Setting the register

You can make water heating using a boiler welded from sheet steel or a coil from pipes with your own hands if you have the skills to work with a welding machine.

When making it yourself, you need to take into account that the thickness of the sheet metal or pipe walls must be at least 3-5 mm. Heating of such a coil will occur slowly compared to thin-walled devices, but its service life will be much longer. Burnout of thin metal walls will lead to a major overhaul of the furnace in which the heating element is installed. In self-made coil designs, an old battery (heating radiator) made of cast iron can be used. To use it as a heat exchanger, preliminary preparation is required: the radiator must be disassembled into sections, washed from the inside to remove scale and rust with appropriate compounds and checked for defects (leaks). Reconnect the serviceable sections, using an asbestos cord impregnated with drying oil as a seal between them. The prepared radiator can be installed in the firebox of a brick or metal stove, either on the side or above the flame. In the latter case, the battery must be located in a horizontal plane.

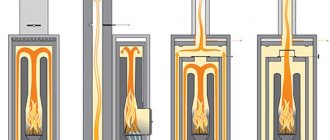

The welded heat exchanger of a water heating system can have different shapes. If the oven is not planned to be used for cooking, the register or boiler can be made in the form of a U-shaped structure from pipes or sheet metal. So the efficiency of a homemade boiler can be increased by increasing the surfaces heated by the flame. To allow cooking on a stove located above the firebox, a different design will be required. In this case, the containers located on the side surfaces of the furnace and the stove, located as it is usually installed in cooking structures, will heat up.

Laying pipes throughout the house

The heating system circuit, made of steel pipes with a diameter of 7-10 cm, is designed according to the principle of heating distribution from any type of boiler: after leaving the heat exchanger, hot water must rise to a height sufficient for circulation, and then, having gone around all the rooms of the house in a circle, return back to the boiler according to "reverse". At the top point of the pipe leaving the boiler, in a gravity system, it is necessary to install an acceleration manifold and install an expansion tank to create pressure in the system.

When installing an electric pump in the system, the possibility of a power outage must be taken into account. In this case, autonomous water heating will not work. In order to avoid getting into a situation where heating the house is impossible due to lack of electricity, it is recommended to install the pipes according to a gravity heating scheme, and build the pump into it as an auxiliary device. In this case, the installation of the electric unit must be carried out on a pipe welded in parallel through the bypass. This will allow you to turn off the flow of coolant through the water pump using a tap if it stops and continue heating by natural circulation of water under the influence of gravity.

Butt welding of pipes is not recommended. To prevent the possibility of leaks during the operation of self-made heating during welding, it is necessary to chamfer the edges of the pipes and place them with a shift relative to each other by at least 5 mm. The types of radiators used in the system can be any.

After the wiring has been completed and all work on connecting the pipes to the boiler has been completed, the system must be filled with water and checked for welding defects at the pipe joints. If leaks are detected, drain the water and correct the defects. Only after the final sealing of the joints can the water heating system be heated.

author Sergey Sobolev 3k Views Opinions

If anyone thinks that a garage is just a place to park a car, it’s women. Little do they know that the garage is actually a men's club, where you can not only repair the iron horse, but also receive friends. One problem is that in our climate from October to April the air temperature does not allow much lingering in unheated rooms. Today we will take a closer look at the types of heating and choose the most economical method. Heating a garage and everything you need to know about it is in our material.

Read in the article:

Furnace design, its specifics

The important elements of a potbelly stove are:

Furnace compartment. It is located approximately in the middle third of the oven. Designed for burning fuel - wood or coal. Equipped with a door on the side wall of the oven for loading. An ash pan is necessary to collect solid residues after burning wood or coal. It is disconnected from the part for the firebox at the top by grates, which are cast iron rods of a specialized shape. Ash awakens in the gap between them and penetrates into the waste collection tray. At the bottom of the ash pan, a bottom is made of sheet metal 1.2–1.5 mm thick. The container with the coolant is a tank made of sheet metal, filled with water or the rest of the heating agent. This device requires absolute tightness. At the top of the tank there is a hole for the outlet of water, at the bottom there is a return pipe through which the coolant cooled in the heating system is returned. The smoke exhaust duct is installed on top of the stove body; it can be vertical, horizontal or inclined. It is brought out through the wall. For potbelly stoves, in most cases a pipe diameter of 150 mm is used. The supporting part is legs made of profile metal, providing a clearance between the body and the floor of at least 20–25 cm. Under them it is necessary to install a protective sheet of metal with an asbestos backing

This is very important if the heating unit is placed on a floor made of combustible materials.

Pipe coils

The design of this unit depends on the design of the furnace. There are different types:

- With right angles. Such thermal units are made of sheet metal up to three millimeters thick. Naturally, the most technologically advanced pipe coil is made in the form of a jacket located around the combustion chamber. The distance between the walls of the jacket and the furnace body depends on the volume of the heat exchanger. The higher it is, the very slowly the heating of the coolant in it occurs. Often containers are installed on top of the combustion chamber, but in this case the surface for cooking the stove becomes inaccessible.

