Nowadays, many companies from the former CIS countries are successfully developing the heating equipment market. Every year they compete more and more confidently even with the strongest foreign brands. The demand for solid fuel boilers made in Ukraine is also growing. Next we will talk about the most famous brands and their attractive sides.

Long-burning solid fuel boilers in Ukraine

General characteristics of boilers produced in Ukraine

Specialists who understand boiler equipment will probably notice that in their design, solid fuel boilers manufactured in Ukraine are very similar to the elite equipment of the brands Herz, Herlt, Hargassner and some others, and we are talking about their full-fledged versions, and not the lightweight ones with which our consumers have to deal with most often.

When mastering the production of solid fuel boilers in Ukraine, manufacturing companies are actively adopting the experience of their foreign competitors, but not just copying it, but trying to improve it, taking into account the conditions characteristic of our countries.

Foreign dealers prefer to supply “stripped-down” models, for example, without combustion chamber lining. Such boilers do not work well on raw fuel and, since they are widespread almost everywhere, many users mistakenly attribute this drawback to all solid fuel boilers.

Pyrolysis boilers CET

Ukrainian-made pyrolysis boilers are manufactured with full equipment. It is mandatory to line the combustion chamber with heat-resistant concrete and other compounds.

Even raw firewood with a humidity of up to 50% can be used as fuel for such a unit, while its performance characteristics will remain at the highest level.

How else do Ukrainian products compare favorably with those imported from abroad? There are several advantages:

1. Versatility. Ukrainian manufacturers take into account the difficulties associated with low quality fuel and interruptions in its supply, so their boilers are practically “omnivorous”.

2. Reliable electronics. It is no secret that the quality of electricity supply in our countries, especially in settlements remote from cities, leaves much to be desired. This circumstance is taken into account when developing electronic control and monitoring systems for Ukrainian solid fuel boilers, so they are able to remain operational even with significant fluctuations in voltage in the electrical network.

3. Availability of spare parts. In the event of a breakdown, delivery of spare parts for a Ukrainian boiler will take less time and money than for its imported “colleague”.

4. Low cost. While in terms of equipment, Ukrainian solid fuel boilers correspond to the most expensive models of elite foreign brands (which, we remind you, practically never come to us), they have the same cost as economy-class units from the same manufacturers. This circumstance is partly due to the fact that the sale of solid fuel boilers in Ukraine is carried out directly by manufacturers, and therefore does not involve dealer markups.

Solid fuel boilers made in Ukraine

Considering these advantages, as well as a wide range of functions and durability of Ukrainian boilers, more and more consumers are choosing them.

Pyrolysis boilers SET type

The average price of a boiler of this brand is 1.5 thousand US dollars . This equipment is produced fully equipped; the combustion chamber is lined with compounds that are resistant to high temperatures.

Firewood with a humidity of up to 50% can be used as fuel for this brand of boiler. At the same time, the performance characteristics of the boiler will remain high.

The main advantages of Ukrainian boilers of the brand in question are as follows:

- Boilers are universal. Manufacturers take into account the difficulties associated with the poor quality of fuel materials and difficulties in delivery. For this reason, Ukrainian boilers work on almost everything.

- The electronics work flawlessly. It is no secret that the electricity supply in our countries is far from perfect. This condition is also taken into account by manufacturers when they develop electronic monitoring and control systems for Ukrainian boilers. For this reason, the equipment of this type is not afraid of fluctuations in electrical networks.

- Spare parts are available for purchase. If necessary, spare parts for Ukrainian boilers can be purchased, spending less time and money than when purchasing spare parts for a Western-made boiler.

- Affordable prices. Ukrainian solid fuel boilers make a strong impression not only because they can compete with elite equipment from Western countries, but also because the prices for Ukrainian boilers are much lower than for equipment from foreign countries. To some extent, this feature is due to the fact that boilers from Ukrainian manufacturing companies are often sold without intermediaries and, accordingly, without extra markups.

Taking into account these strengths of Ukrainian boilers, as well as the fact that they are equipped with a large set of functions and are characterized by durability, it is not at all surprising that an increasing number of consumers give their preference to this particular technique.

Some tips for choosing

When purchasing a long-burning solid fuel boiler, you need to pay attention not only to the numbers on the price tag. It is important to consider the thermal power of the equipment, its maximum operating pressure and the duration of the filling until the next refueling.

To calculate the heater power, you need to calculate the thermal load of the system and multiply it by the safety factor. Unfortunately, it is quite difficult to carry out such calculations on your own, but for ordinary consumers a formula has been invented - 10 sq.m. premises will require 1 kW of energy. Based on this formula, you can select the desired boiler power. This means that the money will be invested rationally.

