The high-tech Korean gas boiler Navien is a leader in the heating equipment market. Units with a wide range of power are produced for heat supply to houses with a main gas subscriber station. By design, they can operate on liquefied gas. The model range allows buyers to make a fine selection of equipment based on real technical conditions and financial capabilities. They have an impeccable minimalist design. The elegant appearance of the boiler fits into kitchens of any size and configuration.

How to set up a Navien gas valve

To set the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale.

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

12 . Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm Home.

Source

How does liquefied gas differ from natural gas?

As is known, the main gas composition is dominated by methane, whose lower calorific value is approximately 9 kW/m³. The substance is transported and burned exclusively in a gaseous state; the transition to the liquid phase occurs as a result of cooling to deep low temperatures.

LPG – liquefied hydrocarbon gases, used in boilers, water heaters and internal combustion engines of cars, are a homogeneous mixture of propane and butane. Let us list the properties of this fuel:

- calorific value - about 6.4 kW per 1 dm³ (liter);

- gas easily transforms into the liquid phase under pressure;

- LPG is transported and stored in the form of a liquid, pumped into standard cylinders or storage tanks;

- Before combustion, the fuel must evaporate; propane-butane is supplied to the boiler burner or internal combustion engine cylinders in a gaseous state;

- Over time, condensation accumulates at the bottom of the container, taking away the useful volume of the container.

Addition. A significant advantage of methane over LPG is its price - natural gas is significantly cheaper. Even the higher calorific value and lower propane consumption do not cover the difference in cost. A more detailed comparison of different types of fuel is presented in a separate review.

When refueling with liquefied fuel, the container is never filled to the top. 1/5 of the tank (20%) must remain empty - this volume is used to transfer the fuel into the gas phase. If the vessel is filled to capacity, the evaporation area and the amount of LPG ready for combustion will sharply decrease. A standard 50 liter cylinder can be filled with a maximum of 40 liters of propane.

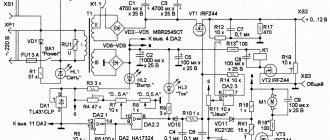

DIP switch functionality

After installing the gas boiler and the entire heating system, there is no need to rush to start up the equipment. It is important to configure the unit correctly, because the efficiency and safety of its operation depends on this.

Adjustment is made using the control board, which is located in the lower right part of the device. It contains small DIP switches for the Navien boiler in two positions. On older versions of the board there are only 10 of them, on newer ones, for example, Prime - 12 pieces. Let's get acquainted with their role in boiler control.

- The first switch is switched to the on position to ventilate the system. This procedure is performed when the heating system is started for the first time. After turning on the toggle switch, the circulation pump will operate continuously for two hours. If this time is not enough to bleed the system, restart the function again by turning the switch off and on.

- The second DIP switch is responsible for setting the maximum pressure of the gas valve. When the toggle switch is active, the unit operates at maximum values.

- The third switch forces the heat generator to operate at the minimum pressure value.

- The fourth DIP switch is responsible for the chimney. Position FE corresponds to a split chimney, where there are two different pipes at the air intake and exhaust. The FF mode should be turned on in boilers with a coaxial combustion product exhaust system. Such models use “pipe-in-pipe” technology, where the inner tube removes hot soot and heats the air entering through the outer pipe.

- The fifth switch determines the type of fuel with which the gas equipment operates. The “Off” position means that natural gas (G20) enters the boiler, and the “on” mode should be activated if you have propane.

- The sixth DIP switch determines the boiler model: Navien Ace Coaxial and Navien Deluxe Coaxial.

- The seventh toggle switch is responsible for the boiler frequency. Typically, Navien equipment operates at a frequency of 50 Hz. In this case, the switch should be in the on mode. The off position is activated for a frequency of 60 Hz.

- The eighth, ninth and tenth DIP switches of the Navien Deluxe boiler set the power of the gas appliance. The parameters of each specific boiler are indicated in its operating instructions. A special table indicates the equipment model and the required positions for each of the last three switches. For example, for the 16 KW modification, the 8th toggle switch will be turned on, and the 9th and 10th will be turned off. Using these elements, you can regulate the boiler power, but it is important to remember that the values are set either as in the manufacturer’s manual, or lower, if the burner allows. Switching these DIP switches of the Navien 24k boiler must be done when the power supply to the boiler is turned off.

In Navien Prime models, the functionality of the last 6 switches will be slightly different:

- The seventh is responsible for choosing the country.

- The eighth and ninth define the model.

- The tenth, eleventh and twelfth adjust the power of the heating device. Their correct position for each specific model is indicated in the corresponding table. Switching the last three DIP switches must be performed when the boiler power is turned off.

Setting up the Navien boiler

Common malfunctions and their solutions

Errors in the operation of the boiler are displayed by corresponding codes on the control panel.

Among them:

- E01. Boiler overheating. Occurs when the circulation pump fails, or less often when the coolant filter is dirty.

- E02. Coolant circulation error. Indicates the formation of leaks in the system or the boiler itself (connections).

- E03. No flame on the burner. This indicates either a failure of the ignition coils or a lack of gas in the system.

- E04. Parasitic flame. There is a gas leak or a spark jumps between the flame sensor and the ignition electrodes.

- E05, E06. Open circuit (short circuit) of the extract air (heating water) temperature sensor. Occurs when the contacts close, most often due to the presence of condensation or other moisture on the board with the sensor.

- E07. DHW heating sensor failure. It is necessary to check the contact or quality of connection of the sensor.

- E08. Short circuit of the DHW heating sensor. The sensor or the entire controller needs to be replaced.

- E09. Fan failure (failure). Check the contacts and, if necessary, replace the fan.

- E10. Malfunction of the smoke removal system. Usually occurs due to blockage of the chimney by ice from condensation.

NOTE! There are other error codes that appear when certain problems occur. A complete list can be found in the user manual for this device.

SR Series

Universal air heating sections for indoor or outdoor installation

Thermal power from 122 to 1,160 kW

Navien presents a universal water heating system

Navien Ace gas boilers are not afraid of low pressure of gas and water, they are not afraid of voltage drops in the network. The operation of Navien gas boilers is characterized by a long service life and economical gas consumption. All Navien gas devices comply with the standards and regulations of the Russian Federation and have the appropriate certificates.

Frost protection system stability

If the room temperature drops, the automatic protection system is activated

from freezing. When the temperature of the heating water drops by more than 10 degrees Celsius, the circulation pump automatically starts, resulting in constant circulation of the coolant in the heating system. If the temperature of the heating water drops to 6 degrees Celsius, the burner is automatically turned on and the coolant warms up to 21 degrees Celsius.

Safety of operation during frequent power surges

According to the instructions, the voltage can fluctuate within ±30 percent due to the triggering of the Switched – Mode Power Supply (SMPS) protective chip on the microprocessor. At the same time, the boiler operation does not stop

, which prolongs its service life and prevents breakdowns.

Operating conditions for heating and hot water:

- subject to low inlet pressure in the gas pipeline system, stable and safe operation of the Navien Ace gas boiler is possible at a gas pressure of four mbar (40 millimeters of water column);

- subject to low incoming water pressure in the water supply system - stable operation of the Navien Ace gas boiler is possible provided that the incoming water pressure drops to 0.3 bar, which allows this gas device to be used in homes

where there is low water pressure in the water supply system, including where there are frequent pressure drops in the water supply system.

