Elimination

If you notice that the bottom is significantly colder than the top, then urgent action is required. It is necessary to follow the following algorithm to find the cause:

- Checking the correct connection.

- Inspect the radiator, bleed and clean it.

- Assess the condition of the control valves.

- Check the pipes.

- Determine the type of heating system, install or replace the circulation pump.

The first step is to check the correct connection. To do this, it is necessary to estimate the temperature of the lower pipe. If the return and supply were connected incorrectly, it will be hot. You will need to reconnect and build the circuit correctly. When connected correctly, this element remains slightly warm.

Often the cause is an air lock in the battery, which does not allow the coolant to spread throughout the radiator. The design must include a Mayevsky valve or bleeder for air removal. It is necessary to shut off the supply, open the drain and remove all air and batteries. After the tap is turned off, the heating valves are turned. In some cases, this procedure turns out to be effective.

If an adjustment valve is installed in the system, then there is a high probability that the problem is there. It is necessary to dismantle this element and carry out an inspection. If the section is narrowed, you will need to expand it using specialized tools. But it is better to purchase a higher quality part and reinstall the tap into the system.

I will describe my problem in detail, since the mechanics of the local management company shrug their shoulders, and I myself cannot understand what the reason is ((And it all started like this: We have 2 risers in our apartment - one in the hall, the other in the kitchen, which is connected through crosspieces in the kitchen and children's room. Last year everything was changed to propylene from the basement, we have a second floor, there is a bank below us, there are 2 more floors above us, the neighbor in the 5th compartment has his own apartment and is heated independently. Riser systems are based on the "supply-return" system , last year they worked well, and this year, as soon as the heating was turned on, everything was fine. It worked for a month without interruptions, the return and supply were hot. 2 weeks ago the return cooled down, and then the pipes completely cooled down. They gave a request, a mechanic came, He said that we need to wait for the cold weather, that maybe the boiler room is not adding pressure or whatever. I go upstairs to my neighbor - there is circulation above me, both risers are hot, return and supply. I go up to my neighbor on the 4th floor - everything is there, both risers heat perfectly. I am perplexed - why am I having a problem on the second floor? I think maybe something is clogged? But the pipes are new, sawn everywhere - what could be there? I don't understand. A mechanic comes, lowers something in the basement, and the risers begin to heat up. They heat up normally, cool down after 15 minutes. There is no airing, I constantly bleed through Mayevsky - only water comes out, no air. Yesterday I shut off the American 3/4ths in front of the battery, removed it, washed it (Sandital radiators, aluminum with anti-corrosion coating), put it in place (first I drained the water from the riser - both from the return and from the hot one in case there was something there got into trouble), filled it with water - the supply and the upper part of the battery began to heat up. I turn off the supply, release the return through the battery - it starts to heat up, I stop draining - it cools down. Thus, the upper half of the battery worked until 23:00, then it began to cool down. This morning the mechanic came again, threw up his hands and went up to the neighbor: everything was fine with him. As a matter of form, he went down to the basement and pumped something there - it began to circulate, then died out again. In general, help me solve the puzzle! I can't figure out what's wrong:

- Everything worked for 1.5 months, there was circulation. Return and feed worked.

- Two weeks ago everything disappeared, but only here, on the second floor. The neighbors above have everything.

- There is no blockage or clogging in the radiators, and no in the risers either.

- There is no circulation. What the heck? We didn’t change anything structurally, the circuit worked the same way last year, everything was warm!

- The housing department said that some residents also have this problem, which means I’m not alone. But they may just be airy.

- There is no airiness, everything is lowered 100 times through Mayevsky and removing the batteries.

Quite often in residential apartment buildings during the heating season you can encounter the following problem: the riser is hot, but the radiators are cold. This applies to both new buildings and old houses. Residents in most cases do not know how to cope with such a situation. That is why their attempts to repair the heating system on their own do not lead to the desired result. In this matter, you definitely need help or advice from a specialist. After all, only a person who has the necessary knowledge and experience can solve the problem of why the pipes are hot and the radiators are cold.

Types of radiators for heating apartment buildings

In multi-storey buildings there is no single rule allowing the use of a specific type of radiator, so the choice is not particularly limited. The heating scheme of a multi-storey building is quite universal and has a good balance between temperature and pressure.

The main models of radiators used in apartments include the following devices:

- Cast iron batteries

. Often used even in the most modern buildings. They are cheap and very easy to install: as a rule, apartment owners install this type of radiators themselves. - Steel heaters

. This option is a logical continuation of the development of new heating devices. Being more modern, steel heating panels demonstrate good aesthetic qualities, are quite reliable and practical. They combine very well with the control elements of the heating system. Experts agree that steel batteries can be called optimal for use in apartments. - Aluminum and bimetallic batteries

. Products made from aluminum are highly valued by owners of private houses and apartments. Aluminum batteries have the best performance when compared with previous options: excellent appearance, light weight and compactness are perfectly combined with high performance characteristics. The only disadvantage of these devices, which often scares off buyers, is the high cost. However, experts do not recommend saving on heating and believe that such an investment will pay off quite quickly.

