The electric boiler is a simple and environmentally friendly device, and is widely used especially in places with a shortage of centralized supplies of natural fuel. Automatic control of an electric boiler with a modern level of computerization guarantees not only the specified level in a house or apartment, but the safe operation of boiler equipment and electrical networks. The electric heating system is equipped with stabilizers to prevent voltage surges. Reliable and efficient operation of the boiler is possible provided that the entire interrelated package of requirements for selection, installation, piping and configuration is met. In this case, one of the most important stages is piping the electric boiler (EC).

Tying scheme classic version

The connection diagram of the electric boiler must ensure that there are no significant temperature changes.

The most commonly used are double-circuit boilers. passing through the small circuit, the water (oil or antifreeze) heats up, after which it flows through the large circuit. This also needs to be taken into account in the diagram. Electric boiler wiring requires the presence of:

- Brackets;

- Filter;

- Shut-off valves;

- Valves (check and safety valves);

- Expansion tank;

- Pump (if required);

- Thermometer and pressure gauge;

The following types of strapping are distinguished:

- With the installation of a hot water circuit (oil or antifreeze): before entering the tap, the coolant passes through an electric boiler;

- With connection to the heated floor system;

- Regular electrical connection.

When piping a double-circuit boiler, its type is determined by the model (with or without a mixer). It is quite difficult to install it at home with your own hands, since here, along with the correct connection to the electrical network, you also have to control the connection to the hot water supply.

Each model has its own connection diagram for the electric boiler (it is included when purchased along with the device). If you don’t have enough time or you are not sure that you can do everything correctly yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. For 5-30 thousand rubles, specialists will do such work. But if you make mistakes at the first stage, you can subsequently not only incur much greater expenses, but also endanger yourself and other residents of a private house.

Replacing the heating element

Replacing the heating element and other elements, as well as diagnostics to determine the cause of the malfunction, is carried out in a passive way when the electrical equipment is disconnected from the external alternating voltage source.

This issue cannot be resolved on your own if you are not an electrician and such work is carried out accordingly if you have knowledge of the regulatory documents of the electrical safety approval group.

So what is the need for these details? — You may ask, if in this or that case there is a malfunction, you can call the electrician directly.

Well, let's put it this way - knowledge of electrical and electrical engineering will not be superfluous for you.

Connecting an electric boiler

Let's consider connecting the EVAN S1-30 electric boiler to a four-wire, three-phase network with a neutral wire.

The fifth PE conductor in the diagram in Fig. 1 is grounding and is connected to the body of the EVAN S1-30 electric boiler. Reading the connection diagram:

The electric boiler is equipped with so-called buses; a network cable with a plug is connected to buses N, A, B, C. From the buses, three phases A, B, C have branching. One branch of phases A, B, C is connected to the first contacts of the heating elements of two blocks.

The second branch from the same four buses is connected through a starter to the second contacts of the heating elements of two blocks.

Here it should be taken into account that for each individual block with heating elements, each individual heating element is connected to phase wires as follows:

Phase A and neutral wire N from the busbars are connected to the control panel. In its combination, the control panel is connected to a voltage of 220 V, the conductors from the control panel are connected:

- with pump;

- with air temperature sensor;

- with thermostat sensor;

- with self-resetting thermal switch.

The control panel consists of electronic elements that are not indicated in the diagram.

For electronic elements, diagnostics are outlined in this blog.

After carrying out repairs to replace one or another electrical part:

- block with heating elements;

- self-resetting thermal switch

and other parts included in the electrical circuit, it is necessary, before connecting the electric boiler to an external source of alternating voltage, to check the electrical circuit of the boiler for resistance. Diagnostics of the resistance in the electrical circuit of this circuit is carried out either with an ohmmeter or a multimeter with the appropriate function.

If, as a result of measuring resistance, the device indicates a zero value, in this example you should reconsider the connections you have made. A zero resistance number indicates a short circuit in the electrical circuit.

