During the cold season, residents often complain about problems with heating appliances. The radiators heat weakly or partially, so the air temperature in the apartment is below normal. What to do in such a situation?

Let's consider a way to improve the situation, correct a situation that brings discomfort and unnecessary costs, namely a heating radiator flow extender .

- What is a flow extender

- Where are flow extenders installed?

- Review of popular brands

- How to make it yourself

- Installation features

What it is

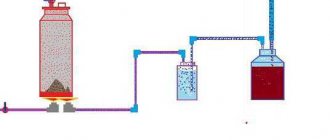

With a side connection, which most often occurs in apartments, the hot coolant enters from above, then through the control valve it supplies hot water to the radiator.

If we analyze the situation, then with good circulation, the water should pass in a circle from the upper position along the perimeter of the radiator to the lower one and exit into the pipe (return).

Thus, hot water flows to all sections of the radiator. But with insufficient circulation, heat does not reach all elements, makes the circle smaller and returns to the riser, thereby not completing the full cycle of passage through the radiator.

Radiator flow extension

To solve such problems, there are special radiator flow extenders. This additional element allows you to deliver hot flow to all sections of the radiator.

The part is designed to ensure that the coolant is directed in the desired direction to pass through the entire section of the radiator: from beginning to end. So heat transfer occurs in full.

A flow extension for a radiator is a part structurally similar to a fitting, with connecting dimensions of ½' or ¾'. Futorka is a device for connecting through threads inside and outside parts or structures. You can make a futorka at home with your own hands on a machine from a steel billet. The bushing will be threaded on both sides.

The internal one is for fastening the extension pipe, the external one is for connecting to the main pipes through the valve structure. In this case, the fitting connects the main coolant pipe and the extension (the pipe passing inside the lower part of the radiator).

The pipe can be made of the following materials:

- metal-plastic;

- polyethylene;

- stainless metal;

- become;

- copper

It is worth remembering that under no circumstances should you use copper tubes and parts in combination with aluminum radiators, since the metals oxidize upon interaction.

Restoring the functionality of the heating device

Let's figure out how to make an extension cord. To get started, you should stock up on the following tools and materials:

- solder coupling (twenty);

- a piece of copper water pipe with walls more than 1 mm and a cross-section of 18 mm;

- adjustable gas burner with nozzle;

- a pipe cutter (it will allow you to cut the required piece of copper pipe without deformation);

- solder;

- metal brush;

- a chamfer remover (without it it will not be possible to qualitatively remove burrs at the ends of a tubular product);

- a stiff brush;

- silicone gasket;

- flaring tool (a pipe expander can be used instead).

Now that you are fully prepared, you can begin the process of restoring the bimetal radiator to normal operation. Shut off the shut-off valves on the pipes leading to the battery. If a one-pipe connection scheme is implemented, close one tap. After this, drain the water from the radiator.

Flow extender with thermal head

Theoretically, the extension cord can be installed on the battery without dismantling the heating device. But performing such a procedure will be inconvenient. Therefore, it is recommended to dismantle the radiator. This is not difficult to do. Unscrew the plug together with the detachable connection. Check the condition of the silicone gasket immediately. If it leaves much to be desired, install a new element. The gasket costs a penny and still performs an important function. In this case, there is no need to waste time on trifles. After this, disconnect the radiator from the pipes and carefully remove it from the brackets. You can proceed to the main stage of the operation.

Can it be used everywhere?

The flow extender is installed in the lower part of the heating structure. Where the water drains out, at the radiator outlet.

Thus, the hot coolant enters the upper hole, passes through all sections of the radiator and enters the farthest corner diagonally to the inlet. Then the water flows into the installed extension tube. This way the fluid circulates through the radiator much better.

The circulation of water, that is, the coolant, occurs diagonally. This circuit is suitable for connecting the radiator to the battery sideways.

Let's look at an example of how to install a flow extender.

In old-style batteries (cast iron), it is installed extremely rarely. For a bimetallic radiator, you can use a flow extension only if the connection is on the right or left. Water inlet and outlet should be on one side.

So, using the example of a lateral connection, we will consider installing a radiator flow extension.

Serial and parallel connection of a heating radiator

In this device diagram, the coolant approaches the radiator from the side, from the top corner. This part can be left in place by turning off the tap of the flow of liquid into the radiator.

We are now working only on the lower part, where the water leaves the device, giving up its thermal energy. This will save both time and effort.

We make and install an extension cord - minimal costs and excellent results

Let's move on to the main thing. First of all, separate the required size from a piece of copper pipe using a pipe cutter. The edge of the product must be truly smooth. This can be achieved if you hold the copper tube strictly perpendicular to the pipe cutter. Using a stiff brush, carefully remove burrs from the edge of the cut product, and then take a steel brush and process the inner surface of the copper pipe.

