Your own heating system in a private house is much preferable to connecting to a central heating system.

Dependence on suppliers, rising tariffs, worn-out networks and other problems disappears.

Installing your own boiler requires a certain initial investment, which subsequently pays off in significant savings on heating the house.

There are high-quality and relatively inexpensive gas devices that provide heating and hot water for domestic needs.

One of these units is the Navien Ace boiler, which should be taken a closer look.

Navien Ace gas boiler series

Navien boilers of the Ice (Ace) series are a family of gas double-circuit units manufactured by the South Korean company KyungDong NAVIEN.

They provide heating to the home and at the same time supply it with hot water. A special feature of Navien equipment is its specialization in Russian conditions, climatic and technological.

It is possible to work at low pressure of gas and water, resistance to changes and sudden surges in pressure.

In addition, there is a protective system that compensates for voltage drops in the power supply network up to 30%.

In addition, the company’s pricing policy is such that the cost of Navien boilers is approximately 2 times lower than European equipment of the same power. Such advantages are highly appreciated by users; the demand for Navien units is stable and gradually growing .

IMPORTANT!

Incorrect operation or difficult operating conditions can damage the boiler in a short time. This is not a consequence of poor quality assembly, but the result of insufficient attention and failure to take proper measures to create optimal working conditions.

Settings

“Navien” is programmed for winter (heating and DHW) and summer (DHW) operating modes - with the “Snowflake” and “Sun” icons. The network temperature is adjusted on the LCD remote control when the “radiator” icon on it is lit. In some options, the “Heating Mode” is started, in others the knob is turned. A flashing LED records the set water temperature.

If the icon just lights up without pulsating, the actual temperature in the network is displayed. By selecting the icon, use “+” or “-” to increase or decrease the temperature. After a couple of seconds the LED will stop flashing and show the actual temperature. They regulate the heating temperature from 40.0 C to 80.0 C. If it is set incorrectly, an error code will be displayed.

Note! DHW temperature adjustment is carried out in the same way, only on the remote control there are pictograms with a tap, range from +30 to +60 C

What models and what power exist?

The Ace series included the following models:

- Ace Atmo

- Ace Turbo

- Ace Turbo Coaxial

Atmo models had an open (atmospheric) combustion chamber and required an effective smoke removal system.

Their efficiency was noticeably lower, but this was successfully compensated for by installing a copper heat exchanger, which has greater productivity compared to stainless steel units.

The Turbo model range was distinguished by a closed combustion chamber design and turbocharging - a special fan supplied fresh air, increasing combustion efficiency and increasing draft in the smoke removal system.

A Korean or European (coaxial) chimney model was used to remove gases.

The first option consists of two separate pipes - one for air supply, the other is a chimney.

A coaxial chimney is a “pipe-in-pipe” system, where a chimney is installed inside and an air supply pipeline is installed outside.

The power of all models was 10, 13, 16, 20, 24, 30 kW, etc. The most popular models are 16k and 24k, optimally suited for servicing a private home. .

Specifications

The technical characteristics of almost all models (with the exception of the Atmo series) are similar and differ only in the power of the unit.

It corresponds to the heated area - 13 kW boilers are capable of serving 130 m2, 24 kW - 240 m2, etc.

For ease of consideration, the main parameters of Ace series boilers should be summarized in a table:

| Parameter | Ace | Ace coaxial | Ace Deluxe | Ace ATMO |

| Boiler type | Gas wall-mounted double-circuit | |||

| Combustion chamber type | Closed | Open | ||

| Efficiency | 91,2 % | 86 % | ||

| Thermal power of the boiler according to the air conditioner | 9-16 kW | |||

| Primary heat exchanger material | Stainless steel | Copper | ||

| Coolant temperature in the heating system | 40°-80° | |||

| DHW temperature | 30°-60° | |||

| Control type | Electronic | |||

| Mains voltage | Single phase, 230 V, 50 Hz | |||

| Weight | 28 kg | 26 kg | ||

| Case dimensions | 440x695x265 mm | 430x720x340 mm | ||

The difference in performance is due only to the type of combustion chamber and all related design features.

It should be noted that the 16 kW models are a complete analogue of the 24 kW models with reduced software capabilities, which provides a large margin of safety for the units.

