Roll insulation is a material with a low thermal conductivity, which is additionally characterized by sufficiently low rigidity, but at the same time holds its shape well. Coatings of this type are flexible, which allows finishing areas of complex configurations. Laying such material is not difficult. However, it is important to choose the right dimensions. Insulation in rolls is attached end-to-end; it is unacceptable to leave significant gaps between adjacent sections of thermal insulation. This will lead to the formation of cold bridges.

Peculiarities

There are several types of insulation, mainly divided by composition.

Minvata

One of the most common thermal insulation materials on the Russian market is mineral wool. This is mainly due to a combination of price and technological properties of the material itself. It is very easy to use. It is advisable to choose a white, soft and self-adhesive material for the timber.

The name “mineral wool” is inherent in many thermal insulation materials that differ in their composition and properties. Not particularly popular is insulation, which is made by melting certain rocks to form certain fibers. During manufacturing, these fibers are woven into a single carpet; this wool is called “basalt”. Any resident of Russia and the CIS is familiar with the term “glass wool”.

This thermal insulation material is an outdated technology, but due to its price it is still in demand today. It is made by melting broken glass into single fibers. There is also cotton wool obtained by melting waste from the metallurgical industry (slag wool).

Due to the raw materials used in its manufacture, its price is much lower than that of glass wool or basalt wool.

Characteristics, pros and cons

Cotton wool differs from each other in technical characteristics. Glass wool has a high temperature threshold of 450 degrees, after which the material becomes irreversibly damaged. The density of glass wool is 130 kg/m3, and the thermal conductivity is about 0.04 W/m*C. This material is not flammable, it does not smolder, and has a high vibration and sound absorption threshold.

Over time, there is virtually no shrinkage, including options with long-term use.

The disadvantages include the fact that when water gets in, all the positive properties of this material disappear. Glass wool is a rather brittle and brittle material. Upon contact with skin, it causes irritation and itching, which is difficult to remove.

If it gets into the organs of vision, it can seriously harm them, as well as if it gets into the nasopharynx. You need to wear closed clothing when working with such material.

Basalt wool can withstand high temperatures (up to 710 degrees). Its thermal conductivity is about 0.04 W/m*C, density varies between 210 – 230 kg/m3. Unlike glass wool, this material is not afraid of moisture and does not lose its properties. When contacted with skin, roll insulation does not cause irritation or itching.

Slag wool has the greatest mass and density. Its density ranges from 390 to 410 kg/m3, and its thermal conductivity is about 0.047 W/m*C. However, its temperature maximum is much lower (about 300 degrees). The slag melts, and during the melting process its structure is destroyed, irreversibly.

The sizes of these materials vary, depending on the manufacturer's standards. However, the most common ones are:

- length from 3 to 6 m;

- standard width is 0.6 or 1.2 meters.

Some manufacturers make other width sizes (0.61 m). The thickness of the wool is standard (20, 50, 100 and 150 mm).

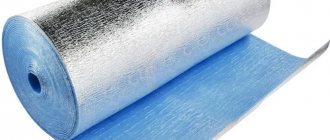

Foil material

Often one side of the insulation is covered with a layer of foil material. This allows you to protect the coating from moisture and ultraviolet rays. Most often, such materials are used for internal insulation of premises; the wool itself can be absolutely anything. The types of such material are varied. These include polystyrene foam, cork, and polyethylene.

The most popular material on the market is polystyrene foam. It is very practical and inexpensive. Copes perfectly with sound insulation and vibration. The length of the roll is usually 10 m, the width does not exceed 0.5 m. This material copes well with moisture and fungus. However, in terms of thermal insulation, it is significantly inferior to foamed polyethylene.

Thermal insulation with cork is characterized by high strength, light weight, harmlessness and good appearance. For wet rooms, it is recommended to use cork flooring with wax impregnation. The dimensions of this material are the same as those of expanded polystyrene. A fairly good material is foamed polyethylene. It consists of small cells filled with air, with cardboard or paper along the edges.

The substrate is secured by lamination. Due to this, it is possible to achieve the most durable and reliable connection with any type of base. Roll insulation has good thermal conductivity characteristics. Depending on the purpose, there are foil and metallized coatings.

For vapor reflection, a foil type of material is more suitable; for vapor containment, metallized spraying is required.

Spraying is very fragile and is damaged by small mechanical impacts. The foil material has excellent heat-reflecting characteristics. It is less susceptible to mechanical damage. Today, silver material with a reflector is quite popular.

What materials cannot be used

Relatively recently, a popular method of thermal insulation was covering walls with foam plastic (expanded polystyrene).

