To lay an electric heated floor, it is important to perform the screed correctly, since the uniformity of heat distribution in the room, structural strength and heating efficiency depend on it. Arrangement of the screed is the most labor-intensive stage of laying a heated floor.

Laying screed for heated floors

Its functions are as follows:

- protection of heating elements from mechanical influences and the negative influence of air;

- uniform heat distribution over the surface of the floor radiator to heat the entire space of the room;

- creating a level base for the finishing coat.

Please note the following during installation:

- the thickness of the entire screed, as well as the upper and lower layers around the heating element;

- what manufacturing method to choose;

- taking into account the specifics of solution preparation and cable casting technology.

Screed thickness

The concrete layer is the floor screed itself. It is strongly recommended to use a concrete screed rather than a cement-sand screed. To achieve the required strength of a slab using a cement-sand mixture, the amount of cement that will have to be used will lead to the fact that the cost of the floor will significantly exceed the price of a structure of similar strength made of concrete. The thickness of the screed should be 30-45 mm above the level of the pipes.

To make a concrete layer, concrete of a grade not lower than M300 should be used, and crushed stone should have a fraction of at least 5 mm and no more than 20 mm. With a screed thickness of 50 mm, the weight of 1 m² of such a floor will be about 120 kg, so you should always ensure that the floor beams in the room where the warm water floor is installed are sufficiently strong.

The installation process takes place using metal beacons of the PN-28 type, located around the perimeter. Leveling the mixture is done using a rule.

It is recommended to strictly adhere to the ratio of the required ingredients in order to avoid additional difficulties during the installation process. The optimal composition of the mixture prepared using 12-liter buckets is as follows:

- 1 bucket of cement

- 2 buckets of crushed stone with a fraction from 5 mm to 20 mm

- Water 7-8 liters

Superplasticizer for concrete SP1 - 0.4 liters of solution prepared in advance. Recipe: add 2 liters of powder to 5 liters of water and mix well.

If available and upon request, add 3-4 buckets of granite screenings with a fraction of up to 5 mm.

If special plasticizers and granite screenings are not available, then a screed of similar strength can be prepared by increasing the amount of cement from 1 to 1.5 buckets.

After the surface of the concrete layer has dried, the heating system starts in test mode with a coolant temperature not exceeding 25 °C. You can use water heated floors to their full potential only after 30 days.

Compositions and types of screed

A concrete screed for an electric heated floor will turn out to be of high quality if you select the correct proportions of materials and mix them thoroughly.

Cement and sand alone are not enough to prepare a screed. It requires plasticizers and additives that increase the plasticity and uniformity of the mass.

Might be interesting

Thermal insulation

Insulating the ceiling in a bathhouse - methods, materials, useful...

Thermal insulation

Tables of comparative characteristics of thermal insulation…

Thermal insulation

Why polyurethane foam insulation is the best...

Thermal insulation

Self-adhesive thermal insulation: how to choose and apply?

Dry screed

Advantages of dry screed over wet screed:

- no special equipment is required: mixers, containers for solution, etc.;

- less effort is spent on delivering the material;

- speed of work completion (in 1-2 days);

- there is no need to wait for the screed to mature;

- the possibility of stage-by-stage installation of heated floors divided into zones;

- absence of dirt and excess moisture;

- low specific gravity of the screed;

- the floor acquires sound absorption and thermal insulation properties without the use of special materials, the price of which is sometimes high;

- the possibility of laying communications in the thickness of the material;

- the surface is smooth and ready for finishing floor coverings.

With all the advantages, the coating is quite light and durable. It will not withstand the load from an interior partition made of gypsum boards or bricks, but frame structures made of plasterboard can be installed on it.

Dry screed is not used in the following cases:

- if there is a slope in the room;

- in the presence of large dynamic loads (vibration effects or high intensity of human flow);

- in rooms with high humidity or the possibility of water spills on the floor;

- in cramped spaces where it is not possible to compact and level the composition efficiently.

When preparing dry screed, the following materials are used:

- Waterproofing film.

- Damper tape around the perimeter to compensate for temperature deformation.

- Dry backfill made of fine gravel, expanded clay, slag pumice, perlite. Instead, high-density insulation boards can be used, for example, extruded polystyrene foam, etc.

- The top layer is sheets of moisture-resistant plywood, asbestos cement, chipboard, OSB. They are also used for large thicknesses. The best option is to use waterproof gypsum fiber sheets that are suitable for any floor finish.

