Additional pump in heating: why and when is it needed?

The circulation pump is the main type of equipment that is installed in the heating systems of private houses. The pump allows you to quickly and evenly pump coolant to the heating devices in the house, which is the key to uniform and high-quality heating of the premises.

Installing a circulation pump is mandatory if the house has heated floors and a closed heating system. But even in such cases, one pump may not be enough, especially when it comes to two-story mansions. In what cases is it recommended to install additional pumps in the heating system? Will it be possible to increase the efficiency of the heating system by installing another pump?

Is it necessary, and in what cases?

Many owners of country real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then it will be necessary to remove air plugs or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

Important! If the heating system calculations are incorrect, the installation of additional equipment will lead to a decrease in the heating efficiency.

Before installing an additional pump, balance the heating system using balancing valves.

An additional pump in the heating system may not be needed if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the radiators and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Answers from experts

Alexei:

It is logical that a hydraulic gun needs to be made.

Use a hydraulic separator to decouple the boiler-pump circuit of the boiler and the heating system from its own pumps.

Vladimir Kolpakov:

The standard pump on the boiler is always in the return line. sequential operation of pumps is not desirable. But in general I’m interested in what the problem is, what makes me install additional. pump

Vladimir Petrov:

The Weiland boiler already has a pump and it is quite enough. And there is no need to install another pump. The boiler is designed for a certain heat flow and there is no need to increase it.

Fursov Yuri:

Or maybe remove the filter and clean it? and that's where it all ends

husky:

or better yet, install two pumps... and so that they work towards each other... then you don’t have to worry about how to connect to the standard

Onotole Chake:

There seems to be a return line there, which is sufficient along with the standard pump. If in doubt, ask on some thematic site then

Semyon Arazaev:

There is no point in this at all, given that there is more than enough return there. Well, some kind of quick burst is basically normal, but this needs to be clarified with a specialist in these same boilers from s pechki

Egorych:

Underfloor heating is not done like that, you need a thermostat and a separate pump, well, something like that

Grandfather Au:

The pump is usually placed on the return line

Vladimir:

What's the question?

Dmitriy:

it all depends on the connection diagram, without knowing that you won’t hear any useful advice...

Drifter of the Seas:

Read the DHW consumption in the passport of your water heater; if you have more water consumption than the water heater can heat, then your hot water will be cool

Alexey Lesyuk:

Vitaly, if your heating system was installed incorrectly, installing an additional pump will not help you, and will also harm you if the boiler is a double-circuit one. It is necessary to change the connection diagram of the boiler to the heating system to install additional. nasoa

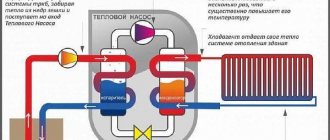

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

Operating principle of hydraulic separator

Such devices are recommended for use in heating systems where the coolant is heated using long-burning boilers. The fact is that the heating devices in question can operate in several phases (fuel ignition, combustion process and attenuation), and for each of these phases it is necessary to maintain a certain combustion mode.

Installing a hydraulic needle in the heating system allows you to create a certain balance in the operation of heat and warming up the system. The anuloid itself is made in the form of a pipe with four outlet pipes. The main functions of such a device include:

- Automatic removal of accumulated air;

- Collecting sludge particles (works as a dirt trap).

Note! From these characteristics it can be understood that the hydraulic separator is considered an important device in the heating system, so it must be installed without fail if there is a pump.

Hydraulic separator in the heating system

Heating in a private house performs many functions that must be implemented regardless of coolant flow and possible pressure drops in the pipelines. It is quite difficult to achieve efficient operation of the system, because the liquid enters the pipeline circuits from one source of thermal energy - the boiler, which will ultimately lead to unbalanced heating. To prevent such situations, the hydraulic separator serves; it performs the function of decoupling.

Advantages of pump heating

Not so long ago, almost all private houses were equipped with steam heating, which was powered by a gas boiler or a conventional wood stove. The coolant in such systems circulated inside the pipes and batteries by gravity. Only centralized heat supply systems were equipped with pumps for pumping water. After the appearance of more compact devices, they also began to be used in private housing construction.

This solution provided a number of advantages:

- The coolant circulation rate has increased. The water heated in the boilers was able to flow much faster into the radiators and heat the rooms.

- The time it takes to heat homes has been significantly reduced.