Due to its low cost, the material is often used to this day for facades, ceilings and other surfaces. However, it has huge disadvantages and is not suitable for wallpaper upholstery:

- Wallpaper glued to polystyrene foam is easily subjected to mechanical stress and comes off. This occurs due to the fact that the material does not have the required rigidity;

- To achieve the desired level of insulation, you will need a layer of foam plastic at least five centimeters thick. Such a design will not stand out aesthetically;

- during the subsequent renovation of the room, you will have to remove not only the wallpaper, but also the insulation itself. It will not be possible to remove the finishing material without damage;

- One of the important reasons why foam cannot be used is flammability. According to the rules, during installation it must be insulated with another non-flammable layer.

Scope of application of roll insulation

This type of material is universal, due to its properties (low rigidity and density, flexibility). This means that it can be used at facilities for various purposes (private, commercial, public, etc.). However, it should be remembered that each type of such material may have restrictions on its use, for example, if it does not meet operating conditions. Roll insulation is suitable for installation on horizontal and vertical surfaces. It is dense enough to maintain its shape.

A coating with a metallized layer is installed on objects and surfaces where it is important to provide the highest level of protection against heat loss: in baths, saunas, when installing water/electric heated floors, etc. The desired effect is achieved due to the presence of a heat-reflecting layer.

Roll insulation is the only affordable materials that are suitable for protecting surfaces with complex configurations: with differences in levels (stepped), bends, joints, and hard-to-reach places. This opportunity is due to flexibility and low rigidity.

Directions for using this type of thermal insulation:

- covering walls outside and inside for decorative finishing of any kind (hard boards, soft materials and even wallpaper);

- floor protection, in this case the roll insulation is protected from deformation by the lathing;

- insulation of flat/pitched roofs;

- reduction of heat loss through the ceiling;

- protection of pipes for various purposes.

conclusions

Rolled thermal insulation is in many cases preferable because it is characterized by flexibility. In addition, the material of this group has low thermal conductivity, which allows it to be used to insulate an object. However, it should be borne in mind that fiber roll coatings do not tolerate contact with liquids well, so they must be carefully protected with waterproofing.

If you plan to use foam insulation, it is important to remember that they do not allow steam to pass through, which means the microclimate in the room may worsen. To avoid negative consequences when installing this type of insulation, it is recommended to install supply and exhaust ventilation or increase the efficiency of natural air circulation in the room.

So which option is better to choose: cotton wool or polyethylene foam?

The main point that is important to understand is that foamed polyethylene or polypropylene in the form of rolls is precisely thermal insulation, that is, a material whose purpose is to slightly improve the characteristics of walls, and not to fully insulate them. Regardless of where it will be fixed - from the inside or from the front.

But basalt wool is already a real insulating layer. True, if used indoors, the wall will still freeze, but noticeably less heat will escape from the room.

It turns out that foam propylene from the inside will give less effect than cotton wool, since the temperature will only rise by a degree and a half. And even if you carry out external installation, the “picture” will be the same, but with only one positive aspect - the wall will freeze a little less and condensation from the room will disappear.

At the same time, the material has an undeniable advantage - it is cheap and very easy to install. It is more difficult and expensive to work with cotton wool because you will need to make a false wall (usually drywall) to protect the basalt fibers, and in addition, it is important to take care that moisture does not get into the structure of the material. If this happens, then the effect of all the work done will be zero, since all the thermal insulation qualities will very quickly disappear.

Here it seems that cotton wool is better anyway (because it’s “warmer”), but everything is decided by the nuances of the situation. Yes, cotton wool seems to be good, but what is the point in it if, for example, you need to insulate a shower room not in the house, but, for example, in the country and you don’t want to invest? The obvious budget solution in this case is a metalized insulator - stick it on the wall and forget it.

But in the case of a more or less capital approach, but again in the absence of significant financial resources, it is better to opt for mineral wool and insulation from the inside. It turns out that there is no ideal option and you need to make a decision only based on the characteristics of the project.

Roll insulation

is the name of a whole class of lightweight thermal insulation, widely used in civil and industrial construction. They are made from staple fiberglass with the addition of various binding materials, fillers, water repellents (substances that repel water), which give them softness, elasticity and resilience. Rolled thermal insulation is the most inexpensive of all types of insulation, and therefore is in consistently high demand among builders.

Insulation characteristics and popular brands

The insulation is a sheet of foamed polyethylene foam or expanded polystyrene, onto which durable paper is glued on both sides. Its main characteristics:

- Density from 200 to 300 g/m2;

- Width 50 cm;

- Roll length 10-14 m;

- Thickness 3-6 mm.

The foam base gives the material excellent soundproofing properties and resistance to moisture. At the same time, the material is light and durable. The diagram below shows all the insulation indicators for wallpaper.