The operating pressure of the unit is selected only when the height difference between the highest and lowest points in the water circuit of the house is determined. But this parameter is important for multi-storey buildings, where the boiler is installed in the boiler room, which in turn is located in the basement or on the ground floor. For such calculations, you need to know that 10 m of water column height exerts a pressure of 1 bar. For one-story houses, devices with 1-1.5 bar operating pressure are suitable.

Well, as for the duration of combustion, usually the technical passport for the product contains this information. The interval between fillings depends not only on the selected fuel, but also on the size of the loading chamber itself. Therefore, if you do not want to go down to the boiler every 8 hours, then you should choose units with a large combustion chamber. But you should be prepared for the fact that this will directly affect the dimensions of the boiler itself.

Such simple points will help you choose boiler equipment. But the money will be invested rationally.

Purchase of a Ukrainian-made boiler

When choosing gas boilers made in Ukraine, pay attention to parameters such as productivity (1 kW for every 10 sq. m. area) and the energy carrier used. The type of combustion chamber also influences the choice - a closed one is installed in apartments of multi-storey buildings, an open one - only in private buildings. A properly selected equipment configuration will ensure efficient heating of your home at minimal cost.

Foil reflective thermal insulation, according to reviews, is not as effective as manufacturers claim.

About ceiling insulation with Penoizol is written here.

It is most profitable to use gas for heating premises if they have a gas supply system. The next most economical option is electricity. A solid fuel boiler is suitable for ensuring energy independence from all communications.

Types of boilers by power

The choice depends on the tasks set for heating. The first thing to determine is the purpose of the boiler.

Industrial

Designed for heating large buildings, drying chambers, heating equipment. The power is calculated based on the needs for thermal energy; often the boiler is selected 25-30% more powerful. The design requires a separate boiler room, complex piping and automatic control; operation and maintenance are carried out by trained stokers.

Photo 1. Long-burning industrial-type solid fuel boiler connected to the heating circuit.

The design is aimed at automatic reloading and pyrolysis decomposition of wood. In enterprises where waste consists of shavings and sawdust, this fuel is used predominantly. In this case, bunker reloading systems with auger routes are used.

Domestic

Designed to improve comfort of use. Maximum autonomous combustion time, the ability to control the temperature of the coolant depending on the season, energy independence, type of fuel - all these features are taken into account when choosing the type of boiler.

Danko

The Danko company has been on the market since 2002.

In the model range you can see solid fuel boilers with a power from 12.5 to 50 kW. All of them have individual design and quality. There are several options that run on gas fuel. Wall-mounted units have a capacity of up to 23 kW, parapet units - 7–15.5 kW, floor-mounted units - 96 kW.

The Danko company provides a quality guarantee for its products for up to three years and guarantees high productivity of up to 91%.

Popular series of Danko gas boilers are discussed below.

| Series | Characteristic |

| Danko - 23 VKE / Danko - 23 3KE | These are Ukrainian middle-class gas boilers with a power of 23 kW. They have two circuits. Installed on the wall. They have an open and closed combustion chamber, as well as two heat exchangers (the main one is a copper heat exchanger for heating water in the heating circuit, the secondary one is a stainless steel plate heat exchanger for supplying hot water). The series has compact dimensions and a modern attractive design. They function perfectly at reduced pressures down to 2 mbar. The design is equipped with electronic ignition and an anti-freeze function. |

| Steel gas boiler Danko | The series is represented by a wide range of models with a power range from 8 to 24 kW. The letter “B” means that the boiler has a water heating function. The letter “G” means that the boiler has a horizontal flue. There are both single-circuit and double-circuit models. Tubular heat exchanger made of 3 mm steel. The average efficiency is 91.5%. |

| Cast iron gas boiler Danko | This is a series of gas floor-standing boilers with a cast iron heat exchanger. They have an open combustion chamber and one circuit. The power of the models varies from 16 to 50 kW. Working pressure reaches 0.2 MPa. Coolant outlet temperature up to 90°C. The models are characterized by high heat transfer, resistance to rust and a long service life (more than 25 years). The efficiency is 90%. Danko cast iron gas boilers operate in open and closed water heating systems, with forced and natural circulation. |

The following are Danko solid fuel boilers.