The quadrangular shape of the stove is most suitable for a potbelly stove

Cylindrical vertical potbelly stove is very cheap

A potbelly stove can be made from a metal pipe needed for a high-pressure pipeline

Lining can be compared with thermal insulation

You can also heat the room with sawdust

Making a potbelly stove with a hydraulic circuit with your own hands

When installing this type of heating system, you can either build a water boiler into a potbelly stove or create the stove itself from scratch. Thanks to this, figuratively speaking, the process can be divided into 2 stages.

Development of the potbelly stove

Before work begins, drawings are drawn up that include all dimensions of the furnace, and key materials are prepared for working with metal: an inverter unit, a hammer, an angle grinder, as well as pliers and special protective clothing.

When creating a diagram of a potbelly stove with a water jacket with your own hands, it is important to take into account the thickness of the components of the future unit. Once the metal has been cut, we proceed to the next steps:

Once the metal has been cut, we proceed to the next steps:

Combine the bottom with the walls, excluding the front. All parts should be welded at right angles.

Important: It is better to place the bottom of the stove at a level of 25-30 cm from the floor. Likewise, engineered iron legs can reduce the effect of heat on the flooring

A partition is welded into the space between the combustion chamber and the blower. You need to drill several longitudinal holes in it through which the ash will be removed.

The blower opening must be up to 3 cm smaller compared to the blower itself.

- Openings for doors are made on the front wall. After which it can be placed to the key structure;

- Roof protrusions are added to both sides of the front part and doors are installed;

It is better to equip all doors with deadbolts

A chimney pipe is welded to the part on top of the stove. At the end of the work, all parts should be checked for flaws in the seams. If none are found, we proceed to the second stage - adding a hydraulic circuit.

Adding a hydraulic circuit to a potbelly stove

The basis of a similar type of furnace is a pipe coil, which can be constructed from various materials, for example, hollow steel pipes or steel sheets. In addition to the heat exchanger, to create a potbelly stove with a hydraulic circuit you will need:

- Finished furnace body.

- Heating appliances.

- Pipes.

- Sheets of metal.

The system installation process is as follows:

Two holes are made on top of the base of the potbelly stove for the supply and return of water.

Drawing up a drawing of a future potbelly stove with a hydraulic circuit, created on your own, can help make the work easier.

- A water tank is formed from metal or other suitable non-usable materials; the largest space should be allocated for it when compared with the combustion chamber and ash pan. Holes for the pipes are made in the tank, then it is placed behind the combustion chamber. The space is disconnected by a sheet of metal.

- Next comes the process of installing the pipework. It can be one-pipe, two-pipe or manifold.

Important: A two-pipe design is considered more preferable, as it makes it possible to change the temperature using installed taps and provides the same heating, unlike a single-pipe design. The collector is considered very difficult for independent construction

The next step is the methodical connection of pipes with heating devices throughout the house.

It is recommended to install heating appliances under windows. This will increase the heat conductivity of the stove. The design of a potbelly stove with a hydraulic circuit is examined for the absence of holes where water can leak through the circuit.

An expansion tank is installed to the supply line, which will prevent the supply of cold water. Its size is selected based on the volume of water that will be located in the entire system - the tank must be made 20% larger.

Example of a potbelly stove with an expansion tank

With proper construction, the water will heat up in the heat exchanger, pass through the pipes to the heating devices, cool and return to the pipe coil.

We recommend reading in detail about the types of heat exchangers for all this material.

The finished structure can be painted or finished using brick, depending on what appearance the owner prefers.

Video: project of a potbelly stove with a hydraulic circuit

With the help of a potbelly stove with a water jacket, designed with your own hands, you can save a lot on heating a country house. Such a structure can provide the required amount of heat to any room.

Care and maintenance of the potbelly stove

The stove will serve you for a long time if you follow the rules for caring for it:

- The condensate collector installed on the chimney must be opened weekly to drain the water.

- at the beginning of the heating period, the chimney must be cleaned of soot with a specialized tool.

- During operation, the stove body and pipe must be constantly monitored for smoke penetration into the room.

- Monitor the condition of supply and exhaust ventilation.

Self-made iron wood stoves can not only be spectacular, but also become a real interior decoration of the room. But do not forget about the need to follow all installation and operation rules.

Important information for your safety

The second possible danger after carbon monoxide poisoning is a garage fire. There are always flammable materials here, including the contents of the car's fuel tank. Neglect of safety measures is fraught not only with the loss of your garage and your beloved horse, but also with a serious lawsuit from neighbors in the parking lot.

For these reasons, we consider it useful to remind you of the basic rules:

Think about the fact that it would be a good idea to install the simplest smoke detectors in this room.