The secret to warm walls is two layers of paper and polyethylene foam between them

The following brands are available on the market

| Image | Description of material |

| Insulation "EcoTap". Made from foamed polystyrene. . The material can be 3 or 6 mm thick and 50 cm wide. Mold has appeared on the slopes, is it possible to remove the cause of the slopes being sealed with wallpaper insulation? Vera, here are the possible causes of mold: 1. Windows with wooden frames had slits; they created air circulation in the house. These gaps contributed to drafts and heat loss, but the humidity was brought back to normal. As soon as the plastic windows were installed, the situation changed: there was no more oxygen flow and greenhouse conditions were created for mold to grow on the slopes. 2. In order for harmful microorganisms to develop at a high speed, two things are needed - increased humidity and heat. Wood allows water vapor to pass through and evaporates condensation, but plastic is not capable of this due to its tightness. 3. In addition, it happens that plastic windows are installed in violation of technology. As a result, moisture collects on the slopes and gives impetus to the development of mold. Based on the reason for the appearance of mold on your slopes, you need to act. Source: obustroeno.com |

Types of materials in rolls

There are two groups of insulation materials, characterized by flexibility, low density and rigidity:

- Based on expanded polystyrene, polyethylene. Such materials are characterized by a closed-porous structure, which is achieved by foaming the raw materials. As a result, most of the volume is a gaseous medium. By foaming polyethylene, a flexible coating of small thickness is obtained. Roll insulation of this type is characterized by low thermal conductivity, wear resistance, and lasts a long time.

- Mineral wool is presented in varieties: glass and slag wool, basalt or stone wool. These are natural insulating coatings characterized by low thermal conductivity. Disadvantages include low strength, tendency to sag during operation, and hygroscopicity. The last of the properties is the reason for the short service life of the coating. This insulation is suitable for walls, floors, ceilings, attics, basements, and roofs. If you provide protection from moisture in areas with high loads, you can avoid deformation of the coating.

Foam insulation is divided into types, taking into account differences in the production method:

- physically stitched;

- chemically cross-linked;

- gas-foamed.

The first 2 options are characterized by similar properties, but are manufactured using different technologies. In addition, insulation materials are divided into types, taking into account differences in structure: foam with additives (fire retardants), foil. The last option has improved properties. It not only reduces heat loss, but also reflects thermal radiation, returning it back to the room.

Glass wool

The material is based on glass industry waste and sand. Raw materials are exposed to high temperatures (+1450°C). During the melting process, the finest fibers appear. To obtain a thermal insulation material, a binder is added to glue the fiberglass together. Then molding occurs. In order for the binder component to obtain the desired properties, it must undergo a polymerization process. At the last stage, the material acquires a yellowish tint as a result of dyeing

This type of thermal insulation layer protects different types of objects. Glass wool is a universal coating option. However, when working with it, you need to use personal protective equipment (respirator, goggles, gloves, closed clothing) . This is due to the fact that the insulation contains particles that are characterized by small mass and can be released into the environment under the influence of external factors. Dust enters the respiratory tract, settles on the skin and mucous membranes, which provokes tissue irritation.

To slightly improve the strength indicators, the rolled material is reinforced. The disadvantages, in addition to the release of abrasive particles, include relatively low thermal conductivity. In terms of this parameter, the insulation is inferior to its foam counterparts. Another disadvantage is hygroscopicity. The vast majority of mineral coatings strongly absorb moisture.

Advantages of glass wool:

- good sound insulation properties;

- sufficient level of strength;

- the material is lightweight, which means it will not weigh down the structure;

- installation does not require special skills;

- flexibility;

- vapor permeability;

- fire safety;

- elasticity, due to which the insulation can restore its original shape;

- small width means glass wool will not hide the space;

- resistance to mold and fungi;

- insulation is unattractive to rodents.

When choosing, not only positive/negative qualities are taken into account, but also coating parameters. Glass wool is characterized by the following properties:

- the thermal conductivity value is in the range of 0.039-0.047 W/(m*K);

- water absorption coefficient of glass wool for partial immersion – 15%;

- This type of insulation is used at temperatures of -60…+250°C;

- upon contact with water during the first day, the coating will absorb water in the amount of 1.7% of the total volume of thermal insulation material;

- sound absorption rate: from 35 to 40 dB.

In terms of thermal conductivity, glass wool is similar to the following insulation materials: mineral wool, expanded polystyrene.