Manufacturers of building materials produce special complete and balanced dry floor systems. A whole line of Knayf dry screeds is produced for different types of premises. Among them, two-layer gypsum fiber boards with the possibility of assembly with locks are popular. For housing, “Vega” compositions are produced based on small expanded clay screenings in bags and other components.

When using industrial waste, for example, solid expanded clay or slag, for dry screed, the fraction size should not exceed 5 mm. Otherwise, the floor will begin to sag and creak.

The thickness of the backfill must be more than 30 mm, otherwise the required quality cannot be achieved. If the upper limit is higher than 60 mm, intermediate spacer sheets will be required. The top of the screed is additionally covered with a sheet covering, the thickness of which is about 20 mm.

The base for backfilling must be level.

Semi-dry screed

The screed is a cement-sand mixture with the addition of fiber fiber and plasticizers, but with a low water content. A distinctive feature is the large layer thickness of 70-100 mm. If the thickness is less, the layer may crack.

The advantages of semi-dry screed are its heat and sound insulation properties due to its porous structure.

The disadvantage is the need to use construction equipment, but in small rooms the screed can be laid manually.

The ratio of components, which include cement, sand and water, is 1:3:0.4, respectively. Fiber fiber is added to them in an amount of 600-800 g/m3.

The screed is laid using beacons, similar to the wet method. A special machine is used for grouting, which can be rented. It is difficult to compact the screed manually.

Seal semi-dry screed

Wet screed

A screed is a layer of mortar or concrete applied to the surface of the base.

It is laid in several layers, the functions of which differ:

- Leveling the base. The first layer is always used for uneven surfaces. It is necessary even when a dry screed is placed on top.

- A layer on top of thermal insulation for laying heating elements. If the cable touches the insulation, it may overheat at this point.

- The third layer covers the heated floor, evens out the temperature field and holds the floor covering in place. It is often combined with a second layer, if the thermal insulation is covered with a waterproofing film on top.

In all cases, it is advisable to reinforce the layers to prevent them from cracking and maintain the integrity of the heated floor. At the same time, the thickness of the floor increases significantly, which leads to a decrease in the height of the premises. It can be reduced through the use of leveling compounds.

The classic screed is cement-sand. But the composition is not limited to just two components. Plasticizers are added to it, as well as crushed stone or expanded clay. A mixture of 3 parts sand, 1 part cement and PVA glue, added in an amount of 1 kg per bag of cement, works well.

Cement-sand screed for heated floors

When using ready-made mixtures, high quality screed is achieved. Each composition has its own preparation instructions.

Any heated floor must be installed on a flat surface. To obtain a level base, a regular cement-sand mortar is used, and leveling compounds are most often placed under the finishing coating. Their cost is high, but the filling is perfect.

The thickness of the tie depends on the diameter of the cable and is 3-5 cm. If it is made smaller, the required strength of the slab and uniform heating will not be ensured.

When cracks appear in the screed, the reliability of the heated floor decreases sharply. Due to the violation of the integrity of the layer, the heating of the floor becomes uneven. Areas with high temperatures appear, as a result of which the cable overheats and its service life is reduced.

The technology for laying the screed must be performed correctly. The strength of the cement takes 4 weeks; no work can be carried out during this period. It is important to ensure uniform fixation of the layer. To do this, cover it with film and keep the surface damp.

The main screed is installed after leveling the base and laying the cable. First, a damper tape 10 cm wide is rolled out along the perimeter of the walls from below and secured with tape in places adjacent to the subfloor. It is also placed in places of transition to other rooms.

Cracks will not form in rooms larger than 40 m2 if they are divided into rectangular zones and T-shaped strips of porous material are laid between them. Damper tape is not suitable here because it is flexible. Thin foam sheets are usually used. Where the cable passes through expansion joints, a short corrugated hose is put on the cable so that it does not break due to temperature deformations.

A reinforcing polymer mesh is placed under the cable. It should be rigid and located at a distance from the insulation.

The laid heated floor must be tested - apply voltage and check the uniformity of heating.

In order for the screed to be exactly horizontal, beacons should be installed at a given height. A laser level is used for this. If it is not there, the usual one is used, but then the upper boundary of the fill should be drawn on the walls.

The first beacons are installed at a distance from the wall, and the next rows are made at a distance slightly shorter than the rule. Beacons are made using a solution, after which you need to wait for it to set.