Rational design

Navien gas boilers are small in size and light in weight, they are convenient to transport, they are easy to install and there is the possibility of rational use of room space. For ease of installation, the connecting tubes are located on both sides of the device, which greatly simplifies the piping and installation of the Navien Ace gas boiler.

Fuel preheating (KR series)

At low temperatures, the viscosity of the fuel increases, resulting in a waxing effect, which significantly impairs the flammability of diesel fuel

and the operation of the Navien gas boiler becomes unstable. This feature of operation is relevant for regions with harsh climates, therefore arctic and winter diesel fuels were created for these conditions.

Navien gas devices operate on any Russian-made diesel fuel

However, the cost of winter or arctic diesel fuel is much higher than that of summer diesel fuel, and the use of summer fuel is impossible at low temperatures without preheating it.

The heating element, which is built into the burner of the Navien gas unit, preheats it before supplying fuel to the nozzle, resulting in high-quality fuel atomization and uninterrupted ignition. Due to preheating in Navien Ace gas boilers, it is possible to use inexpensive summer diesel fuel

, which leads to significant savings.

Design

1. The heat exchanger is made of stainless steel

Stainless steel is used to produce the heat exchanger, so it is not subject to corrosion

, which significantly extends the life of the Navien Ace boiler.

2. Modern diesel burner

Thanks to a modern, efficient diesel burner, low-noise, stable operation with minimal fuel consumption is ensured. According to the instructions , the burner can work with any diesel fuel

, taking into account all types of fuel produced in the Russian Federation.

3. Fuel filter with replaceable cartridges

The fuel supply system is equipped with a filter to remove unwanted impurities, as a result of which the stable operation of the Navien Ace gas boiler is disrupted. The Navien device comes with additional replacement cartridges.

4. Russified control panel

Using a fully Russified remote control panel equipped with a liquid crystal digital display, it is possible to save fuel consumption and reduce heating costs

, as well as constant maintenance of a comfortable room temperature thanks to the room temperature sensor built into the control panel.

For which rooms is it best suited?

The power of the Navien Ace 24 K boiler is designed for operation in industrial, public or residential premises with an area of up to 240 m2.

There are no specific requirements for premises. The units performed well in difficult conditions, with unstable gas and water supply parameters.

The only condition for high-quality operation of the equipment is the proper installation of the boiler itself and the heating system and an uninterrupted supply of electricity.

Relatively small fluctuations (up to 30) in voltage are not a problem for devices, however, judging by user reviews, the automation cannot cope with fluctuations and requires a stabilizer.

Setting up a Navien gas boiler

Next, we’ll look at how to set up a Navien Deluxe gas boiler with your own hands. Manipulations are carried out using a remote control with a built-in room temperature sensor.

Heating settings

To set the heating mode and set the coolant temperature, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture blinks, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Navien wall-mounted gas boilers - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the “+” and “-” buttons with the “radiator” icon flashing. The possible range is from 40ºC to 80ºC. Once the temperature is set, it will be automatically saved. The “radiator” icon will blink for a few seconds, after which the actual temperature of the coolant will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, you need to hold down the “radiator” button until the image “house with thermometer” appears on the screen. It means “Heating with room temperature control” mode.

When the “house with thermometer” symbol is flashing, the desired room temperature is displayed on the screen. When the icon is not flashing, the display shows the actual room temperature.

When the icon is flashing, using the “+” and “-” buttons, the desired level of heating in the room is set, adjustable in the range of 10-40ºC. The temperature is then automatically saved and the icon stops flashing.

Setting the hot water temperature

To set the hot water temperature, you need to hold down the “water tap” button until a similar flashing symbol appears in the right corner. You can then set the desired hot water temperature between 30ºC and 60ºC. The settings will be automatically saved and the “water tap” symbol will stop flashing.

Note! In the “Hot water priority” mode, the water heating temperature is regulated differently. Now let’s look at how to configure the Navien Deluxe gas boiler in the “Hot water priority” mode. To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen.

Now you can set the desired temperature using the “+” and “-” keys. When changing the DHW temperature, the “water tap” icon should flash above the “tap and light” symbol.

To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. When changing the DHW temperature, the “water tap” icon should flash above the “tap and light” symbol.

Now let’s look at how to configure the Navien Deluxe gas boiler in the “Hot water priority” mode. To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. While the DHW temperature is changing, the “water tap” icon should flash above the “tap and light” symbol.

The “Hot water priority” mode involves preparing a supply of water at a given temperature even if it is not in use. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The “Away” mode means the gas boiler operates only for preparing hot water. To switch the unit to this mode, you need to press the button that shows an arrow and a water tap. The “water tap” symbol that appears on the screen means that the “Away from Home” mode is set. The actual temperature in the room is displayed next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating

Setting the Timer mode

The “Timer” mode is necessary to set the time for stopping the operation of the gas boiler within the range from 0 to 12 hours. The unit will work for half an hour, turning off for the specified interval.

To set the “Timer” mode, hold down the “radiator” button until the “clock” symbol appears. When the icon is flashing, use the “+” and “-” keys to set the interval time. The set value is saved, the “clock” stops blinking, and the display shows the actual air temperature.

Navien Deluxe Operating Instructions

After completing the installation work and piping with the in-house engineering systems for water, electricity, hot water supply and the heating circuit, the heating network is pressure tested to ensure there are no leaks.

The unit is filled with water, with a pressure usually up to 2 atm. Filling is carried out at positive outside temperatures. During the process of filling the network, monitor how the automatic air vent works, relieving air plugs.

After filling the boiler, they begin to ignite, before this they check the functionality of the gas equipment and the smoke exhaust system so that the draft in the boiler corresponds to the regime map specified in the factory instructions.

Press the start button, depending on the boiler model, and monitor the operation of the piezo igniter. On the operating panel, the required temperature regime is set for the heating and hot water circuits.

After the Navien boiler reaches operating mode, control the operation of the boiler equipment, pump, fan and burner device. Operation should be virtually silent, the flame should be even and without popping, and flue gases should be completely vented to the atmosphere.

The pressure and temperature of water in the DHW and heating circuits must correspond to the specified mode.

Features of Navien Ace TURBO

Compact arrangement of boiler elements.

The wall-mounted double-circuit boiler is characterized by the following:

- application for heating water and heating residential buildings;

- the equipment contains a steel heat exchanger coated with anti-corrosion, which significantly reduces the cost of the equipment in comparison with boilers equipped with copper heat exchangers;

- Navien Ace gas boiler (operating instructions included with each model) is easy to use;

Wall mounted hardware has brains. This means that the unit ensures that the coolant does not freeze in the heating system pipelines. Automation works in two cases. The first is when the water temperature drops to 10 degrees. At this time the time turns on. The second situation occurs when the coolant temperature is less than 6°C. In this case, the gas burner is turned on, heating the coolant to 21 degrees.

Navien products have positive reviews. This is due to the long period of use and high efficiency of the unit. The equipment is characterized by high fuel and electricity savings. This is facilitated by the presence of turbocharging and an APS sensor, which monitors air pressure.

Installation technology and connection instructions

Installing the boiler is not difficult. Floor samples are simply installed in a designated place, and wall samples are hung on a durable surface using elastic noise-absorbing pads.

It is prohibited to hang boilers on fragile partitions made of plasterboard or other similar material.

The boiler is connected by connecting all necessary communications and power supplies. It is necessary to be careful and carefully monitor the correct connection of the pipelines.

Main attention should be paid to gas pipe connections. Using a soap solution, check for leaks

There are usually no significant problems with the connection, but representatives of service centers insist on involving their specialists in the installation. It is believed that this option allows for proper connection of equipment and eliminates the possibility of errors.

