Why do you need an expansion tank?

What is the expansion unit used for?

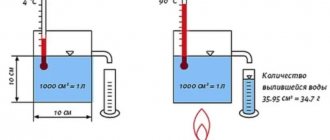

The fact is that any liquid increases in volume when heated. Thus, the volume of water when heated to 100°C increases by 4.5%, antifreeze and antifreeze - by up to 6%. To prevent the coolant from pouring out of the system when it is heated, an expansion tank is needed, which is a kind of buffer or compensator. Until the middle of the last century, there were no expansion tanks under the hood, since ordinary water was used as coolant, and the role of a compensator was played by the upper radiator tank, which was not topped up “to capacity.” With the advent of ethylene glycol-based coolants (antifreeze), the coefficient of volumetric expansion of which is greater than that of water, additional expansion tanks appear so as not to enlarge the radiator.

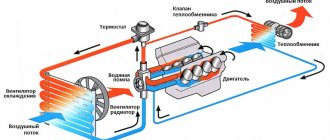

Digator cooling system design

Thus, the expansion tank (EB) is designed to compensate for the volumetric expansion of the coolant as its temperature increases. The RB is located in the engine compartment so that the fluid level is approximately at the middle of the height of the tank. In this case, the liquid in the radiator and tank is located at the same level according to the principle of communicating vessels. Since the RB is located above the radiator, the expansion tank cap is used as a filler neck, which will be discussed below.

Replacing the expansion tank with your own hands

Anyone can change the expansion tank on any car.

The procedure for performing the work is approximately the same for all brands and models:

Drain the liquid from the tank and pipes.

You need to place a container under the drainage area in advance so that antifreeze or antifreeze does not fall on the floor or ground. Do not forget that this liquid contains methyl alcohol, so the drainage area can be considered a fire hazard.

Disconnect the fastenings from the tank (usually they are made in the form of ties or clamps).

Remove the pipes from the tank.

Install a new expansion tank, connect the supply hoses to it, and secure them with new clamps for reliability.

Fill with new antifreeze/antifreeze.

Make sure that there are no leaks at the joints of the tank and pipes, and also that the same amount of liquid was filled in as was drained.

Video: the process of replacing the tank on VAZ cars

Thus, the driver can solve any problems with the expansion tank independently.

This product is not at all expensive, so in most cases, car enthusiasts prefer to buy new tanks rather than repair old ones.

Source

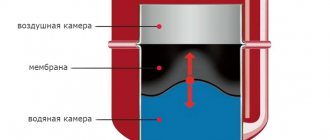

Design and operation

The expansion tank consists of a polypropylene body, a cover and two pipes for connecting hoses of the liquid system.

Using the lower hose, the device is connected to the cooling line, the upper one serves to remove vapors and air bubbles from the system. On modern models, float coolant level sensors are often installed. For this option, the expansion tank is equipped with another neck on top, intended for installing a sensor. Several control marks are applied on the side surface of the container, from the bottom - min to the top - max. The coolant level should be located in this interval.

How does the device work? First, a little theory. The table shows the operating temperature conditions of modern engines

. As we can see, the engines operate in critical temperature conditions.

To raise the bar for permissible temperature, designers increase the pressure in the coolant (more than atmospheric), due to which its boiling point increases. To do this, the system is closed hermetically and excess pressure is maintained in it. For different engines, this value ranges from 0.1 to 0.5 bar (kg/cm²).

At the same time, significant vacuum (more than 0.03 - 0.1 kg/cm²) in the free space of the expander is unacceptable, since air will be sucked into the system, which will lead to the appearance of air pockets that impede coolant circulation and, consequently, to engine overheating . Maintaining the coolant pressure at the required level is the responsibility of a special regulator located in the filler cap.

How to choose the right device?

The main characteristic on the basis of which equipment is selected is its volume. In this case, the following factors must be taken into account:

- Number of people using the water supply system.

- The number of water intake points, which include not only showers and taps, but also household appliances, for example, a washing machine and dishwasher.

- The likelihood that water will be consumed by several consumers at the same time.

- Limit number of start-stop cycles in one hour for installed pumping equipment.