Registers for a water-heated furnace

When creating a water heating system, a heat exchanger is used. It may be in the form:

- small boiler;

- coil;

- register.

The main advantage is that a standard water-type heating design can be connected to the heat exchanger.

Registers may have different structures. Most often they are made of steel sheets or metal pipes.

A high-quality register should work in such a way as to ensure the highest heating of water and its continuous and uniform circulation throughout the system.

When creating a register, it is necessary to pay special attention to the heating area and a suitable shape that will give better water circulation. It should be noted that a heat exchanger made of steel sheet is easier to use. It is easy to clean from the deposits that have formed, and it is much cheaper in cost.

However, its heat-absorbing properties are not so high. Registers and coils are more efficient since they are made from pipes and provide maximum heating area

It is easy to clean from the deposits that have formed, and it is much cheaper in cost. However, its heat-absorbing properties are not so high. Registers and coils are more efficient because they are made of pipes and provide maximum heating area.

Air convector

There is not always enough finance to purchase a ready-made heat exchanger. In principle, it is not difficult to make a heat exchanger for a heating furnace. For this, copper and aluminum are used; if desired, you can completely do without welding. With proper preparation and accurate calculations, the budget is significantly saved.

First, a location is selected, parameters are calculated, and you need to decide what material to choose to make the heat exchanger. You can build a structure from an old cast iron radiator, a radiator from a car. The main thing is to take into account the conductivity of heat. It is also important to think over a set of tools, prepare everything in advance, each detail makes installation much easier.

Assembly must begin with drawing up a drawing taking into account the dimensions. If the stove is weak, a disproportionately large heat exchanger will do harm. When using copper for the coil, its length is maximum 3 m. The speed of heating depends on the length of the pipe and the number of curls. It is important to remember that distortions reduce the life of the equipment.

Air convector equipment

To twist the pipes into a spiral, a template is required. This is any available part in the shape of a cylinder. Its diameter must fit into the size of the firebox.

The sequence of actions is as follows:

- bend the pipe, wind it around the workpiece to form a spiral;

- keep the dimensions to fit the coil;

- the average design power of the heat exchanger is 1 kW per 10 m2.

Construction of an exhaust furnace with a water circuit

The design consists of two chambers connected by a pipe through which air is supplied. When heated in the lower tank, the fuel forms oil vapor. In the pipe it mixes with air, causing the combustion process to become more intense, and in the upper chamber it burns out. The products of the chemical oxidation reaction of the substance are removed through the pipe.

When making a unit with your own hands, the design is often supplemented and changed depending on the required functions of the product and the material used. The thicker the steel of the body of a homemade oil furnace for mining with a water circuit, the longer the device will last. In addition to sheet steel, unnecessary cylindrical products (for example, gas cylinders) are also used.

Features of operation

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

The operation of such a stove is similar to a conventional brick stove. Although it does not retain heat so well. Therefore, a brick potbelly stove made with your own hands will have to be heated again 4-6 hours after the last coals have burned out.

This indicates the unprofitability of using such a design for constant heating. However, for heating a garage, cottage, etc. periodically, it may well be used.

This stove runs only on solid fuel. This is another drawback.

At the same time, the design is simple to manufacture and operate. This is what determines its popularity.

Equipping a potbelly stove with a hydraulic circuit

To remove this significant design disadvantage, such heating units are equipped with an additional heating system.

The purpose of this modification is to increase the overall heat capacity, which will make it possible to maintain a favorable temperature in the room for a longer period and, therefore, to fire the stove less often.

The heating medium is heated directly from the combustion chamber of the furnace. There are several options for this:

- Arrangement of “pockets” on the side walls into which the coolant is poured.

- Installation of a water tank with outlets to a traditional heating system.

- The process of installing a collector around the chimney very close to the stove, passing through which the air is heated specifically from the chimney.

- Installation of a water heater in the combustion chamber of a furnace.

The potbelly stove can be used for traditional heating

When starting to make a potbelly stove with a water heater, the home craftsman focuses, first of all, on the materials available and determines the heating method himself.

The advantages of this heat supply device include its speed. The room can be heated to a suitable temperature too quickly, and maintain the required level for a long time.

The disadvantages usually include the following:

- Such a stove requires continuous attention and timely heating within 24 hours.

- In a house outside the city, where you sometimes appear as a coolant, it is necessary to use antifreeze or mineral oils, preferably transformer oil, but regular oil can also be used. Otherwise, the water will freeze in winter and rupture the parts of the heating system. Repairs in cold weather are unrealistic.

An iron furnace with a water jacket has a high level of efficiency

Possible difficulties during construction

The gas cylinder valve is screwed on very tightly. It's not easy to remove. Unscrewing will require a good adjustable wrench and a lot of physical effort. To make the process go faster, it is recommended to fix the cylinder.

