When it is impractical to install electric heating, and connecting a gas pipeline is impossible, an alternative can be a do-it-yourself stove heating with a water circuit, made according to a well-thought-out, reliable scheme. The traditional, centuries-tested method of heating a house with a stove has one huge drawback that forces homeowners to think about radical measures - uneven heating. Closer to the stove it is warm and cozy, on the couch, if there is one, it is generally a royal bed, but the further you move from the hearth, the cooler it becomes. One solution to this problem could be to combine stove heating with a water circuit into a single system.

A stove can become not only a source of heat, but also a real decoration for a country house

Features of organizing stove heating with a water circuit

A stove with a water circuit combines the advantages of two types of heating and distributes heat evenly throughout all rooms. In fact, an ordinary stove becomes a kind of variation of a solid fuel boiler, only in addition to the coolant in the combined system, the housing is also heated, which also provides heating.

After combustion ends, the batteries cool down quickly, but for some time the heat will emanate from the heated walls, which contributes to a smoother cooling of the room. A unit with a water circuit differs from a conventional wood-burning stove by the presence of a radiator (aka coil, boiler, heat exchanger).

It can be installed directly into the firebox, but this is fraught with leaks or even an explosion caused by boiling of the coolant. A safer option is to install coolant in the chimney cap. In addition, this will increase the efficiency of the furnace; most of the hot vapor will go to heating the coolant, and not the street.

Furnace construction: heat exchanger installation

More often, the heat exchanger is made of pipe or sheet steel with a wall thickness of at least 3-5 mm. The minimum size of the thermal jacket is 4 mm. You can purchase a ready-made cast iron coil. In any case, the thermal gap between the furnace and the register must be at least 1-1.5 to ensure the possibility of sufficient expansion.

It is better to organize a stove heating system with a circuit at the stage of planning a house, but only after weighing all the pros and cons. The stove model is chosen based on the size and layout of the heated home. The water circuit is designed based on the rules for arranging heating structures.

You can make a heat exchanger from sheet steel yourself

It is also possible to rebuild an existing stove, but in such cases the heat exchanger often takes up a significant amount of the usable area of the stove, which was not designed for it. To compensate for this factor, the heat exchanger is prepared in advance, and the furnace is rebuilt based on its dimensions.

Water heating from a stove: ensuring an optimal temperature microclimate

Wooden houses in the classic version with stove heating warm up very unevenly. Heated air is constantly near the stove, and distant corners are cool. Using multiple ovens is quite expensive. It is better to combine heating - stove and water, as many of our compatriots do, who strive to achieve the warmth and comfort of their existence.

The solution is to equip a conventional brick oven with a heat exchanger shaped like a coil. It is installed in fuel rooms or at the base of chimneys. The heat from the stove warms up the water in it, which then goes to the radiators located in the rooms. Buildings are heated evenly.

The advantages of such systems include:

- Efficient and uniform heating - batteries are installed in different rooms and provide constant heat.

Complete independence - such heating systems are not affected by gas or gas pipelines. The only dependence is on the owner, who determines when and how much to heat.

- There is no need to attract specialists to service heating systems. It is quite within the capabilities of consumers themselves.

The disadvantage of such heating using stoves is its rather high fire hazard, which requires compliance with building protection measures. This option cannot be considered mobile, since movement is excluded. Not used in two-story houses. It is necessary to resort to the construction of an additional furnace, which entails considerable costs.

Despite the need to start heating daily from a water-heated stove, significant fuel savings are felt. Another disadvantage is the need for constant monitoring of the functioning of the system.

The principle of operation of stove heating with a water circuit

From a functional point of view, a furnace combined with a water circuit can be described as a closed cycle system. The heat exchanger is heated by hot air, which rises from the firebox, and transfers thermal energy to the coolant; most often, the circuit pipes are filled with ordinary distilled water. It passes through a circle through natural or forced circulation, heating the radiators and returns to the heat exchanger, where it heats up again.

Advice! If people do not live in the house permanently during the cold season, then antifreeze is poured into the system to prevent freezing.

Conditions for optimal system performance

The system will be operational provided there is constant circulation of coolant in the pipes. This is ensured by a mandatory slope, as well as the desirable installation of a circulation pump, which guarantees the necessary movement and prevents water from boiling.

Small in size, but with sufficient power, the pumps guarantee good circulation. They are necessary especially if the heating system is long. Installation of such a pump is carried out on the return line, that is, on the coolant return pipe.