Consider the following electrical circuit for two types of boilers EPO-7.5 and EPO-9.45. The electrical circuit shown in Fig. 2 is identical and the difference here is only in the power of electric boilers. Let's follow the connection diagram:

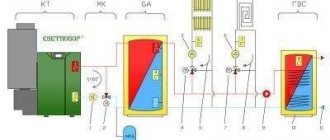

Connection of equipment with other boilers and heat accumulator

To integrate a heat generator into the system, you need to use a circuit with two check valves, a surface-mounted thermostat and a room temperature controller. This heating boiler piping scheme will allow the cooling coolant to be captured and redirected to the heater after the heating element has been turned off.

Let's look at how to connect an electric boiler to a solid fuel boiler in stages:

- While solid fuel equipment (SF) operates as the main one, the electric boiler is auxiliary and operates in standby mode.

- After the fuel burns out, the temperature in the room drops. As soon as the heat level drops to the standard set by the owner, the room thermostat will turn on the electric heater.

- A surface-type thermostat will note a decrease in the temperature of the coolant in the return pipeline and turn off the pump.

- After adding the next portion of fuel, heating is restored, the thermostat turns on the pump. The electric boiler sensor “detects” the heated coolant and will not start the equipment into operation until it receives a command from the thermostat.

To make the installation of an electric boiler into the system clearer, watch the video from professionals.

On a note! The shown method of how to install an electric boiler into a heating system is also useful for piping gas and diesel equipment. In this scheme, the equipment is auxiliary, not main.

It would not be superfluous to integrate a buffer tank or heat accumulator into the circuit. This equipment will store energy while generating excess energy and then redistribute the heat supply when needed. For example, when the boiler operates at full power at night (in the case of electric boilers, it is more profitable to do this at night tariff), the accumulated heat will be enough to maintain a comfortable temperature during the day.

A mixing unit with a three-way valve will perform the task of redirecting the coolant at the required temperature to the radiators. Thermal accumulators maintain a heating level of up to +80 C.. +90 C. When installing water heated floors in rooms, it is necessary to equip a second mixing unit that heats the coolant to +45 C - this is the established water heating indicator for underfloor heating circuits.

Materials used

Materials for the piping circuit of an electric boiler must ensure safe operation of the equipment and comply with the requirements of state regulations and standards for operation, rules for the technical and safe operation of consumer electrical installations.

Requirements for piping electric heating boilers:

- The power supply is carried out by a copper wire with a cross-section indicated in the passport;

- grounding must be carried out in accordance with the requirements of the PUE, and checked annually for operability;

- a separate cable with an automatic safety switch must be installed;

- It is prohibited to use gas, water and sewerage systems as a grounding loop.

Before choosing a material for piping an electric boiler, you need to familiarize yourself with its technical capabilities, which affect the operation of electric heating. For pipes, important characteristics are thermal insulation properties, the ability to create complex structures and the cost of piping. The most common piping solutions are polypropylene or copper pipes.

Copper piping

Carrying out installation using copper pipes requires certain experience from the performers, and significant financial resources from the users. Advantages of copper pipes:

- High heat transfer coefficient of copper - heating of the room is carried out not only by heating devices, but also by the piping system.

- High anti-corrosion protection, although pipes become covered with a thin layer of corrosion over time, it does not affect performance.

- There is no threat of rupture of the pipeline system from freezing. This is due to the fact that copper is more ductile and can withstand freezing loads without compromising its integrity.

Piping an electric boiler with copper pipes

- High installation cost;

- Copper pipes should not be buried in the wall;

- the need for high-quality insulation;

- protection against stray currents, the effect of which is detrimental to copper.

Tying with polypropylene pipes

Many users consider polypropylene to be an ideal option for EC strapping. This pipe option is reinforced with fiberglass reinforcement to resist heat. The smooth, anti-corrosion inner surface of the pipes ensures excellent circulation speed of heating water. Installation technology using special welding equipment ensures high quality work without coolant leaks. When preparing a thermal heating scheme and dividing it into heating sections, you should take into account the features of plastic - a high coefficient of expansion and heat loss. Therefore, it is not recommended to choose areas with a long length of pipes.

