit of the room, a battery of this type ensures temperature maintenance even if the heat source is turned off.

Helpful advice! If water heating of the house is produced from electricity, registration of a night tariff with reduced rates for the cost of 1 kW/h. will save you money on bills. It will be enough to heat the heating system at night, and the heat accumulator will work during the day.

The heat accumulator is used to maintain water heated to a certain temperature

This device also performs other functions. The main ones include:

- Reduces fuel consumption by almost a third. At the same time, the efficiency of the fuel installation increases;

- protects heating devices from overheating by collecting excess heat;

- heats water for the domestic hot water system. That is, in fact, this is one of the types of indirect heating boiler. The price of this unit varies within a very wide range: from 13 to more than 300 thousand rubles;

- the heat storage tank can connect several heat sources operating on different types of energy or fuel;

- The design of the device allows for the selection of coolant at different temperatures.

Design of a heat accumulator and rational connection of external devices

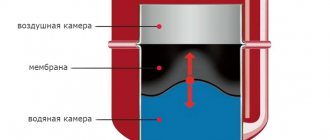

The main part of this unit is a cylindrical stainless tank filled with a liquid characterized by a high heat transfer coefficient. Its piping is carried out with heat-insulating material. In combination with the installation of a top jacket, this design solution increases the cooling time of the heat accumulator. Inside the cylindrical container there are 1 to 3 heat exchangers. The number of coils is determined by the capabilities and needs of the homeowners.

Heated water from solid fuel or gas boilers enters the cavity of the battery tank from above, and the cooled liquid settles closer to the bottom and is pumped back into the boiler for heating.

Diagram of a heat accumulator with the ability to connect to alternative energy sources

The lower compartment usually has a temperature of about 35-40°C. Therefore, it is advisable to connect it to a heated floor system. The temperature of the middle part is 60-65°C. Therefore, heating devices should be connected to it. The top of the tank is connected to the hot water supply. The water temperature there reaches 80-85°C.

Operating principle of boilers

Electric water heaters and indirect heating boilers heat water using heating elements or coils through which the coolant flows. The water in the tank is under pressure and is supplied through a supply pipe - it is connected through a return valve to the water supply. After plugging in the water heater (or opening the coolant supply), you need to set the desired heating temperature and wait until the desired temperature is reached.

Typically, cold water enters the tank from below, and as it heats up, hot water rises up, from where it enters the hot water supply.

Temperature control is carried out using a thermometer. As soon as the water heats up, the device will automatically interrupt its heating. Further, the temperature will be maintained by thermal insulation. As soon as you open the tap, hot water will flow out of it. The missing volume will be instantly replaced with cold water. As soon as the temperature in the tank drops below the permissible level, the heating will automatically turn on.

Where can I buy

You can purchase water heating equipment as quickly as possible at your nearest specialized store. The optimal option, in terms of price-quality ratio, remains purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| Photoelectric water heater, 220-240 V, 3000 W | TINTON LIFE multi-tap electric water heater with tap, LED display | Electric water heater, touch HYUNDAI |

| Instant water heater 3000W | 8L Stainless Steel Tankless Water Heater | FRUD Instant Heating Electric Faucet |

Correct selection of a water heater with indirect heating

The indirect heating boiler (IBC) is a highly efficient device with modern automation systems for thermal processes, used to produce hot water T up to 65 C.

Externally, the BKN is similar to a traditional electric water heater, although its modern modifications have a more ergonomic rectangular shape.

The source of thermal energy is a heating boiler that runs on any energy source from waste to electrical energy.

The basic element is a steel or brass coil-type heat exchanger with a large heating area in a relatively small volume of a storage tank coated with a protective enamel layer.

Before installing the BKN, it is necessary to correctly select it for the actual operating conditions: the source of heat supply and the volume of water use for DHW services.

Basic parameters for choosing a connection diagram for an indirect heating boiler:

- Working volume in liters. In this case, the terms “total volume” and “working volume” are different, since the coil heat exchanger takes a certain part of the tank, so you need to choose according to the working indicator.

- External heating source, fuel type and coolant outlet temperature.