| Series | Characteristic |

| Danko-TL | The model range includes nine items. All boilers operate on solid fuel, namely coke, wood, coal. You can also use shavings, pellets, sawdust, and peat briquettes. The units are designed for heating rooms up to 470 m², in systems with forced and natural water circulation. The series is easy to operate and maintain. The service life can be up to 25 years. The Ukrainian-made solid fuel boiler has a durable cast-iron heat exchanger and a water-cooling grate. The efficiency is at least 75-80% |

| Danko-TN | This Ukrainian-made long-burning solid fuel boiler has a steel heat exchanger and operates on solid raw materials, namely peat, wood, and coal. The model range includes four items with capacities from 12.5 to 27 kW. The service life of the units is more than 15 years. |

| Danko-T | The model range is represented by three items. These are Ukrainian solid fuel boilers with a steel heat exchanger. Raw materials used: anthracite, coal, wood. The units have a modern design, are distinguished by reliability and quality. The total heating area is 720 m². Designed for heating individual residential buildings and other areas. |

| Danko AKTV | This is a solid fuel boiler, represented by the Danko AKTV-15 and Danko AKTV-20 models. It has a steel heat exchanger and a cast iron stove for cooking. Suitable fuels include wood, coal, and anthracite. The total heating area is up to 200 m². The special design allows you to adjust the cast iron grates to different levels and rationally use the boiler depending on the time of year outside the window. |

You can also turn to Czech and Russian solid fuel boilers.

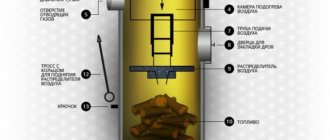

Top combustion boiler

Top combustion boilers are the best solid fuel combustion boilers made in Ukraine. How is good autonomy achieved?

Firstly, there is no grate or ash pan. There is a blind pan at the bottom; burning in the lower part is unacceptable.

Secondly, the firebox is made of a cylindrical shape. Air is supplied from above - this ensures combustion of the top layer of the bookmark.

Thirdly, the air distributor in the firebox is movable. When fuel is added, the air rises and as it burns it falls.

Fourthly, oxidation of hydrocarbons occurs only partially. Combustion products along with ash are carried to the upper part of the furnace.

Advantages of long-burning solid fuel devices:

- Work without a report can only be determined by the size of the firebox; it is not limited by anything else.

- High efficiency, fuel burns completely, without any residues.

- The devices are not fault-tolerant, all automation works fine.

Disadvantages of long-burning solid fuel devices:

- The devices are quite sensitive to temperature. A slight increase in circulation speed means condensation and accelerated corrosion on the heat exchanger.

- Long-burning solid fuel devices are quite expensive.

- The support beam and disk burn out quite quickly.

- If the load is incomplete, it will be difficult to light the firebox.

Manufacturers of solid fuel boilers in Ukraine

Today, heating boilers using solid fuels in Ukraine are produced by about a dozen companies. We will talk about those of them whose products are most widespread.

Trademark "Aton"

Well-known boilers produced by Aton, which are produced at the Lebedinsky Engine Plant, which is part of MotorSich OJSC. The operation of the units is based on the use of pyrolysis technology, the essence of which is the formation of flammable gas during the smoldering of wood fuel in conditions of lack of oxygen. Such devices are also called gas generators or long-burning boilers.

Solid fuel boiler Aton

The power of Aton boilers varies from 16 (domestic models) to 360 kilowatts (units for industrial use).

The design of the boilers allows them to be refueled with various types of fuel:

- firewood;

- peat briquettes;

- wood briquettes;

- briquettes made of straw and sawdust;

- waste from wood processing and furniture manufacturing enterprises (chipboards, plywood, etc.).

The dimensions of the firebox allow you to place logs up to 1 m long and up to 410 mm in diameter, thus freeing the user from the need to chop wood.

Thanks to innovative solutions, the developers of Aton boilers managed to reduce fuel consumption by six times, thanks to which the purchase of a boiler pays for itself in just a year. For every 100 sq. m of heated room area, the boiler consumption is no more than 30 kg of firewood per day.

A mullite-corrundum mixture is used to line the combustion chamber. Electronic control units installed in Aton boilers are produced by the Polish company Tatarek. The warranty period for Aton boilers is 5 years.

Trademark "Buran"

Buran boiler

Due to the possibility of long-term operation without user intervention, long-burning solid fuel boilers made in Ukraine are in high demand. Therefore, when developing their units, engineers relied on this technology.

The catalogs of this manufacturer present both wood-burning boilers and those oriented towards the use of coal fuel. The advantage of coal boilers is their ability to operate at low temperatures.

Like other low-temperature solid fuel units, Buran coal boilers can operate without refueling for three to five days. For wood-burning models, this period is about 30 hours.

By using a specially designed heat exchanger, the developer managed to increase heat transfer by 40% compared to other models of solid fuel boilers.

