A gas boiler in the basement is allowed to be installed provided that the selected room meets the requirements specified in SNiP. This installation option is often allowed in country houses or country cottages. There are cases when organizing such equipment in the selected premises is prohibited. If you want to know all the details regarding this issue and not become a victim of a fine, or even more so an accident, we recommend that you study our material today to the end.

Gas boilers in the boiler room of a large private house Source sombuka.ru

What technical conditions must be met?

In order for the installation of heating equipment in a basement or basement to remain legal, certain technical conditions must be observed. Read more about them below:

- the number of boilers that will be responsible for heating the house as a whole should not exceed four units;

- the total power of the devices that make up a single heating system should not exceed 200 kW;

- The owner has permission to install a boiler that runs exclusively on natural gas.

Even if all of the above requirements are actually met, it is still too early to start installing a heating source. It is necessary to order a design for the future boiler house from the relevant authorities. This document must be signed and officially approved by the licensed business.

Large gas installation in the basement of a house Source bk.biz.pl

Option for placing equipment in the boiler room of a private house with gas heating Source vodakanazer.ru

Advice from professionals

Before you start building a basement in a building, it is important to know the required stages of the process, which will be useful both when ordering construction from craftsmen, and when doing the work yourself.

To ensure that the building structure from the basement to the roof is strong and reliable, the following steps must be followed:

- Soil analysis, you need to know its characteristics and groundwater content.

- Planning, it is necessary to prepare design documentation in accordance with construction norms and standards.

- Preparing the area, draining in case of high humidity, digging a pit.

- The construction of the basement is carried out using high-quality building materials, observing technical standards.

- The final stage of work includes finishing the walls, installing wiring, ventilation, and heating as necessary.

Building a basement in a house is not an easy process, which involves a lot of work, so that everything is of high quality and reliable, it is better to turn to a specialized construction company with experience for help.

Requirements for the premises in which a gas boiler room will be installed

Assuming that the conditions from the section above have already been met, you still cannot start the system until you are sure that the premises meet the following requirements:

- Sufficient ceiling height. The optimal distance from the floor to the ceiling is 2.2-2.5 meters. But it is better to start from the maximum point.

- The basement should not border on living rooms. That is, if the basement is located under a corridor or kitchen, then installing a gas boiler is acceptable. If this is a living room, bedroom or recreation room, then it is better to refuse installation of heating equipment.

- Login parameters have been met. It is necessary that the organization of the entrance to the basement is carried out correctly. The optimal width of the opening is at least 80 cm, and when installing the door leaf, you should refuse to install a threshold (that is, a fairly wide gap should form under the door. It is also better to additionally leave several convection holes in the door leaf.

- Maintain the distance between the wall and the boiler. In this case, there must be at least 1 m from the partition to the rear wall of the unit. This applies even if the smoke duct is installed through the wall.

- The presence of forced exhaust. It promotes spontaneous weathering of gases and explosive substances from the room. In cold weather, do not cover such openings with rags and insulation. They must work all year round. Once a year, when performing maintenance, the performance of the hood must be checked by specialists.

- Application for finishing non-combustible materials. Decorative wallpaper, polystyrene foam, laminate, wood, plastic - all this is prohibited from being used for surface finishing in a gas boiler room. Preference should be given to tiles, plaster, and concrete screed.

- The presence of a window opening is required. Moreover, the frame parameters should be selected based on 0.03 m2 for every 1 m3. It is important that the opening faces the street and that the window opens. Please note: if the window in the room is less than ¼ per 1 m2, then this room is not suitable for a boiler room. The distance from the window to the boiler is also taken into account: at least 1.5 meters.

- Availability of protective shields in the premises. These are necessary to protect surrounding objects from fire. Ideally, it is better to get rid of them altogether.

- Ease of maintenance and operation. From time to time, gas equipment needs to be checked for serviceability. In order to conveniently carry out maintenance (maintenance) of the device, it is necessary to provide access to it from all sides, and this is at least 1 meter.

On a note! It is better not to install the atmospheric type of gas boiler in the basement. It is advisable to place heating equipment with an internal combustion chamber here.

Normal distance from the wall to the boiler in a boiler room in the basement Source thebauernhaus.blogspot.com

Insulation of the basement space

If the question arises about the need to insulate the basement, you need to consider what it gives:

- The temperature regime is never sub-zero;

- Protects the room from condensation and dampness;

- Extends the life of construction by preventing excess moisture;

- Prevents the appearance of mold and fungal organisms on the walls, which contribute to musty air;

- Protects the foundation from moisture and premature destruction.