- An increase in flow rate entailed an increase in the circuit capacity. This means that smaller pipes can be used to deliver the same amount of heat to its destination. On average, the pipelines were reduced by half, which was facilitated by the forced circulation of water from an embedded pump. This made the systems cheaper and more practical.

- In this case, to lay highways, you can use a minimum slope without fear of complex and extended water heating schemes. The main thing is to choose the right pump power so that it can create optimal pressure in the circuit.

- Thanks to household circulation pumps, it has become possible to use heated floors and closed systems of high efficiency, the operation of which requires increased pressure.

- The new approach made it possible to get rid of many pipes and risers, which did not always fit harmoniously into the interior. Forced circulation opens up possibilities for laying circuits inside walls, under floors and above suspended ceiling structures.

A minimum slope of 2-3 mm per 1 m of pipeline is necessary so that in the event of repairs, the network can be drained by gravity. In classic systems with natural circulation, this figure reaches 5 or more mm/m. As for the disadvantages of forced systems, the most significant of them is the dependence on electrical energy. Therefore, in areas with unstable electricity supplies, it is necessary to use uninterruptible power supplies or an electric generator when installing a circulation pump.

You should also be prepared for an increase in bills for consumed energy (with the correct selection of the power of the unit, costs can be minimized). In addition, leading manufacturers of equipment for heating systems have developed modern modifications of circulation pumps that can operate in increased economy mode. For example, the Alpfa2 model from Grundfos automatically adjusts its performance depending on the needs of the heating system. Such equipment is quite expensive.

Where to put

In the autonomous heating system of a private house, it is recommended to install circulation pumps with a wet rotor, which rotate without the use of special lubricants. The coolant and lubricating element here are the coolant. When installing such a device, the following rules must be taken into account:

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

Note! The only requirement for installing a pump is considered to be ease of maintenance, that is, such a device can be mounted between the boiler and heating radiators on the forward or return pipeline. Pumping equipment cannot be installed between batteries.

Connection

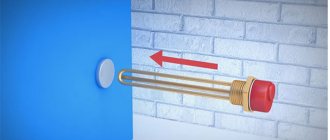

Using the central screw, remove excess air from the pipes.

If the work is carried out correctly, liquid will begin to ooze from the special hole. For a manually operated pump, you should bleed the air before starting work: turn it on for a couple of minutes and open the valve, repeating the steps a couple of times. The pump unit is connected after the system is started, when the pipes are filled and all air has been released. This must be done before each startup of the device.

In systems with natural circulation, when connected to the electrical network, a circuit breaker is used so that the circuit can be disconnected. It is installed at a distance from the boiler of at least 0.5 m.

In designs with forced circulation, the device begins to operate when the thermal relay is turned on. When installing an additional pump into the heating system of a house, it is necessary that it and the built-in device work simultaneously. To do this, also connect the new unit to the relay or to the built-in parallel one.

If you have an electric boiler, connect the pump directly to it. This will allow the circulation device to operate only when the water is heated.

Safe operation of the circulation unit is possible when using a grounded socket.

Independent installation of a pump in a home heating system is only possible if you follow all installation rules and take into account the nuances of connection.

This issue should not be taken lightly, relying on “maybe”, so as not to put your family at risk. Accurate adherence to all requirements will ensure your home is warm and comfortable.

Installation diagram

In practice, two schemes for installing a circulation pump are used in a single-pipe and two-pipe heating system. Before carrying out installation work, you must carefully study the attached instructions. At the preparatory stage of work, water is drained from the system and the pipes are cleaned of contamination by additional pumping of liquid. The pump is installed according to the attached diagram, then coolant is poured into the circuit and the unit is turned on.

As we have already said, it is best to install the pump on the return side using a tap or, as it is also called, a bypass. Such a device is necessary to shut off the water and replace the pump in case of breakdown. The diameter of the outlet pipe should be smaller than that of the central pipeline.

Installation diagram of an additional pump in the heating system

At each edge of the bypass, before entering and after exiting the pump, taps are installed for emergency shut-off of the coolant. Another valve is installed on the central line to direct the flow of liquid through the pump. Before entering the pumping equipment, a special filter is attached that will accumulate harmful particles in the water.

Installation technology

Installing a circulation unit is a process that requires compliance with a certain sequence of work.

Preparation

Experts recommend purchasing a pump with split-type threads. If they are not available, then you need to buy these parts additionally. You will also need a deep cleaning filter.