Izolon

This is foamed polyethylene foam, which is characterized by a closed-porous structure. Available in the following varieties: simple, with a foil layer on one or both sides. Izolon is a fairly dense, but at the same time soft insulation. Its characteristics:

- the average thermal conductivity is 31 W/(m*K);

- density – 33 g/m³, with a decrease in the value of this parameter, thermal conductivity increases;

- the water absorption coefficient is 1%, which indicates that the insulation has no tendency to absorb moisture;

- the material does not allow steam to pass through;

- the ability to perform its main task (reducing the intensity of heat outflow) at low temperatures - down to -60°C, while the insulation does not lose its properties, does not break, does not deform;

- service life is about 100 years;

- resistance to negative factors is noted: precipitation, high loads;

- no toxic substances are released during combustion;

- the material is environmentally friendly;

- Izolon insulation protects the object from noise, and a decrease in the intensity of sound waves is noted even with a minimum thickness of the material.

If we consider the foil coating, we should highlight its ability to reflect heat. The insulation reflects 97% of the heat back into the room. Isolon is not deformable. This means that under the influence of moderate loads it retains its properties.

Plates in rolls

In this case we are talking about materials with increased rigidity, which are formed into rolls. These include basalt wool. This material is characterized by a fibrous structure and is superior to glass wool in terms of hygroscopicity and thermal conductivity. In addition, basalt wool in rolls is almost no different in density from isolon (30 kg/m³). Thermal conductivity of the material is 0.039 W/(m*K). In terms of water absorption coefficient, the insulation is inferior to foam analogues (15%). The main advantage of this coating is its non-flammability.

Material from popular manufacturers

Mineral wool is not resistant to moisture, so you need to purchase a waterproofing film.

Materials from different manufacturers are available on sale. Among them there are leaders whose impeccable quality has been tested over the years:

- Knauf. Mineral wool from a German manufacturer has low thermal conductivity and excellent sound insulation properties.

- Izover. The material from a French manufacturer has a wide range of applications, thanks to a thickness of 2 – 15 cm. There are options with a foil layer.

- Ursa. The material has a long service life and excellent sound insulation properties. It does not burn and will not release toxins when heated, and is elastic. It is used in private homes and industrial facilities.

Foil materials also include Penofol and Topizol.

When choosing insulation, you should take into account the requirements for thermal insulation of the room and operating conditions. Not all materials are moisture resistant, so they need additional protection with waterproofing materials.

Roll Size Chart

For comparison, we take insulation whose thickness does not exceed 50 mm. This is due to the fact that more massive rolled thermal insulation materials roll up much worse. The review involves fiber coatings. Manufacturers of insulation in rolls:

| Material grade | Width, mm | Length, mm | |

| Ursa M-11 | 1200 | The manufacturer offers two options: 7000 and 9000 | |

| Heat Knauf Dacha | 1220 | 7380 | |

| Isover Classic | 1220 | 8200 | |

| Isover Sauna | 1220 | 12500 |

To compare coatings by cost and determine the most suitable option, take into account the number of strips in the package.

What type of insulation is used for wallpaper?

This is what cork insulation looks like after installation.

Literally 20 years ago, in order to insulate the wall from the inside, old newspapers were glued in two or three layers. Today it’s hard to even imagine this, because many alternative options have appeared. Insulation for wallpaper is available in rolls, tiles and in the form of plaster.

The most popular insulation materials for wallpaper are:

- plaster with the addition of sawdust;

- plaster with the addition of expanded polystyrene and foam glass;

- cork insulation in rolls and tiles;

- foamed polyethylene;

- thin foam.

The cheapest option would be to insulate the walls with plaster and sawdust. But such insulation for walls inside an apartment under wallpaper is intended only for dry rooms, since it quickly accumulates moisture, and fungus will undoubtedly develop in a humid environment. Therefore, it is not recommended to use it to insulate a balcony, loggia or a room that is not heated.

Plaster with the addition of foam glass does not have this drawback. Expanded polystyrene and polyethylene absorb sound well and have a low thermal conductivity coefficient. Due to its elasticity, polyethylene is easier to work with. Cork is beyond competition.

There are many ways to heat a dacha in winter. Possible options: gas (if available), solid fuel, diesel fuel, electricity.

Read how to heat a garden house with your own hands here.

Types of mineral wool in rolls

There are several varieties of insulation in this group. Their structure is the same, they differ in composition.

- Basalt wool. This material is made by melting rocks into the finest fibers that are intertwined randomly. By adjusting the density of the material, manufacturers obtain hard or elastic wool. The latter is applicable for rolls. The thermal conductivity of the material is the lowest of all similar options. This allows it to be a fairly common type of insulation. The weight of one cubic meter of cotton wool ranges from 30 to 100 kg. The maximum temperature it can withstand is 700 degrees. Manufacturers claim that the basalt components of cotton wool are safe for health. However, over time, particles of fibers and binders are found in the air.