There are several types of basement insulation:

- Internal, the simplest, it requires additional waterproofing in the room to prevent condensation between the wall and the insulation;

- External, protecting the outer wall from freezing, not taking away meters inside, but it is carried out during the construction of the building;

- Combined, which provides internal and external insulation simultaneously with double-sided waterproofing, is the most effective.

The method of insulation depends on the following circumstances:

- Purpose of the basement space;

- Room humidity level;

- Heating in the basement;

- The presence of a drainage system around the base.

On the shelves of construction stores there is a sufficient assortment of insulation, the choice of which depends on the owner of the future home.

The most popular materials for basement insulation are the following materials:

- Polystyrene foam, the most cost-effective and accessible. In the process of thermal insulation, foam plastic is used whose density is 25 kg/m. cube It is popular due to its technical properties:

- Light weight

- Rot resistant

- High thermal insulation

- Water repellency

- Long service life.

Therefore, the use of foam plastic for thermal insulation of the basement is one of the most well-known ways to improve the thermal insulation of the basement space. But you need to take into account that polystyrene foam is not used in rooms with a high risk of fire in order to prevent a fire, because it is flammable and, when burned, releases toxic substances harmful to the body;

- Expanded polystyrene, a foam-like material with the same properties, but with a higher density, therefore stronger. It's more expensive, but it doesn't crumble during processing.

- Polyurethane foam, material for thermal insulation in the form of spraying. A special feature of polyurethane foam is its ability to fill the smallest cracks. It does not allow moisture to pass through, does not rot, does not burn, and creates complete tightness in the room. An insulated basement with polyurethane foam will create a good layer of insulation on the outside. The disadvantages of this insulation are the high price and the inability to carry out the work independently;

- Mineral wool is used as insulation indoors if there is no moisture in it, since when wet it loses its insulating properties;

- Expanded clay, a loose type of insulation that has excellent thermal insulation properties, but its use is best suited for thermal insulation of the floor and external foundation as a drainage layer.

The type of insulation and its thickness are selected individually for each individual case. It is better to entrust the selection of thermal insulation material to a specialist who will calculate the required thickness, taking into account many factors. Or you can make calculations in person, using recommendations approved by the government.

Rules for installing a heating boiler

A gas boiler in the basement is organized taking into account special requirements. These data are taken from SNiP:

- For basements, the installation of closed type equipment is strictly recommended. Its peculiarity is that the device independently captures air from the street to improve ignition;

- if it is necessary to hang the boiler, then take into account that the distance from the floor should not exceed 80-160 cm, while it is important that there is a gap of 1 meter or more to the ceiling.

From year to year, the requirements in SNiP may change and be adjusted; There are also those that completely lose their power. Therefore, in order to know exactly about the regulatory requirements, it is better to consult a heating engineer with an existing heating engineer.

Installation of a gas boiler in the basement of a house on a concrete pad Source sense-life.com

Heating using electrical appliances

Electrical appliances for heating basements are the simplest and most cost-effective option. Today, a heater is an indispensable device that is used when it is necessary to maintain a certain temperature regime.

In order for heaters to work properly, the basement of a private house requires high-quality electrical wiring designed for their total power.

Electrical equipment can be very different. Let's consider its main types.

Convector heaters

To fully heat a large basement of a private house, convectors are best suited. Heaters of this type will help cope with cold air even in the bitterest frosts. Convectors can be made in different types of designs, so you can choose the most convenient type (on the wall or on the floor).

Among the main advantages of such heaters are the following: the room warms up quickly and fully, the device is easy to install, it does not make noise, it can heat the entire building or individual rooms. The main disadvantage is the serious energy costs.

Requirements for how to organize a chimney in a room

The chimney for a gas boiler in the basement or basement must also be arranged in accordance with the requirements. The following must be taken into account:

- the smoke exhaust pipe should not pass through living rooms;

- The “neck” of the chimney must not be covered with decorative objects in order to hide the unaesthetic appearance;

- the number of chimneys must be equal to the number of installed gas boilers. It is impossible for combustion products from several gas units to be discharged through one system;

- the chimney must be organized separately, and not use a pre-prepared ventilation shaft for it.

Chimney pipe for a heating device installed in the basement Source drive2.com

The most optimal method of smoke removal is along the outer wall of the building, since this method is the simplest. For boilers with an internal combustion chamber, a vertical type coaxial chimney is installed.