You should not rely only on the pump and install pipelines without a slope, since interruptions in the supply of electricity may lead to boiling and failure of both the pump and the system itself. In such cases, it is better to resort to installing expansion tanks that compensate for the expansion of water.

Design work is completed by familiarizing specialists with the diagrams. They will help eliminate errors leading to unstable operation of water heating from the stove. This is also an opportunity to avoid security violations.

Methods for installing a combined heating system

There are three main ways to organize a combined heating system:

- With the construction of a new furnace. The need to build a new heating device makes it possible to choose the most suitable furnace model and heat exchanger, as well as to develop a competent scheme for the main project.

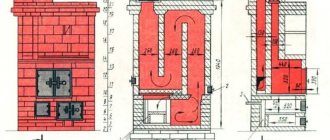

Diagram: device of a heating furnace with a water circuit

- Installing a heat exchanger in a finished furnace. This option is the most difficult to implement. First of all, this is due to the need to correctly calculate the dimensions according to which to make the coil. After this, you will have to disassemble part of the furnace, install the register and, if the draft was normal, reassemble everything in the same order. You can do this yourself if you have some experience as a stove maker or at least a mason.

- Installation of a factory furnace with a ready connection to the water circuit. Fireplaces, potbelly stoves and stoves with an installed water circuit have long been available for sale. All that remains is to create a closed system, connect pipes, radiators and the necessary equipment.

Is it possible to install a heating register in an existing furnace?

It would be more correct, of course, to build the furnace around the manufactured register. But, if the stove is already standing, you can still build a water circuit into it. True, you will have to try hard - they are of considerable size and must somehow hold on. So the task is not an easy one. In addition, do not forget that you will have to make two more conclusions - to connect the supply and return pipelines.

The best option is to make a water jacket under the shape of the stove (this one is for a metal stove with burners)

Finding a place to locate the register is also not very easy. Its direct contact with fire is very undesirable, but it should be in an environment of hot gases. In this case, you can hope that the heat exchanger will last a long time.

Features of stove masonry

To build a stove, select a suitable building material. Normally fired brick is considered the best option, but for the walls of the combustion chamber and smoke duct it is better to buy refractory brick.

Kiln masonry

- Before laying a brick, it is immersed in water and held until air bubbles stop appearing;

- Each row and corner must be tied;

- The solution is applied immediately along the entire row, in a layer of approximately 5 mm, and on the end of each brick immediately before laying;

- When laying the firebox, it is recommended to distribute the clay solution not with a trowel, but with your hand;

- Having laid about 5 rows, carefully cut off the mortar between the seams and rub the seam with a wet sponge;

- Of course, the verticality and horizontality of the walls being erected must be controlled.

Important! It is imperative to ensure unobstructed access to the combustion chamber and pay attention to safety. Only fireproof materials are used in and around the stove.

Features of water circuit pipe routing

The pipe system is connected to a heat exchanger installed in the furnace through sockets that are inserted through one of the walls. The water circuit in such a system is often arranged in the form of a two-pipe system. The wiring can be either lower or upper.

Register for the stove from an old battery

Naturally, the heating circuit must be fully equipped. The expansion tank is installed at the highest point of the line, safety and air valves are installed, and a safety unit with a pressure gauge is also included in the system; valves are connected at the inlet and outlet of the radiators.

The water circuit can be connected to a circulation pump; it significantly increases efficiency and allows for a more flexible approach to solving the issue of pipe routing. But there is a problem with this approach. If the pump stops working due to a power outage, the water will not circulate and will begin to boil in the coil.

In the cold winter, when the boiler is working at full capacity, one minute can be enough for the consequences to be disastrous. The stove, unlike a gas boiler, cannot be turned off quickly. For these reasons, it is recommended to use a combined wiring method.

Exiting pipes for heating

In the supply pipe, after it leaves the furnace, an acceleration manifold is installed, raising the pipe vertically by 1-1.5 m, and then lowering it to the level of the radiators. Sections of the highway are located at a slope of 3-5°. In case of emergency mode, coolant circulation will be natural.

It is better to install the circulation pump in the return circuit as close as possible to the expansion tank using a bypass, and the pump axis should be located strictly horizontally.

What is stove water heating?

Stove heating is another type of solid fuel method of heating a living space. However, modern methods make it possible to use not only wood or coal, but even waste and gas. In the past, stoves were used for heating and cooking, they were used to heat water for bathing and to warm themselves. In the 21st century, the stove in the house is also of an aesthetic nature.

The design of the Russian stove is simple - it consists of three parts:

- rude;

- bed;

- front end.