- Thermal power of an external source. The boiler must provide not only the heating load, but also DHW. So, to heat a volume of water of 200 liters, a reserve power of at least 40 kW will be required.

- Material of the working container: coated with enamel, glass ceramics and glass porcelain, stainless metal or heat-resistant plastic.

- Thermal insulation - to protect the BKN from heat losses, it is best if polyurethane is used as thermal insulation.

- Protection and regulation system.

Important Features

In addition to choosing the geometric and thermal characteristics of the BKN, it is necessary to take into account many parameters so that the thermal circuit for connecting an indirect heating boiler to a gas boiler is as efficient as possible.

To do this, the user must fulfill certain conditions:

- Choose the optimal location; experts say that the location of the BKN should be as close as possible to the boiler.

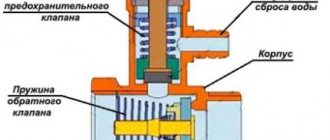

- To provide protection against thermal elongation of the structure, to do this, integrate a membrane hydraulic accumulator with a volume of 10% of the working volume of the boiler into the BKN circuit at the DHW outlet from the device.

- Before connecting the boiler, each supply/discharge line for the heating and heated medium is equipped with ball valves.

- To protect against backflow, a check valve is installed on tap water.

- Water purification is carried out with the installation of a filter before supplying tap water to the BKN.

- The installation of the BKN wall structure is carried out on permanent walls with preliminary treatment with fireproof materials.

- The installation of the BKN is carried out above the level of the boiler unit or at the same level as it.

Selecting tank volume

In the trading network today there are many offers for BKN devices, both domestic and foreign manufacturers, with containers of round and rectangular cross-section, floor and wall mounting. And if for electric heaters the most popular are models with a volume of 80 to 100 liters.

For BKN, more powerful options are used, ranging from 200 to 1500 hp. This is due to the fact that many owners use this design to create a storage tank in order to create a uniform load on the heat supply source at night. In this scheme, water for domestic hot water is heated at night and consumed during the day.

The size of the working tank is chosen taking into account the need to provide all family members with hot water. There is a formula for calculated water consumption.

In practice, the following data is often used:

- 2 users – 80 l;

- 3 users – 100 l;

- 4 users – 120 l;

- 5 users – 150 l.

The dimensions of the BKN are also important to consider during installation. For wall mounting, installations with a tank working volume of up to 150 liters can be used, and with larger sizes it is allowed to be installed only with floor placement

The installation site must have free access so that the piping can be properly completed and auxiliary equipment in the form of shut-off and control equipment, safety valves, air vents, pumps and a hydraulic accumulator can be placed.

Main characteristics

The main technical characteristics of the boiler are:

- Case material (enamel, stainless steel, plastic).

- Type of placement (wall, floor, vertical, horizontal).

- Rated voltage of the electrical network (220 or 380 V).

- Water pressure (especially relevant for instantaneous water heaters). If the pressure in the water supply is low, the heating element may deteriorate.

Horizontal water heater model

- Volume of the tank.

- Weight.

- Overall dimensions (depth, width, height).

- Maximum power.

- Availability of water temperature regulator, magnesium anode.

- Thickness and material of the thermal insulation layer (the most highly effective is polyurethane foam).

- Heat losses (directly depend on the thermal insulation layer; the thicker it is, the lower the losses and the more economical the water heater).

- Type of control (hydraulic, electronic, LCD display).

All characteristics of the water heater are indicated in the passport, so when purchasing you need to read it carefully.

Gas boiler

The undoubted advantage of gas boilers is that hot water begins flowing into the tap almost immediately after it is turned on. You don't have to wait.

gas boiler

How does a gas instantaneous boiler work?

All the main elements of a gas instantaneous boiler are mounted inside a durable metal casing. The water coming from the water supply line passes into the heat exchanger, under which the gas burner is located. The device is quite simple at first glance, but in order for the gas heater to work without accidents, the entire system must be equipped with rather complex automatic devices.

Immediately after you open the hot water tap, a valve opens in the boiler automation, which opens the gas supply. In good models, the incoming gas is ignited automatically, but in more modest ones you will have to press a special button.