Advantages and disadvantages of Navien Deluxe

Boilers have been sold on the world market for more than 30 years. They have gained popularity due to their reliability and functionality. The high level of safety of gas equipment is ensured by several protection systems:

- From freezing of the heating system, during prolonged shutdown of equipment in the cold season.

- From destructive operating modes of the electrical network, during power surges.

- From low operating conditions of the gas network.

- From emergency operating conditions of the water supply system, when the coolant pressure decreases to 0.1 bar.

The safety group of the Navien boiler contains primary sensors for temperature and pressure, a control pressure gauge and a safety relief valve against excess pressure in the heating circuit. To protect the internal surfaces of water heating from scale, a filter is installed to purify water from hardness salts.

An SMPS chip is built into the electronic board of the boiler control system, which protects the boiler equipment from fluctuations in the network +/- 30% of the normal voltage of 220V.

Specifications

Modern Navien units are equipped with a remote control panel, which receives a signal from a temperature sensor.

Its readings are instantly transmitted to the control unit chip, which gives a signal to the actuator to increase/decrease the gas flow rate to the double-circuit boiler. Similarly, a command may be received to completely shut down the unit if an emergency situation occurs in its operation.

The most popular modifications of Navien gas boilers are double-circuit wall-mounted units with a closed firebox, a thermal power of 20-24 kW, capable of efficiently heating a room from 160 to 240 m2 and preparing hot water for the domestic needs of a family of 4 people.

Technical characteristics of Navien wall-mounted gas units with a closed combustion chamber:

- Navien Deluxe Plus – 20k, heating – 160 m2, maximum/minimum performance – 20/9 kW, expansion tank – 8 l, electric pump – yes, heating + hot water supply, efficiency – 91.7% gas consumption – 2.15 m3/hour, price – 31,080 rub.

- Navien Deluxe Plus – 24k, heating – 192 m2, maximum/minimum performance – 24/9 kW, expansion tank – 7.5 l, electric pump – yes, heating + DHW, efficiency -90.5%, heat exchanger – steel, gas consumption – 2.58 m3/ hour, price – 31,230 rub.

- Navien Deluxe Plus -24k COAXIAL, power 24 kW, heating - 240 m2, maximum/minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 90.5%, heat exchanger - steel, gas consumption – 2.58 m3/hour, price – 28,500 rub.

- Navien ACE-20AN, heating -190 m2, natural combustion, maximum/minimum performance - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water, efficiency - 91%, heat exchanger - plate, gas flow - 2.06 m3 /hour, price – 29,130 rub.

- Navien Deluxe – 20k White, heating – 186 m2, maximum/minimum performance – 20/9 kW, expansion tank – yes, electric pump – yes, heating + hot water, efficiency – 90.5%, heat exchanger – steel, gas consumption – 2.15 m3/hour , price – 32,160 rub.

- Navien Deluxe – 24k White, heating – 220 m2, maximum/minimum performance – 24/9 kW, expansion tank – yes, electric pump – yes, heating + hot water, efficiency – 91.5%, heat exchanger – steel, gas consumption – 2.58 m3/hour , price – 29,980 rub.

- Navien Deluxe-20k COAXIAL White, heating – 190 m2, maximum/minimum performance – 20/9 kW, expansion tank – yes, electric pump – yes, heating + hot water, efficiency – 90.5%, heat exchanger – steel, gas consumption – 2.15 m3/ hour, price – 32,160 rub.

- Navien Deluxe-24k COAXIAL White, heating – 220 m2, maximum/minimum performance – 24/9 kW, expansion tank – yes, electric pump – yes, heating + hot water supply, efficiency – 90.5%, heat exchanger – steel, gas flow – 2.15 m3/ hour, price – 29,090 rub.

- Navien SmartTok – 24K, heating – 220 m2, maximum/minimum performance – 24/9 kW, expansion tank – yes, electric pump – yes, heating + hot water, efficiency – 91.0%, heat exchanger – steel, gas flow – 2.6 m3/hour, price – 34,430 rub.

- Navien Deluxe S COAXIAL-24k, heating – 200 m2, maximum/minimum performance – 24/9 kW, expansion tank – yes, electric pump – yes, heating + hot water supply, efficiency – 91.2%, heat exchanger – steel, gas consumption – 2.58 m3/ hour, price – 31,060 rub.

Characteristics of the Navien Ace line of wall heating devices

A wall-mounted, double-circuit gas heating device from the manufacturer Navien, belonging to the Ace line, is represented by the following models: Navien Ace ATMO, Navien Ace TURBO. Moreover, the latest model is presented on the market in two modifications – Korea and Coaxial.

The Navien Ace wall-mounted boiler, regardless of modification, has a power from 13 kW to 40 kW, which allows the equipment of this manufacturer to be placed in rooms of various sizes.

Features and characteristics of Navien Ace TURBO

The Navien Ace gas wall-mounted boiler can be placed in rooms of any size.

The manufacturer claims that Navien Ace TURBO boilers are ideal for use in domestic conditions. They can operate at low gas pressure in the pipes, significant voltage surges, and retain their functionality even when they are left unplugged for a long time and the coolant in the heating system begins to cool.

In addition, wall-mounted dual-circuit heating elements, Navien Ace TURBO, have other characteristics:

- this is a double-circuit unit, that is, it is suitable for heating a room and for preparing hot water for domestic purposes;

- The double-circuit heating device has a steel heat exchanger with a protective anti-corrosion coating. Its cost is several times lower compared to copper analogues. And the insufficient boiler power due to the reduced thermal conductivity of steel is compensated by turbocharging of the gas burner. Today, Navien Ace TURBO can compete in power with devices that have a copper heat exchanger;

- This gas wall heating element ensures that the coolant in the heating system does not freeze. So, when the water temperature in the heating system drops to +10°C, the boilers immediately turn on the circulation pump. By distilling water through the heating system, it prevents the formation of ice crystals. If the coolant temperature drops below +6°C, the gas burner is turned on. It heats the water in the heating system to +21°C;

- Navien Ace TURBO gas heating units are characterized by economical energy consumption. This is due to the synchronous operation of the turbocharging system and the APS (Air Pressure System) air pressure sensor. The boilers use a pressure sensor to control the rotation speed of the fan under the burner, thereby mixing the gas in optimal proportions with air, which allows the energy carrier to be completely oxidized. Consequently, the efficiency of the equipment increases, but the gas consumption does not increase;

- These boilers have a long service life, thanks to a reduction in the number of on/off cycles in the event of power surges and low water pressure in the system. Thus, double-circuit boilers will continue to operate if the voltage drops by 30% from 230 V. They will not turn off if the water pressure is 0.1 bar, which is important for houses with autonomous water supply.

Navien double-circuit boilers have two modifications. The Navien Ace TURBO Coaxial gas unit has a coaxial chimney. It is useful for those rooms in which it is difficult to ensure air flow for the boiler. That is, the coaxial chimney takes air for the combustion reaction from outside the building. Korea boilers take air from the room. They work silently.

Features and characteristics of Navien Ace ATMO

Navien Ace ATMO gas boilers operate even at low voltage.

The Navien company has developed double-circuit heating boilers that run on gas, but with an open combustion chamber, that is, without turbocharging. These are Navien Ace ATMO boilers. They feature the same functionality as turbocharged models. This is an adaptation to domestic operating conditions.