Laying screeds along beacons

The heated floor is poured with careful leveling and filling of all voids manually. The solution is poured 1 cm above the level of the beacons and compacted with a hand tamper. Then another layer of screed is applied on top and pulled out using the rule. After this, you should immediately rub the surface with a trowel, making circular movements. At the same time, the horizontal level is regularly checked by adding solution to the holes and removing excess.

The work of pouring the screed is done within one day with minimal interruptions during manual mixing.

The drying surface is covered with a film and moistened for a month until the concrete matures. If you rush and turn on the heated floor earlier, it will crack and all previous work will be done in vain. In addition, removing a frozen screed will not be easy.

Difference in heating depending on the thickness of the screed

A competent calculation of the thickness of the layer poured when installing a screed is also necessary because of its influence on the process of uniform heating of the room.

If the layer is thin, then it objectively warms up faster, ensuring that after the water circuit starts functioning, heat spreads into the room without a long wait. At the same time, in such conditions, it is more likely that cracks may appear in the screed, negatively affecting the uniform heating of the floor.

Scheme for laying layers for water heated floors

An excessively thick layer has good heat capacity, so it retains heat longer, allowing it to be distributed across the floor plane, but it takes longer to warm up. There is also a large load that has a negative effect and can cause the screed to break. To avoid this phenomenon, it is recommended to install expansion joints.

When deciding to level the floor using a screed, you need to understand that the thickness of the layer installed using a wet, semi-dry or dry method will be different, therefore, uniform heating will not be achieved.

Total thickness of finished subfloor

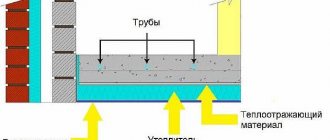

Recommended thickness of each of the layers that make up the warm water floor cake. The order of arrangement of each of the layers is shown in the diagram below:

The subfloor must be smooth and durable. The thickness of each layer placed on top of the subfloor, in order from bottom to top, will be as follows.

A layer of insulation 30-90 mm thick made of fibrous polystyrene rigid boards. They must be strong enough to withstand the high load of subsequent layers, and therefore the material density is chosen to be at least 35 kg/m³. The thickness varies depending on how cold the crawl space is. If there is a heated room below the floor, then a layer of 30 mm will be sufficient, and if the floor is laid on the basement floor of a private house, then it is better to place a layer of insulation with a thickness of at least 90 mm.

Multifoil 3 mm thick is laid on top of the thermal insulation. Its main function is to waterproof the next layers of the floor. If the waterproofing layer has already been laid on the rough concrete floor, laying multifoil is not required.

Reinforcing mesh 100x100x4 mm or 150x150x4 mm serves to increase the strength of the screed, which, when reinforced, becomes more resistant to tensile loads. For the convenience of laying pipes according to the diagram, they can be fixed at the desired points on this grid.

The pipe is laid according to one of the diagrams shown below. These circuits are called "coil" and "helix". The first is classic and suitable for any room, while the second is not recommended for use on wooden floors and is most effective for rooms that require particularly intense heating. The permissible distance between pipes is from 10 to 30 cm. The presence of joints inside the floor is unacceptable; the pipe is laid in one piece, the ends of which go into the collector. The average layer thickness is 20 mm.

Before moving on to the screed, we need to talk about the damper tape. It is pre-laid around the perimeter of the walls in order to avoid creating unnecessary stress on the walls. The fact is that the concrete screed, when heated from the heat of the pipe, will expand and create pressure on the walls, and to prevent this, it must be fenced around the perimeter with a special “spring” material. The minimum thickness of such a tape is 5 mm, the optimal is 10 mm.

As a result, taking into account all the described requirements for the arrangement of a water-heated floor screed, the thickness of all layers and a separate concrete screed will be as follows:

- The entire floor is 80-135 mm, taking into account the thermal insulation layer and the thickness of the concrete layer

- The thickness of the screed is 50-65 mm, depending on the selected layer height above the surface of the pipes.

Number of screeds for heated floors

At first glance, it is a very strange question about how many screeds should be installed for a heated floor system. In addition to the rough screed, an optimal screed is made for underfloor heating on top of the pipes. The last layer will serve as the basis for finishing the floor in the room. An alternative to a rough screed is a floor slab. But in this case, it should be almost perfectly smooth and without defects. Otherwise, you will have to arrange a layer for leveling.

A warm water floor must be installed on the base without errors. It should be smooth. This is necessary so that the pipeline is subsequently evenly distributed in the concrete screed for finishing.