The combustion of natural gas produces combustion products that are removed through the chimney. There are options for gas boilers with closed combustion chambers, in which combustion products are removed through a metal coaxial hose.

gas boiler connection

As a rule, gas heaters are installed in houses connected to main gas supply systems. They are certainly the leaders in terms of price-quality ratio under such conditions. Gas instantaneous boilers have rather modest dimensions. The low cost of gas consumed to heat water allows them to be called a successful economical option. Thus, the cost of heating water in such a device is approximately three times lower than in its electric counterpart. Apparently as a result of this, and also because of the need to supply such devices with reliable automation, the cost of the gas water heater itself is higher than that of an electric boiler.

A gas instantaneous boiler recommended for installation in an apartment can supply up to 17 liters of hot water per minute to the tap.

How to choose a gas instantaneous boiler

The first characteristic that you need to evaluate when choosing such a device is its power. As a rule, manufacturers divide gas heaters according to the number of liters of water that the device can heat per minute.

Therefore, it is necessary to soberly assess the possible consumption of hot water in your apartment, especially if it has several bathrooms. With low productivity, simultaneous morning washing will turn out to be somewhat uncomfortable. Typically, the temperature of the water supplied to the tap is regulated in a modern gas boiler using a thermostat.

In this case, the system can automatically increase power as the number of consumption points increases. So, if you are basking in the shower, then when you turn on the hot tap in the kitchen, the system will automatically increase the burner fire and the volume of heated water.

It is also important to choose the type of fire ignition in your gas boiler. If earlier, to ignite the burner, you had to use considerable sleight of hand, operating a tap and matches, now boilers equipped with a piezo ignition system allow you to ignite the fire under the burner by simply pressing a button

There are also systems with automatic ignition, activated by the flow of water. But if you are away for a long time, it is better to turn off such a system to avoid troubles. Although very high-quality devices are equipped with a multi-stage protection system that will turn off the gas in any emergency situation, for example, excessive heating or fire extinguishing, a sharp decrease in gas pressure or stopping the water flow.

A system with “smart” electronic ignition can also operate on built-in batteries; such a column can also significantly save gas consumption, reducing it by 15 percent. The HydroPower ignition system has no electrical power at all - the piezo ignition in it is powered by a small water turbine, which begins to generate current when a flow of water enters it.

How to install a gas instantaneous boiler

Due to the fact that geysers are considered high-risk objects, they are subject to special installation requirements. Moreover, they include not only requirements for equipment, but also requirements for the room in which the device is installed. The installation of a gas boiler itself is usually entrusted to a specialized company. During installation, a gas pipe, cold water supply and hot water supply pipelines, and, in some cases, an electrical power cable are connected to the device.

Tips for choosing a boiler

Like any household appliance, a boiler has its positive and negative sides.

The most important advantage of this technique is that under any external circumstances there will always be hot water in the house. For small towns and villages where there are problems with hot water supply (or it is completely absent), this is the only way out.

When choosing a water heater, you need to consider the advantages and disadvantages of each of them. For example, by installing a flow-through boiler, you will not have to wait for the hot water to warm up; its quantity will not depend on the volume of the tank. But you will need a powerful hotel machine and a power cable to connect the device, and electricity consumption will also increase significantly.

Boilers with different tank volumes

A storage boiler consumes less electricity, but only produces a certain amount of hot water. And its main drawback is that it takes up a lot of space.

When choosing a boiler, you must adhere to certain criteria.

Purpose of installation

The main criterion when purchasing a water heater is the purpose of its acquisition:

- have a reserve in case of shutdown of hot water supply;

- instant heating of water for washing dishes or taking a shower;

- constant supply of apartments (houses, cottages) with hot water.

External dimensions and volume

You must immediately decide on the installation location of the water heater. The equipment is large and cannot be placed or hung anywhere. When selecting external parameters, we must not forget about such an important criterion as the volume of the boiler. This value depends on the number of people living in the house. The equipment of the bathroom also plays a certain role, that is, what is used for bathing - a shower or a bath. Using a shower is much more economical; this type of bathing consumes about 15-20 liters of water per person. In the bathroom, for such a procedure you will need 50 liters.

