Here you will learn:

- Advantages of a barrel stove

- Assembly sequence

- Modernization of the design

- Interesting potbelly stove with stonework

An old 200 liter metal barrel is an excellent material for making a simple potbelly stove. The resulting stove is suitable for heating any non-residential premises, from garages to outbuildings. A 200-liter barrel stove has a simple design and does not cause any difficulties even for novice craftsmen. Let's look at the features of this simple heater and discuss the assembly instructions.

About the design

A homemade potbelly stove made from a barrel has a height of 89 cm, a diameter of 60 cm and a weight of 21 - 25 kg, has a solid hearth and a fairly high chimney. Sawdust, shavings, dry firewood and fuel briquettes are used as fuel. Due to the rather thin metal walls and the height of the body, the efficiency of such a furnace does not exceed 15 - 20%.

The principle of its operation is quite simple: wood is placed in the firebox and ignited. When burning, firewood releases a large amount of thermal energy, which is transferred to the body of the potbelly stove. The heated metal releases heat into the surrounding atmosphere and heats the room. The amount of heat increases due to the long chimney through which hot smoke moves to the street.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

For the correct flow of gas-dynamic processes in a potbelly stove made from a 200 liter barrel, the blower should be located as low as possible. Otherwise, the lower part will take a significant part of the thermal energy and redirect it to the ground. If you need to place the ashpit higher, you can wall up the lower part of the container with bricks.

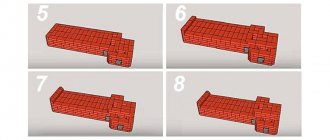

Types of stoves depending on location vertical model

Depending on the plane in which the metal tank will be located, there are two types of homemade potbelly stoves: vertical and horizontal.

Each of these types of heating devices has its own advantages and disadvantages. A vertical barrel stove is installed not on the floor, but on legs. To make the door, you will need to cut out the side of the tank and provide it with hinges

It is important to remember that the hinges must be fixed to the barrel and the door not from the inside, but from the outside.

A mandatory element of this design is a perforated metal plate, which is called a grate. To fix such a grille, you can use ordinary corners. In order to make a blower, you will need to prepare a metal pipe with a gate valve. The thickness of the metal walls must be sufficient, otherwise the structure will quickly burn out.

The damper for a long-burning wood stove, located in a vertical plane, is fixed with special bolts. When igniting fuel inside the tank, open the blower as far as possible.

A hole in the shape of a circle must be made in the upper part of the canister. It will be needed to connect a chimney structure to a homemade stove. The pipe is joined to a metal surface using welding equipment.

The function of the grate is to protect the bottom of the canister from burning out, as well as to retain thermal energy. Thus, this element is necessary when installing a homemade long-burning stove.

Design features are determined depending on the purpose of the device and the place where it will be located. If you wish, you can download a ready-made drawing of a potbelly stove on the Internet. However, in this case it is necessary not to make a mistake with its volume.

The vertical version of a homemade heating device is easy to assemble. You can find application for such a unit both in a private home and in the country. The firewood used to light a heating device of this type is selected depending on the dimensions of the firebox.

Choosing a quality barrel

To make a potbelly stove, you can use any steel barrel used in the petrochemical, paint and varnish, chemical, and metallurgical industries for storing and transporting technical products:

- bulk - oils, solvents, paints, diesel fuel, sodium liquid glass;

- pasty - thick lubricants, bitumen;

- bulk - caustic soda, various plasticizers.

They are produced in two types - with an open and closed top; they also differ in the thickness of the bottom, lid and shell.

Any of these containers can be used as a potbelly stove if you first thoroughly clean and rinse its inner surface. However, the thinner the walls of the container, the faster they will burn out and the stove will fail. Therefore, for a potbelly stove you need to choose a product with a metal thickness of more than 2 mm.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

Well, the best option is a stainless steel barrel. High-alloy stainless steel is most resistant to high temperatures in the fuel combustion zone, which means a stove made from it will serve for a longer period.

Waste oil stove

Used engine oil is a multi-component, slightly flammable substance that, in order to be burned, must first be broken down into simple components. For this purpose, the method of pyrolysis or flame separation is used, in which fuel is heated and evaporated.

To do this, light a fire using a rag soaked in gasoline or kerosene. Fuel, when heated, splits into simpler, flammable substances. Then the pyrolysis combustion process supports itself.