These heating boilers have the same chip, which ensures their constant operation at low voltage and system pressure. Gas equipment is equipped with a steel heat exchanger. A double-circuit boiler makes it possible to prepare hot water for domestic needs. However, the open combustion chamber ensures quiet operation, unlike turbocharged boilers.

Starting the boiler

After all installation work has been completed and pressure testing has been carried out, the first commissioning start-up of the boiler equipment is carried out. All work is carried out by service center workers with the preparation of appropriate documents, which in the future will preserve the manufacturer’s warranty obligations.

When starting the Navien boiler, the instructions must be followed impeccably. Sequence of work:

- The circuits are filled with water through the unit’s make-up unit, built into the structure, with a special tap at the bottom next to the tap water inlet.

- Monitor the pressure gauge; when the pressure rises to 2.0 atm, close the tap.

- Remove air pockets. At the first start, it is performed in manual mode, and at subsequent starts, through an automatic system. They start the process from the most distant battery, opening the Mayevsky tap, and alternately go through all the points of the heating circuit.

- After etching the air plug, the pressure in the circuit will drop, so re-filling will be required.

- Discharge the air mixture from the circulation pump.

- To turn on the unit, press the “Power” button.

- The electric ignition will work and the unit will start, after which it is necessary to adjust the temperature regime.

Advantages and disadvantages of Navien Deluxe

Boilers have been sold on the world market for more than 30 years. They have gained popularity due to their reliability and functionality. The high level of safety of gas equipment is ensured by several protection systems:

- From freezing of the heating system, during prolonged shutdown of equipment in the cold season.

- From destructive operating modes of the electrical network, during power surges.

- From low operating conditions of the gas network.

- From emergency operating conditions of the water supply system, when the coolant pressure decreases to 0.1 bar.

The safety group of the Navien boiler contains primary sensors for temperature and pressure, a control pressure gauge and a safety relief valve against excess pressure in the heating circuit. To protect the internal surfaces of water heating from scale, a filter is installed to purify water from hardness salts.

An SMPS chip is built into the electronic board of the boiler control system, which protects the boiler equipment from fluctuations in the network +/- 30% of the normal voltage of 220V.

DIP switch settings for boilers of different manufacturers

Navien brand boilers are produced in several countries. Depending on the origin and brand of equipment, control panel switches 7, 8 and 9 will be in different modes:

- Navien Deluxe, Russia - all turned off;

- Navien Ace, Russia - off/off/on;

- China - off/on/off;

- Brazil - off/on/on;

- Navien Ace, Kazakhstan, Cuba - on/off/off;

- Iran - on/on/off;

- Navien STS HE, Kazakhstan - on/off/on;

- installation error - everything is enabled.

Source

Setting the heater power

The heater power is adjusted by the last three DIP switches on the control board. In different models, these may be the 8th, 9th and 10th toggle switches or the 10th, 11th and 12th. The position of each of them depends on the weight of the model:

- 10 kW - off/off/off;

- 13 kW - off/off/on;

- 16 kW - off/on/off;

- 20 kW - off/on/on;

- 24 kW - on/off/off;

- 30 kW - on/off/on;

- 35 kW - on/on/off;

- 40 kW - on/on/on.

Navien boiler inside https://i.ytimg.com

Setting the gas pressure of Navien boilers

To set the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale. A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

12 . Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm House.

Hello! Tell me, is it possible to programmatically reduce the boiler power and if so, how to do it?

Will they lie to you if you succeed, because this is determined by the very model of this particular boiler. (IMHO)

tusat wrote: is it possible to programmatically reduce the boiler power and if so, how to do it

does Fondital Tahiti 24CTFS have this capability?

tusat wrote: Hello! Tell me, is it possible to programmatically reduce the boiler power and if so, how to do it?

The boiler power can be reduced to 13 kW. Without loss of power for hot water supply. To do this, set DIP switches No. 8-9-10 on the boiler control unit in a certain position. Settings for different powers are given in the user manual. After installation, it is necessary to check and adjust, if necessary, the gas pressure on the burner MIN and MAX according to the installed power.

Boiler equipment

The design of the unit includes:

- Two heat exchangers are made of stainless steel, which guarantees their long and reliable operation.

- Remote display of the control unit, which is completely Russified. For the Russian consumer this is a very important condition.

- Built-in circulation pump.

- Expansion tank.

- Safety valve.

- Air vent operating in automatic mode.

- A bypass valve, which is also adjusted automatically.

- Traction sensor.

- Electric current stabilizer.

- Remote control, which is convenient in terms of maintenance.

The South Korean boiler navien ace is fully equipped with Japanese automation. In this case, the manufacturer provides a warranty period of 2 years. This is a fairly compact device with excellent technical characteristics. The operating instructions for Navien boilers make it easy to understand all the intricacies of setting up the device, modes and temperature ranges.

. and without construction experience

My works for 2022.

How I set up the Navien boiler, hysteresis on the burner

The boiler heats up, life goes on, but something told me that everything is not so rosy, first of all, a mistake was found among many buyers of gas boilers, they all buy with a reserve of power “just in case,” well, I, like everyone else, I took it with a reserve, with a reserve for hot water supply and frosts, i.e. It turned out that in warm weather outside, the Navien boiler continues to cycle , which is very unfortunate for it, and can lead to breakdown, first of all, there may be a breakdown of the ignition system , since it constantly lights the boiler, and most often wears out, this is not for me I want to. As an inquisitive researcher, with a stopwatch in my hands, I studied the cycles of the boiler in different modes of its operation, in warm weather, in cold weather, and decided to test the capabilities of the boiler at work depending on the temperature in the room, for this I selected the room mode in the boiler settings.

At first everything was happy, the boiler obediently stood up, waiting for the set temperature to drop, but the joy was short-lived, cold was already creeping across the floor (the heat from the radiators, which cut off the cold air from my many windows, disappeared, and the house became not very comfortable, in the upper part the room where the remote control for the boiler, in which the temperature sensor is located, hung. It was in a warmer zone, we immediately understood that this was not suitable for us, at first there were thoughts of hanging the remote control down, closer to the floor, but, firstly, this is inconvenient for control, secondly, it can be ruined by domestic cats, thirdly, the boiler may not turn off at all, trying to catch up with the temperature below, when it is already hot in the middle part of the room in height.

The room temperature test did not pass and was not suitable for me, at the same time I remembered the person who connected the gas, who advised that the boiler should not be turned on in this mode.

Time passed, but the cycles did not give me peace, and one day it occurred to me, while regularly observing the boiler, that the hysteresis (delta) in the turn-on-switch-off segment of the gas boiler was probably too small, and I would like the boiler to drive the coolant longer to a higher level. low CO temperature, but it was unclear how to do this, I certainly know how to program, but programming languages for this boiler are inappropriate, and I don’t have equipment to connect to the “brains” of the boiler, and one day, purely by chance, I came across one well-known forum for a person who knows how to do this, and with the help of only one remote control, by entering the engineering menu of the Navien boiler!

This is literally what needs to be done. to change the delta between boiler start-stop.

1. With the Navien boiler remote control turned off, press the + and – buttons for 5 seconds

2. The number 8 or 9 or 10 will appear on the remote control display (for me)

3. Again, use the + or – buttons to change the value (this is delta) in the range from 2 to 20 (I set it to 12)

4. We wait 5 seconds, after which the boiler remote control goes out

5. Turn off the boiler by removing the plug from the socket for at least 10 seconds

Design and main elements of the boiler

It is important to know your boiler in order to carry out basic maintenance. Although the model may vary from model to model, the main elements can be found in the case:

- combustion chamber;

- heat exchanger;

- expansion tank;

- gas burner;

- circulation pump;

- Control block.