- Glass wool. The same fibers are melted, but using glass waste . It has the lowest cost and density up to 25 kg/m³. It can withstand high temperatures, its maximum is about 450 C°. The above indicators destroy glass wool thoroughly. She copes with her main task well. A negative feature is the impact on the respiratory tract and skin during installation and operation. Therefore, thermal insulation made of glass fibers is mainly relegated to the role of only the outer layer.

- Slag-like. The third type of insulation is made from metallurgical waste (blast furnace slag). The price of rolls is also reasonable. However, this type of cotton wool is outdated; it was popular back in the USSR. Due to the fragility and allergenicity of the fibers, it is not used in residential areas. The density of the material is different: wool with an indicator of 75 kg/m³ is used for floors, 125 kg/m³ is suitable for walls. It is highly hygroscopic and loses its properties when wet. Not flammable, melts at temperatures above 300 C°.

Any type of wool must be covered with a vapor barrier, especially in rooms with high humidity. And it also holds back the smallest particles of fibers that appear over time and negatively affect a person. Raw materials often contain formaldehyde, which also affects health. High-quality rolls should have a minimum of this substance

Before laying mineral wool, a frame must be installed. On the walls, the panels that hold it in place are pressed firmly so that the canvas does not move out over time. For the necessary protection from the cold, the number of layers can be increased.

Manufacturers often divide their products according to the purpose of the insulation. For ceilings and floors, the rolls will be lighter. For the main floor, walls, and other surfaces, the density of the material is usually increased. Due to this, the dimensions of the roll also change:

- length from 3 to 8 meters;

- thickness in 3 options (50 mm, 100 mm, 150 mm);

- width from 0.6 m to 1.22 m.

Foamed polyethylene for insulation

Has many positive qualities. It is obtained by filling heated polyethylene with gases. As a result, a mass is formed with many closed bubbles inside, which subsequently hardens. For special strength, it is also “cross-linked,” i.e., the bonds of molecules are strengthened chemically.

two options on sale . Both types have very low thermal conductivity, but the first one still has better characteristics, and therefore costs more (its density is 30 kg/m³). The general properties of the materials are:

- they are durable;

- absolutely do not absorb water;

- easy to install;

- do not harm the environment and humans;

- they are not afraid of organic destroyers such as bacteria and fungi;

- The layer thickness required to retain heat is much smaller than, for example, mineral wool.

The difference is that cross-linked polyethylene foam is capable of absorbing sounds well, but its brother cannot boast of this. It works worse as a sound insulator. Under mechanical stress, the uncrosslinked version loses its shape irrevocably. Cross-linked has greater compressive strength, which means it can be used for insulating horizontal surfaces.

Due to the thinness of the material, rolls can be up to 30 meters in length, width from 0.6 to 1.2 m. Thickness reaches 1 cm. Negative nuances for polyethylene are flammability and current conductivity (electricity passing nearby must be well insulated) . To secure the material to the wall, special glue is required.

Manufacturers of insulating wool

Construction stores offer a wide selection of mineral wool. Let's look at the features of materials from some companies specializing in this area:

- Isover. This manufacturer produces mainly glass wool, which has decent characteristics. The materials are breathable and recover their shape well after mechanical stress. They do not emit harmful substances when heated. However, when installing any type of mineral wool, it is necessary to use personal protective equipment . Options for roofs have high protection against moisture and good sound insulation. Cotton wool of the “Sauna” brand (for baths and other wet rooms) has an aluminum coating, reinforced with reinforced mesh, which makes it possible not to use a vapor barrier.

- Ursa. Both universal and specialized glass wool is produced under this brand. For example, for hot pipelines or equipment heating up to 270 degrees. The manufacturer also offers a product with Pure one technology. It allows you to bend around irregularities due to the “spring” effect. The binder for the raw material is safe acrylic, which prevents the fibers from breaking. It is a good option for rooms with children.

- Rockwool. Produces durable basalt wool for technical use, which can withstand temperatures of 1000 C°. It is environmentally friendly and does not lose its thickness over time, as the manufacturer claims.

Knauf

The German company produces excellent mineral insulation materials. They are free from formaldehyde and other harmful substances, and thanks to the specially designed fiber structure, they do not provoke allergic reactions. However, the manufacturer recommends carrying out installation work with thick gloves. They perfectly muffle noise and are impregnated from insects, rodents and mold.

Mineral wool Knauf 1220Х6148Х50

- Dimensions 1220Х6148Х50 MM (15 m2).

- Thermal conductivity: 0.037 W/(m°K).

- Density 12 kg/m3.

- Cost 1100-1200 rubles.