The desire to use used oil as fuel led professionals and craftsmen to the creation of a special stove. Its design creates conditions for the combustion of low-flammable oils and ensures user safetyStep-by-step description of work

The manufacture of a potbelly stove using waste oil is carried out in the following sequence:

- Take two pieces of pipe with a height of 100 and 115 mm, a diameter of 350 mm - they will serve as the basis for creating two chambers.

- A bottom and a cover with holes are welded to the ring with a higher height: the first with a diameter of about 100 mm for the pipe; the second is small in size for air intake. For the blower, a damper is made from a circle of slightly larger diameter.

- In the pipe, which is fixed on top of the fuel compartment, holes are drilled evenly along the entire length.

- A second chamber is made with holes for the chimney and secondary combustion pipe. A partition is made from a rectangular sheet of metal inside it.

- A chimney pipe is installed on top, and legs are welded to the base.

The design of a cylindrical two-volume boiler during exhaust operation ensures high temperature and complete combustion of fuel. Instead of cylindrical ones, rectangular chambers can be used.

This type of potbelly stove design is often found both in home-made designs and in industrially produced products.

Operating principle of the furnace

Fuel is poured into the lower reservoir of the potbelly stove through a small hole. At the same time it serves as an evaporator and a primary combustion chamber. A small hole on the lid is also intended for ignition, air supply and regulation of air flow (using a damper).

You can make the process of adding fuel safer if you use a tube leading from a separate container into which oil will be poured while the stove is burning

The next cylindrical container is equipped with an internal partition to reduce the speed of movement of combustion products, ensuring an increase in the degree of oxidation of nitrogen compounds. At the same time, it serves as both an infrared and convection heater.

The factory circuit of a potbelly stove operating on waste oil may include a water jacket or circuit. This improved stove-stove can be used for heating and providing the house with hot water

It is in potbelly stoves for garages that waste is most often used as fuel. Of all heating devices, it is one of the most dangerous.

If someone decides to violate fire safety rules and make a stove on their own, it is better to allocate a separate room for the boiler room or fence it off with a brick wall.

Additional materials

To build a heating device, in addition to the 200-liter metal barrel itself, you will need the following additional building materials and stove fittings:

- small steel sheet;

- corner;

- fireclay brick for a vertical model or a reflector for a horizontal one;

- a small piece of channel;

- steel pipes for the chimney;

- fittings for the grate;

- sand, clay for making mortar;

- asbestos cord;

- combustion door;

- blower door;

- basalt wool for chimney insulation.

Stove from a 200 liter barrel: dimensions and installation of the grate

Metal reinforced rods are used to assemble the grate. The diameter of a standard canister that has this volume is usually 571.5 mm. When assembling the grate, you need to take this indicator into account. In any case, it should be smaller.

The grate is installed between the doors of the firebox and the ash pan. Metal corners are used to secure it. Video materials on this topic allow you to give a more accurate answer to the question of how to make a stove with your own hands using a barrel.

When making an ash pan, you should take into account approximately how much fuel will be processed per day. Such homemade heating devices generate quite a lot of ash, so the recommended depth of the collecting compartment is 10-13 cm.

The doors for the ash pit and combustion tank must be enlarged using welding equipment and strips cut from metal sheets. The width of the strips should be approximately 2 cm. It is recommended to mark this stage of work in advance in the drawing of the potbelly stove. You will need to design handles with your own hands. The simplest option involves welding individual pieces of reinforcement to the doors. Then you need to install the hinges.

Metal reinforced rods are used to assemble the grating.

The next stage involves assembling the supporting elements. In order to make the legs, you need to prepare sections of dense reinforcement. And also for this purpose you can use metal corners, the thickness of which should be at least 3 mm. When choosing the optimal stand height, you must be guided by individual preferences. The standard distance from the floor to the heating device is 10 cm.

Required Tools

To build a high-quality potbelly stove from a 200-liter barrel with your own hands, you need to prepare a minimum set of tools, consisting of:

- welding machine;

- grinders or hacksaws for metal;

- standard hammer, pliers and chisel;

- steel brush;

- drills with a set of drills;

- measuring instruments: tape measure, level and plumb line.

Personal protective equipment is also needed when welding: a protective mask, dielectric gloves, protective clothing made of thick fabric and closed shoes.