Installation recommendations

If you decide to use a film structure, then using a screed compound is not advisable. Here you should use a special tile adhesive. The elements are fixed on it. Naturally, the thickness of the layer should be minimal, and the upper part of the film floor should be visible. Next, you can lay the tiles. First you need to wait for the previous layer of glue to dry. This method of installing tiles will avoid peeling of the floor covering.

Technology for laying heating mats for electric heated floors

https://youtube.com/watch?v=fY3jneItmIs

Semi-dry coating

Today, many people prefer dry mixture for laying screed. It is less problematic to pour than a cement-sand mixture. This installation method has its own characteristics. The semi-dry mixture is considered stronger than ordinary cement. After pouring, the drying period is much shorter, which makes it possible to finish laying heated floors faster.

Experts say that the material does not crumble or collapse under the influence of heat emanating from the pipes. It is easier and more convenient to work with this type of mixture.

Before laying the semi-dry mixture, you should carefully prepare the base. All debris is removed, the base is laid with a vapor barrier material. If there are deep cracks or depressions, it is recommended to fill them with a viscous cement solution. Rolled materials are laid with an overlap, and it must also overlap the walls. The seams are treated with special tape. The semi-dry mixture is poured onto the finished base.

The mixing proportions that should be used are indicated on the packages of the semi-dry mixture. The consistency of the material should not contain a lot of water. If you squeeze it in your hand, you get a dense lump. Moisture should not flow down your hand. In this way, they check that the ingredients of the mixture are mixed correctly. Very often, fiber fiber is added to the dry mixture to make the coating even more stable. The fiber is well distributed throughout the structure in all directions.

The minimum thickness of the screed will be 4 cm. Its height also depends on the method of laying the pipes themselves and what material they are laid on. The floor and its maximum height can reach 20 cm. If the base for pouring has significant unevenness, the height must be raised significantly. In general, the thickness will be at least 4 cm and no more than 20 cm.

The coating may be destroyed by improper drying methods. Just because you can walk on the floor does not mean the grout is truly dry. A liquid cement-sand mixture 4 cm high takes at least a month to dry. The mixture prepared from dry materials dries within several days, depending on the height of the coating. In order for the material to harden correctly and without cracking, the surface should be moistened with water and covered with film. As a result, the base will not sag, will dry well and will not crack.

The size of the water coating depends on the type of fill and the characteristics of the base. The more significant irregularities on the surface, the higher the structure will be. This happens due to the application of several layers - this is a necessity to achieve the zero level.

Based on experience, experts say that the relative total height of the warm water coating is 10-15 cm, taking into account absolutely all materials used, including the floor covering.

Pouring composition

First, you need to decide on the brand of cement for the mortar. It should be M200-M300, depending on the purpose of the room itself. In addition, the composition may contain plasticizers to avoid the appearance of cracks on the surface after pouring, as well as for better distribution over the base. When installing a screed under a warm floor, the thickness must meet all requirements and recommendations. Usually it is 50-70 mm. The start of the fill level comes from the top of the system pipeline. Manufacturers of dry mixes for preparing concrete mortar can also advise on optimal parameters. This should also be followed during installation.

Instead of plasticizers, “folk” remedies in the form of PVA glue can also be used. Such methods were applicable 15-20 years ago, when technology was not so well developed. It is worth noting that the cost of various additives is currently not so significant and you can afford to purchase them. In addition, their consumption is not large per volume of concrete solution. In this case, the thickness of the screed above the heated floor pipes can even be slightly reduced due to improved strength characteristics.

Thermal insulation of the base

Before installing the heating system, it is necessary to insulate the base. The thermal insulation layer will protect the water circuit from heat loss going into the basement or foundation of the house. The following is used as insulation:

- Styrofoam;

- extruded polystyrene foam;

- foil-coated backing.

The listed materials are characterized by high strength to mechanical load, resistance to moisture and temperature changes. The thickness of the insulation is 30-50 mm, it is laid on a layer of waterproofing polyethylene film. The canvas is laid overlapping on a clean, dry base; it will protect the insulation from getting wet. Thermal insulation boards are laid end to end, the joints are coated with glue or blown in with foam, the excess of which is cut off.

Penofol or a similar sheet of reflective insulation is placed on top. A layer of aluminum foil is directed upward, this will reflect the bulk of the heat back towards the room. The joints of the foil insulation are taped with special tape. Penofol will protect the insulation from the aggressive effects of concrete. A metal reinforcing mesh is laid over the thermal insulation. This element evenly distributes the high load from the water circuit system and the concrete structure.