Attention! Do not start cutting the cylinder without first filling it with water, as residual propane can lead to an explosion. Cutting metal, cutting sheet steel with a grinder is a labor-intensive process

The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

Cutting metal and cutting sheet steel with a grinder is a labor-intensive process. The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

A finished potbelly stove placed on a base may wobble. This happens if the heater legs are of different lengths. Trim them using a grinder.

Furnace design with a water circuit

The classic design of the stove consists of a firebox divided by grates into a firebox and an ash pan, surrounded by walls made of brick or metal. When fuel burns, heat is transferred to the premises through radiant heat transfer from the enclosing surfaces of the furnace. The use of furnaces is usually caused by objective reasons:

- Lack of other types of fuel other than firewood and coal, namely natural gas and electricity of the required power;

- The relative cheapness of firewood in many regions of our country;

The main disadvantage of the heating design is the uneven distribution of heat throughout the heated rooms, as well as the cyclic mode of operation of the heating unit. In addition, the ovens are operated manually.

The introduction of a water circuit into the furnace design greatly improves heating performance. A metal heat exchanger allows you to remove part of the heat from fuel combustion and ensure its transportation through a liquid coolant - water or antifreeze.

Furnaces with a water circuit are divided into 2 types:

- Brick;

- Metal.

Brick kilns are built independently or with the assistance of specialists. Metal furnaces are made from steel or cast iron and can be built independently, but this requires professional skills as an electric welder. Moreover, industrially produced models have better characteristics compared to home-made ones - they are made of heat-resistant steels and are carefully calculated by designers.

Brick kilns take longer to heat up, but they also give off heat over a long period of time. In essence, brickwork partially functions as a heat accumulator.

Metal stoves heat up and cool down at a faster rate. Cast iron stoves are more profitable than their steel counterparts in this regard - cast iron accumulates a significant amount of heat.

Heat exchangers for water circuits of furnaces are usually made of steel. Heat exchangers have a wide variety of shapes and sizes and differ in location. In shape, these can be rectangular containers connected by round or profile pipes, coils, registers, and so on. The thickness of the steel for their manufacture is at least 3 – 5 mm.

In brick kilns, heat exchangers are most often placed in the fireboxes. It is not recommended to place devices in areas directly surrounded by flame, especially in furnaces using coal as fuel. The temperature in these areas reaches high values and the service life of the metal will be significantly reduced. Heat exchangers are placed in the edge zones of the flame and along the path of movement of hot combustion products.

In metal furnaces, heat exchangers are often made in the form of water “jackets” encircling the furnace space of the combustion chamber. In essence, stoves with a water circuit are an analogue of a solid fuel boiler.

Heat exchangers are equipped with threaded pipes for connecting heating system pipelines. Smoke removal is carried out using natural draft, that is, the construction of a chimney is required. The amount of combustion air supplied is regulated by a chimney damper and a damper on the air intake.

It is worth noting that to improve heat removal, smoke ducts are sometimes equipped with a labyrinth type or an additional heat exchanger is installed in the chimney duct for DHW or heating needs. In this case, the aerodynamic resistance increases sharply and a more accurate calculation of the parameters of the chimney will be required - and at a minimum, an increase in its height.

In addition to water heating circuits, stoves can be equipped with additional elements:

- A door with fireproof glass - a fireplace stove is created;

- Hot water preparation tank;

- Hob;

- Oven.

With an increase in the number of options, the dimensions and weight of the oven increase, and the cost increases. Some models of factory-made stoves are equipped with heating elements built into the heat exchanger (with the ability to be removed and replaced). Usually they cannot completely cover the entire thermal power of the furnace and serve as an additional or backup heat source.

Power calculations

It is almost impossible to independently calculate the power of a recuperator in the absence of initial data (furnace power, temperature and amount of exhaust gases per unit of time, contact area between the heat exchanger and the metal of the chimney, the speed of passage of air or water through the device). You can measure the power of an already installed heat exchanger.

Roughly, you should expect that the heat exchanger on the chimney of a solid fuel stove or fireplace will warm up a couple of small radiators, increase the temperature in the garage, or make a room in the attic or a dressing room in a bathhouse warmer.

Conditions for optimal fuel combustion

How to properly install a potbelly stove in your home to get maximum heat transfer from fuel combustion?

In order for the draft in the stove to be sufficient, the height of the chimney (counting from the stove grate) must exceed 5 mm. If the installation of a potbelly stove is carried out in a one-story house, the roof ridge is located at the highest height. In this case, it is possible to save the maximum amount of heat by placing most of the chimney inside the house. At the same time, the attic (or attic) space is also heated, contributing to the overall heating of the house. The absence of a temperature difference along the length of the chimney will also help stabilize the draft in the stove, which depends, among other things, on the heating level of the chimney.