Advantages and disadvantages

Like any equipment, the Bubafonya stove has both positive and negative sides. Among the advantages, the following are noted:

- long burning period;

- uncomplicated operating conditions;

- simplicity of design;

- low cost of fuel raw materials;

- cheap components;

- availability of self-installation of equipment, provided that you have skills in working with a welding machine;

- easy transportation due to small size and weight.

The disadvantages include the following:

- Difficulties in maintenance: it is inconvenient to clean the bottom of the tank and remove combustion products, namely soot and ash.

- The appearance of condensation on the pipe walls, which leads to a decrease in efficiency.

- The classic version of the stove is characterized by insufficient heat accumulation. To correct this point, you should construct an additional water jacket, cover the stove with heat-insulating material, or make brickwork.

- Heating the bottom of the fuel tank requires placing non-combustible material underneath it or constructing a small foundation.

- The need for ventilation in the room.

Where is the best place to install?

When installing a potbelly stove from a 200 liter barrel in a garage, it is important to follow established fire safety rules. In a small room, the heating device should be placed in a place opposite the door. In this case, the distance from it to the walls or other interior items should be at least 50 cm.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

No flammable items should be placed near the stove, and when moving, you should be careful not to accidentally contact exposed skin with its body to avoid burns. The room where the potbelly stove is installed should be well ventilated, at least naturally.

Making a potbelly stove

When a certain moment comes, many people wonder how a potbelly stove should be made from a barrel with their own hands. And in general, how to make a potbelly stove from a 200 liter barrel.

The potbelly stove is created in different sizes and shapes. It can be round and square, vertical and horizontal. It all depends only on your imagination.

Horizontal stoves are considered simpler than vertical stoves. In such a stove, in place of the door, a part of the bottom is attached, which is cut out. She sits on her hinges. At the opposite end of the barrel there is a hole to which a metal pipe should be attached, which will serve as a chimney for such a stove. Then you should put a grate in the middle of the barrel. It plays an important role, as it will help retain heat for a longer time, and also protect the so-called bottom from burning out. If you really want to create a hob, you will simply have to weld thick steel wire.

Do you want to build? See detailed instructions on our website!

Before you get to work, you will need to prepare some tools. To begin with, it is best to stock up on a welding machine, as well as a full set of clothes for working with it, a grinding machine, wheels for grinding and cutting metal, a hammer, a wire brush, pliers, a tape measure and a drill.

At the required level in the barrel, you should first mark and then cut two rectangular holes that will serve for the ash pan and firebox.

The parts that remain after cutting should not be thrown away, as they can later be used to make the door. To make the door complete, metal strips are attached to it, and then a special latch with a handle is installed.

Then, on the inside of the barrel, just below the firebox, no more than 10 cm, angle-type brackets are attached, which will later serve for laying the grate.

For the manufacture of the grate, ordinary fittings are used. You need to cook it yourself.

It is best to weld the legs to the bottom of the barrel, but in the upper part you need to cut a hole for the future chimney and weld a pipe into it.

The door is installed on the hinges that have already been attached in advance. Only after installing the door is a hook for the lock attached.

If you want to achieve a more aesthetic appearance for your stove, then you should carefully clean all welding seams. Heat-resistant paint is suitable for painting, after applying which your potbelly stove will be practically indistinguishable from the factory one.

After complete completion of all work, the potbelly stove is connected directly to the chimney, which is already connected to the street.

Features of operation

When operating the stove, it is necessary to alternate its lighting cycles, which include:

- fuel storage;

- ignition of the stove;

- direct combustion process with room heating;

- cleaning of ash products from the combustion and blower sections.

The most important stage is the placement of fuel, which must be placed in a certain order to facilitate the ignition process. First you need to put paper and thin dry firewood on the grate, light a fire and close the door.

Once the kindling material has ignited, larger logs can be added. Wood must be loaded carefully to prevent the fire from dying out. Once the wood has been fully loaded, the fire door must be closed tightly.

The draft in a potbelly stove can be adjusted by using a valve on the chimney or by slightly opening the ash door.

While the stove is burning, you must not touch its body to avoid getting burned.

To restore draft after a long period of burning, it is necessary to periodically disassemble the chimney and clean its elements from accumulated soot.

The principle of operation of "Bubafoni"

The well-known law of convection states that when heated, warm masses move upward, and cold ones take their place. The work of “Bubafoni” is based on this principle: when the fuel burns, the air heats up and rises, entering the outlet pipe; the cold flow enters the stove through the pipeline. This is how constant circulation of air masses occurs. This in turn supports the fuel combustion process.