Another improvement is the air diffuser, which has an unusual design, which ensures that the air flow in the combustion zone rotates clockwise. Thanks to this technical solution, fuel combustion in the Buran boiler occurs evenly over its entire area. The air supply device itself can also rotate around its axis, so it can be used to clean the combustion chamber from soot and tar deposits.

Trademark "POZH INKA"

The specialists of this company can not only install a boiler, but even build a boiler room for it, since the company has a construction license.

For the production of "POZH INKA" only high-quality steel with a thickness of 6 to 10 mm is used. Each model comes with a 5-year warranty.

Like the models described above, POZH INKA boilers are gas generator boilers. The design of the firebox allows you to burn any biomass in it, be it sawdust, rhizomes, reeds or coal. By using a heat exchanger of its own design, the developer managed to bring the boiler efficiency to a fairly high level - it ranges from 80% to 92%.

Trademark "Kordi"

Kordi boiler

Over the years of its activity, it has mastered the production of a wide range of products, which, in addition to solid fuel boilers, includes various water heating devices and solar panels.

In a series of industrial boilers, the company produces 4 models designed for heating premises ranging from 900 to 2700 sq. m. m. The most powerful of them is the KOTV-250 boiler with a power of 250 kW.

For domestic use, the company produces conventional boilers and boiler-stoves, distinguished by the presence of cooking burners. There are ten models in total in this line. They can be used to heat rooms with an area of 100 to 950 square meters.

Buran

The average price is $1,100. They are popular in the market due to the fact that they can function for a long time without human intervention. It is clear that the creators of the boilers relied on this factor.

Among the Buran brand boilers there are models in which firewood can be used, and there are also models for coal fuel. The strength of coal-type boilers is that they can operate at low temperatures. Like many models of this type, low-temperature boilers can operate for up to five days without additional refueling. Models that operate on wood can operate for up to 30 hours without additional refueling.

When creating Buran brand boilers, it was planned to equip the unit with a specially designed boiler, due to which heat transfer increased on average by 40%.

Another feature of the Buran brand is an air diffuser with an unusual design, thanks to which the air flow rotates and this ensures uniform fuel combustion.

In conclusion, it can be noted that Ukrainian manufacturers rely on the quality of boilers, which often exceeds the quality of Western-made units. At the same time, Ukrainian boilers have affordable prices. This explains the demand for solid fuel boilers made in Ukraine.

Reviews

Anatoly Reznikov, 27 years old, Perm

Quite recently we bought a solid fuel boiler KT-2E (Ukraine). This unit has a power of 25 kW, which is enough for us to heat 120 sq.m. Although the technical data sheet states a figure of 250 sq.m. The fuel bunker is designed for 56 kg, the volume of the loading chamber is 62 cubic mm. When fueled with ordinary firewood, combustion lasts about 8 hours, but just recently I tried to switch to pellets. So now one refill is enough for 2-3 days. Overall, this is not a large boiler, but for us this was the main requirement since the house does not have a basement. Therefore, we installed a boiler in the summer kitchen. I am very pleased with the purchase.

Konstantin Abramov, 30 years old, Orenburg

We had an Austrian Herz boiler. Six months later it stopped working. When I called the experts, it turned out that some part was out of order (I don’t understand boiler equipment, so I didn’t remember its name). In order for my boiler to work again, I had to order the original part directly from Austria and its cost should have cost me about 500 dollars. And this is not a small amount. So I decided to approach the situation differently. Through a friend, I ordered a similar part from a warehouse, but it was not original, but from a different boiler. After installing it, my unit still worked for 3 months, after which it completely failed. Although the first craftsmen warned me that high-quality repairs were needed, I did not listen to them. For which he paid. It’s good that the boiler equipment failed in early April, when there was no longer severe frost outside. Now we are choosing a boiler from neighboring countries and are thinking about choosing Danko TL, since I have heard a lot of positive reviews about it. And repairs, if anything happens, will now be cheaper and more reliable. I won't make that mistake again.

Alexander Ivanov, 32 years old, Gorbatov

I work at a furniture factory, and in winter a solid fuel boiler provides us with heat. My friend is responsible for the maintenance of this unit. Our factory occupies an area of 320 sq.m., that is, it is quite large. At the same time, we spend about 70-80 kg of fuel per day for such a quadrature. Well, since our products are made of wood, we have no problems with refilling - we use all the wood waste that we have. Moreover, in the summer, we simply store them, and when the cold comes, we immediately put them to work. Now I’m thinking about installing the same boiler at home, only with less power. My friend calculated that for my house (101 sq.m.) daily fuel consumption should not exceed 30 kg.