Polypropylene pipes are connected in 2 ways: soldering and using fittings. The first method is the most reliable, practically does not allow leaks, the second is less reliable, even with a slight displacement - hot water begins to leak.

Modern polypropylene pipes are distinguished by long service life - 40 years or more and high strength, able to easily withstand environmental pressure up to 25 Bar. The latest modifications of these pipes have received protection against excessive expansion; today, even heating the coolant to 95 C does not cause deformation.

Installation nuances

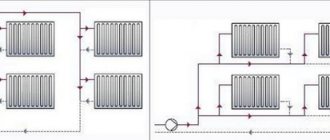

First of all, it should be said that there are two types of systems with an electric heat generator:

- With natural pressure on the coolant (the electric boiler is located at the bottom of the circuit).

- With forced circulation (you can find a video with a detailed analysis of pump installation on the website). The boiler can be located at any point in the chain (except for the highest).

Many private home owners install not one, but two electric boilers. "just in case". If the backup device does not operate at full capacity, then the electric boiler is installed in parallel, so that both generators work with the same power.

Conclusions and useful video on the topic

Electric boiler installation procedure:

Although using an electric boiler as a heating device is considered too expensive, its advantages are obvious. Such devices are safe for people and the environment, operate automatically, are accessible and easy to use.

If the type of heating system is chosen correctly and all its components are professionally installed, the boiler will operate for a long time without unnecessary costs.

Do you have experience using an electric boiler to heat your home? Or want to ask questions on the topic? Please comment on the post and participate in discussions. The feedback block is located below.

Strapping scheme

As already mentioned, correct tying is of paramount importance.

In this case, it is especially important to take into account not only how to calculate an electric boiler for heating, but also its main purpose - to control the level of temperature difference of the coolant at the inlet and outlet of the boiler. Initially, the coolant, having reached a certain temperature, passes through a small circuit

And only after this hot water is distributed throughout the system, heating the radiators, and thereby increasing the air temperature in the room. From this we can draw a simple conclusion - in order to create in the system the temperature necessary for its high-quality operation, it is necessary to create several heating circuits.

To create a harness you need:

- circulation pump;

- distribution valve;

- balancing valve;

- pressure gauge;

- pass filter;

- radiators;

- pipes of different diameters;

In addition, you may need wrenches and a welding machine. Of course, a heating system with an electric boiler will not be able to function without tees, adapters, valves (safety, check, air), fasteners (couplings, bolts, nuts).

There are 4 different principles for piping an electric boiler:

- with natural circulation;

- with forced circulation;

- classic wiring;

- on primary-secondary rings.

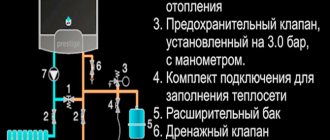

Scheme with forced coolant circulation

Scheme with forced circulation of coolant. 1 – room temperature level controller; 2 – safety block (safety valve, pressure gauge); 3 – radiators; 4 – heating boiler; 5 – closed expansion tank; 6 – pump; 7 – tap for replenishing the amount of water in the system; 8 – anti-condensation pump; 9 – check valve; 10 – minimum temperature sensor.

If the heating system with an electric boiler is based on the operation of a wall-mounted heating boiler, all the elements that it includes are also included in the piping.

Moreover, it may include, in addition to heating, also hot water supply and a “warm floor” system. It should be noted that connecting the system according to the instructions will not be a problem if you follow all the instructions exactly. However, this only applies to single-circuit systems. When installing double-circuit systems, everything is much more complicated. In this case, you can perform both direct tying and mixing. The main difference between these types of strapping is the principle of temperature control.

Pumping and mixing unit

It is possible to construct a heating system according to a combined scheme in a private house using a pumping and mixing unit. The design with it is the most effective, but will be more expensive compared to using a 3-way valve, although the operating principle is the same.

Cooled water from the return pipe dilutes the hot coolant, and the presence of balancing taps allows this to be done in the required proportions.

This unit comes in different configurations. It depends on the purpose and cost of the equipment. The standard device includes:

- thermostatic valve;

- immersion temperature sensor;

- balancing valve with fixing spring valve;

- circulation pump;

- immersion thermometer;

- threaded sleeve;

- bypass and shut-off valve;

- drain and ball valve;

- air vent;

- bypass bypass.

