Aluminum is interesting because it opens up wide opportunities for energy savings due to the high thermal conductivity of the metal. Aluminum radiators heat the room faster than steel radiators. This means less hot water consumption and faster response to changing room temperature requirements. Radiators of this type can reduce up to 10% of annual heating costs. The main technical characteristics of aluminum heating batteries include:

- heat transfer (power);

- working and testing pressure;

- dimensions;

- center distance;

- weight and capacity (internal volume) of one section;

- maximum permissible coolant temperature.

Center distance

Average size

This parameter characterizes the distance between the collectors (the centers of the upper and lower holes) of the device.

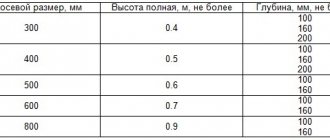

The standard provides three standard sizes according to the center distance:

- 500 mm;

- 350 mm;

- 200 mm.

But on the market you can also find non-standard radiators, the center distance of which can vary from 200 to 800 mm.

The distance between the axes of the collectors plays an important role when choosing a heating device: the overall overall size of the radiator depends on it .

Advantages and disadvantages of an aluminum heating device

Aluminum products have a number of positive qualities, which are the reason for the popularity of these products.

- Aluminum radiators weigh relatively little, which makes them easier to transport and allows you to install them yourself.

- Such batteries look attractive and can not only heat, but even decorate various rooms.

- The characteristics of the material and the well-thought-out design of the batteries result in high heat transfer. Aluminum batteries can significantly save heating costs by reducing the volume of coolant in each section.

- Such batteries quickly respond to changes in the coolant supply: they cool and cool almost instantly. This allows you to warm up the premises in a short time and increases the efficiency of thermostats, which also reduces heating costs.

- Powder coating simplifies battery maintenance and eliminates the need for periodic painting.

- There are models that can withstand high pressure.

- All this is combined with a relatively low price.

But such products also have several disadvantages that you need to know about before purchasing:

- Prefabricated devices use rubber sealing elements, which makes it impossible to use antifreeze as a coolant.

- Low protection from corrosive processes. To extend the operating period, it is necessary that the water has neutral acidity and does not contain abrasive particles that can damage the protective film.

- An accumulation of air may occur inside the heating device; to bleed it, it is necessary to equip the battery with an air vent.

- The weak point of such a battery is the threaded connections.

Yet, for the most part, the properties and features of aluminum heating devices make them ideal for heating systems.

Operating pressure

This parameter indicates at what coolant pressure the radiator can be operated.

- Two types of aluminum radiators are available:

- up to 6 atm (normal);

- up to 16 atm (reinforced).

In private houses equipped with an autonomous heating system, the average coolant pressure in the network usually does not exceed 1.4 atmospheres. In houses with central heating, this parameter is within 10 - 15 atm. But in the heating main, the operating pressure is much higher: it can reach 30 atm.

READ ALSO: Review of manufacturers of aluminum heating radiators: which models are better

Obviously, to install aluminum radiators on central heating, you should choose devices with a higher operating pressure.

Some manufacturers indicate in the passport the working pressure not in atmospheres, but in MPa. To convert mega Pascals to atmospheres, multiply the parameter by 10 (for example, 1.5 MPa corresponds to 15 atm.).

Casting

In this case, each section is made separately from silumin (an alloy of aluminum and silicon). The part of silicon in the material does not exceed 12%, which is quite enough to obtain the required strength. The casting process takes place under high pressure conditions, which allows the sections to be given any desired shape. Finished products are designed for a working pressure of 6-16 atm. To achieve free circulation of coolant inside the radiators, the water channels are expanded. Improving the strength of batteries is achieved by increasing the wall thickness.

Crimping pressure

Pressure testing of the heating system

Before the start of the heating season, the central system is checked for leaks - that is, it is pressurized. This operation consists of supplying coolant under pressure exceeding the working pressure by 1.5 - 2 times.

Standard values for crimping pressure are from 20 to 30 atm.

If the radiator is not designed for such pressure, it may fail during testing of the heating system.

If you have central heating in your house , be sure to pay attention to this parameter when purchasing a battery: according to the data sheets of many models, it is only 18 atm. Such models are only suitable for autonomous heating systems.

Strengths and weaknesses of aluminum radiators

List of positive characteristics of aluminum batteries:

- Economical.