Izover

The French company launched production at local sites. Offers a wide range of rolls with thicknesses from 20 to 150 mm, allowing you to retain heat in all weather conditions. There are many foil models that can be used in rooms and buildings with high humidity.

Penofol brand polyethylene foam

Penofol insulation appeared recently, but has already stood out among its peers. It is not destroyed by weather conditions and aggressive environments. Thermal insulators of this company have several varieties:

- the foil covering can be fixed on one or both sides;

- rolls with an adhesive layer (even more simplifies installation);

- specialized type of insulation for communication networks;

- insulation for harsh conditions with a thickness of up to 40 mm.

The combined technology makes it possible to further reduce the thermal conductivity of insulated surfaces. A moisture-resistant and durable material that does not require the cost of vapor barrier, can be used in various directions. Does not lose its properties in the temperature range from -60 to +100 C°.

Properties of roll insulation

All roll insulation materials have approximately the same properties, which determine their widespread use, namely:

- low thermal conductivity;

- good sound insulation;

- optimal hygroscopicity;

- high water-repellent properties;

- ease of transportation and operation;

- resistance to aggressive media (acids, alkalis, solvents);

- fire safety;

- optimal price.

If they are used to insulate a pitched roof that has a frame supporting system made of wood or metal, the insulation is placed inside the frame. When working with rolled thermal insulation on vertical and inclined surfaces, it is necessary to use a lathing or frame. The insulation is installed with compression to cover the “cold bridges”.

Classification of rolled materials by insulating composition

In the production of rolled waterproofing coatings, the following materials can be used as the main protective ingredient:

- Bitumen composition - is a bitumen resin mixed with crushed basalt/shale chips. This coating is used for the manufacture of roofing felt, roofing felt, glass roofing felt.

- Bitumen-polymer composition - made with the addition of special additives to bitumen that increase its elasticity and heat resistance. Artificial rubber or artificial plastic act as modifiers. Additives help increase the resistance of bitumen to high temperatures and ultraviolet radiation. This type of coating is indispensable in regions with hot climates.

- Membrane insulation is the most high-tech material of the new generation. Made from high- or low-density polyethylene, PVC (polyvinyl chloride) or TPO (polyophene) and is a thin film, the thickness of which varies from 0.2 to 2 mm. Some types of membrane coating provide for the application of a corrugated layer, which gives a more effective result in adhesion to the solution.

Waterproofing membranes have a number of advantages:

- strength and resistance to external damage;

- durability – service life reaches 50 years;

- protection from corrosion, rotting, decomposition or exposure to aggressive liquids;

- possibility of use at various temperature conditions – from -400 C to +500 C;

- environmental Safety.

Advantages and disadvantages

The main advantages of rolled material are:

- Versatility. Suitable for thermal insulation of any surfaces. For complex spatial shapes, including curved ones, you can cut out a suitable piece.

- Minimum requirements for surface preparation before installation.

- Benefits in terms of material price and work productivity when insulating large areas of walls, especially straight sections.

Roll materials have disadvantages.

- High labor intensity when laying in frequent lathing; additional time is required for cutting.

- Low rigidity does not allow them to be used where it is necessary to withstand significant loads.

In general, the advantages compensate for the disadvantages, which explains the high popularity of roll materials among consumers.

The materials are harmless to health provided they are used correctly and fire safety regulations are observed.

What to consider when working

Insulation with mineral roll materials can be carried out at any time of the year, it is only important to ensure that the material is protected from precipitation.

The use of foam materials mounted on an adhesive layer depends on the air temperature. Usually the limit is down to –10C. Special adhesives are also produced that are effective down to –20C.

Before insulation begins, minimal surface preparation is required:

- Dismantle pipes, electrical wiring, lamps, decorations, plants, etc.

- Clean the walls from remnants of old coatings, debris and dust.

- Install lathing for mineral insulation.

- Level and clean the surface for gluing foam thermal insulators.

Installation does not require special equipment; the tools you will need are:

- construction knife;

- stapler;

- screwdriver;

- hammer;

- double sided tape.

It is more convenient to carry out installation and cutting of roll insulation together by two people, especially for large volumes of work. Small volumes can be done by one master.

Insulation process

The sequence of operations when installing mineral insulation is as follows:

- A vapor barrier film is attached to the prepared wall.

- The sheathing is made of wooden bars or metal profiles. The recommended guide pitch is 50 or 60 cm.

- Rolls are cut in accordance with the selected pitch. The cutting must be carried out so that the insulation fits tightly between the guides and, when straightened, provides a better fit to the guide.

Disc-shaped dowel The not always convenient and functional thermal insulation boards are replaced by an improved version of thermal insulation - roll insulation, equally effective for walls and for ventilation ducts, pipes, roofs and other surfaces. The material has improved technical parameters and, unlike mineral wool in slabs with high rigidity and density, allows it to be used for elements with complex geometries.