Conclusion

The correct choice of batteries for a centralized heating system depends on the performance indicators that are inherent in the coolant in the given area. Knowing the cooling rate of the coolant and its movement, you can calculate the required number of radiator sections, its dimensions and material. We should not forget that when replacing heating devices, it is necessary to ensure that all rules are followed, since their violation can lead to defects in the system, and then the heating in the wall of a panel house will not perform its functions (read: “Heating pipes in the wall ").

It is also not recommended to carry out repair work in the heating system of an apartment building on your own, especially if it is heating within the walls of a panel house: practice shows that residents of houses, without the appropriate knowledge, are able to throw away an important element of the system, considering it unnecessary.

Centralized heating systems demonstrate good qualities, but they need to be constantly maintained in working order, and for this you need to monitor many indicators, including thermal insulation, wear and tear of equipment and regular replacement of worn-out elements.

In a heating radiator, the top is hot and the bottom is cold. What to do?

If the top of the heating radiator is hot and the bottom is cold, this indicates that it is not functioning correctly. In this case, it is necessary to look at the entire heating system and, of course, the radiator itself. Let's figure out what the problem might be here.

Typically, this problem occurs if any work has been done on the heating system, including when changing the radiator. There may be two problems here. Either there is an air lock in the heating radiator, or the taps on the heating radiator are clogged. The reasons may be different, including incorrect starting of the heating system or heating radiator.

Now let's figure out how to fix this defect. There are two options. Let's start with something simple. As mentioned earlier, the reason for such operation of the heating radiator in 99% of cases is an air lock. To remove it using the first method, there must be a Mayevsky tap or drain on the battery. It is installed instead of the top plug.

What should be done? It is necessary to close the connection to the heating radiator - this is the top pipe. Leave the return line open. Next, open the bleeder and wait until all the air comes out of the battery. Then close the drain and open the feed. Often such a simple manipulation helps.

What to do if there is no drain in the heating radiator or the previous method does not work? For apartment buildings with a central heating system, the answer is clear: call a locksmith. For those who have an individual heating system, the work procedure is as follows.

First, you need to turn off the supply. Open the drain at the top point of the heating system and use return pressure to squeeze out all the air from the system. If we are talking about dumping air from one riser, then you can turn off the supply only on it. But at the same time, there must be a drain on this riser.

Bottom of radiator is cold

Differences between them

The difference between the described concepts is as follows:

Important! Some tips need to be followed. The entire system must be completely filled with water or antifreeze . Maintaining fluid speed, circulation and pressure is equally important.

Temperature difference across radiators

The temperature difference should be 30 °C . In this case, the batteries will feel approximately the same to the touch . It is important to ensure that the difference in these values is not too large.

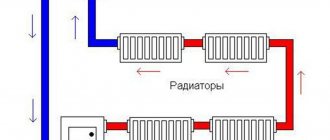

Photo 2. Heating diagram for 6 radiators: changes in flow and return temperatures on each of them are indicated.

Methods for installing return flow in a heating system

Radiators used in heating are made using excellent technologies from different materials, known varieties are steel panel, bimetallic (sectional) made of steel and aluminum, tubular, slightly reminiscent in appearance of old cast-iron radiators. For connection, three methods are used to connect their outlet pipes to pipes.

Lower

In modern cottage-type houses or dachas, it is fashionable to use heating of rooms with heated floors without the use of radiators that degrade the aesthetic appearance of rooms and take up a certain area. Most often, a combination of two methods of heating rooms using floors and radiators is used, while in order to level the floor levels on the entire floor, the pipeline leading to the radiators is placed in a screed. Pipe outlets are mounted from the floor or wall at a low height, to which the radiator is then connected using an N-shaped unit (binoculars). In addition to ease of connection, this liner has an aesthetic appearance, and when placed in the walls it creates additional advantages when cleaning rooms and washing floors.

A special bottom connection unit is used in one-pipe and two-pipe distributions; one of the single-pipe varieties, “Leningradka”, used for horizontal placement, has also become widespread.

Schemes with lower piping, despite their aesthetic appearance, have a significant drawback, which is weak heating of the upper part of the radiator and, accordingly, 20% less heat transfer. To eliminate this phenomenon, some lower connection units have an external bass-pass connected to the upper pipe - this is how more efficient carrier liner.

Rice. 11 Where is the supply and return in a heating system with bottom supply

Lateral

The most common, but not very effective method in terms of heat transfer, is used in all heating systems of apartment buildings, gravity circuits of individual houses and cottages, the hot coolant enters the upper radiator pipe, and the return flow exits through the lower pipe in the same plane.

In apartment buildings, when the coolant is supplied from above, its temperature decreases as it passes through the entire circuit, and the radiators below emit less heat. Therefore, to equalize the temperatures on the lower floors, the number of radiator sections is increased compared to the upper ones, but they are often faced with the main disadvantage of the side connection system - poor heating of the most distant sections.