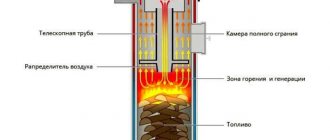

Operating principle and advantages of pyrolysis boilers

The secondary combustion chamber is the main structural addition that the natural draft pyrolysis boiler received. The traditional firebox has a secondary role: it serves as a loading hopper for fuel and a source of combustible gas. It is generated from fuel during slow smoldering, when the supply of oxygen to the firebox is limited. Entering the secondary chamber, the gas mixes with heated air and enters into a thermochemical reaction with it. As a result, pyrolysis combustion begins, which produces the main amount of heat.

Natural draft pyrolysis boiler

Conventional solid fuel pyrolysis boilers operate due to the natural draft created by the chimney pipe. This solution is very convenient for homes where there is a problem with power outages. But the operation of the installation largely depends on the draft force of the chimney, since pyrolysis boilers have a higher air path resistance due to the complexity of the design. To overcome it and create stable air movement in both chambers, you need to ensure good draft, otherwise the unit operates with low efficiency.

Long-burning pyrolysis boilers

The solution to the problem was to add a device to the air tract that creates forced draft. For this purpose, centrifugal fans are used, which develop sufficient pressure to overcome the resistance of the boiler tract and part of the chimney. Such pyrolysis boilers cannot operate without electricity, but they burn fuel efficiently and have a number of advantages:

- The space of the main firebox is increased, which allows you to load more fuel into it. Its slow burning, due to the process technology, increases the interval between loading firewood to 12 hours.

- As a result of the process, little waste is left in the ash pit and there are fewer emissions into the atmosphere.

- The efficiency of the pyrolysis boiler reaches 90% due to efficient combustion of fuel.

- For the same reason, fuel consumption is less than that of direct combustion counterparts.

Aten

The average price for a boiler of this brand is $176. Manufacturing company - Lebedinsky Motor-Building Plant. The boilers operate on the basis of pyrolysis technology, which consists in the fact that when there is a lack of oxygen and smoldering fuel from wood, a gas characterized by combustible qualities is formed.

These boilers have a long burning time and have a second name - “gas generator”. The power of the equipment of the brand in question can be very different and depends on the purpose:

- boilers for domestic use have a power of 16 kW,

- equipment for industry – up to 36 kW.

Thanks to the design, the boilers can be fueled with a wide variety of fuel types. Firewood, sawdust and straw briquettes, peat briquettes, wood briquettes, as well as waste from furniture production and wood processing can be sent into the combustion chamber. Thanks to the size of the firebox, a log up to a meter in size and a diameter of up to 0.41 meters can fit into the boiler. So, when using this unit, it is not at all necessary to chop wood.

The creative approach of the creators of Aton boilers made it possible to reduce fuel consumption by 6 times. Within a year of use, the cost of the boiler will pay off in full. The combustion chamber is treated with a mullite-corrundum mixture. The manufacturer of electronics for boilers of this brand is Tatarek (Poland). The boiler warranty period is 5 years.

Proskurov

Proskurov is a Ukrainian company that produces boilers for space heating and hot water supply. The products are popular among consumers due to their high quality and reasonable prices.

The boilers have universal operating capabilities and are economical in fuel use.

Proskurov units are of excellent quality, high efficiency and a 100% manufacturer’s guarantee.

All Proskurov boilers have safety automatics with a gas valve (from the German manufacturer Honeywell).

The manufacturer produces gas, solid fuel and electric boilers.

Gas units are available in two types: parapet boilers and chimney boilers.

Solid fuel boilers are divided into categories: with and without a fan. There may be designs with a slab (AOTV-K with a slab).

Some popular models are discussed in the tables below.

Gas boilers

| Series | Characteristic |

| Parapet gas boilers Proskurov | A number of models consist of the names AOGV-7, 10, 10U, 13, 13U, 16U. They have a closed combustion chamber, do not require electricity, and are equipped with a vertical chimney. Oxygen enters the combustion chamber and pollutants are removed through special ducts outside the building. |

| Chimney gas boilers Proskurov | These are Ukrainian-made gas boilers, represented by models AOGV-10V, 13V, 16V, 24V, 30V, 50V, 98V. They are double-circuit, floor-mounted, and have built-in pneumatic automation (they are not afraid of power surges). |

Gas boiler Proskurov AOGV

Solid fuel boilers

| Series | Characteristic |

| Proskurov AOTV with fan | Models in this category are AOTV 16, 22, 28, 34, 40, 50, 75, 100, 150. The boiler runs on solid fuel, namely wood, wood waste, peat, coal, pellets. Raw materials must be fed into the furnace every 8 hours on average. Suitable for heating areas from 160 m² to 1500 m². Weight category of boilers is from 220 kg to 750 kg. |

| Proskurov AOTV-N without fan | Represented by models AOTV-12N, 16N, 22N, 30N, 40N, 50N. They are safe to use. Designed for heating not only apartments, but also country houses and cottages. Suitable for heating areas from 120 m² to 500 m². Weight category of boilers is from 120 kg to 240 kg. |

Is it worth buying a Ukrainian boiler?