Precautionary measures

The room where the boiler is located must be well ventilated.

Gas cylinders, if used, should be stored in a separate cool room.

Do not dry things on gas heating pipes.

The power supply parameters must meet the requirements for the specific model (For example, 220V, 50 Hz).

The unit must be plugged into a separate outlet (other devices cannot be plugged into it); extension cords and adapters are not allowed.

Do not touch the body of the device with wet hands or plug it into the mains.

A working device must be in a protective housing.

You cannot install or repair gas equipment yourself - this is the work of government services. Once a year, these services will conduct a preventive inspection of the boiler.

If bubbles appear, immediately turn off the gas valve, provide air flow and call emergency services.

Advantages and disadvantages

The advantages of Navien Ace boilers include::

- The optimal combination of price and quality.

- Environmentally friendly process.

- Simplicity and convenience of adjustment and configuration of operating modes.

- Adaptation to Russian conditions, ability to work on unstable gas pressure, water pressure, and power supply voltage.

- Simultaneous provision of heating and domestic hot water.

- Long service life without service checks.

The disadvantages of Navien Ace boilers are::

- Dependence on the availability of electricity, gas and water.

- High noise level.

- Only original spare parts are suitable for repairs.

- The structure is not resistant to hard water.

Most of the shortcomings are not the result of errors or defects during assembly, but rather relate to design features.

They are inherent in almost all gas boilers, regardless of the manufacturer . To prevent the formation of lime deposits caused by excessive water hardness, use electromagnetic softeners or other types of appropriate equipment.

Where is it used?

Gas double-circuit boilers Navien Ace series are designed for organizing heating and hot water supply of residential premises or offices of the appropriate area.

This limits the scope of use of these units, although they can be installed in any premises. The main task is to ensure that the serviced area matches the capabilities of the equipment and the availability of all the necessary resources - gas, electricity and water (coolant).

NOTE!

In addition to the area, it is necessary to take into account the volume of the room, which may be too large for this Navien boiler model. The product passport indicates the maximum volume possible for the normal functioning of the system.

What's included

The unit components include the following elements:

- Heat exchangers (primary and secondary, the primary can be made of copper or stainless steel, the secondary can only be made of stainless steel).

- Remote control panel.

- Circulation pump.

- Expansion tank.

- Three way valve.

- Safety valve.

- Traction sensor.

- Automatic air vent.

- Connecting pipelines, other structural elements.

In addition to the main elements, the boilers are equipped with mounting brackets and other additional parts.

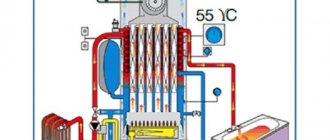

Device

The main design element of Navien Ace boilers is a primary tubular heat exchanger connected to the combustion chamber.

At the top there is a chimney connected or combined with an air supply pipeline. On the left side of the body there is an 8-liter expansion tank, under which a three-way valve and circulation pump are installed.

It ensures the movement of coolant and hot water through the system . Passing through the heat exchanger, the coolant receives a high temperature.

Then, using a three-way valve, a cold stream is added to achieve the desired system temperature. , the flow is removed from the boiler and sent to heating devices - radiators, convectors, etc.

Cleaning the heating water filter

Filters collect all the impurities contained in the water.

They need to be cleaned periodically, for this:

- Drain the water (see previous paragraph).

- Wait until the equipment cools down completely.

- There is a filter located not far from the drain plug. To remove it, first remove the mounting bracket, then pull out the filter itself.

- It must be rinsed under pressure with clean water.

- Then reassemble in reverse order.

If the filters are not cleaned in time, the boiler will overheat.

Connection instructions

Installing the boiler is not difficult - you just need to install anchor bolts and hang the unit on the wall.

It is recommended to install elastic gaskets between the housing and the wall to dampen noise. Do not install the equipment on fragile or weak structures - plasterboard partitions or other similar surfaces.

You need a solid brick or concrete wall that can support the weight of the boiler (about 30 kg).

Communications should be connected to the appropriate pipes. It is necessary to carefully monitor the compliance and tightness of connections.

The main attention should be paid to connecting gas pipes. Check all connections for leaks using a soapy solution.