Particular attention should be paid to the design of the lower part of the case, since this is where the inputs and outputs of the circuits are connected, and other important parts are located.

Navien boiler diagram

Closer to the wall there are 4 connecting pipes:

- Feed input.

- Return inlet (with safety valve).

- Hot water outlet.

- Cold water.

Next is a small gas supply pipe.

In front of the return inlet there is a hot water filter, and even closer there is a drain plug.

In front of the DHW outlet there is a make-up tap, through which the system is filled with water.

If the temperature continues to drop and it reaches -6°, the burner is activated, which heats the water to +21°.

Features of the Navien gas boiler

Navien produces devices of various capacities designed to provide heating for gas-fired homes. However, the technical features of the models allow them to be converted to an autonomous gas supply, that is, connected to cylinders.

A wide range of models allows you to choose a model to suit any needs and capabilities.

- wall and floor;

- single-circuit and with hot water supply;

- with atmospheric and closed combustion chamber;

- with different heating outlet sizes (three options: 20, 25, 32);

- with different chimney diameters;

- and of course, the models differ in power and size.

The manufacturer did not neglect the design.

The devices have an elegant appearance and fit well into a kitchen or any other interior.

Security systems supplied with Navien boilers:

- Modulated turbocharging.

- Protection against coolant freezing.

- A special chip (SMPS) protects against 30% power surges.

- A control panel with a temperature sensor that allows you to maintain t constant and adjust the operation of the boiler to special circumstances.

Modulated turbocharging. The system is based on the interaction of a fan supplying combustion air and a pressure sensor (APS).

The fan rotation intensity changes in proportion to how much gas is supplied at the moment. This allows you to use resources economically and increase efficiency without wasting fuel.

Owners take the choice of equipment such as a gas boiler seriously. Read information about the Baxi gas boiler, the manufacturer, as well as the unit models on our website.

Read about the purpose of an air valve for heating here. Operating principle and design features.

And in this topic https://microklimat.pro/sistemy-otopleniya/elektricheskoe-dachnogo-doma.html we will consider options for electric heating of a private house. Types of electric heaters and electric boilers.

Reasons and principles of boiler conversion

From the first lines, we would like to warn you that work on re-equipping the boiler to switch to a different type of fuel must be carried out by the foreman of the organization with which an agreement has been concluded for the supply of gas and maintenance of equipment.

However, any owner should know the essence and stages of the process for basic control of the actions of invited performers. And doubts about their competence sometimes justifiably creep in. Therefore, it is better to monitor the implementation of the procedure, on which, by the way, the safety of the home and household depends.

Image gallery

Photo from

Connecting the boiler to liquefied gas cylinders

Installation of a group of gas cylinders

Operation of low-power gas equipment

Autonomous system with floor boiler

It also happens that a gas service representative cannot get to a remote location. In this situation, the home master, of course, will try to do everything with his own hands. But for the result of the efforts of a craftsman inexperienced in the gas sector, he himself will bear responsibility, and the manufacturer’s guarantees will be void.

When purchasing a gas boiler for domestic use, we receive a device configured to process main-line fuel. A centralized gas pipeline supplies us with a mixture of flammable gases, in which methane predominates. The main gas enters the devices with a natural density and pressure of 21 mbar.

Liquefied gas is an exaggerated name for a mixture of propane and butane, in which either the first or the second component can predominate. It can contain predominantly butane with a slight admixture of propane, or vice versa, propane predominates by 99%.

The density of the liquefied mixture increases 600 times. The pressure does not increase as much, but it is still higher than that of natural fuel, 30-31 mbar.

To produce liquefied gas, the pressure of propane and butane is increased approximately 600 times. This procedure makes it possible to reduce the volume of fuel and store it in a liquefied state before use.

The types of gases that boilers operate on are standardized. They are assigned codes that the manufacturer indicates in the technical documentation. Thus, the boiler’s consumption of main gas is marked with code G20. The ability to operate the boiler from a liquefied mixture with a predominance of butane is designated G30, and from a mixture with a predominance of propane - G31.

In order for blue fuel to fulfill its significant duties, gas enters the combustion chamber through nozzles. There, gas is mixed with air using a burner in proportions that are optimal for a particular type of fuel. This means that gas must be supplied to the burner in the volume necessary for normal combustion.

Normal mixture formation is possible if the diameter of the nozzles is suitable for its implementation. The size of the supply holes determines how much gas under a certain pressure will enter the combustion chamber with a specific volume of air. That is why nozzles with different cross-sections are installed for liquefied mixtures and for main gas.

To switch to the consumption of liquefied gas, you do not need to radically alter the equipment, much less buy a new unit. You just need to change either just the injectors or the manifold (ramp) with injectors

Note that the cross-section of the nozzles is determined not only by the type of gas, but also by the power of the boiler itself. For your information, to operate a 10 kW unit operating at maximum operating mode, main gas requires 1.2 m³/h, liquefied mixture of any type 0.86 kg/h.

The more powerful the equipment, the more fuel is required to operate it. The larger should be the size of the nozzles that pass blue fuel into the combustion chamber. Their cross-section is clearly calculated and strictly regulated by the manufacturer, who produces burners with nozzles of a given diameter for a series of boilers of a given power.

When gas enters from the nozzle, the gas is mixed with a portion of the air it requires for the normal combustion process. Both components must be supplied to the combustion chamber in strictly controlled proportions

So how can you switch to liquefied gas if you didn’t initially think of buying a boiler for liquefied gas? That's right, replace either the entire manifold with the entire set of injectors, or just the injectors, leaving the manifold in place. The second option is not possible in all boilers.

In addition to replacing devices for supplying liquefied gas, you will also need to reconfigure the burner of a gas boiler with an electronic control type. This is necessary for the complete delivery of air in the volume required for the uninterrupted combustion process. The new settings will also ensure that the gas supply is interrupted if a risky situation arises.

You will also need to install a reducer designed to regulate the pressure of gaseous fuel. One or a group of cylinders can be connected to the gas reducer. The gas valve may need to be replaced if necessary.

To connect the boiler to cylinders or a gas tank, you need to set the reducer to the operating value of the gas pressure. Sometimes it is also necessary to change the gas valve in the boiler if it is not suitable for supplying gas at the required pressure

In any situation, before ordering a contractor to convert a wall-mounted or floor-standing gas boiler to liquefied fuel, you should consult the gas service that oversees your equipment and the gas supply to your facility.

They will tell you which devices you should purchase for translation. They will calculate how much the modernization will cost you along with the specialist’s payment.