Experts recommend using the following indicators as a guideline when choosing an expansion tank:

- If the number of consumers does not exceed three people, and the installed pump has a capacity of up to 2 cubic meters. m per hour, a tank with a volume of 20 to 24 liters is selected.

- If the number of consumers is from four to eight people and the pump capacity is within 3.5 cubic meters. m per hour, a tank with a volume of 50 liters is installed.

- If the number of consumers is more than ten people and the productivity of the pumping equipment is 5 cubic meters. m per hour, choose an expansion tank of 100 liters.

When selecting the desired device model, it is worth considering that the smaller the tank volume, the more often the pump will turn on. And also the fact that the smaller the volume, the greater the likelihood of pressure surges in the system. In addition, the equipment is also a reservoir for storing a certain supply of water. Based on this, the volume of the expansion tank is adjusted. You should know that the design of the device allows the installation of an additional tank. Moreover, this can be done during the operation of the main equipment without labor-intensive dismantling work. After installing the new device, the volume of the tank will be determined by the total volume of the containers installed in the system.

In addition to technical characteristics, when choosing an expansion tank, special attention should be paid to its manufacturer. The pursuit of cheapness can result in much more significant expenses. Most often, to produce models that are attractive for their cost, the cheapest materials are used, and, as practice shows, they are not always of high quality. The quality of the rubber from which the membrane is made is especially important. Not only the service life of the tank, but also the safety of the water that comes from it directly depends on this.

When purchasing a tank with a replaceable membrane, be sure to check the cost of the consumable element. Very often, in the pursuit of profit, not always conscientious manufacturers significantly increase the price of a replacement membrane. In this case, it will be more appropriate to choose a model from another company. Most often, a large manufacturer is ready to be responsible for the quality of its products because it values its reputation. Thus, it is worth considering models from these brands first. These are Gilex and Elbi (Russia) and Reflex, Zilmet, Aquasystem (Germany).

The volume of the expansion tank for water supply may vary; it is selected based on the needs of the users. If a larger volume is subsequently required, an additional device can be installed

Tank cover - two in one

So, the RB cover, in addition to its protective function, also performs the task of a pressure regulator.

As stated above, the pressure inside the tank should be up to 1.1 - 1.5 kg/cm². How is this achieved? For this purpose, two valves are mounted in the lid: safety and vacuum. The first is a spring-loaded rubber diaphragm that is pressed from the outside and releases when the pressure exceeds the force of the spring. The second consists of a rubber washer with a small spring installed inside a large one.

At operating coolant temperature, both valves are closed, the pressure in the tank does not exceed the design pressure. Since the expansion tank is hermetically sealed, the pressure increases as the temperature rises, causing the safety valve to open and release some of the air vapor, returning the valve to its previous position.

The absence of a safety mechanism would lead to coolant leaks, damaged connections, and even rupture of the cooling radiators and heater.

After stopping the engine, the liquid in the system cools and decreases in volume, which leads to a vacuum inside the tank. The result may be air leaking through the connections, which will lead to the formation of air bubbles during subsequent startup. And this can lead to overheating and engine failure.

This is where another small valve comes to the rescue - a vacuum valve. Under the influence of vacuum, it opens and equalizes the pressure in the tank with atmospheric pressure.

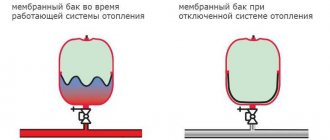

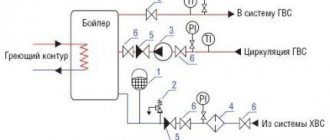

Where to put it in the system

The expansion tank in a closed system is placed after the boiler before the pump, that is, so that it creates a flow in the opposite direction. This way the system works more reliably. So the specific installation location depends on where you have the circulation pump.

Installation diagram of an expansion tank for heating

It is connected to the system via a tee. You cut a tee into the pipe, direct the perpendicular outlet upward, and screw the tank onto it. If the wall does not allow you to place a container, you will have to make an elbow, but the tank will be turned upward. Now we can assume that the expansion tank is installed.