There are not too many methods to combat this phenomenon; in addition to increasing the diameter of the supply pipes, they use homemade flow extenders in the form of a regular tube, inserted into the inlet radiator pipe and directing the main coolant flow to remote sections.

Rice. 12 Supply and return in a heating system with side, diagonal and bottom connections

Diagonal

As mentioned above, the side connection does not always cope with sufficient heating of extended radiators along the entire length; in this case, diagonal connections come to the rescue. When organizing the supply diagonally, the coolant from the boiler enters the upper radiator pipe and exits into the return line through the outlet located below at the opposite end.

Diagonal connection is very often used for single-pipe and two-pipe connections in individual houses; compared to other types, it ensures maximum heat transfer from radiators.

Rice. 13 Options for side cross (diagonal) and bottom eyeliner

You might be interested: Do-it-yourself heating in a private house from polypropylene pipes

Ways to control the temperature of a heated floor

To ensure the specified requirements of sanitary and technological standards, user preferences, the heated floor can be adjusted using the following adjustment methods:

The starting points for changing system settings can be measurements of the coolant temperature in the supply or return distributors. Indeed, for water heating, unlike electric heating, it is not typical to install thermal sensors in the floor structure - they are mounted directly on the collectors. Most often, such sensors or sensitive elements are parts of thermostatic valves, through which the heated floor is adjusted.

Control signals to automatic devices can also come from air temperature sensors located in heated rooms.

Causes of heating problems

Most residents of city apartments believe that they have no need to know the structure of engineering systems. Any central heating problems that arise in their high-rise building must be resolved by the employees of the management company. And it is right. It is better if only one responsible owner is involved in all matters. Indeed, in an apartment building, problems with heating often arise precisely because of unauthorized interventions in the smooth functioning of the heating system.

But individual homeowners are forced to understand problems with heating in a private home and keep the situation under control. The owner of the house must know at least in general terms about the causes of problems and be able to correct them.

The following reasons can lead to problems with the heating system:

- the system is not properly designed;

- equipment does not meet design requirements;

- the system was unbalanced due to unauthorized connections;

- installation was performed poorly;

- air pockets interfere with coolant circulation;

- radiators are installed incorrectly;

- pipelines have become unusable;

- the tightness of the connections is broken.

Let's take a closer look at each of these reasons and ways to eliminate heating problems in an apartment and in a private house.

Design features of the heating circuit

Modern buildings often use additional elements, such as collectors, heat meters for batteries and other equipment. In recent years, almost every heating system in high-rise buildings has been equipped with automation to minimize human intervention in the operation of the structure (read: “Weather-dependent automation of heating systems - about automation and controllers for boilers using examples”). All the described details allow you to achieve better performance, increase efficiency and make it possible to more evenly distribute thermal energy throughout all apartments.

Operating pressure in the heating system

Working pressure is considered to be the pressure whose value ensures optimal operation of all heating equipment (including the heating source, pump, expansion tank). In this case, it is taken equal to the sum of pressures:

- static - created by a column of water in the system (in calculations the ratio is taken: 1 atmosphere (0.1 MPa) per 10 meters);

- dynamic - due to the operation of the circulation pump and the convective movement of the coolant when it is heated.

It is clear that in different heating schemes the operating pressure will differ. So, if natural circulation of the coolant is provided for heating the house (applicable for individual low-rise construction), its value will exceed the static value by only a small amount. In forced schemes, it is taken as maximum permissible to ensure higher efficiency.

Numerically, the working pressure is:

- for one-story buildings with an open layout and natural circulation of water – 0.1 MPa (1 atmosphere) for every 10 m of liquid column;

- for low-rise buildings with a closed layout - 0.2-0.4 MPa;

- for multi-storey buildings - up to 1 MPa.

Options for solving the return problem

Depending on what is the root cause of the problem, appropriate methods are selected to eliminate it. For example, if the return flow does not work well due to insufficient pressure or water speed, it is recommended to purchase a special pump.

His job will be to push water into the system with a certain force to avoid stagnation and ensure continuous movement of liquid through the batteries.

Pressure, water speed and return temperature in the heating system

Basically, the requirements for heating systems imply dividing the specifics of heating into two types:

- independent, here the source of heat energy is located directly in the room - used in an individual house or in multi-storey buildings of an elite type;

- dependent, where a network of pipelines is connected to the heating complex - used in most houses in the urban area and urban-type settlements.

Due to the specific nature of the circulation of the coolant, water is predominantly used, where the speed of water in the heating system directly affects the temperature in the radiators. Circulation is divided into natural (based on the principle of gravity) and forced (heating system using a pump). According to distribution, it is customary to distinguish between a heating system with lower and upper pipe distribution.

Temperature

Despite the wide selection of heating systems provided, the options for heat supply and return are quite limited. The maximum temperature in the heating system must also be set according to the rules in order to avoid further malfunctions.