Determining the volume of fuel fill

For the potbelly stove to operate efficiently, it is important to load the optimal amount of fuel into it, and for each type of fuel it is necessary to find its own indicator. If you overload the furnace, there will be too many combustion products and they will block circulation; if you underload, there will be few of them, which also makes circulation impossible

The volume of the bookmark is selected as follows:

- fuel is collected in a bucket;

- they take a handful from the bucket and, placing it in the firebox, set it on fire;

- add fuel in small portions until the initial section of the hog is cherry red hot. Now they estimate how much fuel is taken from the bucket - this is the minimum volume of the stowage;

- continue to add fuel (the portions must be increased) until the dimensions of the hot section reach 80%-85% of the length of the “hog”. At this moment, the volume of fuel taken from the bucket will correspond to the maximum fuel load.

The test is carried out in moderate lighting: if during the day, then in cloudy weather (winter); If it’s clear outside, it’s closer to evening. When loading high-calorie fuel (pellets, anthracite), the hot area sometimes takes the form of a ring with different widths, occupying different positions along the length of the hog.

Then the volume of the bookmark is determined as follows:

- maximum: the section of the hog farthest from the furnace is hot for 1/3 of its length;

- minimal: the hot zone is located in the middle and is 3-4 palms long.

What is a potbelly stove with a water circuit? The advantages and disadvantages of a popular stove

A potbelly stove is characterized by high heat transfer and fuel burning rate. These qualities are given to it by the materials from which the firebox is made (cast iron, steel, iron). The potbelly stove quickly flares up and heats up, and if a water circuit is connected to it, then the warm flue gases along the way also manage to heat the water for domestic needs.

When choosing the material from which it is best to make a potbelly stove, you need to be guided by the following indicators:

- Thermal conductivity is the property of metals, liquids and gases to conduct heat through themselves. The faster heat is transferred, the faster the object heats up or cools down. Foam plastic has low thermal conductivity - 0.036–0.050 W/m*C. Taking it in our hands, we will immediately feel that it is warm, because the foam does not transfer heat, but accumulates it. If you take a metal bar, you will feel the cold due to the high heat transfer.

- Heat capacity is the property of a material to accumulate heat. Water has the highest heat capacity, air is in second place, and cast iron, steel and iron are at the end of the list. Therefore, a metal stove heats up quickly and cools down just as quickly. In city houses, central heating radiators are filled with water, which gives off heat for a long time, heating the home.

List of materials used to create a potbelly stove:

- Steel.

- Cast iron.

- Iron.

- Brass.

- Aluminum.

- Copper.

Copper is the most thermally conductive material of all those listed in the table. Its disadvantages are cost and melting point. Aluminum and brass have the same limitations. At high temperatures, a cast iron or steel stove will only turn red, but will do its job, while a copper, aluminum or brass stove will melt.

Potbelly stoves are most often made of steel because it has a high melting point and the highest heat capacity among all available materials

Making a stove from steel, iron and cast iron is justified due to the prevalence of these materials. From the point of view of thermal conductivity and heat capacity, they need fine-tuning. It is more expedient to use the thermal energy of the stove to heat water, otherwise it will simply go down the chimney

To limit heat loss, it is also very important to achieve complete combustion of the fuel.

The ideal way for a potbelly stove to work is when barely warm air comes out of the pipe, and all the energy is directed into hot water supply and heating the house.

Table: advantages and disadvantages of a potbelly stove

As can be seen from the table, a potbelly stove has a lot of disadvantages, so if you decide to install this design, you will have to take into account all its weaknesses.

Advantages

A potbelly stove with a battery has numerous advantages that make it popular for heating garages. Among the advantages, the following can be highlighted:

- Availability of fuel - the potbelly stove can operate on wood, briquettes, coal, peat, etc. The cost of all these types of fuel is low and they are available to almost everyone.

- Savings - due to the low cost of a potbelly stove with a water circuit compared to other heating systems, it allows you to save a lot, while at the same time making it possible to effectively heat the room.

In addition, since the size of the potbelly stove is small, you can easily find a place to install it in the garage.

Attention: A potbelly stove, if you make it yourself and do not buy it ready-made, must be made of high-quality, durable materials. Steel with a thickness of at least 3 millimeters is best suited for this purpose.

The manufacture of a potbelly stove with a water circuit consists of several stages. The first and very important is preparing the drawing. To make it, you first need to decide on the place where the stove will be installed, take all the necessary measurements and transfer them to the drawing.

Installation of the system in a finished oven - all the nuances

If the house already has a stove, then only a certain part of it is disassembled and a register is installed. In this case, more frequent fuel supply will be required.

If desired, you can change the number of smoke channels or their direction. However, this is only allowed in the most difficult situations.

All work must be carefully thought through, since after the actions taken it is important to maintain good traction. When dismantling the structure, it is recommended to sketch the location of the masonry

In the future, using this scheme it will be possible to easily disassemble the oven

When dismantling the structure, it is recommended to sketch the location of the masonry. In the future, using this scheme it will be possible to easily disassemble the stove.