Installation of flow extension

Important point! Some craftsmen try to clean the pipe with sandpaper. This is categorically unacceptable. Always remember that copper is a very soft material by its structure. If you treat it with sandpaper, abrasive crumbs will remain on the pipe, which will not allow for high-quality and reliable soldering. Then proceed according to the following scheme:

- Apply soldering flux to the pipe and the made sleeve. Using a brush, distribute the composition evenly. There is no need to apply too much flux. When you start soldering, the excess volume will flow into the pipe and solidify in it. Subsequently, during operation of the heating system, such a frozen droplet will cause loud noise when the coolant moves through the battery.

- Insert a homemade flow extender into the pipe. Remove the squeezed out flux with a rag or a regular napkin.

- Heat the ends of the pipes with a gas burner. Continue heating until the solder turns silver. This color indicates that the flux is completely ready.

- Apply solder to the joint of pipe products and watch how the flux begins to melt, filling microscopic gaps and all existing voids.

The soldering is pumped in at the moment when the flux begins to form droplets. It is necessary to keep the ends of the pipes pressed for another 1–2 minutes. This time is enough for the solder to harden properly. That's basically all. Evaluate your work. Insert the homemade extension cord into the radiator and put the heater in place. Tighten the cap and enjoy the uniform heating of the battery due to the flow you made yourself.

The length of the extension cord can be chosen differently. But usually they make sure that its end falls in the middle of the very last section of the bimetallic battery.

However, some experts advise making the device described in the article no longer than the middle of the radiator. And one last thing. Do not attempt to install a copper extension cord into heating units made of aluminum. In this case, chemical interaction between non-ferrous metals will be observed. Over time, this will lead to the formation of oxide on the pipes and their destruction.

Review of popular brands

There are two leading companies on the market producing radiator flow extenders and heating systems.

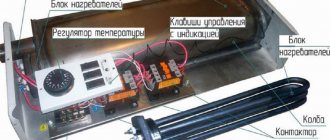

Flow extension for VALTEC radiator is the most popular solution. VT. 503 is an abbreviated name for the system. It is manufactured in two types: right (D) and left (S). The exclusive part system was developed by VALTEC engineers.

The use of an extension cord is the best solution for operational problems when the heating system does not deliver a flow of hot liquid deep into the radiator. VT. 503 is a brass alloy sleeve with a nickel coating that protects the part from the external environment and metal irritants.

Heating radiator extension VT. 503

The fitting pipe has an internal thread through which an extension pipe of the required size is attached. The length of the pipe is 6–8 cm shorter than the radiator. If there is a thread in the pipe, fastening does not require additional tools; it is done by screwing in.

It should be noted that the parts have a service life of up to 50 years. The test pressure corresponds to 24 bar. Working pressure 16 bar. The sealing agent is silicone. Scope of application: cast iron, aluminum, bimetallic sectional radiators.

The radiator flow extender from Rifar is also not a bad solution. The company produces bimetallic and aluminum heating systems from various numbers of sections. Suitable for use in Russian conditions for private houses and apartments, for arranging heating systems in apartment buildings, enterprises and other premises.

The company is located in the city of Gai, Orenburg region. Convenient location allows you to expand the sales market in all directions. The company's central office is located in Moscow. Rifar company was founded in 2002. A year later, the production of radiators under the brand name began. The company's branded product is bimetallic radiators.

Product improvement occurs every year. A big event was the release of radiators of a new design, which has no analogues in the global industry - MONOLIT with a pressure limit exceeding 150 atmospheres.

Flow extenders are suitable for radiators, both in a monolithic design and in a prefabricated design. Thus, extension cords from other companies are best suited for the rifar brand, since all Russian manufacturers adhere to standard sizes and material combinations.

Radiator extension Rifar

Rifar is the world's strongest competitor in the production of equipment for plumbing and heating systems. Currently, radiators with a heating system connection, where both the inlet and outlet of the heating fluid are at the same level, on one side, are in great demand.

This type is in demand due to its convenient installation, repair and maintenance, despite the increased price. The latest Rifar models are available with an integrated radiator flow extension design. Suitable parts are provided for different battery models. Most of them are 0.75 inches. The Rifar company mainly produces sectional radiators, using bimetal and aluminum for their production.

What is a flow extender? Main characteristics and place of application + Photos and

At the beginning of the heating season, the problem of uneven heating of the radiator reminds itself. Even in the case when the correct number of compartments and connections were made correctly, but only the first couple of sections are hot and the rest are cold, a flow extender for the radiator will help solve this problem. The flow extender distributes heat evenly along the entire length of the radiator.