Radiators are connected to the heating system in one of three ways: bottom, side or diagonal.

Also, the lower connection is also called differently: “Leningradka”, saddle. According to this scheme, the return and supply are installed at the bottom of the battery. In most cases, it is used when pipes are laid under the baseboard or under the floor surface. The return temperature in the heating system should not differ from the supply temperature.

Water speed

If there are few sections, heat transfer will be extremely ineffective compared to other schemes - the speed of water in the heating system decreases, which leads to heat loss.

Side heating is the most popular type of connecting radiator batteries to heating. The supply of water as a heat carrier is carried out in the upper part, and the return is connected from below, so that the return temperature in the heating system is considered equal.

To avoid a decrease in the efficiency of this type of connection when increasing the radiator sections, it is recommended to install an injection tube.

Pressure

The diagonal type of connection is also called a side cross circuit, because the water supply is connected at the top of the radiator, and the return is organized at the bottom of the opposite side. It is advisable to use it when connecting a significant number of sections - with a small number, the pressure in the heating system increases sharply, which can lead to undesirable results, that is, heat transfer can be halved.

To finally settle on one of the options for connecting radiator batteries, you must be guided by the methodology for organizing the return flow. It can be of the following types: single-pipe, double-pipe and hybrid.

The option you should choose will directly depend on a combination of factors. It is necessary to take into account the number of floors of the building, where the heating is connected, the requirements for the price equivalent of the heating system, what type of circulation is used in the coolant, the parameters of the radiator batteries, their dimensions and much more.

Most often, their choice is made on a single-pipe heating pipe layout.

As practice shows, such a scheme is used precisely in modern high-rise buildings.

Such a system has a number of characteristics: they are low in cost, fairly easy to install, and the coolant (hot water) is supplied from above when choosing a vertical heating system.

Also, radiators are connected to the heating system in series type, and this, in turn, does not require a separate riser for organizing the return. In other words, water, having passed the first radiator, flows into the next, then into the third, and so on.

However, there is no way to regulate the uniform heating of radiator batteries and its intensity; high coolant pressure is constantly recorded in them. The further the radiator is installed from the boiler, the more heat transfer decreases.

There is also another wiring method - a 2-pipe scheme, that is, a heating system with return. It is most often used in luxury housing or in individual homes.

Here is a pair of closed circuits, one of them is intended for supplying water to parallel-connected batteries, and the second is for draining it.

Hybrid wiring combines the two schemes described above. This could be a collector circuit, where an individual wiring branch is organized at each level.

What Causes Return Problems?

Of course, first of all, you should consider what reasons may cause problems with the return line.

When a cold return is detected, it is recommended to first pay attention to the water pressure inside the system. In order for the return to work as it should, the system must be designed in such a way that water continuously circulates within the circuit.

When the speed of water pushing decreases, the coolants will not be able to push cold water through in a timely manner. This in turn will cause the batteries to cool down. Rooms on the upper floors of houses are most susceptible to the problem of insufficient water pressure.

The second most common problem is a clogged system. Unfortunately, cleaning of heating pipes in multi-storey buildings is carried out much less frequently than required by the rules. Consequently, sediment settles inside the pipes, which over time clogs the circuit and causes poor water permeability, significantly reducing its speed.

It is believed that the most problematic reason is poor heating installation. That is, when an inexperienced beginner takes on the installation and laying of pipes, without the necessary knowledge, there is always a risk that he may make a mistake somewhere or select elements that do not fit together in size. That is why it is advisable to seek the services of specialists.

Control of operating pressure in heating circuits

For normal, trouble-free operation of the heating system, it is necessary to regularly monitor the temperature and pressure of the coolant.

To check the latter, deformation pressure gauges with a Bourdon tube are usually used. To measure small pressures, their varieties can be used - diaphragm devices.

Figure 1 – Strain gauge with Bourdon tube

In systems where automatic control and regulation of pressure are provided, various types of sensors are additionally used (for example, electric contact).

- at the inlet and outlet of the heating source;

- before and after the pump, filters, mud traps, pressure regulators (if any);

- at the exit of the main line from the thermal power plant or boiler house and at its entry into the building (with a centralized scheme).

Figure 2 – Section of the heating circuit with installed pressure gauges

Modernization of the circulation system

Instant access to hot water in the circulation system is only possible if it is constantly heated, which is certainly associated with certain energy costs. However, these costs are less than when we simply flush the cooled water down the drain. However, it is possible to make the circulation system even more economical.

Recently, experts have begun to use new thermostatic balancing valves

(photo on the right), which calibrate the flow of such a cross-section that will ensure minimal water circulation, but while maintaining the specified temperature in the circuit. As the water cools, the valve increases flow capacity. If the temperature increases above a predetermined level, the valve closes, thus ensuring optimal circulation.