Approximate diagram of the organization of a chimney for a gas boiler in the basement Source rosstin.ru

Relationship with other communications

In order for the boiler room in the basement to function well, it is necessary that all necessary communications be organized in it. Therefore, the room in which the heating equipment will be installed must meet a number of conditions:

- When installing a single-phase electrical circuit, be sure to pay attention to the voltage. Its values should be minimal (220 Volts), and as for the current strength, it should reach no more than 20 Amperes. It also requires the mandatory installation of grounding and a circuit breaker in the event of a short circuit;

- If one boiler is installed in the boiler room, there must be one locking mechanism. If several units are installed, the number of shut-off valves should be similar;

- the water supply in the room where heating is installed must be part of a single water supply system that is present in the house. Also in the same room there should be a valve and a pipe through which the system will be powered before the heating season;

- objects such as water supply, chimney, ventilation shaft, located in the basement, need protection from condensation. Therefore, you will also have to organize the removal of excess moisture;

- presence of gas detection sensors. Ideally, it will be a signaling device model with a shut-off valve included in the kit.

What types of basements are there?

According to SNiP 31-02-2001, basements can be:

- Basement. It is a floor in which the floor level of the room is lower than the planned ground level and more than 1/2 the height of the room. It can be heated, with the installation of heating devices, or without heating.

- Underground. This is the space located under the building between the ceiling of the first floor and the ground surface. The lower part of the building, the room where communications are laid and engineering equipment is located, is the technical underground.

- Ground floor. It is arranged when the floor level of the room is lower than the planned ground level by a height of no more than half the height of the rooms. The basement floor differs from the underground floor in the presence of natural light and greater functional content.

- Cellar. It is a device buried in the ground used for storing food all year round. It can stand separately from buildings, be located under a residential building or any outbuildings.

(

How to install a wall-mounted gas boiler in the basement

Often, when installing a boiler room in the basement, they try to use wall-mounted units as the basis for the equipment, despite the fact that they differ in labor costs. The main condition that installation must meet is reliable fastening of the equipment.

When trying to install a gas boiler, it is necessary to take into account nearby structures. The distance from the boiler to a nearby object (pipes, other structures) must be at least 20 cm.

When installing to a wall, it is necessary to leave about 2-3 cm from it. Also, according to the standards, it is allowed to install a gas boiler above other equipment, the main thing is that the requirements for the distance from the ceiling surface are met (as mentioned above - at least 1 meter).

Installation of a wall-mounted gas boiler in the basement of your own house Source terman-s.ru

The installation must begin from the preparatory stage. The necessary tools, fastening elements, and other components are assembled. The installation can be entrusted to specialists or follow the instructions that come with the gas equipment.

On a note! There must be a plate on the gas boiler that specifies the technical characteristics. Before installing the unit, you need to make sure that the instructions contain exactly the same data.

It is possible that the partition in the basement will be covered with wood. If you have to mount gas equipment on it, then you must first cover such a wall with fireproof material. The minimum thickness of such insulation is 3 mm.

Wall-mounted gas boiler in the basement on a brick wall Source terman-s.ru

Next, proceed to installing the brackets. For them, grooves are prepared, and then hook-shaped fasteners are screwed into the holes or driven in (if they are anchor dowels). Any wall-mounted equipment is supplied with mounting strips and clamps, as well as a mounting diagram. In order for the gas boiler to rest securely on the wall, you must act strictly according to the diagram.

Having hung and slightly secured all the fasteners, you should check whether the heating device is in a horizontal position. Its performance depends on this. Due to the out-of-level installation, there is a risk that the wick will go out from time to time when air from the street enters the pipe.

Important! Since during transportation of the boiler the pipes through which the coolant will pass become clogged, they must be cleaned. It is better to do this under water pressure (for example, from a Karcher, but the main thing is not to overdo it). As for the water input, a fitting with a filter and a shut-off valve must be installed on the pipe. It will prevent large particles of dirt from entering the system.

Checking pipes before installing a gas boiler Source gazservis72.ru

Installation of this type of equipment requires professionalism. Even if you can install the device yourself, you will have to hire gas service specialists to connect it, but the boiler room in the basement must comply with the standards.

Errors and consequences of violating the technology of plinth construction

1. The main mistake when building a basement is the lack of external thermal insulation of the foundation walls.

The erroneous misconception that thermal insulation is not needed is based on the sufficient thickness of the walls, which supposedly do not freeze. It is worth considering that even with very thick walls, frost tries to penetrate the room, which leads to the formation of a dew point inside the foundation. And when heating the basement floor, the temperature difference becomes greater, which leads to the formation of condensation in the foundation structure.

2. The second common mistake is the lack of waterproofing of the base. This happens either due to excessive cost savings, or due to confidence in the reliability of the waterproofness of the base.