Scheme of water heating with a stove

However, ordinary Russian stoves do not satisfy the needs of owners of private houses, so a reservoir is installed in them, which turns them into a solid fuel boiler, which are used for a hydraulic heating system. This tank is filled with liquid, a pipeline and sometimes a pump are connected to it to circulate the coolant.

Important! Pumping equipment is used to prevent water from boiling in the tank.

In addition, modern stove heating of a private house includes an expansion tank, which is necessary so that the pipes simply do not burst if the water boils. In this case, the system pressure increases, and it is better to avoid this.

Tip : Stove heating is quite cheap, so it is recommended to buy a high-quality and large expansion tank. It is better to spend more money once to protect the entire system than to change pipes every time, which will burst from boiling coolant.

In the front part there is a combustion chamber - this is the place where fuel is loaded. This part is, in fact, multifunctional, because with proper planning, it can be used to organize a place for cooking. Thus, the owner of a private house can save a lot on gas or electricity, which he consumes for cooking.

Then the heated air passes through the wells, heating the wall. As a rule, Russian stoves had stove beds installed here, but modern models or fireplaces may not have this part and immediately turn into coarse wood.

Buleryan can also be considered a type of stove, which is popularly called a “potbelly stove” - as ancient as the world, and at the same time very effective in use. Buleryans are quite common in the world, and in Finland alone, more than 70% of the population use such stove heating for a private home.

Advantages of combined heating systems

- Cost-effectiveness of the system. Construction of a stove or re-equipment of an already finished one will not require serious financial investments, and as a heating device it does not require complex and expensive maintenance.

- You can combine a stove with a fireplace and get not only a heating device, but also a unique decorative element that can become the main attraction of the interior.

The appearance of the stove can be chosen by the home owner

- The house creates a special coziness and atmosphere that can only be created with the help of this living heating method.

- Relatively high efficiency. If the stove is built by a competent specialist according to a good design, its productivity will be quite high, up to 60% in comparison, for example, with an oil-fuel boiler.

conclusions

Considering the question of how to make water heating from a stove, we started talking about the use of various heating systems. At the same time, as practice shows, stove heating is the most popular in our country. The prevalence is explained by the use of available fuels.

The proposed modern gas or electric units operate on rather expensive sources. Water-heated stoves are more economical systems that can be easily equipped with your own hands, which also guarantees lower costs.

This heating is based on the combination of traditional stoves, known to us for centuries, and modern technologies. The result is the desired warmth in residential buildings, which people have always strived for and strive for.

A heater of this type means long service life without dependence on centralized sources. With proper care of heating units and furnaces, you can not worry about the temperature microclimate for many decades.

Disadvantages of combining a furnace and a water circuit

- No matter how high-quality the stove is, it still remains a fire-hazardous heating device.

- Another significant disadvantage of such a system is the labor-intensive operation and prolonged heating of the system.

- Stoves will take up a significant part of the area and surrounding space in the house.

- Some uneven heating will remain one way or another. The air temperature near the stove will be slightly higher than near the walls.

Operating the stove requires constant human presence

- The likelihood of carbon monoxide accumulation due to improper operation of the stove.

- Due to dust, sawdust from firewood, soot and ash, the room where the stove is installed will have to be cleaned more often.

- It is impossible to precisely regulate the combustion process and retain heat, but only with the help of dampers.

A combined system of a combustion furnace and a water circuit undoubtedly has the right to exist, and in some cases it may not only be the only possible option, but also completely justified. But all this is provided that the heating scheme is designed correctly, taking into account all the nuances and fully meets safety requirements.

How to regulate the temperature?

Buleryan with water circuit

Every private owner has a logical question about how to regulate the temperature in the room, since stove heating is often uncontrolled. However, this is not true: there are at least three ways to perform regulation:

- Increase the amount of fuel. Thus, you can significantly increase the temperature in your room if it is not enough. However, you should understand that after adding fuel to the combustion chamber, you should wait until it burns out, otherwise, if you overdo it in the house, it will be too hot.

- Install pumping equipment. By connecting a pump to the system, you can significantly improve the heating of not only one room where the stove is used, but also others where radiators are installed.

Tip : Installing a pump may be necessary to avoid boiling.

- Dampers and blower. Thanks to such elements, you can lower the temperature level of the room, if necessary. In addition, they allow you to control the movement of coolant in the network.

- Quality and type of fuel. Remember that coal produces more heat during combustion than wood; this can also be used as a temperature level regulator.