Such valves allow you to set the water temperature in the system within 40-60°C. Previously, throttle flanges or pre-set control valves were used for this. These devices are not automatic and therefore require regular adjustment. New thermostatic valves themselves determine the required distribution of water depending on the prevailing conditions, for example, when actively dispensing water from several taps. This makes it possible to ensure optimal water distribution and slightly reduce energy costs. In addition, thermostatic valves allow you to maintain different water temperatures in the circuits. So, with their help, you can make sure that hotter water flows into the kitchen than into the bathroom, where there is no need to supply water hotter than 45°C.

DHW with circulation and thermostatic valve

. A simple circulation circuit with a new generation thermostatic valve consists of a hot water source (boiler, storage water heater), a circulation pump, a thermostatic valve, pipes and tapping points. Hot water from the boiler enters the circulation circuit. The thermostatic valve is installed on the return pipe after the last water draw-off point, but before the circulation pump, which is located immediately before the “return” entrance to the boiler. If the system consists of several hot water circuits, then they are connected in parallel, i.e. depart from the supply pipe and return through thermostatic valves to a common return pipe, which, passing through a circulation pump, is connected to the boiler.

Maintaining the optimal temperature in the circulation circuits can also be ensured by circulation pumps, the operation of which is controlled by a thermostat. When the water temperature in the circulation circuit reaches a predetermined level, the thermostat turns off the pump and turns it on when the water temperature drops a few degrees.

The pump can also be controlled by a programmable timer, and this scheme is quite common. Its advantage is that circulation in the DHW circuit occurs only during the period of its use. For example, the pump can be turned off at night when everyone in the house is sleeping. However, it makes sense to choose this option if the family lives according to a certain established regime, which, however, is not uncommon. Energy savings in this case are the highest. Typically, timer systems also allow manual pump control. For example, if on some holiday hot water will be used at night, then it is enough to turn on the pump and circulation will take place in continuous mode.

Manual control of the pump is, in principle, very reliable, but there are inconveniences, since you have to turn on the pump in advance and then remember to turn it off. For manual control, it is recommended to additionally equip the pump switch with a shutdown timer. However, even in this case, situations will often arise when one of the residents forgets to turn on the pump and drains all the water from the pipes.

The boiler is working, but the radiators are not heating, why is there cold return in the heating system?

The heating system is a complex structure consisting of several elements combined into one circuit and put into operation through a chain reaction.

What is return in a heating system?

The return is a coolant located inside the heating system. During operation, it passes through all heating devices and gives off heat to them. Then, already cooled, the coolant returns to the boiler, where it is heated and begins a new cycle.

Photo 1. Heating diagram with a circulation pump and expansion tank. The arrows show the movement of the coolant.

Both ordinary water and antifreeze act as a coolant. It is put into operation either naturally (under the influence of gravity) or forcibly (using a pump).

Causes of problems with return flow in the batteries of a private or apartment building

- insufficient water pressure in the system;

- small section of the pipe through which the coolant passes;

- incorrect installation;

- airiness or contamination of the system.

If a problem with cold return occurs in an apartment, then the first thing you should pay attention to is the pressure. This is especially true for rooms on the upper floors. The fact is that the principle of operation of the return flow is to quickly and continuously circulate liquid through the system

And if its speed drops, then the coolant will not have time to push out cold water and the batteries will not heat up

The fact is that the principle of operation of the return flow is to quickly and continuously circulate liquid through the system. And if its speed drops, then the coolant will not have time to push out cold water and the batteries will not heat up.

The main reason for interruptions in the operation of the heating system in a private home is incorrect installation. Most often this happens when installation is carried out without the participation of specialists. Being incompetent in this matter, it is quite easy to confuse the supply and return pipes or choose pipes of the wrong size.

Troubleshooting methods. Why is cleaning necessary?

To understand exactly how to solve a problem, you first need to establish its source. If the batteries become cold due to insufficient water circulation, installing a special pump will help. It will regularly push water into the circuit under a certain pressure, thereby preventing the system from stopping or slowing down.

If the reason is that the pipes are clogged, then they simply need to be cleaned. You can do this in several ways:

- using a water-pulsating mixture;

- using biological products;

- by means of pneumatic hydraulic shock.

In the event of a malfunction resulting from improper installation of the equipment, contact a specialist. A qualified specialist will certainly understand the problem and eliminate all problems. In addition, he will give practical advice and recommendations on the care and operation of the system.

Useful video

Check out the video, which talks about one of the possible problems with the return flow - battery contamination.

What problems arise in the apartment due to cold return

Firstly, the batteries in this case do not heat up properly, or even do not work at all. Accordingly, the room itself becomes cold, which is certainly not encouraging.

This entails the accumulation of condensate on the walls of the boiler, which begins to react with carbon dioxide released from fuel combustion. The consequence of this process is the formation of acid, which corrodes the walls of the boiler, thereby destroying it.

To live without fires and explosions: how to ground a gas boiler in a private house with your own hands?

What is needed to connect a gas boiler to a gas source?