Before installation, prepare a check valve: this normalizes the operation of the heating system.

You will also need special keys, fittings, a small pipe with a diameter equal to the diameter of the riser.

Place

Modern circulation pumps can be installed both on the water supply pipe and on the return pipe.

Installation carried out on the bypass (a jumper or a piece of pipe installed between the direct and return wiring of the heating radiator) requires preliminary testing of the device’s ability to withstand strong pressure of hot water.

If there is a membrane tank, the bypass with the pump is placed on the return pipeline, closer to the expansion tank.

Installation

The heating system can be made of metal or ecoplastic. There is no difference for the installation of pumping equipment. It is inserted by going around it. If the pipeline is made of metal, then you can purchase a ready-made structure to bypass the main line.

First you need to drain the water and clean the heating structure, rinsing it several times.

Then, according to the diagram, a U-shaped piece of pipe is mounted on the side of the main pipe, in the middle of which a pump is built. Ball valves must be installed on both sides of this unit. What is it for?

Firstly, the natural circulation of the coolant will be restored if one of them is closed. Secondly, you can repair or replace the circulating equipment if you turn off both taps, without needing to drain the water from the system.

After this, the system is filled with coolant and checked for functionality. Any errors should be corrected at this stage.

Then, unnecessary air is removed from the pipeline using a central screw. If everything is done correctly, liquid will begin to leak out of the special hole.

Pumping equipment with manual control requires air to be removed before starting work: it is turned on for a few minutes and the valve is opened, this is repeated several times.

After the pipes are filled with water, the pumping device will turn on. The presence of air in the pipeline is excluded.

With warm floor

Note! In the “Warm Floor” system, the circulation pump is installed in a horizontal position after the mixing unit in the supply pipeline section. In some wiring schemes, several such devices are installed, each of which will pump liquid within one floor.

Installation diagram of the pump in the “Warm Floor” system

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

Types of additional pumps - choosing the appropriate unit

For efficient media circulation, it is best to use “wet” or “dry” pumps. In the first case, the rotor is located inside the coolant, that is, it pumps water while being directly in it. As the fluid circulates, it cools the engine. A stator is used to supply electricity. Wet pumps have many advantages. Firstly, they are able to last for a fairly long period of time. Secondly, such devices do not require frequent maintenance. Thirdly, they make less noise. And fourthly, they are not large in size.

Disadvantages include not very high efficiency, limited scope of use, and the inability to use pumps for drinking water and other food-related devices. Such units are used only in mansions and residential high-rise buildings.

In the design of dry-type pumps, the rotor is located outside the coolant. Such devices use a seal that is designed to separate the motor and the pump itself. The approximate efficiency of the equipment is 75%, which is why these units are used in situations where it is necessary to regularly pump large amounts of water. Such units are used more in manufacturing and shopping centers than in residential buildings.

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.

Main advantages

Owners of private houses will receive many benefits if they install an additional pump in their heating system. The main advantages of the device:

- The overall efficiency indicator increases several times.

- The air in living rooms warms up twice as fast.

- Heat circulates better in the main pipe.

- The pump creates pressure due to which air does not accumulate in the channels.

- It consumes little fuel, so it is considered economical.

- Towel dryers and thermostats can be installed.

- Instead of large pipes, you can install small diameter pipes.

- Low price.

In this video we will learn how to install an additional pump:

Equipment parameters

Before purchasing and installing a circulation pump, you need to familiarize yourself with its technical characteristics.

This includes: the pressure force with which it works, the density level of the coolant, the temperature of the water and the diameter of the pipes located in the house.

All technical characteristics are indicated on the pump packaging and in its passport. Legend:

- The letter “H” shows how high the pump can lift water. This indicator is measured in meters.

- The letter “Q” means how much liquid the heating system can consume. The indicator is equal to the boiler power and is measured in cubic meters. Its value varies depending on the diameter of the laid pipes. When purchasing a device, special attention is paid to this indicator, since the main task of the pump is to improve circulation inside, and not to lift liquid.

Calculation of the liquid consumed is done independently if the boiler is not equipped with a pump.

If an old boiler model is installed in the house and additional extensions have been made to it, then it is necessary to install 2 pumps. The equipment has an increased noise level, and its full capabilities are not always used, so you should not buy too expensive equipment.