If the brick remains in good condition after dismantling the masonry, it can be reused

If it is necessary to replace the material, it is important to select bars of the same quality and shape as the previous ones

Installation work

For water heating in the garage you will need a set of instruments and parts, including:

- heating boiler;

- metal radiators with good thermal conductivity;

- connecting pipes made of metal or plastic;

- accessories for fastening;

- locksmith tools.

Project development

Before installing the heating system, you need to determine the diameter of the pipes that will connect the radiators. Risers with a large cross-section will increase the flow of hot water to the batteries, increasing the efficiency of the design.

It is worth considering that heating large volumes of liquid will lead to increased electricity costs. The optimal scheme is a balance between the room temperature and the cost of heating. These parameters are also affected by the number of radiators in the insulated garage.

Expansion tank

The design of the garage heating system involves the use of expansion tanks. These items are made from simple plastic containers or large canisters with fill holes cut in the top.

The water circulating in the system constantly evaporates and requires regular addition of liquid, and the steam formed during boiling needs to be removed. The tank is installed at the lowest point of the heating system and at a half-meter distance from the floor.

Boiler

Before installing the boiler with your own hands, you will need to prepare a metal pipe of a certain diameter with a half-meter or meter length. Its extreme end is tightly welded with a metal sheet.

The next step will be assembling flanges for attaching tubular electric heaters and fixing them to the boiler using bolts. To supply the working fluid to the installation, two sections of pipe with the diameter that will be used in the heating system are welded.

Radiators

Heating batteries are attached to the walls of garages using special reinforced dowels. The distance from the floor to the radiator should be at least fifteen centimeters. For effective heating, you need to leave a few centimeters of free space between the walls and the heating elements for air circulation.

The individual structural elements are connected into a system using metal or plastic pipes with special fittings. The seams of their joints and forks require special attention during installation so that leaks do not occur in the future during operation.

Installation

The connection of metal pipes is carried out using a welding machine. Working with polypropylene will require the use of a special soldering iron. Regardless of the material of the pipes, they should be placed on the walls at a slope - this will improve the circulation of liquid.

The water heating system is considered ready after connecting the radiators to the risers and connecting them to the boiler using a rubber hose. Before starting operation, it is recommended to re-inspect the line, search for defects and seal problem areas.

How can you heat a garage?

So, we are talking about autonomous heating of the room, therefore, we need to choose the principle on which the heating system will operate. If earlier the conversation was only about a banal potbelly stove, now the choice of suitable devices is so wide that we will divide them into several categories.

The most economical ways to heat a garage with electricity

This type of heating is the first option that comes to mind. Indeed, the choice of electrical heating devices is very large. Such units are characterized by high efficiency and reasonable price. And what’s important: they don’t require you to stock up on fuel; it’s always in the electrical wiring.

The first possible method is to use a fan heater or heat gun. In both cases, it is a very compact device that takes up little space in the garage. Install the electric heater for the garage on the floor or on a workbench.

The fan heater heats up a small garage in a matter of minutes, driving air through hot heating elements

The only thing that will bother you is the smell of burning dust and the noise of the fan.

Another option is to use a convector. This method is considered more effective. In addition, convectors can be used in rooms with high humidity. A small, neat convector can be mounted on the wall or moved around the garage on wheels.

This type of heater is convenient because its power is easy to regulate.

Related article:

Convector type heater. In this publication we will look at the design of convectors, their types, advantages and disadvantages, the secrets of choosing the right one, and a review of popular models and manufacturers.

An electric floor is also a good idea. If you lay the heating cables evenly over the entire floor area, the garage will always be warm. The air temperature can be adjusted using a thermostat. The only thing that is important in arranging such a system is the use of durable materials that can withstand the weight of your car.

Infrared heating is gaining increasing popularity among owners of residential and non-residential premises. The operating principle of the IR heater is based on the effect of infrared rays on the surface. Everything that comes into the field of action of the device heats up and gives off heat to the air.

Some tips for installing electric heating in the garage:

- all wiring must be insulated using a plastic or metal box;

- Do not use wiring with aluminum content, it is very fragile;

- Sockets in the garage must be grounded and protected from moisture. Don't install them too low to the floor;

- It is better to place the switch for the inspection hole at the top.

A method of water heating in a garage without using electricity

The traditional water heating scheme is as follows: it includes a boiler, a system of pipes and radiators, and an expansion tank. When solving the problem of how to heat a garage in the cold season, consider installing a water circuit. This type of heating is good because the heat in the room is retained for a very long time.

For the water circuit, you can use a single-pipe or two-pipe circuit. In the two-pipe version, heat is evenly distributed over the entire area. Schemes of water heating in the garage for DIY installation with natural and forced circulation:

The only drawback of such a system is the need for constant operation. If you simply turn off the boiler and leave the garage unattended on a frosty day, the water will freeze and burst the pipes. It turns out that you will have to either drain the water during frosts, or constantly maintain the operation of the heating device. So the question arises: if you drain the water, then why have a heating system that cannot quickly start at the right time? Until you fill it up again, until you start the boiler, more than one hour will pass.