Types of plasticizers, features of their use

Plasticizers (surfactants) are surfactants. Surfactants are produced in liquid or powder form, with antifreeze additives and reinforcing polyamide fibers.

During the development process, the composition is endowed with properties that modify and improve the quality of floor screeds:

- Ensuring the plasticity of the solution;

- Increasing the degree of mechanical strength and moisture resistance;

- Improving surface smoothness;

- Elimination of possible damage to electrical devices by corrosion.

Laying a heated floor with your own hands, using strengthening active substances in the screed, makes its use comfortable and safe.

Sometimes modern plasticizers for screed are classified as environmentally friendly products.

But still, do not forget that they contain chemicals that have the property of changing the structure of the concrete mixture.

Therefore, in the process of preparing screeds for electric or water floors with your own hands, it is recommended to include in their composition the amount of additives corresponding to the information indicated on the packaging.

Some manufacturers of surfactant additives for cement-sand screeds, in order to get ahead of competitors, keep their composition and recipe for their preparation secret.

In addition to unknown individual components, plasticizers include the following ingredients:

- Concentrated sulfuric acid (strong oxidizing element);

- Phenolic production waste (phenolic resin, water);

- Concentrated sodium hydroxide solution;

- Defoamer, formaldehyde and water;

- Plastic reinforcing fibers (present in some surfactants).

Liquid plasticizers are added to the dry mixture: at the rate of 1-1.5 liters per 100 kg; Before use, shake the substance thoroughly and pour in simultaneously with water as mixing progresses.

Powdered - take at a ratio of 1:2 (surfactant/water); mix thoroughly, let stand for a couple of hours (the further mixing procedure is the same as with liquid).

Common mistakes

Not every person understands how to properly fill a heated floor and not disrupt the operating technology. The following describes common mistakes that inexperienced craftsmen make when doing work with their own hands.

Often the screed cracks after it dries. Why is this happening? In most cases, this is caused by errors:

- in the process of creating a solution. It is definitely worth adding a reinforcing additive to its composition, as well as plasticizers;

- in the location of deformation gaps. The technology for pouring heated floors in large rooms or rooms of complex shape does not involve the creation of a monolithic slab. The floor must be divided into small zones (with an area of no more than 30 “squares” and a side length of no more than 8 m) by using a damper tape. Achieve a 1:2 ratio between the length and width of the squares. If the room is of a non-standard shape, it should be divided into squares with dividing lines 1/3 deep, using a trowel;

- when drying floors, the poured screed should not dry out, otherwise cracks cannot be avoided. In order to ensure an optimal level of moisture, the floors must be covered with film and watered with water for a week;

- when starting the heating system. Often people are in a hurry and turn on the “warm floors” too early, which leads to cracking of the solution in 80 percent of cases. Experts recommend waiting 28 days from the moment the floors are poured. This time is necessary for the solution to gradually harden.

If the floor you created with your own hands does crack over time, you can repair it yourself. However, it is better that it does not come to that. Do not violate the technology for installing heated floors, and problems of this nature will never affect you.

Features of floor screeds of various thicknesses

The thickness of the screed for a water heated floor is the most important component in organizing room heating. There are 2 types of covers used, characterized by thickness: thick and thin screed. Each of the listed types has its own specific advantages and recommendations for use (depending on specific conditions). To learn how to make a screed over a heated floor, watch this video:

https://youtube.com/watch?v=fY3jneItmIs

Thin screed for warm water floor

There must be a layer of concrete above the pipe of at least 4 cm

To determine the minimum thickness of a heated floor, there are certain requirements that are enshrined in special documents (SNiP).

It is worth saying that many of the prescribed sizes in official documents are ambiguous.

For example, SNiP states that the minimum thickness of the screed for a warm cover can be at least 20 mm, but this applies to a cover made on a cement-metal base.

When calculating the height of the floor, do not forget to add the thickness of the laid covering

What thickness the screed should be when using other mixtures is not stated. But it is indicated that the minimum layer of pipe cover should not fall below 4 cm.

This means that together with the pipe (average section 20-25 mm), the thickness of the solution can reach 60-65 mm. Most often, this is exactly what the screed turns out to be (SNiP recommends 6-7 cm).