Are the pipes cracking angrily and not heating well? It's time to flush the gas boiler and its heat exchanger

Requires extreme caution! Principles for replacing a gas boiler in a private house

Fine-tuning the heating system, accessible to everyone: how to connect a room thermostat to a gas boiler

You can save money, just be careful: do-it-yourself instructions for repairing a gas boiler

This is interesting: How to bend drywall for an arch with your own hands at home: read in detail

Possible reasons why return pipes are cold or too hot

If there is insufficient heating of the premises, you should look for problems in the heating system, and it is useful to know how to determine the supply and return taps; the cold temperature of the latter indicates a malfunction in the heating circuit. In this case, the operation of all automatic systems and thermostats associated with responding to the temperature parameters of the output coolant is disrupted - this can lead to a malfunction of the entire system.

The main causes of cold return pipes are:

Installation errors. A similar situation can most likely occur when panel steel radiators that have two built-in terminals with a standard axial size are installed at the bottom using special units. In addition to the fact that their built-in radiator channels are designed to connect only their supply or return line, the correct operation of the units themselves becomes impossible if the pipes suitable for them are mixed up, the type of which is indicated by arrows on the device body.

Airing. The presence of air in any risers, pipelines or radiators leads to malfunctions of the system, in which an insufficient amount of coolant is supplied to the heat exchangers, as a result of which the temperature of the exiting liquid will be too low.

Rice. 14 Return pipeline in the collector distribution

Reducing the channel cross-section. In case of mechanical defects, contamination of the channels as a result of the use of hard water or expired antifreeze, in which the cross-section is narrowed, the volume of coolant entering the heater is too small and the return will have a low temperature. Often the narrow passage channels of shut-off plumbing fittings become clogged - in this case, the tap must be dismantled and cleaned with a means to remove lime deposits or other decomposition products.

Equipment breakdowns. Failure of the circulation pump will lead to the cessation of fluid flow, cooling of all circuits and cold return; this problem can occur from insufficient fluid flow in the line, which occurs when the circulation electric pump is faulty or insufficiently powerful. In case of mechanical damage or loosening of compression couplings, depressurization occurs, coolant leaks out and, accordingly, the entire system loses its functionality.

Technological reasons. In forced circuits, the movement of the coolant is carried out using an electric pump; when it is turned off due to lack of electricity, the movement of the liquid and the heating of the premises stop, the electric boiler also does not work and the batteries remain cold. If the supply of fuel to a gas heating boiler or diesel fuel is cut off, the house will also be left without heating.

Rice. 15 Violations when soldering polypropylene

Overfeeding

Reducing the flow helps to reduce the temperature of the return line, there are several reasons for this, in addition to clogging of the main passage due to contamination, narrowed channels in the places where the shut-off valves of control valves are located, in branches with connected auxiliary devices, such as liquid meters or thermostats, are often clogged.

In many cases, the determining factor for low flow is gross errors in installation, and you need to pay attention first of all to technology violations associated with soldering polypropylene pipes by inexperienced specialists. When the surfaces overheat during joining, the molten polyprolene is pressed into the pipe shell and the passage channel is narrowed, leading to insufficient heating of all heaters and a cold return.

If there are blockages, you will need to flush the system with hot liquid and resolder all joints if the polypropylene pipes are connected incorrectly.

Rice. 16 Clogged heating pipe

Poor coolant circulation

Poor circulation is often found in open gravity systems; it occurs when there is insufficient temperature difference between the medium at the inlet and outlet of the boiler. In a closed circuit, if operational problems arise, its low speed is associated with poor operation of the circular electric pump, clogging of the channel and fittings with limescale, and antifreeze decomposition products.

It may be necessary to flush parts of the system and drain the coolant; in case of severe contamination, individual devices (pump, hydraulic valve, three-way valve) are removed and cleaned separately. On the circulation pump, you should select a higher rotation speed of the electric motor shaft with an impeller (the standard device contains 2 or 3 speeds).

Return coolant overheating

Sometimes a situation arises when the average temperature of the return water is too high; this phenomenon can lead to a malfunction of the system, the mode of which is associated with measuring the temperature of the medium in the line. The main reasons for this phenomenon are too high a rate of water circulation through the heating circuit and flow through the bypasses of single-pipe systems connecting the supply and return pipelines. Since the carrier transfers heat with low efficiency, transferring it to radiators in too large a volume or bypassing them via the bypass jumper, this phenomenon leads to unjustifiably increased energy consumption and a decrease in the efficiency of the entire system.

To eliminate the negative consequences of overheating in a private house, reduce the rotation speed of the centrifugal wheel of the circulation pump, reduce the heating temperature of the working fluid, narrow the bypass passage channel, installing pipes of a smaller cross-section or installing control valves in each of them; similar operations with bypass are carried out in apartment buildings .

Rice. 17 How to choose a connection scheme from an efficiency point of view

To implement heating in private houses, one-pipe and two-pipe systems are used, the former are the most cost-effective, and the latter ensure uniform heating of all heat exchangers when using a Tichelman loop. It should be noted that the return of the heating system plays an important role: its correct installation increases the efficiency of the system, and temperature parameters are used in the operation of automatic devices that optimize heating and increase efficiency, as well as in identifying faults.