Installation example with tap

But for the convenience of checking, it is advisable to install another tee after the tank, and install a shut-off valve on the free outlet of it. This makes it possible to check the membrane tank without draining the entire system - it cuts off the tank. Turn off the tap and bleed water from the boiler. Check the pressure on the disconnected branch (in the boiler). It must be zero. Afterwards, you can carry out all other setup work.

Expansion tank malfunctions and causes

Decrease in coolant level:

- leakage of the plastic body of the tank due to aging of the material, in particular, this was a chronic disease of the tanks of VAZ cars;

- The safety valve does not work, as a result of which increased pressure squeezes antifreeze through the joints.

Engine overheating:

- due to decreased volume of liquid due to leaks;

- The vacuum valve does not work, resulting in air appearing in the liquid (“airing”).

Visible fluid leaks:

- expansion tank is leaking;

- safety valve malfunction.

Expansion tank repair

It is worth remembering that the design of the expansion tank is the simplest, so it doesn’t even occur to drivers what exactly could fail in it.

However, due to the fact that this is a container with a rubber lid, it is the gasket that often causes problematic situations on the roads.

After all, loss of tightness for the cooling system is unacceptable.

There are frequent cases of tank leakage at the inlets and outlets of the hoses.

The only option is to replace the hoses and secure them with new clamps.

Occasionally, due to an accident or other mechanical impacts, the plastic body of the tank itself may be damaged.

Valve cover jammed

Do not forget that the cap does not just act as a plug, it also serves as a valve that releases excess pressure in the engine cooling system.

If a hiss starts to be heard from under the cover while driving, it means that the rubber gasket has worn out - the cover must be urgently replaced.

Lids are inexpensive, so you can always buy products in stock

If the cover hisses on the road and there is no way to buy a new one, you can repair the product yourself:

- Wait until the engine cools down and the pressure in the cooling system drops.

- Unscrew the lid.

- Disassemble the lid into pieces (pull out the rubber band and valve spring) - these procedures can be performed either by hand or with a screwdriver with a thin flat blade.

- Saw off part of the spring into several turns and reassemble the cover.

- Even if the rubber seal is severely worn out, these measures should be enough for some time to create a tightness in the system.

Tank housing rupture - what to do

Also (rather rarely) the tank body itself may rupture.

However, in these cases, the product cannot be repaired - it is easier to buy a new tank and put it in place of the old one.

However, some car enthusiasts try to glue cracks on the body; the main thing in this matter is to choose the right material.

There is such a good thing - cosmofen 12. I may be wrong in the letters, but in general the name is like that.

Used for gluing plastic. Glues within five seconds. for a long time. I accidentally glued my fingers together and only tore them off with the meat. It's hard to find. Ask those who make outdoor advertising from plastic. They must have this. You need to glue it the first time. Degrease well. Because it doesn’t apply to the second layer. And since it eats into the plastic, removing it will be problematic. The number after the name may vary. I don’t know why, ask where you find it what it means. Bolivar

https://www.delicaclub.ru/forum/index.php?/topic/1869-remont-radiatora-i-rasshiritelnogo-bachka/

It is important to choose high-quality glue that can withstand high and low temperatures

Violation of the tightness of the connection between the tank and the pipes

This problem is usually associated with incorrect selection of the diameter of the pipes for the inlet and outlet of antifreeze.

If the hoses are larger than the tank fittings, it is recommended to treat the joints with automotive sealant.

Just before processing you will need to drain the coolant from the tank and disconnect the hose itself:

- Apply a layer of sealant first to the inside of the pipe, then to the outside.

- Wait 5 minutes for the sealant to dry.

- Place the pipe onto the tank fitting and tighten with a new clamp.

- Only after a day can you fill in the coolant, since the sealant must dry as efficiently as possible.

The pipe must match the size of the fitting; in case of mismatches, sealant will help

Checking the functionality of the lid

Simplified test: are the valves working?

We start the engine and, being careful, unscrew the cap: if you hear the hissing sound of a deflated chamber, the bypass valve is working (however, whether it is correct or not is unknown).

After removing the cover, squeeze any hose of the cooling system with your hand. Continuing to hold it in this way, put the cover in place. If it then regains its shape, the vacuum appears to have been filled. But if, even before starting the engine, the hoses look like they are flattened, the vacuum valve is definitely not working.