Circuit on antifreeze

Continuing the topic of how to heat a garage in winter with your own hands, it should be noted that contour heating is not an entirely hopeless type. What if you fill the circuit not with water, but with antifreeze? Antifreeze is usually used in cars to cool the engine. It does not freeze even at minus 45 degrees, and this is right in our favor.

With such contents, the heating circuit in the garage will not break even in severe frost

If you decide to install heating in your garage using antifreeze yourself, purchase a special mixture for heating systems. It replaces toxic ethylene glycol with propylene glycol, which is not toxic to humans. Such mixtures are more expensive, but they are safe.

It should be remembered that viscous antifreeze heats up and cools more slowly than water. Its shelf life in the system is 5 years. Antifreeze cannot be used for dual-circuit systems.

Gas system

The likelihood that network gas will be supplied to your garage cooperative is very small, but, nevertheless, it is possible to use blue fuel to heat the garage. You can arm yourself with gas cylinders and thus decide how to cheaply heat your garage. Indeed, gas compares favorably in price with electricity. You can use a regular stationary gas boiler with a water or antifreeze circuit. This option is perfect for craftsmen who work in the garage all the time. With the help of such a device, you can heat the room around the clock, without fear of the sudden onset of frost.

How to make a potbelly stove with a water circuit

To heat several rooms or premises with a potbelly stove, the stove, first of all, must be made of durable, reliable material.

Ideally, you should consider a material such as sheet steel or brickwork. At the first stage of construction, it is necessary to develop a sketch drawing. First, to do this, you should decide on the placement of the stove. Using a tape measure and other measuring devices, it is necessary to take measurements, after which the dimensions of the structure itself will be calculated. These measurements will form the basis of the drawing.

When the drawing is ready, we begin marking the foundation and laying it.

In order to lay the foundation, it is necessary to dismantle the floor coverings and dig a rectangular pit 40-50 cm deep

The bottom of the pit is filled with rubble, which can be fine brick chips, crushed stone, or sand. The rubble mixture is poured with cement, and it is important to maintain the horizontalness of the pour by checking it with a building level. Several layers of roofing material are laid on the dried layer of cement, which serves as a waterproofing material and a material that prevents the influence of moisture from the soil on the furnace structure

How to make your own stove with a heating circuit

The main part necessary for installing water heating on wood with your own hands is a heat exchanger. This unit can have a different design: made of pipes (register, coil) or in the form of a closed container (boiler). In any case, its purpose is to heat the volume of coolant contained in it in a short time and send it to the distribution pipes. The hot coolant flows through the pipes throughout all rooms, heating the radiators, and cools back to the boiler. This system is called gravity and can be used to heat small rooms.

If it is necessary to heat a residential building, especially one with 2 or more floors, the circulation of the coolant in the pipes must be forced. For this purpose, an electric pump is installed on the return line. Its purpose is to pump cooled water under pressure into the heat exchanger, forcing it to circulate more intensively and not stagnate in the radiators. The use of a pump is also possible for one-story buildings in order to speed up the heating process of pipes and radiators when igniting the furnace.

So, to install a water heating circuit you will need:

- heat exchanger (boiler, register);

- large diameter pipes for wiring;

- water heating radiators, convectors of any design;

- expansion tank;

- electric circulation water pump;

- welding machine;

- "Bulgarian".

Heat exchanger from a cylinder

To use already exhaust gases for additional coolant in the heat exchanger, you need to slow down the exit of smoke by creating a barrier in the chimney. For construction you will need three empty gas cylinders, sheet metal and scrap metal. The sequence is:

- Build a firebox from a cylinder - cut out the top so that the diameter of the hatch reaches 200-250 mm.

- Mark a rectangle measuring 50 by 20 cm on the wall, apply a mesh with cells 30 by 40 mm. Make holes in the crosshairs.

From a cylinder

- Build an ash pan slightly larger than the area with the holes. It must have a lid. This is a collection for ash. Supports are welded to the wall at the corners.

- At a distance of 4 cm from the bottom of the cylinder, at the rear wall of the firebox, a hole is first marked, then a hole 3 cm smaller than the cylinder itself is cut.

- It is better to make the door for the firebox from the head of the second cylinder, cutting a hole in the center of it. A piece of pipe with a diameter of 7.6 cm, equipped with an adjustable damper, is attached to the hole. The mobility of the sash is supported by hinges and locks of inventory drawers.

Balloon frame design

- Construction of a heat exchanger from the second cylinder. Make 3 bulkheads from 4-5 mm metal so that they cover the internal size of the cylinder. They cannot fit around the edges of the hole according to the diameter of the chimney pipe and for a margin of another 2 cm.