- Small mass. The weight of an aluminum battery greatly simplifies the installation and dismantling of devices.

- Possibility of temperature adjustment.

- The highest efficiency among all household radiator heaters.

- Presentable appearance, allowing the use of aluminum radiators both in ordinary homes and prestigious institutions.

Weak sides:

- Weakness of intersectional joints (leakages sometimes occur there).

- Unevenness in heat distribution: it is mainly accumulated by the ribbed part of the sections.

- Weakness of convection circulation.

- Low service life. The same cast iron batteries last much longer than 15-20 years.

- Internal gases may form.

- Excessive chemical activity of aluminum. This is the biggest drawback of this type of battery, because of which the presence of the slightest impurities in the coolant can provoke destructive processes on the internal walls.

- Low resistance to pressure changes.

Considering all these disadvantages, the scope of application of aluminum radiators is limited to autonomous heating systems with stable low pressure and a chemically neutral coolant. As for the installation of batteries of this type in ordinary apartments, there is even a special ban on this from the relevant authorities.

Heat dissipation (thermal power)

Heat dissipation is the most important characteristic of aluminum heating radiators. This parameter determines how much area the device can heat.

Depending on the size and geometry of the fin, its thermal power can range from 85 to 150 W. But these figures are average: in the heating market, aluminum radiators with a thermal power of 180 W are no longer uncommon.

This parameter will largely determine how many battery sections need to be installed in the apartment.

Anodized radiators

High quality purified aluminum is used to make these heaters. Thanks to the use of anodic oxidation, the structure of the metal changes, after which it is practically not afraid of corrosion. To switch individual components, not traditional nipples are used, but special couplings (they are mounted outside the device). Thanks to this, the internal surfaces of the anodized radiator are very smooth, which increases the level of heat transfer compared to conventional aluminum batteries. The ability of the heaters to withstand operating pressures of up to 70 atm is also impressive. The cost of devices of this type is quite high.

Other options

Aluminum radiator in the interior of a room

Weight matters when choosing mountings for a heating device.

READ ALSO: Review of manufacturers of aluminum heating radiators: which models are better

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the size, the weight of one section can range from 1 to 1.47 kg.

The volume of water in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average capacity of one aluminum section is in the range of 250 – 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has a direct impact on the volume of coolant required to fill them.

The maximum permissible coolant temperature for aluminum radiators is standard and is 110 degrees.

Which aluminum heating radiators are better - choose a model from well-known manufacturers. A large selection of design solutions for vertical heating radiators allows them to be installed even in rooms without windows. Photos of interesting models.

Design Features

Aluminum radiators

Aluminum radiators look stylish and neat. The sections included in the battery are connected to each other by special nipples. Gaskets installed between the sections provide the necessary tightness. On the inside of the heater there is a system of aluminum fins, which allows for a significant heat transfer area.

Aluminum radiators can be manufactured in two ways, one of which is extrusion. This method allows you to obtain light and very cheap heating devices, which, unfortunately, are not of high quality. Radiators based on aluminum, manufactured by casting. will cost slightly more, but they can provide a longer service life in comparison with their cheap extrusion counterparts.

Bimetallic radiators

The name of these heating devices indicates that bimetallic radiators are made using two different metals. The ribbed battery case is based on an aluminum alloy that can provide high heat dissipation. Inside the bimetallic battery there is a tubular core through which the coolant moves. Core tubes can be made of steel or copper. The internal diameter of the channels through which hot water flows in bimetallic heating devices is smaller than in aluminum radiators, so the likelihood of clogging the channels is higher.

Table with characteristics of some models

| Specifications | GREEN HP 350 (Faral, Italy) | Alux 200 (ROVALL, Italy) | Alum 350 (Rifar, Russia) |

| Distance between axles, mm | 350 | 200 | 350 |

| Working pressure, bar | 16 | 20 | 20 |

| Power (coolant temperature - 70 degrees), W | 136 | 92 | 139 |

| Section capacity, l | 0,26 | 0,11 | 0,19 |

| Weight, kg | 1,12 | 0,83 | 1,2 |

| Dimensions (H/W/D), mm | 430/80/80 | 245/80/100 | 415/80/90 |

The data presented in the table is taken from official sources of manufacturers.

Review of basic diagrams for connecting heating batteries, tips for self-installation. How to calculate the gas consumption of a gas boiler in order to understand how much it will cost to heat your home for the entire heating season. Find out right now!