If there is a common chimney, separate pipeline connections are used - the air channel is led out into the street through the wall, and the smoke channel is connected to the common chimney of the house.

Coaxial chimneys are led outside through the wall, which is much simpler and more convenient for installation.

Download instructions

You can download the instructions here.

Basic malfunctions and their solutions

Malfunctions of Navien boilers are usually diagnosed independently and displayed on the display with the corresponding code. Based on a signal from one or another sensor, a message about the problem that has arisen is activated.

The most common mistakes are:

- 02. Lack/insufficient amount of water in the system. The issue can be resolved by recharging the system or replacing the flow sensor.

- 03. No flame in the combustion chamber. Indicates problems with the ignition system, or lack of gas.

- 05-06. Open circuit or short circuit of the fresh air sensor.

- 07-08. Open circuit or short circuit of the DHW sensor.

- 09. Fan failure.

- 10. Failure of the smoke removal system.

- 15. Problems with the control board.

- 16. Boiler overheating.

The solution to most problems is to replace the corresponding sensors or components, as well as to clean and remove deposits in the connecting pipelines.

IMPORTANT!

It is not recommended to undertake repairs yourself. This procedure should be entrusted to specialists from the service center or other specialized organization.

Troubleshooting

Let's look at how to fix the main problems with a gas boiler. If error 01 occurs, you need to carefully inspect the pump, check the condition of the impeller and electrical unit, clean the dirt filter, and also remove air from the system.

To eliminate error 02 of the Navien boiler, perform the following steps:

- bleed air from the system;

- measure pressure;

- check the resistance on the pump coil, make sure there is no short circuit;

- check the position of the distribution valve, open if closed;

- clean the sensor flag.

Error 03 of the Navien boiler is often displayed if the flame sensor is clogged. It should be cleaned. Gray deposits on the electrode are removed with fine-grain sandpaper. When error 5 appears, you need to check the condition of the circuit section between the sensor and the controller; in case of serious problems, replace the sensor. In case of error 10 of the Navien boiler, you need to :

- check the serviceability of the fan, if repair is impossible, replace it;

- check the contacts in the tubes of the measuring device;

- clean the chimney.

If error 13 appears, replace the sensor. The noise in the system may disappear after flushing the heat exchanger; sometimes it needs to be replaced. The taps should be opened completely, and it is recommended to lower the coolant temperature.

Another important point in servicing a Navien gas boiler: how to refill the system after draining. Such a need may arise after repair/replacement of parts of the system or if the coolant was drained while the house was empty.

Price range

Prices for gas double-circuit boilers Navien Ace range from 26 thousand rubles. (Navien Ace 13K Atmo), up to 32 thousand rubles. (Navien Ace-24K Turbo). It is necessary to take into account that these amounts constitute only the cost of the boiler itself, without delivery, installation, warranty agreement and other additional costs.

Stores only carry out sales, and warranty repairs and maintenance are carried out by service centers, an agreement with which is concluded and paid separately. Many buyers believe that the warranty is automatic upon purchase, but this is a misconception .

NOTE!

The Ace series has been discontinued. It is still possible to purchase such units, since a lot of them were brought to the regions of Russia. But the possibility of warranty service must be clarified immediately, otherwise you may find yourself in an unpleasant situation.

Installation features

Before purchasing a gas boiler you must:

- Prepare the installation site. Atmospheric apparatus requires a separate room, at least 2x2 m in size, with exhaust ventilation.

- The device must be powered from a stabilizer connected to a circuit breaker or outlet that has an emergency shutdown feature.

- The boiler body must be grounded, so you need to connect a grounding wire to the installation site.

- The wall where the device will hang, if it is flammable, must be sheathed with non-flammable material.

After purchasing a boiler, the difficult task of connecting it arises. The factory operating instructions recommend engaging an authorized service center specialist for this.

But if you have skills in working with pipes and taps, you can try hanging it on the wall and connecting the device yourself. The factory instructions describe this in detail.

You might be interested >> Operating principle of Vaillant floor-standing gas boilers

But we must not forget that in any case, you will need to call a gas service specialist to conclude a service agreement and obtain a special permit to operate gas equipment.

Important! Unauthorized connection of gas to the boiler may result in penalties and even criminal prosecution.