Water consumption table

If a boiler is needed only to provide hot water for washing dishes, and nothing else (without bathing), then a device of 15-20 liters will be sufficient. This type of water heater is usually installed in the kitchen directly under the sink.

Power

Power plays an important role when choosing a water heater. The more powerful the heating element (from 1 to 6 kW), the faster the water will heat up, but will the electrical wiring in the house withstand such a load? If it is new and capable of withstanding a load of 6 kW, then the power of the boiler can be easily selected based on the needs and number of residents. In apartments with old electrical wiring, the maximum you can count on is a 2.5 kW water heater.

Tank inner lining

In cheap boilers, the internal coating of the tank is made of enamel or glass ceramics. Expensive models use titanium coating or stainless steel. When choosing, a person proceeds from his financial capabilities, but a high price, as a rule, guarantees quality and durability. In the case of household appliances, there is no need to skimp.

Manufacturers provide a long warranty period for boilers with an internal stainless steel tank.

It is recommended to check the quality of the water heater by weight. The heavier it is, the better it will resist corrosion due to the greater wall thickness.

Internal coating of the tank (stainless steel)

What else should you pay attention to?

- The boiler's degree of protection against moisture and dust (IP) must be at least 23. If the water heater is installed in a bathroom, sauna, bathhouse, a more protected model with IP 44 will be needed.

- It is worth giving preference to models with a dry tubular electric heater (TEN). Lack of contact with water not only prevents the appearance of scale, but also reduces the risk of electric shock, since the heating element is placed in a sealed glass.

- When purchasing a boiler, be sure to ensure that it contains a magnesium anode. Models with overheating protection, power-on indication, and accelerated heating function will be safer and more comfortable in terms of operation.

- When choosing a boiler for a summer house where no one lives in winter, you should give preference to models with a freeze prevention mode.

- When purchasing a water heater, be sure to inquire about its thermal insulation layer. The recommended thickness is at least 35 mm (the thicker, the longer the temperature will be maintained). The highest quality material is polyurethane foam (much better than foam rubber).

Advantages when choosing a boiler

Design features of an indirect boiler

The indirect type boiler is a tank made of stainless steel. The inner walls of the container are covered with a special material, which not only protects the surface of the water heater from corrosion processes, but also reduces the concentration of harmful bacteria and microorganisms.

Diagram of an indirect type boiler with a single-circuit coil

Otherwise, a boiler of the simplest design consists of the following components:

- heat exchanger - a spiral pipe or smaller tank. Depending on the volume of the tank, it can be located in its upper and lower parts;

- inlet pipe - a fitting at the bottom of the device for supplying a pipe with cold running water;

- outlet pipe - fitting for connecting the hot water outlet pipe;

- magnesium anode - additional protection of the tank walls from corrosion processes;

- internal thermometer - a device for measuring the temperature of heating water;

- thermostat - a device that prevents equipment from overheating;

- control unit - rotary knob with divisions for setting the heating temperature;

- thermal insulation - a layer of insulating material that helps maintain the desired temperature of the heated water;

- outlet - valve for draining stagnant water;

- revision - a large diameter hole intended for maintenance, repair and modernization of the boiler.

The design of new tank models may differ slightly and have a number of modifications from manufacturers, but in general, any indirect type boiler consists of the listed elements.

Operating principle of the boiler

An indirect type boiler is part of the heating system and is connected directly to a gas, electric or solid fuel boiler, which heats the coolant using the energy released when fuel is burned.

The coolant circulates through the DHW system and passes through a heat exchanger located in the indirect heating boiler. Due to the release of thermal energy from the hot coolant, the cold water that fills the device’s tank is heated. From it, heated water is transported through an outlet through a pipe to the bathroom, kitchen and other rooms with plumbing equipment.

An indirect type boiler can work with any type of heating boiler

When the heating boiler is turned off or switched to an economical operating mode, the coolant quickly cools down. Thanks to the design of insulating the tank walls with urethane foam, the water in the tank cools very slowly. This allows you to use the entire volume of warm water for several more hours.

Boiler connection and maintenance

The boiler is connected to a circuit that is parallel to the heating circuit. A circulation pump is installed there to ensure that the hot water supply is independent from heating. To connect the boiler to a gravity heating system, it is necessary to use a bypass in front of the heating devices, but after the boiler.