Unfortunately, our man is firmly convinced that domestic manufacturers do not know how to make high-quality products. But, as practice shows, this is not true. Of course, production requirements are more stringent abroad, because there it is quite normal to sue a manufacturer for a low-quality product. Nevertheless, both domestic and neighboring brands delight with their quality.

Ukrainian long-burning boilers have a number of their own strengths, after reading which you can understand that such a purchase is worth the money. And they are as follows:

- Versatility. Not every home owner has the opportunity to purchase high-quality fuel. That is why many try to prepare it themselves. But in order for firewood to have a full heating effect, it is necessary not only to dry it properly, but also to find a good place for storage. But many people simply put them under a tarpaulin or film, which causes them to become saturated with moisture. Ukrainian manufacturers take this point into account, so their devices can “absorb” completely different fuels. And in the private sector there are practically no problems with wood waste.

- Easy repair. No technology can work forever. Ukrainian long-burning boilers are no exception. But if something fails, then you need to be able to get the part quickly and inexpensively. One of the important points is originality. Many try to cheat and install domestic elements on imported boilers. Unfortunately, this is not correct. If the device continues to work, then it is simply luck. But in any case, it will either quickly fail completely or last less than it should. But if Ukrainian boiler equipment is installed at home, then there will be no problems finding spare parts. Not to mention their availability.

- Electronics reliability. Many people know that problems with light can lead to breakdowns of equipment in the house. Therefore, developers of electronic boiler circuits take these points into account. But although foreign manufacturers also take this point into account, energy companies abroad are trying to “even out” the network as much as possible. In our country, voltage fluctuations can reach significant values. And the electronics in Ukrainian boilers are designed to work in such conditions.

- Price. Ukrainian boilers were developed on the basis of foreign analogues, that is, their design is identical to imported models. BUT! Since such units are sold directly by manufacturers and are not transported very far, their cost is quite affordable. Moreover, some economy class models from foreign manufacturers cost as much as the coolest Ukrainian boilers.

Analyzing all the above advantages, it is easy to come to the conclusion that long-burning boilers from a Ukrainian manufacturer are a very good idea to provide your home with heat.

The advantage of boilers produced by Ukrainian companies

People buy pyrolysis boilers, solid fuel, with natural and additional draft from Ukrainian companies, and there are explanations for this.

- Savings - it takes a lot of money to deliver devices from overseas; costs are paid by the buyer.

- Availability of spare parts - if parts are worn out (over time they will definitely require replacement), you can get the necessary elements without problems.

- Convenience - instructions and all buttons are in Ukrainian, so you don’t need to look for a translator or try to figure out the design at random.

- Unpretentiousness to fuel - the boiler does not worry about what kind of firewood or coal it will be “fed”.

- Warranty - factories are located in Ukraine, so in case of breakdowns you can easily make a claim.

In addition, the equipment is manufactured taking into account local climatic conditions.

Buy a boiler from a domestic manufacturer - have a high-quality device that meets all standards, and live in a comfortable, warm home.

Review of Ukrainian boilers

If we compare Ukrainian and Russian boilers, the first representatives rarely have a power of more than 40 kW. But the second models can have a power of 95 kW, and if we talk about Polish boilers, then their figure can be 200 kW. But for heating private houses, such powerful devices are useless.

In Ukraine, about a dozen companies are engaged in the production of long-burning solid fuel boilers. Some of them are more popular, others less. But there are three companies whose boilers are especially popular both in Ukraine and in neighboring countries, in particular Russia. So,:

- "Aten". Solid fuel boilers of the Aton brand are produced at the Lebedinsky Engine Plant, which is one of the components of Motor Sich OJSC. The basis of such units is the pyrolysis principle. That is, during the smoldering of wood fuel, when there is no oxygen, a flammable gas is formed, which becomes a source of heat for the house. Household models have a power of 16 kW and it can reach up to 360 kW in professional devices. But the latter option is used only in industrial production. The design of the Aton is such that they are considered universal. That is, for their work you can use not only firewood, but also peat, straw, sawdust and wood chips, wood processing waste, etc. The dimensions of the firebox are such that meter-long logs with a diameter of 41 cm can easily fit there. This allows you to use large firewood without first splitting it. The combustion chamber lining is made of mullite-corrundum mixture. Aton electronics are Polish. The manufacturer provides a 5-year warranty on its products. A 12 kW unit costs around 24,000 rubles.