The insulation has high performance and technical characteristics and is sold at an affordable price. Roll insulation is used both in repair and capital construction to increase the thermal insulation properties of surfaces:

- basement;

- attic;

- balcony;

- gender;

- ceilings, etc.

Standard roll insulation based on mineral wool under wallpaper on walls in a residential area allows you to increase the temperature by several degrees by reducing heat loss.

Additionally, the material prevents the development of dampness, the appearance of fungus and mold, and if there is an uneven surface, it hides flaws without additional work.

The wide range of application of mineral wool in rolls suggests its versatility. The material is practically indispensable in modern areas of construction; it allows you to create a truly functional and durable layer of thermal insulation both in apartments and houses, as well as in outbuildings, factories, saunas, baths, etc.

Particularly important is the ability of the material to contact pipes and surfaces of ventilation shafts. In this case, roll thermal insulation is installed primarily due to the elasticity and flexibility of the material. The rolls are easy to use and allow you to finish uneven surfaces, including at sub-zero temperatures.

Installation of insulation for walls under wallpaper

The insulation plaster must be applied by a specialist.

It will be very difficult to insulate walls with warm plaster yourself, and even without experience; most likely, nothing will work out the first time. It is necessary that after applying thermal insulation under the wallpaper, the wall remains flat. Therefore, you should entrust this to specialists. The mixture can be applied to any wall: concrete, wood, brick, etc. The plaster can be poured into molds, dried well and obtained into rectangular tiles, which can then be used at your discretion.

Insulation for walls in an apartment under wallpaper in rolls is elastic, cuts well, straightens quickly and is glued in the same way, regardless of the type. The only difference will be the glue that is used during the installation process. Stages of work:

- clean the wall of wallpaper, dirt and dust;

- fill cracks, crevices, remove bumps;

- prepare the material - cut the roll into pieces of the required length;

- coat the wall with special glue;

- glue the insulation joint to joint, like regular wallpaper.

Insulating plasters have a rough surface, so before gluing the wallpaper you need to go over it with finishing putty.

Immediately after installing the thermal insulation, you cannot glue wallpaper. The insulation must dry and stick securely; this will take several days. To prevent the seams from coming apart or peeling off, they can be sealed with tape.

Heat insulator with foil surface: features

Foil thermal insulation materials have one main feature - a side with a layer of foil, designed to reduce the impact of ultraviolet rays on the surface and provide additional protection from moisture. They use materials for insulating indoor surfaces with a base of different types of wool.

You need to work with foil thermal insulation using a special technology, observing some nuances, for example, not forgetting about a small gap (no more than 1.5 cm) between the finish and the thermal insulation material. This is important because as the temperature rises, the insulation will maintain the temperature, transferring it to the back wall, returning it back to the walls, but not into the room, as necessary.

Another important nuance - unlike insulation in rolls based on basalt, fiberglass or slag wool, foil insulation is mounted on the sheathing, placing it overlapping and treating the joints with insulating material.

Main types of insulation

Thermal insulation in rolled rolls can be used both for external and internal laying. There are options specifically designed for pipes and communications. Roll insulation for walls directly under the wallpaper is also available for sale.

The raw materials used for their production are also different. Thermal insulation made from mineral components is the most common. Foamed polyethylene is also popular. Natural insulation materials like cork are less common and used. Some types have an additional layer in the form of foil or paper. Let's consider each option in more detail.

The role of the foil surface

The main feature of such insulating devices is the presence of a thin but durable foil coating. In this way, the material is protected from the negative effects of ultraviolet rays and high humidity, which is very important when equipping industrial premises, kitchens, bathrooms, baths, saunas.

Foil insulation withstands high temperatures well

Laying of foil insulation is carried out in accordance with a special technological process. A gap of 1-1.5 cm must be created between the thermal insulation and the finishing material. This is very important, since at elevated temperatures the insulation maintains a given degree by transferring it to the back wall and then returning it back to the walls, but not to the room.

In comparison with rolled materials made of slag wool, glass wool and basalt base, the foil product must be fixed to the lathing. The layers are overlapped, and their joints are carefully treated with insulation.

Insulation under wallpaper is a simple way to make walls warmer and get rid of noise

Special insulation allows you to create a perfectly flat base for any type of wallpaper

Don’t know how to glue insulation under wallpaper and what it even is? Using this material you can make walls warmer and create effective sound insulation in apartments. The work is so simple that even a beginner can handle it, and I am ready to share the technology of work that I have personally tested.