The furnace design includes a damper on the inlet pipe (gate). By setting the gap at a certain level, you can regulate the intensity of fuel combustion.

The work process ends with the complete burning of the wood and the lowering of the piston with the load to the bottom of the fuel tank. It is possible to stop the operation of the furnace ahead of schedule if you completely close the damper on the inlet pipe. This will stop the flow of oxygen into the stove. Another way to complete the heating process is to use fire safety equipment.

Conclusion

It is quite possible to make a brick potbelly stove from bricks yourself. Such a furnace increases efficiency from 50-60% to 70-75%. However, it is still not cost-effective enough to fully replace stove heating. Although it retains heat more efficiently than iron, it requires the connection of a heating panel for constant use.

As a temporary source of heat, a brick potbelly stove, made with your own hands in a garage or greenhouse, is fully justified.

The design can be further improved by clad in metal. This will increase the service life and protect the stove from damage.

Chimney construction process

The complexity of the process of constructing a chimney for a potbelly stove in a country house directly depends on the location of the stove in the room. For example, bringing a pipe out through a window is much easier than making a hole for a chimney in the roof. In this regard, before installing a potbelly stove, you should take into account the design features of the building.

Safety rules and structural measurements

If you plan to install the stove outdoors, then installing a chimney will not cause much difficulty, the main thing is to choose a suitable location

It is important to remember that the stove structure should be located away from flammable objects and active recreation areas

Constructing a chimney indoors will require knowledge of safety rules that will help avoid fire. The material from which the pipe is made must have increased heat resistance and can easily withstand temperatures above 1 thousand degrees. If you plan to install a potbelly stove near walls lined with clapboard or plastic, then the part of the wall located in close proximity to the stove is sheathed with fireproof material.

Don't forget to decide on the pipe size

The hole through which the chimney will enter the ceiling must also be decorated with non-combustible materials, since the entire structure becomes very hot when the stove is operating. For these purposes, a special glass is used to prevent contact of the hot pipe with the edges of the hole. If there is more than one potbelly stove installed in a building, then a separate smoke exhaust system is made for each of them.

After calculating the diameter of the pipe for the potbelly stove, you will need to calculate the total length of the pipeline, but first you need to accurately determine the location of the stove in the room. Then determine the specific location where the chimney will be vented outside. When measuring the length of the pipeline outdoors, you need to take into account that the height of the pipe above the ridge should be 1.3-1.7 meters.

It is more difficult to carry out installation work indoors

Installation of all system elements

Installing a stove installed outdoors is not difficult. To assemble the system, you will need a pipe of the required diameter, which is placed on the pipe extending from the potbelly stove. The pipe must be put on the pipe, and not inserted into it. Otherwise, smoke will leak out at the junction of the nodes. The procedure for installing a smoke exhaust system in a room is much more complicated and consists of several stages:

- the pipe section is securely attached to the furnace pipe;

- the pipeline is extended using connecting elbows;

- the smoke exhaust is passed through a passage glass and discharged onto the roof or behind the wall;

- all connecting nodes are securely fixed.

A section of pipeline located outdoors must be insulated with heat-resistant material. During operation of the potbelly stove, condensation inevitably accumulates on it. To get rid of the condensate accumulated in the system, a tee is installed on the outer section of the pipeline, equipped with a faucet for discharging liquid. In the place where the horizontal and vertical pipelines connect, an inspection window is made to make cleaning the chimney easier.

The final stage is checking the functionality of the smoke exhaust system. If you managed to properly make a chimney for a potbelly stove, then after igniting the stove the necessary draft will be created and the smoke will quickly be discharged outside. During the combustion process, you need to ensure that smoke does not leak into the joints of the nodes. If a smoke leak is detected, the connections must be sealed using heat-resistant sealant.

Long-burning boiler principle

Before reviewing the unit, you need to understand the principle of its operation. The bubafonya stove runs on solid fuel - wood. Before you start burning it, you need to prepare the wood. In the boiler it is heated to 250 degrees Celsius using paper ignition.

When charring, wood decomposes into simple chemicals: gases and vapors. When the temperature reaches 300o Celsius, the gaseous components ignite, accelerating the thermal reaction.

To protect against fire, and also to prevent it from spreading throughout the entire container, a protective screen is provided on the fireplace. A damper is used to regulate the temperature. When turned off, the air supply stops, as does the combustion process.