- "Buran". These boilers have such a pleasant feature as long battery life, without any human intervention. Buran boilers have a fairly wide range of models. Therefore, from this manufacturer you can find wood-burning and even coal models. By the way, the latter are not only distinguished by long-lasting combustion, but also by the ability to operate at low temperatures. Such coal variations can work for 3-5 days at one gas station. But for wood-burning low-temperature boilers this time reaches only 30 hours. Buran heat exchangers have a special design, which increases heat transfer by 40% compared to other solid fuel analogues. Also worth noting is the modified air diffuser. The new design ensures uniform combustion of fuel throughout the entire combustion chamber. Also, such an element is capable of turning around its own axis, which is why it can be used as a handy tool when cleaning the combustion chamber. The simplest variations of “Buran” start at 60,000 rubles.

- "Reaping." In the production of such boilers, high-quality steel is used, the thickness of which can vary between 0.6-1 cm. Engineers have created a firebox design such that the device runs on any biofuel, be it firewood or plant roots and reeds. And the interesting point is that the efficiency of the unit, even with such “food”, ranges from 80 to 92%, which is not bad at all. Any Pozhinka boiler has a 5-year warranty from the manufacturer. Starting cost from 20,000 rubles.

- "Cordy." This company is known not only for boilers, but also for water heating equipment with solar panels. If we talk about industrial production, the Kordi company has released 4 models for this purpose. They are capable of heating an area from 900 to 2700 sq.m. The most powerful model in this series is KOTV250 with a power of 250 kW. Kordi also has products for home use. These are ordinary stoves and boilers with cooking surfaces, which are equipped with burners on top. The latest models have a horizontal position, which distinguishes them favorably not only in functionality, but also in external design. There are ten household models in total. Such long-burning solid fuel units are designed for 100-950 sq.m. The initial cost of such units is from 60,000 rubles.

- "Danko" These boilers compare favorably with their counterparts in their ability to operate even without electricity. Therefore, those who live in regions with unstable electricity should like this option. Danko has three models in the main series - Danko TL, Danko TN and Danko T. Cast iron is used to make the heat exchanger of the first model, steel is used for the second and third. TL and TN are packed from several sections, and this, in turn, makes repairs very convenient. That is, if a malfunction occurs in some place, the broken section is cut off from the entire system, put in order and returned to operation. Model T has a pump and fan, which are regulated by a built-in controller. Danko TL and TN boilers are designed for houses with an area of up to 450 sq.m., but the Danko T model is designed for an area of up to 700 sq.m. The initial cost is from 45,000 rubles.

Product range and popular models

Power determines the classification of Kordi solid fuel boilers in the series:

- industrial;

- boilers with hobs;

- household units with power up to 100 kW.

The following four device models are most popular among consumers:

- Solid fuel boiler Kordi AOTV 10 kW. Reviews indicate that this modification is often chosen for small houses with one floor and 2-3 rooms. The equipment operates economically and requires virtually no maintenance costs. If everything is designed correctly, then you don’t even have to install a circulation pump and a turbocharged chimney. When the room is small, natural physical laws may be sufficient for the normal functioning of the system.

- The Kordi solid fuel boiler with a power of 14 kW is more powerful, so it can easily cope with heating larger houses. It is installed in small two-story buildings, only in this case the purchase of a circulation pump is mandatory. Regarding the chimney: you can also leave natural ventilation if the weather conditions of the pipe and the conditions of the region allow it.

- A 16 kW device is the best option for many. The boiler heats middle-class houses and most private buildings in the country. The technical characteristics are excellent within the required boundaries, so no problems with operation are expected. The most popular is the model with two circuits (for heating and hot water).

- A 20 kW solid fuel unit is suitable for a large house or office heating. In large rooms, the optimal air temperature will always be. For high-quality work, you will need a powerful circulation pump and a smoke exhauster to remove combustible products.

More information about the types of circulation pumps here

Ross

The manufacturer Ross has been producing products since 1991.

A wide range of models is represented by brands of boilers operating on solid fuel (power from 16 to 100 kW, heat exchangers made of cast iron or steel), on gas fuel (power up to 96 kW, depending on the floor or wall design), on electricity.

The main advantage of Ross boilers is their safety and ease of use. The company is aimed at producing reliable and at the same time externally attractive units.