- Cut off the bottom of the cylinder, cut it in the shape of a fit on the firebox at an angle of 90 degrees.

- Cutting a hole for the chimney in the valve part.

- Installation of the bulkhead - holes in a checkerboard pattern.

- Installation of the heat exchanger, scalding, welding of the pipe.

General requirements

In the case of installing a heating system with your own hands, the property owner can personally choose the timing and need to turn it on.

Most often, the heating is turned on during repair work, and turned off while the car is being stored.

Safety

One of the main requirements for garage heating is its safety. The room contains a large amount of fuels and lubricants, as well as highly flammable items.

In cooperatives where structures are located end to end, a fire in a separate area can lead to the burning out of a significant area. For this reason, all heating systems must be capable of emergency shutdown in the event of an emergency.

Feasibility

For property owners, the economic feasibility of the methods used is important. If the installed heating system requires significant operating costs, you should think about choosing a different method.

Proper garage heating should be reliable and resistant to temperature changes outside the room. This also applies to energy supply interruptions.

Insulation

The garage heating scheme involves preliminary thermal insulation of the room. Heating unprotected buildings is pointless - the heated air will escape through the cracks of the enclosing structures.

What to think about at the preliminary stage

Rarely lucky people are lucky enough to have a centralized heating system in their garage. This is possible if you have a shared indoor parking space or the garage is located directly in the structure of a country house.

Therefore, the heating system must be autonomous. Before you consider purchasing a heating device, do your homework. What should be done:

- The garage needs to be insulated. Simply heating an iron bunker is literally throwing money away. Brick, metal or sandwich - all this needs additional insulation. You need to make sure that all cracks are securely caulked. It is better to place the heat insulator on the outside of the walls, but if this is not possible, the inner layer will also work. Particular attention should be paid to the floor - this is also a large area for heat loss. It should be covered with insulating material.

Don’t forget about the roof - otherwise all the heat will escape through it

- It is necessary to provide high-quality ventilation. Sad statistics show that most tragic incidents in garages occur in winter. Careful insulation of the room does not allow for normal air exchange. Simply warming up the car for a few minutes before leaving can end very sadly. What can we say about the situation when the boiler is constantly running in the room.

Calculations of potbelly stove indicators

Thermal engineering calculations of furnaces are the most complex. In construction and manufacturing, such operations are performed by specialized laboratories. For domestic use, they are significantly simplified, leaving only the key indicators of thermal units for independent determination:

- Calculation of the thermal resistance of a room, in other words, the designation of its ability to retain heat. This indicator depends on the material and thickness of the floor and walls, its thermal conductivity, the structural properties of window and door structures. But in any case, heat resistance also depends on the quality of all components.

- Calculation of the cross-section of smoke exhaust channels, since the quality and rate of fuel combustion in the furnace depends specifically on this parameter. If the diameter is larger than good, then most of the heat will be lost without return, reducing the efficiency of the device. On the contrary, an insufficient cross-section can lead to incomplete combustion of fuel and gas pollution in the room. To determine the size of the chimney pipe, an indicator of 2.7 is used in relation to the volume of the furnace firebox. If this figure is 40 liters, then the suitable chimney size will be 40 / 2.7 = 14.8 cm.

The classic size of a metal chimney pipe is 150 mm. In most cases, 15–20% is added to the calculated value. The final adjustment of the draft in the furnace is carried out using a damper, which makes it possible to perfectly adjust the cross-section of the chimney. It must be said that the amount of thrust will depend not only on the diameter, but also on the weather, so the use of a gate is considered necessary.

The height of the chimney is of priority. There is a limiting parameter - its total height should not be more than 5 meters counting from the point of exit from the combustion chamber. The level of elevation above the roof depends on the location in relation to the ridge.

It is fundamentally important to determine the dimensions of the chimney correctly

Economizer Fehringer

The device is used to improve efficiency. It works by extracting heat from the chimney. It has 4 pipes, 60 mm each, with spiral-shaped swirlers.

The passing gases from the smoke swirl, resulting in maximum heat release. The device is made of black steel. It is designed for the entire period of operation of the stove. It allows you to quickly warm up the steam room.

Feringer is valued by bath lovers as one of the best models. They are produced in different versions, but in two main categories:

- Steam - the heater is closed, creating a steam room atmosphere - temperature up to 50-70 degrees, humidity reaches 40-75%.

With closed heater

- Golden ratio - the heater is open, suitable for saunas, where at a temperature of 80 degrees, low humidity is needed - 10-15%.

With an open heater

Since 2011, the company has developed a new line - Lamel. It has a natural stone cladding and small innovations in the design that allow you to confidently heat log steam rooms.

Lamella

The system for securing the decorative stone of the stoves is unique - a holder is installed on the cut plates of the stone. Its hooks are fixed in a groove. The design is simple, at the same time very effective, installation work is simple, it will take no more than 1 hour.