Air locks in heating

If the radiators are not heated in any of the rooms, it means that the air accumulated in the system is preventing the free movement of the coolant. An air lock can form due to many reasons, including the following:

- air enters when water is drained from the system and then refilled;

- Oxygen is released from water when heated;

- a faulty expansion tank creates a local area of low pressure;

- air is sucked into the system through connections with broken seals;

- air diffusion occurs through the surfaces of plastic pipes.

Air bubbles can accumulate either at the highest point of the piping system, or only in one of the radiators. Then the bottom of the battery will be hot and the top will remain cold. The presence of air in the pipes also provokes the appearance of unpleasant gurgling sounds. Most often, heating devices on the top floor of a building stop heating.

Due to air bubbles, not only does the heat supply through the piping system stop, but also corrosion of metal elements begins. The smooth operation of the circulation pump is also disrupted.

The use of simple technical devices will help get rid of the problem of clogging the heating system with air locks.

The most effective way to remove air from a closed heating system is to use automatic air vents. If they are mounted in several problem areas at once, then the air from each group of system elements will be released as it accumulates.

In addition to automatic ones, there are also manual air vents (Maevsky valve). Such a device is installed at the end of the radiator, located on the topmost floor. You can learn how to use it from the video presented here.

How to bleed air through the Mayevsky tap

Depending on how the heating system is designed, it may sometimes be necessary to bleed air through an expansion tank in the attic. The circulation pump can also help expel air pockets from the system.

How to find the supply and return pipelines for heating an apartment

Why is it necessary?

It is important for every apartment owner to know where the central heating input is located. Because, if a coolant leak occurs on any section of the pipeline or radiators, you need to react quickly and turn off the shut-off valves at the heating inlet to the apartment, in order to avoid flooding your apartment and the apartments of your neighbors below you. Since the pressure in centralized heating systems of apartment buildings is 3-5 Bar (atmospheres), the slightest leak will quickly turn into a deep river of boiling water (the temperature of the heating system varies from 40 to 90 °C).

Depending on the characteristics of the intra-house heating system, the input of thermal energy into the apartment may be located:

- directly in the apartment itself, in which case all that remains is to find out where the supply is and where the return is.

- in the heating niche located in the corridor on the floor where the apartment is located;

- in the heating niche located in the corridor 1 floor below the apartment;

- in the heating niche located in the corridor 1 floor above the apartment;

We will consider cases 2-4 in more detail below.

If each of the apartments has its own heating niche located near/under/above the entrance to the apartment, then all that remains is to find out where the supply is and where the return is.

In cases where we are dealing with combined heating niches (1 niche for the entire floor, 1 niche for every 2-4 apartments), a seemingly easy task can turn out to be a serious challenge. Everything is decided by chance. The following options are possible:

1. Numbering – trust, but verify!

If builders or operating organizations have numbered the outlets from the heating system comb, there is a possibility that your apartment number and the outlet number will match, and the search process will come to its logical conclusion. However, as the famous proverb said, “Trust, but verify!” How to do this is described below in this article.

2. The pipes do not intersect.

Builders often follow this rule when installing heating systems. Based on it, you can conduct a visual analysis of the direction of laying pipelines and find your pipes. However, in our country everything is possible and both written and unwritten rules, as well as any elementary logic and rationality, can be violated. So, if you want to be sure of something, check it yourself.

3. Plans and drawings do not correspond to harsh reality.

Armed with a floor-by-floor layout diagram of heating networks and engineering drawings, you can also get into trouble. Due to the fact that there is often a big difference between the project and the actual execution, it begins with the developer’s banal desire to save money and ends with the arbitrariness of the builders. So, if you want to be sure of something, check it yourself.

4. Clinical cases.

Sometimes you can simply encounter clinical cases of general negligence and irresponsibility, when, in the process of research, it is revealed that your incoming and outgoing pipes are not located symmetrically one below the other, but are located at different poles of the comb. That is, for example, your incoming pipe on the comb is the 1st on the left, and the outgoing pipe is the 2nd on the right.

Sequence of actions when adjusting batteries

It should be noted that the adjustment of radiators in centralized heating systems comes down mainly to setting the control devices to a comfortable temperature regime. In autonomous schemes, this process is more labor-intensive, because It is not only the batteries that need to be regulated, but also the boiler. In addition, if several heating devices are connected to a closed heating circuit (one- and two-pipe systems with bottom wiring), it is necessary to achieve a balanced heating circuit.

To solve this problem, at the initial stage you should determine the coldest room in the house, because... Battery adjustment will begin with this. To do this, all taps are closed, and after the radiators have cooled, the temperature in each room is measured.

In the found room, the shut-off valve opens completely, and after reaching the required level of heating, they move to another radiator, adjusting the position of the valve, which ensures a comfortable mode. After all the batteries have been adjusted, begin setting up the boiler regulators.