The material is sold in convenient rolls 50 cm wide and 14 to 20 meters long

Tips for choosing thermal insulation in rolls: what you need to know

Summarizing all of the above, it remains to note several important nuances regarding the choice of materials based on roll-type mineral wool for insulation. Experts recommend first of all taking into account the type of surface and purpose. It is necessary to select materials suitable for thermal insulation of certain surfaces: wood, concrete, brick, etc.

You should not write off the thickness of the base, taking into account temperature indicators and precipitation in the region, especially when it comes to external insulation.

When purchasing materials for thermal insulation based on any of the listed types of wool, you should pay attention to the integrity of the packaging. It is strictly prohibited for moisture to form on the packaging material.

Each of the above types of insulators has its own characteristics, advantages and disadvantages, so the choice must be made after careful analysis, depending on the required functionality.

When insulating large areas, the best efficiency is shown not by insulating boards, but by rolls of insulation. The same applies to pipes and ventilation ducts. Their main difference is increased density, and a consequence of this is high rigidity of the coating, which allows for much better insulation of objects with non-standard geometry.

Characteristics

Thermal insulation material in rolls, produced under various brands, is characterized by general characteristics.

Environmental friendliness

The insulation meets regulatory environmental safety requirements.

As a rule, salts of heavy metals, alkalis, acids, oxides, phenols or toxic organic compounds that are inactive at room temperature are present in minimal quantities.

Due to its low chemical activity, thermal insulation practically does not interact with aggressive environments, and therefore, for example, is not afraid of exposure to solvents.

Biological resistance and fire safety

The material has a high level of biological resistance. As a result, there are no rodents, fungus, or mold in it. It is of no interest to insects and animals as food. Depending on the composition and other characteristics, the insulation can withstand high temperatures.

Air and vapor permeability

If insulation is used to insulate floors or walls, air permeability is an important indicator.

When using rolled materials, you do not have to worry about excessive dampness in the room, condensation and other negative phenomena, provided that the installation is done correctly.

Recommendations for selection

When choosing a material, consult with a specialist, he will help you choose the best material. Before buying soft thermal insulation for finishing a room for any purpose, you need to consider some tips that experts share. The features and type of surface being treated are important, which can be brick, concrete, wood, etc. One should not lose sight of such an aspect as the thickness of the base when it comes to external insulation. In this case, the frequency and intensity of precipitation and the temperature regime by season play an important role.

Rolled heat insulation made from any type of mineral wool must be sold in undamaged packaging. Otherwise, moisture accumulates inside the material, worsening the quality of the product. When choosing the material to be described, its main functionality and purpose are taken into account.

Insulation in rolls is a popular finishing product. They are easy to use, improve the thermal insulation of premises for various purposes, maintaining it at the proper level for many years.

Rolled waterproofing for foundations

The durability of the structure and the safety of people depend on the strength of the foundation. To avoid premature destruction under the influence of groundwater, the foundation must be carefully treated with waterproofing materials.

Roll insulation is the most common option for waterproofing buildings and structures. All existing types of isolates are used in foundation processing - glued/surfaced and membrane.

Hydroprotection of the foundation using roll roofing is carried out at any stage of work - both before pouring the concrete solution and after the foundation is ready.

Waterproofing at the concrete pouring stage

If roll waterproofing is installed before pouring concrete, it should be laid using the “overlapping” method in the existing formwork. Each panel should overlap the previous one by 15-25 cm. The joints between the panels are glued together using double-sided adhesive tape. After this, reinforcement is installed and concrete is poured. For greater reliability, several layers of waterproofing are used, each of which is coated with bitumen mastic.

Vertical installation of waterproofing

The vertical method of installing insulating roll coating is used on ready-made foundations. With this method, glued or built-up waterproofing compounds are glued to the surface of the base.

Before you begin insulating the foundation, it is necessary to carry out pre-treatment - thoroughly clean the concrete surface from protrusions, dust and dirt. The smoother the foundation is at the point of contact with the waterproofing material, the more reliable the protection from moisture will be.

Those parts of the foundation that will be located underground are carefully treated with glue or bitumen mastic. After this, the rolled waterproofing agent is pressed onto the coated surface. If a built-up material is used, the bottom layer is heated with a propane torch until softened and then pressed against the surface of the foundation. The joints and edges of the panels are subject to additional treatment with mastic/glue or a gas torch.

To more effectively protect the foundation, roll waterproofing should be laid horizontally so that water does not penetrate into the joints between the panels. If the building has a basement, then waterproofing is carried out in two stages - first, the walls that will be located underground are treated, and then additional waterproofing is laid for the floors of the basement and first floor.

In foundation waterproofing, proven types of materials are used - roofing felt, filizol, hydroglass insulation.