Specifications

| Indicators, units | NAVIEN Ace-13A Atmo | NAVIEN Deluxe-16K | NAVIEN Deluxe-20K | NAVIEN NCN-25K |

| Heating area, m2 | 98.0 | 128.0 | 160.0 | 220.0 |

| Condensing type | No | No | No | Yes |

| Thermal power, kW | 13.0 | 16.0 | 20.0 | 25.0 t |

| Combustion chamber | open (chimney) | closed (turbo) | closed (turbo) | closed (turbo) |

| Electrical power consumption, for own needs, kW | 110.0 | 150.0 | 150.0 | 130.0 |

| Min. t in the heating circuit, °C | 42 | 42 | 42 | 30 |

| Max. t heating circuit, °C | 80 | 80 | 80 | 95 |

| Max. pressure in the DHW system, bar | 8.0 | 8.0 | 8.0 | 10.0 bar |

| Max. t DHW, °C | 65 | 65 | 65 | 65 |

| Capacity (Δt=25°C), l/min | 9.0 | 13.6 | 13.8 | 14.0 |

| Capacity (Δt=35°C), l/min | 5.5 | 8.6 | ||

| Summer operating mode | Yes | Yes | Yes | No |

| Hot start mode | Yes | Yes | Yes | No |

| Efficiency, % | 86.0 | 91.0 | 91.6 | 98.2 |

| Nominal gas pressure in front of the boiler, mbar | 18.0 | 18.0 | 18.0 | 18.0 |

| Max. hourly gas consumption, m³/hour | 1.33 | 1.72 | 2.15 | 2.51 |

| Expansion tank capacity, l | 6.5 | |||

| Chimney diameter, mm | 130.0 | 60/100 | 60/100 | 80/125 |

| Price as of 07/01/2019 | 32780 rub. | 35200 rub. | 37880 rub. | 69800 rub. |

What pressure should be in the heating boiler?

The operation and efficiency of the heating boiler directly depends on whether the pressure in your heating system is correct. And hence - the local climate in heated rooms, safety, reliability and durability of the equipment. We suggest you consider what pressure should be in the heating boiler, how to keep it under control and why it can fall or increase.

System pressure drop

- the heat exchanger is faulty;

- there are leaks in the circuit.

Similar things often appear when individual parts of the system wear out. Microcracks, pipe ruptures occur, and rubber membranes in the expansion tank are damaged. You can try to find the leak on your own. The most “problematic” places are pipe solders, connection points with batteries, etc. If you find a leak, then this is the reason for the drop in pressure. It is even more difficult to find leaks if the pipeline is hidden in the floors or walls. Here you cannot do without the help of a specialist, because out of ignorance you can, in search of leaks, disassemble the coating where this is not necessary. You will have to spend extra money on repairs.

Features of closed and open systems

There are two favorite types of heating systems currently in use:

- Open. The water here moves naturally due to its special design and the force of gravity. The system itself communicates with the atmosphere through an expansion tank.

- Closed. Here the circulation of the coolant is carried out under the action of a circulation pump.

Closed systems are the most popular right now. Their normal operating pressure is less than 2 atmospheres. But if the circuit is long, then the pressure may be higher. In some cases, several pumps are even installed to ensure the normal movement of the coolant along the circuit. It is recommended to install pumps in parallel - this minimizes the load on the boiler, allowing you to work longer without harm.

Knowing what pressure in a gas boiler is normal, it must be kept under control at all times. Modern units are sure to have a pressure gauge installed, which allows you to immediately find out the real value. The advantage of integrated pressure gauges is that they do not require power to operate. Electric ones don't work without electricity.

But 1 pressure gauge is not enough. To obtain specific values, it is necessary to install additional ones at the inlet/outlet of the boiler, the upper/lower sectors of the system, before and after the pump. Experts also recommend installing pressure gauges at pipe branching points. The rule “the more the better” works here (within reasonable limits, of course). Several pressure gauges will allow you to better assess the situation throughout the entire circuit.

Operating modes

Like many heating appliances, Navien boilers have winter and summer operating modes. On the display, the mode change button is indicated by the “Snowflake” and “Sun” icons.

By pressing this button again, you can change the options:

- Winter mode activates heating and hot water supply.

- Summer is only hot water supply for household needs.

You can adjust the coolant temperature on the remote control when the heating radiator icon lights up on the display.

In some models, to do this you need to press the “Heating Mode” button, in others you need to turn the knob with this icon.

A flashing radiator icon means that the numbers you see show the set temperature of the coolant.

If the “radiator” just lights up, the actual temperature in the heating is displayed.

Having selected “radiator”, you need to press the “+” or “-” keys to increase or decrease the temperature. A few seconds after the desired temperature is set, the radiator icon stops blinking, and the display will show what temperature the coolant is now, and the device will begin to gradually heat it (or cool it) to the selected one.

Settings

“Navien” is programmed for winter (heating and DHW) and summer (DHW) operating modes - with the “Snowflake” and “Sun” icons. The network temperature is adjusted on the LCD remote control when the “radiator” icon on it is lit. In some options, the “Heating Mode” is started, in others the knob is turned. A flashing LED records the set water temperature.

If the icon just lights up without pulsating, the actual temperature in the network is displayed. By selecting the icon, use “+” or “-” to increase or decrease the temperature. After a couple of seconds the LED will stop flashing and show the actual temperature. They regulate the heating temperature from 40.0 C to 80.0 C. If it is set incorrectly, an error code will be displayed.

Note! The DHW temperature is adjusted in the same way, only on the remote control there are pictograms with a tap, the range is from +30 to +60 C.

How to reduce the power of a gas boiler: ways to reduce

Hello, dear readers. Many owners are interested in how to reduce the power of a gas boiler? After all, it begins to consume a lot of fuel, strong noises and clicks appear in it. It feels like it might explode. To resolve the issue, there are general recommendations and points for certain brands and models.

A gas boiler is a necessary device in the house. It handles heating tasks and solves the hot water dilemma (if the model has two circuits). However, there are often cases when the power of the equipment goes off scale, which is fraught with significant waste of fuel and strong heating of the device. Therefore, the question arises of reducing these parameters.

Classic methods

To reduce the power of equipment, you need to apply these methods (one or both):

- Burner power decreases. Parameters are achieved at which the automatic system sets the stable operation of the device with a connected heating system.

- Increasing the maximum power parameters of the heating circuit. The process comes down to installing additional radiators or replacing existing ones with more powerful analogues.

Both options can be used. To do this, the difference between the power of the heating circuit and the device itself is reduced: radiators are changed or more powerful units are installed. The existing difference can be compensated by adjusting the power of the boiler itself.

Method No. 2 is less financially profitable, but if there is an urgent need, it is inevitable. Especially when there are radiators that do not have thermal power reserves.

And in cold weather, to maintain optimal temperature data in the room, it is necessary to send water with readings of more than 75 degrees to the radiators. In this situation, organic dust particles burn on the radiators, and a foul smell is formed in the room.

The boiler also has a negative impact - its polymer, plastic and rubber components deteriorate.

It is more effective to reduce the power of boilers of this brand by reducing the fuel supply to the burner. To do this, reconfigure the gas valve.

The Proterm Cheetah model is taken as an example.

A Honeywell valve is used here. Externally, it is a yellow connector with wires. It is mounted on a stepper motor, which helps change its settings.

The specified electric motor is controlled through the control panel: you need to go to the service menu. Access to it appears after entering the code.

The procedure is as follows:

- Press and hold the “Mode” button for 6-7 seconds. The display will show the number 0.

- Use the + or – buttons to enter the number 35. This is the code. Press the indicated button again.

- When the first line of the menu with 0 signs appears on the screen, also using the + or – buttons, enter the number with the required line number: d.**.

- Changing parameters. “Mode” is pressed again. This is a transition from line numbering ** to the indicators themselves. The “=” symbol and the power parameter are displayed in turn on the screen. Change the values using + or -. After three seconds, the new setting is automatically confirmed.

- Return the display to its original state: press “Mode” for three seconds. After 15 minutes the screen will return to functional mode.

Navien devices

To reduce the power of many Navien models, just use the remote control and visit the engineering menu.

- The remote control is turned off. Press + and – for 5 seconds. This is how the regime is established.

- The numbers displayed on the remote control panel are 8,9 or 10. They change to values in the range 2 -20. Most often the figure is 12 or 13.