Even with improper or poor-quality waterproofing, problems appear over time. Without reliable waterproofing, even in dry weather conditions, capillary moisture penetrates into the walls of the basement floor, which changes the chemical composition of the wall material, leading to its accelerated destruction.

Features of installation of floor structures

This process also requires several steps:

- Preparation of tools and equipment.

- Arrangement of a special foundation cushion or support frame.

- Organization of a chimney, water supply.

- Inspection of the ventilation shaft or its installation (if there was no system previously).

- Direct installation of equipment.

In general, there is nothing complicated, but after installation you need to make sure that the gas boiler is parallel to the floor. If it has adjustable legs, then adjusting the installation position will not be difficult.

Only after you have achieved the ideal level can you begin to install the filter on the inlet water supply and connect the chimney pipe directly to the organized channel. All connections must be treated with sealant. In the case of a chimney, you will have to give preference to an option that can withstand heat.

Correct location of the gas boiler on the floor in the basement Source ef-tehno.ru

Should I insulate a heated floor if there is a heated floor underneath it?

The situation is as follows - the ground floor is half underground, there are heated utility rooms. The first floor is residential. There is a concrete floor between them. It's cool on the 1st floor even in the heat. I have heard opinions that this is due to cooling in the basement. It is planned to have heated floors for the entire 1st floor, without additional radiators. Questions: 1) If you install a heated floor on thermal insulation, will it become hotter in the summer on the 1st floor due to the “cut-off” of the refrigerator base? 2) If you throw away the thermal insulation, then, as I understand it, some of the heat will go to heat the base and fewer radiators will be needed there, but this will not particularly affect the overall gas consumption. But will the remaining power of the heated floor be enough to heat the 1st floor? It seems that the productivity of heated floors, which do not burn your heels, is just enough to heat a well-insulated house.

I would appreciate your opinions.

Not the plinth, but the ceiling of the plinth, these are two big differences. If heating will work in the basement in winter, then multifoil will be sufficient under the heat exchanger on the 1st floor. (link is outdated)

It will. It's better not to do this. I have a similar situation - radiators in the basement and TP on the first floor. Between the ceiling and the screed there is only 2mm of foamed polyethylene, this is required to relieve the tension of the heated floor screed. In extreme heat, the maximum temperature on the first floor was 25-26 degrees, while the floor temperature was 22-24 degrees (I have a pyrometer). The maximum temperature in the base was 20 degrees.

If you do not make the ground floor residential, radiators are not needed at all. At least for the last two winters, I haven't needed them. Last winter, the temperature of the basement floor (with the TP on the first floor running) did not drop below 16 degrees, even in severe frosts. In the “cold” part of the basement, for storing vegetables and thermal insulation cut off from the first floor, there was 12g in the room.

Basement heating is often started due to fear of dampness. In each room on the ground floor I have a direct flow of air through holes in the base and two ventilation ducts leading to the roof. Those. with good ventilation, the rooms will be dry at any time of the year.

I decided to add the technical characteristics: The above-ground part of the base is 60 cm, insulated with EPP. The thickness of the base is 50cm, the material is monolithic concrete. The walls of the house are made of GB 40cm, density 400.

Ventilation arrangement: important points

The best option is natural ventilation. It is most often organized in the ceiling area. If this is not possible, then they do it in the wall, directly under the ceiling. It is noted that for high-quality ventilation of a room with installed equipment with a power of 1 kW, 8 cm2 of inflow is sufficient.

It happens that it is difficult to organize ventilation from the street, so air is taken from the adjacent room. In this case, a boiler with a power of 1 kW will require up to 30 m2 of inflow.

Sometimes natural ventilation cannot be realized. In this case, they resort to artificial methods, for example, installing a fan, which is connected to electricity. They also use duct installations. It is necessary to select mechanical devices according to power, which is pre-calculated according to this principle: the width and height of the room are multiplied by the length.

Forced ventilation in the basement where heating is installed Source drive2.ru

The most efficient ventilation units are those with an aluminum or copper casing. These materials are known to resist melting.

Basement heating calculation

Heating is an important component of a living space. If in the summer heating is an imperceptible and seemingly unnecessary detail, then in winter everything changes dramatically. So, you have already decided what to heat with, now you need to calculate the heating of the basement.

If you have chosen boiler heating, then you need to know the area of the area that you are going to heat. This could be the whole house or just the basement. But it is more expedient - the whole house. So, to calculate the boiler power, decide on the area that needs heating. After this, compare the indicators with the following diagram: with an area of 60-180 m2, the boiler power should be no more than 25 kW, from 200 to 300 m2, the boiler power is 25-35 kW, 300-600 m2 - 35-60 kW, 600-1200 m2 – 60-100 kW.