More accurately, the safety valve can be checked using a pump and pressure gauge. We connect the pump to the lower supply pipe of the tank, and plug the upper one using improvised means: a bolt or a cylindrical drill that fits tightly into the supply hose.

We create pressure with the pump and control the moment when the safety valve is activated (hissing sound). The pressure value recorded on the device scale shows the actual response pressure.

If the safety valve is too tight, it can be repaired. Why spend extra money when it is enough to shorten the pressure spring by one or two turns, and the spring will become softer. The assembly is easy to disassemble, the main thing is not to lose small parts. And don't overdo it by biting off the coils. Do this little by little and check the results.

Features of arranging open heating

Classic open heating equipment

A classic open-type heating system for a private home differs from a closed one in terms of pressure. It is equal to atmospheric. Therefore, to arrange this type of heat supply, significantly fewer components and accurate calculations are required. But this does not mean that an open heating scheme can be drawn up unprofessionally.

To automatically stabilize the coolant pressure in the pipes, the system provides an open expansion tank for open heating. It is the design of this component that distinguishes an open heat supply scheme from a closed one. The coolant can move in two ways:

- Due to thermal expansion of hot water. For this, an accelerating riser is required. According to this scheme, an open heating system with natural circulation is designed;

- Installation of pumping equipment. It allows you to increase the speed of coolant movement. A pump in an open heating system is necessary if the total length of the lines exceeds 25 m.

In addition, it is necessary to reduce the friction of water as it passes through the pipes. To do this, the diameter of the latter must be at least 30 mm. Otherwise, hydraulic resistance will increase, which will reduce natural circulation.

The defining component in the scheme is the boiler for an open heating system

It is important not only to choose the correct design and operating principle of the device, but also to follow all installation rules

Adding coolant

The liquid level in the tank is controlled by two extreme marks: min and max. How to properly add coolant to the expansion tank:

- Check the fluid level on a cold or cooled engine (let it cool thoroughly).

- Open the RB cover (if the engine is not cool enough, grab the cover with a rag) and slowly turn it until steam comes out.

- Add liquid without reaching the max mark.

- Close the lid and start the engine with the heating off. Warm up the engine for about 3 minutes at 2000 rpm and wait until the forced cooling fan turns on.

- Check the coolant level and add it to the max mark.

A little advice:

monitor the external condition of the tank and all elements of the cooling system. Fluid leaks in the engine compartment often indicate a malfunction of the expansion tank, primarily the cap.

As follows from what has been written, it actually depends on such a seemingly secondary unit as the expansion tank of the cooling system how stably the engine of your car will operate.

Summing up

After reading this article, you can learn a few lessons for yourself and not repeat the mistakes that other car owners have made. The main thing to know is that new coolant should only be poured onto a cooled engine, otherwise this may lead to deformation of the engine itself or the cooling system.

You should also constantly pay attention to the cooling system and constantly look at the readings of the sensors, and if they are not there, then often unscrew the tank cap and monitor the pressure. Proper care and constant monitoring of the performance of all components of the car can contribute to rare visits to car service centers and spare parts stores. There is no principle of communicating vessels, so the liquid rises to the top.

Liquids for filling into the tank

Today's cars, built with the widespread use of new technologies, are very demanding of all process fluids, including coolant. The list of requirements is as follows:

Antifreeze is a purely domestic product, synthesized during the USSR

All of the above requirements are met by antifreeze or antifreeze, which is the same thing. The name antifreeze comes from the English word antifreeze, which means “non-freezing”. Antifreeze is a substance created on the same basis from ethylene glycol in the former USSR. The word consists of the abbreviation TOS (technology of organic synthesis) and the ending “ol”, inherent in the names of chemical preparations.

The base of antifreeze and antifreeze is the same - water + ethylene glycol in different ratios. Differences between products from different manufacturers may lie in the package of inhibitory additives, so it is not advisable to confuse liquids. There will be no fatal consequences, but some substances can neutralize the effect of others and the anti-freeze properties will deteriorate. In this case, the color of the liquid does not matter - it is just a dye.