- After 5 seconds the remote control goes out. The boiler is disconnected from the network for 10 seconds.

Baxi products

If you have a small apartment, then for optimal power of the Baxi boiler, the F08 and F10 indicators are set to a minimum.

The modulation interval of a 24 kW device starts at 40% of the maximum power. Then the minimum parameter for its operation is 9 kW. This is enough to heat an area of up to 80 sq.m.

You can also connect a room thermostat to many models. The boiler will start only by its signal when the temperature in the room drops below the set values.

Thanks to programmable thermostats, you can flexibly adjust different modes throughout the day. Even if you reduce the indicator by 1 degree every day, you can save up to 4-5% of fuel per year.

Vaillant technology

Manufacturers of Vailant boilers offer the use of heat pumps in order to optimize the power of their equipment. These devices allow you to generate 2.3 - 4.8 kW of thermal energy at a cost of 1 kW of electricity.

For example, thanks to a pump with a parameter of 15 kW, about 45,000 cubic meters of gas are saved per year. Also, the pump cools the room well in the summer, which eliminates the need for owners to purchase an air conditioner.

What to pay attention to during installation?

Since instructions are included with the equipment, there are no problems with installing and connecting the device. Doing it yourself is not a problem. Even a non-professional can understand the instructions. Moreover, it is written in Russian.

The only thing that experts ask you to pay attention to is the method of removing carbon monoxide. They can be discharged through a regular atmospheric chimney connected to the smoke exhaust system of the house or installed as a separate structure. But if you are not satisfied with any option, you can make a coaxial chimney. Its installation is several times simpler. But keep in mind that coaxial structures are used only when the heated area of the house does not exceed 110 m². They can be installed with boilers whose power does not exceed 11 kW.

Precautionary measures

The room where the boiler is located must be well ventilated.

Gas cylinders, if used, should be stored in a separate cool room.

Do not dry things on gas heating pipes.

The power supply parameters must meet the requirements for the specific model (For example, 220V, 50 Hz).

The unit must be plugged into a separate outlet (other devices cannot be plugged into it); extension cords and adapters are not allowed.

Do not touch the body of the device with wet hands or plug it into the mains.

A working device must be in a protective housing.

You cannot install or repair gas equipment yourself - this is the work of government services. Once a year, these services will conduct a preventive inspection of the boiler.

If bubbles appear, immediately turn off the gas valve, provide air flow and call emergency services.

Answers: Gas boiler NAVIEN ACE

How is the recharge system organized? From the water supply through a check valve?

I would like to know if the heating system is new or old? There was no need to add pressure to the expansion tank. The tank contains not air, but nitrogen, and the pressure is set at 1 atm from the factory. The system may have a leak that is difficult to detect. A slowly flowing drop has time to dry on a pipe or battery, but at the same time the pressure will drop. It is also possible to check the make-up taps and Mayevsky taps.

I would start by checking the pressure in the receiver - there should be pressure of at least 1.5 atm, then I would check the air (emergency) valve, and all the taps. To make it easier to search, turn off all the taps in the system and start opening one tap at a time from the boiler and watch how the pressure drops within an hour. Perhaps air has accumulated in the system and the coolant needs to be replenished (it is useless to pump the receiver without replenishment).

Tips and recommendations for operating the Navien boiler

The main advice from experts regarding the safe operation of the boiler:

- The room where the unit is located must have good ventilation.

- The unit must have a separate independent connection to the electrical network.

- The boiler must operate in a fully assembled and protective housing.

- The user is prohibited from independently repairing the gas equipment of the boiler.

- The boiler must undergo an annual inspection by representatives of Gorgaz.

- The boiler owner must periodically check the joints of the boiler and the gas pipeline for leaks with a soap solution.

Additional Information. If leaks occur, immediately turn off the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have been used by Russian consumers for a long time. They have rightly earned the trust of customers. The lightweight layout with the widest range of modern water heating functions allows you to choose these models from a large list of offers on the heating equipment market.

Korean-made Navien heating boilers are popular in our country. They are reliable and at the same time affordable in price. Due to the great demand for these devices, setting up a Navien gas boiler is a pressing issue among buyers.

Safety Recommendations

Converting the boiler and reconfiguring it to consume liquefied gas dictates the need to “reconfigure” your attitude towards the device for supplying and storing blue fuel.

You must remember that:

- Cylinders or gas tanks, which are gas storage tanks that supply fuel to household appliances as needed, need to be refilled periodically.

- To fill a group of cylinders or a gas holder with gas, you need to contact certified organizations that have equipment to record the weight of the gas in the cylinder and its actual volume in the gas holder.

- Filling closed gas tanks is carried out to 85% of the useful volume of the vessel. This reserve is necessary in case of thermal expansion of the fuel to avoid an explosion.

A non-hazardous situation that requires special attention when replenishing liquefied blue fuel reserves is the filling of liquid with a density different from the density of the previous liquid. Because of this difference, the remaining liquefied gas may not mix with the newly filled portion.

In the tank, due to the difference in density, a kind of two non-connecting sectors are formed, in each of which liquefied gas circulates. However, convective heat exchange will occur at the sector boundary after a short period. After the temperatures are equalized, the densities will be equal and the liquids will be able to mix.

Liquefied gas, like main gas, is a highly flammable, combustible liquid with a high flame propagation speed. To avoid catastrophic situations, you should strictly follow the operating rules and fill the cylinders no more than 85%

Usually this process, meaning direct mixing, is accompanied by intense evaporation of liquefied gas. To avoid associated losses, mixing devices should be used during the filling process. But it is better to choose a method that eliminates the above-described phenomenon.

Replenishing cylinders and gas tanks with blue fuel in general is a process that requires increased attention, otherwise problems can be very serious and even catastrophic. The rapid spread and evaporation of the liquefied gas mixture is recognized as a significant problem.

If the rules for the safe operation of gas-consuming equipment are not violated, main methane rarely explodes. This only happens with significant leaks, if the technical state of the gas in the surrounding space changes dramatically. For example, in a kitchen with obvious signs of a leak, instead of mandatory ventilation, they turn on the light.

When liquefied gas expands in a closed container due to external heating, it will necessarily explode if there is not enough space left in the container for its expansion. Blue fuel burns extremely intensely. Since the gas is quickly absorbed by the atmosphere, the combustion zone expands at high speed.

Filling the boiler and heating system with water

Error code 02 indicates that there was an attempt to start the boiler, but there is no water in the system, or there is not enough water. What to do:

- The appliance is unplugged and the gas supply is cut off.

- At the bottom of the boiler, among many elements, you need to find a make-up valve. Turning it counterclockwise opens it, and turning it clockwise closes it.

- When the tap is open, monitor the pressure gauge. You need to close the tap when it shows 1.3 - 2 bar.

- Now the boiler is connected again, gas is supplied and the start is made.

Don't worry if error 02 appears again. This may be caused by the fact that after bleeding the air (which is automatically done at startup), the water level is again insufficient. The filling operation must be repeated.

Conclusions and useful video on the topic

The following video will introduce you to the organization of heating using liquefied gas and the procedure for converting the boiler to its consumption:

The technical and technological essence of converting a boiler to consume a gas mixture in a liquefied state should be known to both independent home craftsmen and customers of gas service workers.

It should be remembered that the second option is preferable, since the gas is explosive, toxic and flammable. In addition, if third-party intervention occurs, the equipment warranty will be invalidated.

How to increase the time between starting and shutting down a gas boiler?

If there is a problem with frequent switching on and off (“clocking”) of a gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and press two buttons “+” and “-” at the same time.