Sequence of work

A typical piping diagram assumes the location and sequence of equipment installation, the pipe system, the type and type of equipment, the number of circuits, the type of heating elements, the electrical circuit with equipment and protection devices. When the heating system has a high resistance, for example, multi-circuit heating or a “warm floor” system, then a circular electric pump is installed.

Strapping sequence:

- First, install the boiler securely on the wall or floor. The heating element unit is fixed at least 1.5 m from the floor level, induction or electrode devices are fixed lower, according to the piping conditions.

- Install the distribution manifold from the boiler.

- Attach pipes of the required diameter to the inlet and outlet pipes of the EC.

- A three-way valve with a mixer function is installed to regulate the temperature of the coolant.

- Mount the circulation pump on the return line.

- Install heating boiler protection devices, consisting of 2 valves and a pressure gauge installed at the outlet of the EC.

Piping diagram of a natural circulation system

A typical heating system for objects based on the principle of natural coolant circulation requires the installation of the following basic elements:

- Room thermostat for temperature regulation;

- heating devices - radiators and convectors;

- open type air tank;

- shut-off and control valves and taps for feeding the network circuit.

The technology for piping an electric boiler with natural movement of the medium is simple and accessible for self-installation. It is simplified due to the absence of a pump to move the coolant.

Heated water moves along a contour made with strict observance of slopes, thanks to the physical laws of movement of hot and cold media. It is applicable for individual heating of one-story buildings with small heating areas.

Forced circulation piping

In this scheme, the circulation pump is additionally connected: a bypass line, power supply, shut-off and control valves and a security system with temperature and pressure sensors. This is the most optimal scheme for automatic control of heating and hot water levels. The owner of the facility can choose different temperatures for different rooms, although this will require an increase in the cost of heating due to the cost of electricity to operate the pump.

Algorithm for piping an electric heating boiler, diagram of a heating element electric boiler:

- The outlet pipes are connected to the network pipeline through ball valves and an American connection.

- A membrane-type expansion tank and a mesh filter are installed in the return line to filter suspended sludge and debris in the network water.

- To clean the mud pan, a ball valve is installed in front of it.

- A circulation pump is installed in circuits with forced circulation; if it is not included in the boiler delivery set, then it is purchased additionally, the selection is carried out according to the volume of water that is cooled along the boiler contour and indicated in the passport.

- A safety group is installed: a pressure gauge, an air vent and a safety relief valve that prevents pressure from increasing in the system.

Emergency harness

This type of piping is required for double-circuit electric boilers; it is performed for the purpose of safe operation of all equipment, for example, a sudden power outage.

There are several options for emergency piping:

- Water circulation through bypass with tap water make-up. The circuit has little application, because often when there is a power outage, the water is also turned off.

- The emergency power source for the circulation pump is a battery. It must always be charged, so the circuit requires constant maintenance personnel to charge and maintain the batteries.

- Gravity circulation is a special circuit with minimal load connection for cooling the coolant, heating only a small part of the rooms. This scheme is the most effective solution.

We can draw a line, indeed, piping an electric autonomous heating boiler is not complicated. Nevertheless, the contractor will be required to scrupulously perform and ensure the quality of connections. The owner and installation organization will be required to comply with the Electrical Safety Rules and adhere to the accuracy of the manufacturer's wiring diagram indicated in the technical documents of the electric boiler.

Connection features

Installing an electric boiler does not involve complicated work, but it is worth considering the installation recommendations. If the boiler is wired correctly, it can be placed anywhere in the house and still work efficiently.

Electric boilers are suitable for use in different circulation systems. The equipment and supply pipeline must be placed at the lowest point of the heating system, which contributes to better heating of the radiators.

The boiler also needs to be grounded. The use of the zero phase is excluded, since the automation detects this as a short circuit.

In addition to the correct installation of the boiler and the selection of high-quality components, it requires professional installation. If the piping is done according to the rules, it will ensure a minimum temperature difference between supply and return.