On gas

| Series | Characteristic |

| Ross AOGV | The series is produced in floor and wall versions. Ross floor-standing gas boilers do not depend on the electrical network and have two circuits. They are economical and autonomous. They can have a steel (Lux and Premium class boilers) or cast iron heat exchanger. All units have distinctive features and advantages and a long service life. Ross wall-mounted gas boilers can be with one circuit (for heating only) and with two circuits (for heating and hot water supply), with an open and closed combustion chamber. They are distinguished by their low price. They heat both apartments and private houses, production workshops, and residential complexes. |

Construction of a gas boiler Ross AOGV Lux series with a steel heat exchanger

Solid fuel

| Series | Characteristic |

| Ross KOTV-S | Boilers of the KOTV-S series are units with a steel heat exchanger, designed to provide heat to residential buildings, utility rooms and workshops. The series models are represented by the names KOTV-15-S, KOTV-15-S-V, KOTV-20-S, KOTV-20-S-V. Where the number is the rated power, the letter “C” denotes a steel heat exchanger, “B” - the hob. The coolant temperature is 90 °C. Working pressure: maximum 130 kPa. There is a possibility of cooking (hob available). The efficiency is at least 75%. |

| Ross KOTV with automatic temperature control | The model has a steel heat exchanger that automatically maintains the temperature of the coolant. Heats workshops, residential buildings and other facilities. It can work with natural and forced water circulation systems and with pressures reaching up to 200 kPa. It uses wood, brown coal and briquettes as raw materials. There is a possibility of heating with coal. Efficiency - up to 78%. The large volume of the loading chamber causes a longer combustion process. The model is easy to maintain. |

| Ross KOTV-30 | Can work in closed and open heating systems, with forced and natural water circulation, with excess pressure up to 200 kPa. Peat briquettes, wood and wood chip briquettes are used as fuel. In a closed type system, you can use wood pellets, brown and hard coal. The boiler power can be changed within 10-35 kW. Efficiency up to 80%. The heat exchanger is enlarged, made of 3 mm thick steel. |

You can also pay attention to German, Japanese, Italian, Czech, Russian and Korean gas boilers.

Thus, there is a large selection of Ukrainian-made boilers on the market. They operate on different types of fuel and have different technical and economic characteristics.

How to choose and what to pay attention to

Type of fuel

If the client prefers coal when choosing fuel, then it is better to choose a boiler and steel. If firewood is used as fuel, then a cast iron model would be the best choice.

Power

This criterion determines how much area the device will be able to heat and how often it is necessary to add fuel.

NOTE!

For a large room and a two-story private house, a boiler with a capacity of 20-36 kW is suitable.

And for a small country house, 14 kW is enough.

Weight and cost

The large weight and dimensions will cause inconvenience if the client does not have a special place to place the boiler.

Heavy weight also means higher installation and shipping costs. In addition, heavy boilers are much more expensive than lighter models.

Economical

The coefficient of a cast iron boiler is lower than that of a steel boiler. But a cast iron boiler takes longer to cool, thereby retaining heat for a longer time.

The time interval between fuel additions depends on the combustion time. Thus, economical cast iron models can keep warm all night.

Durability of the design

The default lifespan of equipment is about 10 years. But this depends on the careful handling of the owner and the quality of the materials from which the boiler is made.

If you choose a model with good materials, reliable assembly and properly care for the heating equipment, the device will last longer.

Sources

- https://cotlix.com/tverdotoplivnye-kotly-ukrainskogo-proizvodstva-obshhaya-xarakteristika-i-obzor-vedushhix-brendov

- https://aqua-tehnik.ru/tverdotoplivnye-kotly-dlitelnogo-goreniya-ukrainskogo-proizvodstva

- https://oboiman.ru/teplo/tverdotoplivnye-kotly-ukrainskogo-proizvodstva-piroliznye-i-dlitelnogo-gorenia.html

- https://kotel.guru/kotly/tverdotoplivnye/tverdotoplivnye-kotly-dlitelnogo-goreniya-ukrainskogo-proizvodstva.html

- https://chastnydom.com/strojka/sistemy/otoplenie/kotly/osnovnye-tverdotoplivnye-kotly-dlitelnogo-goreniya-ukrainskogo-proizvodstva-obzor-proizvoditelej.html

- https://teplofan.ru/kotly/tverdotoplivnye/kotly-kordi-obzor-tverdotoplivnyx-dlitelnogo-goreniya

- https://top-expert.pro/top-20-luchshih-tverdotoplivnyh-kotlov-rejting-2020-2021-goda-i-kak-vybrat-samuyu-horoshuyu-model/