What is a flow extender? If you have a problem with uneven heating of the batteries, do not rush to buy a new radiator. This problem can be solved without major financial investments if you buy a flow extender.

General information

This is an element that is connected to the radiator with or without a tube. The flow extender is usually mounted to the return connection of the radiator, so that there is a diagonal movement of the coolant in the radiator if it is connected on one side.

How to make it yourself

- You need to close the taps, drain the water and remove the heating structure.

- Carefully, in order not to damage the paint, you need to unscrew the top plug with the installed part of the detachable fastening.

- It is necessary to connect the pipe and sleeve using soldering. You can use fat for soldering as flux and soft solder. The parts are connected and both elements are heated by a burner. You can take a standard small burner, guided by lighter gas.

- After this, solder is applied to the joint. If heated correctly, the solder melts and flows into the joint.

- The diameter of the American from the inside after cleaning from plaque is 19 mm. The coupling diameter is larger. Using a small file, you need to remove the excess to such a state that you can hammer it in with a hammer. However, you should do this carefully so as not to harm the parts. To do this, when hammering, you can take wood spacers.

- That's all. All that remains is the installation of the duct extension for the radiators. You need to “play” with the length. Depending on the water supply, sometimes it is better to leave the length to the middle of the battery. However, you can always cut it off.

- The flow extension and gasket are installed, the radiator is put in place. The work is finished.

- All that's left is to let the air out.

Flow extension (duct) for a bimetallic radiator - Construction

07.12.2019

Flow extender: where to buy, how to make a heating extension, where to put it in the radiator?

When new radiators freeze in the first winter: the first 2-3 sections are hot, the rest are cold - many begin to look for a method of “how to direct the coolant to the distant sections.”

And in the web they find such a divine solution as a flow extender

: you can install it yourself like an amateur and you don’t even need to remove the risers!

And no messy alterations of connection diagrams with burnt wallpaper from welding. In general: the naive dream of any spider.

Flow extender - this tube is inserted into the inside of the radiator after the tap.

With this flow extender: all sections are heated more or less evenly: the water has reached the end of the radiator. It seems like everything is fine!

But in reality, everything is not so: the temperature of the radiator is much lower than the temperature of the risers:

The risers are hot, but the battery is just warm.

Maximum heat transfer can be obtained by moving water inside the radiator from top to bottom: only with such circulation is the natural circulation gravity pump

and the main factor of non-heating (the most important problem) is the draining of the cooled coolant from the radiator from above. A flow extender does not correct this factor!

When the flow is extended in half of the sections, the water moves from bottom to top - again a loss of 50% of gravitational circulation.

And this tube inside the radiator will narrow the upper or lower battery collector. There are already two flows: inside the tube itself and outside between the walls of the radiator.

If the diagonal is incorrect (the diagonals for the top and bottom feed are completely different and are not interchangeable), at least all the pipes pass outside: there are no narrowings inside the battery.

Mixed up diagonal

- and it gives more heat than this extension cord! But you won’t get warm on it either - I’ve already remade it.

To avoid waste coolant escaping from the top of the radiator

— it is better to use a bottom connection: a bottom-to-bottom circuit.

In this scheme there is no concept: distant sections - the entire radiator is also heated evenly as with an extension cord and even better: there is less difference in the temperatures of the riser and the radiator.

But the loss of heat transfer against the upper spill is up to 30% - it depends on the internal flow area of the vertical channels in the sections - it is better to choose radiators with large diameters.

There are imported extension cords on sale for true bottom connections: when plastic pipes run through the floor of the apartment and exit from below under the radiator itself, there are no steel heating risers in the corner of the room.

And many begin to think: this is a factory-certified product, which means it works! Yes - this extension cord works!

But it works in a 2-pipe collector system (there is a pressure difference in the supply and return risers), where all apartments are connected in parallel, and it often happens that the radiators inside 1 apartment are in a parallel circuit.

And the problematic bottom supply is a single-pipe system with a vertical riser inside the room: the pressure in the pipes in front of the radiator is the same (the bypass jumper in front of the battery completely equalizes) and all the radiators on the riser are connected in series.

- In an imported extension cord there is no outlet of waste, cold coolant from the top of the radiator.

- And in fact, it has a purely decorative function: 2 pipes side by side enter the radiator from below from the floor.

- And without an extension cord, the connection will be: 2 tubes separately at the ends of the battery - this is kind of less beautiful!

- This imported hydraulic extension works like a BOTTOM-BOTTOM circuit - just a slightly different visualization.

- There is also a more expensive bottom connection unit for plastic pipes in the floor: an additional external supply pipe to the top of the radiator.