Boiler connection

Maintenance should be performed before and after the heating season. Servicing boilers should only be done in the presence of specialists from service centers, since you will need special equipment to remove scale.

Nuances of operation

Flow-through water heaters attract many consumers because they have no restrictions on the volume of hot water they can use; it is especially convenient to install it in a shower stall - take as many water treatments as you like.

Not everyone knows that installing such a device requires responsibility, because the product is a high-power device and requires a separate connection line. Installation of the line and connection of the product can only be carried out by specialists; if you install it yourself, you can turn off the power not only to your apartment, but also to an apartment building.

In order for the instantaneous water heater to serve for a long time and not upset you with frequent breakdowns, you must strictly follow the manufacturer’s recommendations and pay attention to the following points:

- installation of the product should be done near the place of use to reduce thermal energy losses;

- if there is very hard water in your region, install special protective filters to protect internal parts from scale;

- Do not install the product in an unheated country house under any circumstances;

- in the bathroom, place the device in such a way that splashes cannot get on the body;

- at low pressure, use the product at medium temperature - otherwise the automation simply will not turn on.

Before starting for the first time, carefully follow these steps.

- Check the availability of water in your home water supply and its pressure level - it should be sufficient. If the pressure is weak, you will have to stop using it until better times.

- When the water flow is low, set the required temperature using the buttons on the control panel.

- After you finish taking a shower, you need to turn off the tap and unplug the product.

Before you go to the store for your long-awaited purchase, check the quality of the wiring in the house: old houses are designed for only 3 kW/h per apartment, so to connect you will have to change all the wiring to the electrical distribution panel. Users who live in new multi-storey buildings, and even with electric stoves, are lucky: here the allowance for an apartment is higher and starts from 10 kW/h, but this does not mean that you can simultaneously turn on several electrical appliances at once.

In conclusion, a few words about the domestic electric instantaneous water heater Etalon Copper 350 of a combined type: faucet and shower hose with nozzle. The weight of the structure is only 2 kg, dimensions - 240x160x95, power up to 3.5 kW, maximum heating temperature of the water flow - 65 0 C, productivity - 3.5 l/m. In terms of its characteristics, it is not inferior to foreign analogues and is inexpensive - 2,440 rubles, and components will be much easier to find in case of replacement.

Do-it-yourself electric boiler for the heating system

The price of industrial modifications of heating water heaters is very high - from 12,000 to 70,000 rubles. and higher. Therefore, their alternative can be a heater made in-house. For this case, it is allowed to use an arbitrary steel tank of increased strength, with parameters corresponding to the design ones.

To wire the heating circuits of a homemade water heater, you will need the following parts:

- Tank. It would be preferable to place an order from a specialized organization for a device made of non-corrosive steel or assemble it yourself. It is necessary to place holes on the body in order to solder the inlet/outlet pipes.

- Coil heating element, the best choice is copper. This metal has the best heat transfer coefficient and temperature elasticity.

- Fastening elements for piping heating and hot water systems.

- Automatic safety with primary sensors and protective devices in the form of an air vent and an expansion tank. The kit is purchased in a retail chain according to the parameters of the working tank.

- Thermal protection of the boiler from loss of thermal energy. To do this, a glass wool/basalt heat insulator of at least 5 cm is placed in the layer between the tank and the protective casing.

Advantages and disadvantages

Today, many users, having tried storage water heaters, are inclined to purchase a flow-through version - this greatly saves room space, since they are all quite compact in size, and reduces heating time many times.

Let's list the advantages point by point.

- Simple operation - turn it on, wash your face or wash the dishes and turn it off.

- They provide an unlimited amount of hot water for any need - waiting for heating will take no more than 2 minutes.

- No periodic maintenance by specialists is required.

- Compact size, allowing the product to be installed even under the bathroom sink, so as not to disturb the established interior.

- When a large volume of hot water is not required, such devices become quite economical (compared to the storage option).

- Their initial price is lower than that of storage water heaters.

- When heated, water does not lose its quality because it is consumed immediately. There is no possibility of harmful bacteria multiplying - you can even drink it if you wish.