You can use distilled water to fill the tank in the following situations:

The color of antifreeze does not affect its properties; the additive package is important

Distilled (desalted) water does not meet the above requirements: it freezes at zero temperature and boils at 100 °C. Therefore, it is poured temporarily or as a solvent for antifreeze.

It is unacceptable to pour tap water saturated with salts into the expansion tank. An exception is the breakdown and loss of antifreeze on the way and the absence of a car shop nearby. Fix the leak, fill the cooling system with tap water and get to a garage or service station, then drain it immediately. Otherwise, deposits will form on the inner walls of the water jacket of the engine and other units, impairing heat transfer.

Video: liquids for pouring into the car cooling circuit

Tips for choosing the best tank

When choosing hydraulic tanks, we are guided by the following considerations:

- A hydraulic accumulator with a replaceable cylinder-type shell has a number of advantages over products with a built-in diaphragm - it allows you to change the cylinder, which is beneficial due to the not too long service life of products made from natural materials. In addition, the water in balloon tanks does not come into contact with its walls - this reduces the requirements for the corrosion resistance of a metal tank.

- It is better to choose a removable flange from durable stainless steel with a long service life.

- The required volume of the hydraulic accumulator is determined using the above formulas; to avoid calculations, you can use ready-made tables.

- The cylinder material in drinking water intake systems is chosen from environmentally friendly food grade rubber; butyl best suits these requirements.

- When purchasing, they consider manufacturers taking into account the optimal price-quality ratio; hydraulic accumulators from Zilmet (a holding company headquartered in Italy), Reflex (Germany) are considered to be among the best; it is clear that in quality indicators they are inferior to Russian-made Gilex and Wester units, Aquasystem Russian assembly from Italian components.

Rice. 15 Cost of popular models of hydraulic accumulators in 2019

A hydraulic accumulator is one of the most important components in an autonomous water supply system, its functioning largely depends on its physical parameters, design and materials of manufacture. To select a suitable unit, determine its required volume using simple formulas or tables, then select a model from a number of brands of domestic and foreign production according to the optimal price-quality ratio, considering the materials of manufacture and being guided by reviews and advice from experts.

Design and principle of operation

Modern expansion tanks for cars are a reservoir made of durable thick-walled plastic with a filler neck and fittings for connection to the elements of the cooling system. The shape of the tank does not matter functionally, so manufacturers customize it to fit the location of the tank.

The shape of the tank depends on the location of its installation and can be different - round, rectangular or flat

The capacity of the container for expanding antifreeze is calculated for each car model and depends on the total volume of liquid in the pipes and units. Moreover, in a cold state, the tank is only half filled with antifreeze, the rest of the space is occupied by air that can compress under pressure. The neck of the tank is closed with a plug with a built-in air valve. The principle of operation of the container is as follows:

The design of the container is quite simple - the tank body is closed with a stopper with a built-in valve

In an emergency situation, when antifreeze or water begins to boil for various reasons, the safety valve releases not only air, but also steam.

The built-in sensor sends a signal about insufficient fluid level to the instrument panel

Calculation of accumulator volume

The selection of a membrane tank is primarily carried out according to its main parameter - volume; if it is small, the system will work ineffectively with too frequent activation of the electric pump and small water hammers. If the volume is exceeded, stagnation of water in the tank can make it undrinkable.

To calculate the volume of the hydraulic tank, use the following formula:

Vt = 16.5 Qmax/A Pmax Pmin/(Pmax – Pmin) 1/Pg, where:

- Vt —hydraulic tank volume;

- Qmax – water supply per unit of time, measured in liters per minute, standard water consumption for one family is 3 m3/hour or 50 l/min;

- A – the permissible number of starts of the electric pump in one hour, depends on the power of the unit, for most submersible models the limit is 20;

- Pmax and Pmin are the values of the switch-off and switch-on pressures of the electric pump in bars, their typical average values are 3 and 1.5 bar, respectively;

- Pg – air pressure inside the accumulator in bars, calculated by multiplying Pmin by 0.9 (0.9 x 1.5) = 1.35.

As a result we get:

Vt = 16.5 50/20 3 1.5/(3 – 1.5) 1/1.35 = 91.66 l

As can be seen from the table in Fig. 10, the maximum volume of water inside any expansion tank does not exceed 50% of its rating data.