There is another (simplified) option. To do this, it is necessary to determine the exact sequence of location of the radiators along the flow of the coolant. Then in the first battery the tap or thermal head is opened, for example, by one or two turns, in the next - by two or three, in the third - by three or four, etc. If the temperature in each room meets the needs, the adjustment process is considered complete. Otherwise, the procedure should be repeated, increasing or decreasing the number of turns of the tap.

When designing a heating system, measures must be taken to control temperature and pressure. To do this, it is necessary to install special fittings and devices. How to properly adjust the heating system: radiators, pressure and other elements? First you need to understand the principles of organization of these sections of the system.

Possible problems and their manifestations

A malfunction in the water heated floor system manifests itself in a sharp decrease in the level of comfort in the room.

It is felt physically:

The question arises, why does a water heated floor heat poorly or is there no heating at all?

Often, such problems can arise immediately after installation of the system during the first start-up. That is why it is important to know the requirements for putting a heated water floor into operation, as well as to be able to correctly adjust the system.

In order not to worry, wondering how long it takes for a water heated floor to warm up, you should adhere to all the requirements of the installation technology when constructing a “warm pie”. One of the possible reasons for the low quality of heat transfer from the system is poor-quality thermal insulation.

Periodic recording of energy consumption and temperature can be invaluable in identifying the problem. By checking them, it is much easier to identify the malfunction in time.

Causes

As already mentioned, the bottom of any battery will be slightly cooler than its top. The level of heat transfer from any metal is quite high - the water manages to cool faster than it leaves the radiator sections. For this reason, a temperature difference occurs.

The problem can be diagnosed by the increase in temperature gap. The bottom of each section burns with cold, while the top part heats up (sometimes it is dangerous to touch the battery with your hands, the metal is so hot).

The most common causes of this condition are:

- Slow circulation speed of the working fluid.

- Incorrect connection (supply and return pipes were mixed up).

Violation of the correct installation scheme is not that uncommon. Many owners or unskilled craftsmen make mistakes when connecting pipes to batteries.

As for the circulation speed, it may drop already during operation. This happens for a variety of reasons, each of which requires immediate elimination.

Connection errors

Qualified craftsmen, of course, do not make such mistakes. But amateurs may well make mistakes when installing heating. Most often, the return line is connected to the upper branch pipe of the battery. In this case, the feed is attached to the bottom. As a result, the removal of fluid from the radiator is disrupted, its efficiency decreases, and the entire system does not function properly.

If you connect the supply pipe from below, water flows around the battery in a circle and leaves it, while individual sections do not fill or do not warm up. With the upper return line, the liquid cannot leave the inside of the structure, because the radiator is not able to create increased pressure and squeeze water out through the upper pipe.

When connected correctly, the working fluid enters from above and gradually flows through all sections of the radiator, going down. After which it enters the return line and is transported back to the heating boiler.

The error can be resolved quite simply:

- All pipes are dismantled (disconnected from the pipes).

- The correct connection diagram is ensured: supply from above, return from below.

- All elements are attached to their proper places. After which the heating is started and its operation is checked.

The only difficulty is the danger of stopping the system during the cold season. Therefore, for new heating it is recommended to carry out testing before the first frost.

Speed drop

There are three reasons for improper circulation:

- Violations were made during installation, namely, the cross-sections of the pipes were narrowed.

- The coolant moves too slowly within the system.

- The room temperature is too low.

Slow circulation is typical for circuits without additional equipment. As soon as a pump is installed that provides forced circulation, the problem is completely solved.

The narrowing of the section occurs for several reasons. An old heating system can accumulate rust or scale. Or an adjustment valve with an inappropriate cross-sectional diameter was installed. Alternatively, the polypropylene pipes are soldered incorrectly.

In order to accurately determine the reason that caused poor heating of the radiators, it is necessary to carefully inspect the circuit and analyze its condition.

Why is a valve needed?

The correct design of a heating system is developed taking into account the difference in temperature values in the coolant supply and return pipes.

Often, instead of installing a boiler, another protection option is used that ensures long-term operation of solid fuel boiler equipment.

It helps to connect a bypass, which is a specially embedded pipe that allows the cooled coolant to change the direction of movement around the boiler.

The bypass ensures circulation of the coolant through the so-called small circuit. When forming this circuit, a thermostatic or three-way valve is installed at the junction of the bypass and return.

It operates depending on the preset temperature mode. When the coolant circulating in a small circle reaches the set temperature (usually 55-60°), the valve opens slightly. This ensures the flow of the next portion of cooled coolant from the return system and can significantly reduce the heating time before entering the boiler.

Constant mixing of hot and cold coolant maintains the temperature of the liquid entering the boiler at the optimal value.

Important! A small circulation circle allows you to heat a sufficiently large volume of water, which will prevent the formation of condensation on the combustion chamber and maintain its tightness, and therefore its performance, for a long time