- This type of product heats water no higher than 40 0C;

- with high power of the product, electricity consumption increases;

- when a large amount of water is required, the device operates for a long time and the electric meter will generate a decent flow rate;

- This type of product places special demands on the home electrical network - the voltage must always be a constant value;

- Instantaneous water heaters provide only one water intake point.

The conclusion is simple: water heaters of the type described above are convenient for a family of two, when the need for hot water is minimal; in other cases, it is best to install a storage-type boiler with a large volume that satisfies all household needs.

Optimal operating mode of an electric boiler

Setting the temperature to the minimum permissible is highly not recommended for the following reasons:

- Reduced efficiency of water heating equipment;

- Liquid temperature 30-40⁰ C is an ideal environment for the formation and proliferation of bacteria and mold, which inevitably end up in the water;

- The rate of scale formation increases.

These devices are often equipped with an economy mode option, designated by the letter E. This operating mode means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at a given temperature regime, scale forms the slowest, and accordingly it is necessary to clean the heating element less often. This does not apply to energy savings.

Calculation of the volume of the storage tank and the power of the heating element

The main element of the boiler, which serves to heat water from the heating system, is volume. It can be calculated using the following formula: V=T*N/(t1-t2), where:

- V—volume;

- T is the time spent heating water;

- N is power measured in kilowatts per hour;

- t1, t2 — thermal regime of the mechanism.

The heating element is a tubular electric heater and the main component of the mechanism. It looks like a spiral wrapped in metal. The system must be filled with dielectric. For example, sand can be used as it. This indicator is subtracted using the following formula: P=0.0011*m*(tk-tн)/T, where

- P—power;

- m is the mass of water to be heated;

- tk is the initial temperature;

- tn — final temperature;

- T is the time spent heating the liquid.

Rules for using the Electrolux water heater

The first start-up, switching on after a long period of inactivity, is carried out according to the standard scheme listed above: opening the warm water tap, filling the tank, inspecting for faults and leaks, closing the tap after supplying an even stream without bubbles, heating. After a long period of non-use, it is necessary to thoroughly rinse the tank with a long drain of liquid.

Let's take a closer look at other operating features specified by the manufacturer. The main ones are to carefully monitor the quality of water, which should be supplied without mechanical impurities, petroleum derivatives, harmful substances, etc. Compliance with these requirements eliminates increased scale formation inside the tank and rapid wear of the anode rod.

In addition, it is necessary to carry out timely maintenance of water heating equipment to ensure reliable operation by calling a specialist. Technical work includes:

- Checking the tightness of connections;

- Cleaning filters;

- Inspection and cleaning of the internal space of the water heating tank, heating elements, which depend on the degree of hardness of the heated liquid;

- Checking the pressure in the water supply system;

- Inspection of the condition of the housing, thermal insulation;

- Checking the operation of protective and emergency devices, if they are installed;

- Inspection and replacement of the magnesium anode as necessary.

Advantages

Modern models of gas boilers with one circuit for heating the heating fluid could be called primitive water heating devices if they were not equipped with high-precision control and monitoring equipment to ensure the reliability and safety of all operating cycles. To solve the problems of regulation and safety of boilers, an automatic boiler protection system with gas flow and pressure regulators, fittings that regulate the flow, temperature and pressure of heated water, all kinds of sensors, instruments and safety devices is aimed. This is the main advantage of gas boilers.

Other important benefits:

- simplicity of design and installation of the boiler, which includes a combustion chamber with a gas burner, a loop heat exchanger in the firebox, a system of manifolds and pipelines, and pumping equipment;

- efficiency achieved by automation and adjustment work for optimal and efficient combustion of fuel, mixing processes and regulation of coolant parameters in accordance with standards;

- the ability to connect boilers to cascade heating systems within cities and large towns, which allows not only to centrally control the system, but also to ensure reliable and high-quality heat supply to consumers in residential areas, neighborhoods, microdistricts, as well as enterprises whose boiler houses are included in the cascade;

- more environmentally friendly emissions of gas combustion products into the atmosphere compared to similar boiler houses using liquid and solid fuels.