- A number from 2 to 20 appears on the display. Usually 8 or 10.

- Use the “+” and “-” keys to increase the delta value between start and shutdown.

- After 5 seconds, the remote control goes out.

- The boiler is turned off and then turned on again.

Now the gas unit will operate in a new mode.

Possible malfunctions and ways to eliminate them

Navien error codes:

- 01 – overheating (check if the pump is working and if the filter is clogged).

- 03 – no gas (check if the tap is open).

- 04 – false flame signal (check the serviceability of the gas valve, replace the electrodes or board).

- 05 – 06 – Short circuit on the temperature sensor or open circuit.

- 09 – problems with the fan.

- 10 – problems with smoke removal (check the operation of the fan, whether the chimney is clogged, whether the fan pipes are connected correctly, gusty wind could also be the cause).

- 013 – Short circuit on the OM flow sensor.

If the boiler does not give any errors, but works much worse, the reason may be a clogged filter or an airy system.

Navien boilers, like any other equipment, require good care and proper handling. Regular checks and service control will help avoid breakdowns.

Installation of an internal electrical network is an important stage in the arrangement of a new building. Electricity in a private house with your own hands - how to do the wiring correctly? Read the advice of professionals.

For recommendations on making a gas burner for a boiler with your own hands, read the link.

Draining water from the boiler and hot water supply system

If the boiler is not planned to be used for a long time (especially in winter), it is recommended to drain all water from the heating and hot water circuits. What to do:

- The unit is de-energized and the gas valve is closed.

- The valves of the heating system (2 pieces) and cold water are closed.

- The tap that is usually used opens (above the sink, for example) and drains hot water from the system.

- The tap in the DHW system is closed.

- A plug is opened at the bottom of the housing and water from the heating is drained.

Unexpected rise and fall in pressure: causes and solutions

It is not difficult to find out what pressure should be in a double-circuit boiler - this information is publicly available. But finding the reason for incorrect values is more difficult. Let's look at a few common circumstances.

Increase in pressure in the system

There are many reasons for a sharp drop in pressure:

- due to the increase in coolant temperature, its volume has increased;

- the coolant has stopped moving along the circuit due to a system malfunction or for another reason;

- the system is clogged or an air lock has formed in it;

- you or someone else accidentally closed the valve;

- there were errors during installation;

- the boiler power is set too high or there is a pump malfunction.

Modern boilers are equipped with expansion tanks that neutralize the expansion of the coolant when heated. There are also safety valves that protect the circuit from damage due to high pressure or even water hammer. If you see that the pressure values are close to critical, try to reduce the boiler power. If the situation does not return to normal, contact a specialist. He will see the problem and remove it.

Cleaning the heating water filter

Filters collect all the impurities contained in the water.

They need to be cleaned periodically, for this:

- Drain the water (see previous paragraph).

- Wait until the equipment cools down completely.

- There is a filter located not far from the drain plug. To remove it, first remove the mounting bracket, then pull out the filter itself.

- It must be rinsed under pressure with clean water.

- Then reassemble in reverse order.

If the filters are not cleaned in time, the boiler will overheat.

Reviews on the use of liquefied gas

An undoubted advantage of burning LPG is the convenience and ease of servicing heating equipment. The downside is the rather high price of propane compared to other energy sources. If a house with an area of more than 100 m² is heated from cylinders, then the advantage of convenience disappears - the vessels need to be refilled at intervals of 4-7 days, depending on the outside temperature.

Reference. The cost-effectiveness of autonomous heating using liquefied gas is a myth. As is the case with other energy sources, fuel consumption depends on the heated area, the degree of insulation of the home and other factors.

We propose to present the features of operating liquefied fuel boilers in the form of reviews from real homeowners:

- They decided to heat their house with an area of 120 square meters with liquefied gas from cylinders located in the street closet. The boiler is powered by 5 tanks, the sixth provides the hob. When a light frost arrived (minus 2 °C), the cylinders froze, the heater turned off due to lack of fuel. It turns out that the closet needs to be heated additionally.

- I only use propane in the evenings and on weekends, otherwise the gas runs out quickly. When I leave for work, I turn on the electric heaters. With this approach, 2 cylinders can be stretched for 7 days (the housing area is unknown - note).

- An acquaintance placed the balloon ramp in the basement, but did not install sensors or alarms. There was a leak and propane had accumulated in the lower area of the cellar. The owner, not sensing the smell, turned on the light and there was an explosion. The garage collapsed and the man suffered a concussion.

- I use liquefied gas as an additional energy carrier - the main heating runs on electricity. An LPG boiler allows you to reduce the load on the network on frosty days or sharply increase the temperature in the premises. During the heating season I make 4-6 refills.

Source - popular forum.

Conclusion. It makes sense to switch the boiler to liquefied propane-butane in two cases: when installing a gas tank and organizing temporary heating until a centralized gas supply pipe is connected to the house. Our expert will tell you more about the nuances of installing and operating fuel equipment in his video:

Installation technology and connection instructions

Installing the boiler is not difficult. Floor samples are simply installed in a designated place, and wall samples are hung on a durable surface using elastic noise-absorbing pads.

It is prohibited to hang boilers on fragile partitions made of plasterboard or other similar material.

The boiler is connected by connecting all necessary communications and power supplies. It is necessary to be careful and carefully monitor the correct connection of the pipelines.

Main attention should be paid to gas pipe connections. Using a soap solution, check for leaks

There are usually no significant problems with the connection, but representatives of service centers insist on involving their specialists in the installation. It is believed that this option allows for proper connection of equipment and eliminates the possibility of errors.

Navien boiler for heating: turning the device on and off, possible errors

The Navien wall-mounted gas boiler is an example of products manufactured by the Korean company of the same name for many years. Amateurs and specialists know its products as reliable and high-quality units that can last for many years.

This is confirmed by numerous reviews from people who have purchased and used the equipment for several decades. However, sometimes troubles occur, resulting in breakdowns of some aggregate components.

To learn how to diagnose detected malfunctions, you will need to carefully familiarize yourself with the technical characteristics of the Navien gas boilers offered by the company.

Manufacturer information

Wall-mounted gas boilers Navien

KD NAVIEN is one of the leading manufacturers of heating systems and all types of industrial electrical installations. It was founded in 1978 and since then has enjoyed well-deserved credibility among consumers.

The modern technological base and powerful economic potential of the Korean company allow us to constantly expand the range of attachments. Much attention is paid to new developments and their implementation in the technological cycle.

This approach to organizing production allows you to quickly respond to all changes in market conditions.

An active policy in the field of innovation has allowed KD NAVIEN AS to maintain a leading position in most segments of the heating equipment market for a long time.

The company has achieved particular success in improving the environmental friendliness and waste-free operation of heating installations. Significant achievements have also been noted in areas related to universal systems that allow generating both heat and electricity.

The advantages of products from this company include:

- environmental safety of manufactured products;

- automation of production processes, allowing to reduce the final price of the product;

- the presence of built-in protection against sudden changes in voltage in the network and the possibility of installing double-circuit piping;

- convenience and comfort of operating the unit.

The relative disadvantages of these products include dependence on power supply and excessive noise.

Types of wall-mounted boilers

Atmospheric gas boiler NAVIEN ATMO 24-AN

There are three types of wall-mounted heating devices of this class on the domestic market:

- Navien atmospheric (open) boiler;

- turbocharged wall models;

- condensing devices.

Each of these positions requires separate consideration.

Atmospheric gas boilers