If you want to install a stove, then decide what kind of stove it will be - a potbelly stove, a long-burning stove or a brick stove. If it’s a bourgeois, then with 6-8 m2 you can get by with a simple model that you can make yourself. But at 40-60 m2, a potbelly stove assembled independently will no longer be able to cope with the heating task assigned to it. Here you will need oven models made in production.

Long-burning stoves are suitable for areas up to 210 m2, and the required power of such a stove for your basement can be calculated in the same way as the power of a water heating boiler. A simple brick stove is the simplest option; its power does not need to be calculated, although here you need to not miscalculate the length of the chimney and correctly implement the firebox.

Expansion tank requirements

From the point of view of current standards, an expansion tank must have been organized in a gas autonomous heating system. The installation of such a design is necessary to compensate for the missing amount of water taken from the water supply when starting to power the system.

An expansion tank is also necessary to relieve the resulting water pressure during heating. Additionally, a device can be inserted, which will be responsible for feeding the main heating circuit.

On a note! The current SNiP allows the use of polypropylene pipes with aluminum reinforcement for soldering the heating system. It is important that the use of such material meets two conditions: withstand pressure up to 3 bar and a coolant temperature of 105 degrees.

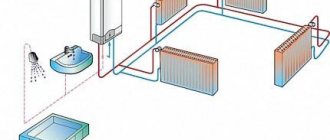

Main types of heating systems

We can immediately distinguish two main types of heating:

- Water heating of a private house, which involves installing radiators and a boiler (gas or electric).

- Stove heating, the organization of which requires the presence of a “potbelly stove” or stove.

Water heating operates on the basis of a boiler (it can be electric or gas). One of the main advantages of such a heating system is the constant availability of warm water.

Simple water heating system: 1- boiler; 2 - expansion tank; 3 - supply pipe; 4 - radiator; 5 - return pipe.

When installing stove heating, the installation of a “potbelly stove” or stove is required. This type of heating is more economical both during installation and during further use, which is its main advantage. In addition, in this case there is no need to look for a place to install a bulky boiler. The stove will produce enough heat to heat a small basement of a private house.

But for the system to operate effectively, it is necessary to provide a chimney. Here you need to approach the issue responsibly and accurately calculate the parameters of the pipes to organize sufficient traction.

Advantages and disadvantages of a gas boiler in the basement

Placing a gas boiler room in the basement is justified by many positive features. Let's define worthy qualities:

- convenient organization of space (if the boiler is placed in the basement, it will not take up free centimeters in rooms such as the kitchen or pantry);

- The design is not spoiled by oversized heating installations. Typically, gas boilers look oversized, which is not entirely appropriate for the chosen interior.

There are also negative qualities:

- There are cases when gas utilities use outdated SNiP, which prohibit the installation of a boiler room in the basement;

- major construction work is required in order to create a sufficient width of window and door openings;

- It is imperative to use fire-resistant raw materials, since the basement becomes flammable.

Gas heating pipes that take up a lot of space Source master-vodoved.ru

As repeated practice shows, bans on installing a gas boiler room in the basement apply to private households with permanent residence. Based on this, we recommend that you do not rush to complete the installation until the official appeal to the supervisory authorities receives a response.

Basement heating problems

Heating the basement is not a waste, but a real necessity. The basement is the most vulnerable place of the entire house, so the basement requires special attention so that moisture and low temperature do not quickly destroy it.

The basement floor is located largely underground, so it is heavily influenced by many negative factors, so during its construction, even the smallest deviations in technology lead to poor operating conditions, which affect the microclimate of the room.

Cost-effectiveness and autonomy: which boiler is better to choose taking into account these characteristics

Installing heating equipment in the basement is also permissible if the source is not blue fuel, but another type, for example, solid raw materials. Here you will have to decide which option is ideal for this purpose. When choosing, you need to focus on autonomy and efficiency.

The concept of autonomy means minimal participation of the owner in the process of connecting the heating. If you need complete independence from humans, then it is better to give preference to electric boilers.

Correct installation of gas equipment in the basement for servicing Source tesystems.ru

Regarding efficiency, it is necessary to pay tribute to the equipment, the source of which is main gas. This fuel is considered the cheapest. As of April 2022, one cubic meter of gas costs 5 rubles 56 kopecks (this is data for the Republic of Crimea).

Do I need to heat the basement floor?

Everything about water supply and sewerage

Pumping stations and wastewater treatment plants

Sewer

Plumbing

Firefighters

The Admiral plant produces complete pumping stations for water supply, fire fighting and sewerage needs. Admiral plant website: admiral-omsk.ru