Many people wonder how to determine the thickness of the screed if a leveling mixture is poured on top or a tile covering is laid. When organizing a cement mixture under the tiles, one established postulate should be followed: the solution should exceed the level of the pipes by 1-1.5 cm. For details, see this video:

Since the tiles are laid on an adhesive base 8-20 mm thick, the total height of the flooring above the pipe will reach 6 cm (taking into account the thickness of the tiles). Using the same principle, a cover is created with a leveling mixture, on which a laminate or wooden floor is subsequently laid.

Thick floor screed

Increasing the amount of mortar will not only increase the cost of work, but also increase the load on the base

The maximum permissible values for the thickness of a heated floor screed are not mentioned in SNiP, but an unreasonable increase in it can lead to certain consequences:

- an increase in material consumption leads to an increase in the cost of the structure;

- to heat a thick layer of coating, a longer period of time and increased energy consumption are required;

- reduction of space in a heated room;

- may lead to the dismantling of the doorway (the door does not open).

But, nevertheless, quite often they resort to measures, organizing a thick flooring associated with leveling the floor and comparing it with the zero point.

The process of leveling the surface is organized on the rough floor, but if for some reason this has not been done, it can be done using a pipe layer of mortar.

The total thickness of the flooring can reach 15 cm.

Based on what has been written, it is worth saying that each owner, when choosing the thickness of the screed for a warm water floor, will rely on his own considerations.

But you should not abandon the above recommendations; they can be useful for any builder who is planning to install a warm water floor in a room.

Purpose

The thickness of the underfloor heating screed will affect the performance characteristics of the entire system, as well as its ability to operate effectively under external loads. It should be understood that the layer must be optimal and comply with the manufacturers’ recommendations if a ready-made construction dry mixture is used.

If a very thin concrete pour is placed on the base of the floor, it will not last long. In addition, there will be a very rapid heating of the surface and a rapid cooling process. She won't be able to bring any benefit. Taking this into account, especially if the room is constantly under load not only from movement, but also from the furniture located, then a minimal screed under a warm floor will very quickly crack and lose its appearance. This will also lead to damage to the flooring that will be laid on top.

A thick layer of poured concrete mortar will also not be able to demonstrate all the qualities of a warm water floor system. Warming up such a design will be very difficult and problematic. There is a high probability of pipeline failure in certain sections. All this will cause large financial investments to pay for heating. After all, a large amount of energy will be required for the heat to pass through the thick layer of screed and warm the base of the floor in the room.

It cannot be said that there are universal indicators for installing a concrete screed over a heated floor system. The fact is that here it is worth taking into account some factors, such as the type of base, the configuration and area of the room where the work is being carried out, as well as its purpose. After all, the load in residential premises will be significantly less than in industrial ones. Therefore, in the latter case, the filling layer should be slightly larger.

Features of installing a rod infrared floor

This type of heated floor consists of rods that are connected to each other by flexible wires. When current is passed through the rods, they generate heat. This type of heating can self-regulate the temperature, so it can be used without a thermostat.

Installation sequence of the rod infrared floor:

- creating a laying scheme;

- preparation of the base;

- laying thermal insulation;

- preparing the location for the sensor;

- laying out the strips and connecting the cable according to the drawn up diagram;

- fixing the strips to the base using mounting tape;

- installation of a thermostat;

- connecting the sensor and cable to the thermostat;

- connecting the thermostat to the network;

- system testing;

- pouring screed;

- laying tiles.

For such a floor, the best finishing coating is ceramic tiles; it is laid in a screed, the thickness of which should be more than 2-3 centimeters.

On wooden floors

To fill a wooden house, you need to perform the following steps:

- Carefully inspect the covering (replace damaged joists, and turn over partially damaged joists);

- Add support beams (if the logs are installed in increments of 40 cm);

- Recess the nail heads into the boards by 2-3 mm (otherwise they will later tear the insulating film);

- Seal the gaps at the junction between the walls and the floor with thin boards (they are removed after pouring, which ensures ventilation of the base and does not allow it to rot);

- Eliminate deep and small cracks;

- Remove debris and dust, sand the base if necessary;

- Prime wooden surfaces (this will ensure their moisture resistance);

- Cover the bottom of the wall with damper tape (10-20 mm thick and 2-3 times thicker than the screed) to cut off its surface from the cement;

- Ensure waterproofing of the base using an intact polyethylene film (its individual parts are overlapped by 10 cm, the overlap on the walls is 20 cm, all tears and punctures are sealed with tape).

Option for installing TP on wooden logs

Attention! It is not recommended to fill if the wooden floorboards are fresh. They can become deformed under the weight of the screed.