Solid fuel boilers of the new type are significantly different from their previous counterparts. They have a modernized control system, which simplifies the operation of the unit, additional functionality, and an increased number of options.

From an ergonomic point of view, setting the required operating parameters is quite beneficial: you perform the action once, and there is no need to periodically adjust it.

The cost of a solid fuel boiler is influenced not only by the availability of high-quality components, but by an improved version of the control unit: the more expensive, the more modern the automation.

The automatic control system is aimed at automating control over the combustion process in a heat generator of this type.

The control unit and fan serve to implement the following tasks:

- maintain the specified temperature of the coolant in the system.

- Provides high efficiency.

- Helps improve efficiency levels.

- They work regardless of fuel quality.

Thanks to equipping the boiler with an automatic system, it became possible to regulate the temperature and increase the burning time of one load by 25-35%.

Principle of operation

Operating principle of a solid fuel boiler

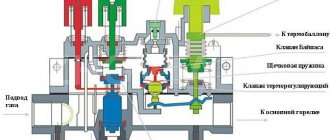

If in older models of solid fuel units, to regulate the air supply, it was necessary to open or close the ash door manually, and monitor the temperature visually using a thermometer, then in new boilers an automatic draft regulator is installed. This device is energy-dependent; its functions include opening and closing the ash pan damper depending on the temperature of the water in the container.

Taking into account the inaccuracy of the settings and the dependence of the operation of the unit on natural draft in the chimney, instead of an ineffective thermostat, a fan was installed to supply the required volume of air to the combustion chamber. And the operation of the fan is ensured by a controller that receives information about the state of the coolant from the sensor.

The controller consists of a screen and a control panel, designed to set the required coolant temperature. Models that do not have such a kit can be equipped with it; the fan is installed on the mounting plate, but you must first disconnect the ash door.

The coolant temperature is adjusted regardless of external conditions.

To maintain the temperature in the room taking into account street conditions, you can install an additional automatic system with an expanded range of capabilities: remote temperature controllers, outdoor air sensor.

Both wired and wireless methods are suitable for connecting them. Thanks to the information received from the sensors, the selected temperature regime in the house is maintained. This is the most rational method.

Safety valve

Modern automatic models have an ignition system, flame control, and continuous fuel supply. For ignition, an electric incandescent element is provided, which turns on after the pellet screw container is fed into the burner.

A stable flame, recorded by a photosensor in the form of a pulse transmitted to the controller, is a signal to turn off the electric ignition. During operation, granules are fed into the auger from a bunker, the volume of which is capable of providing heat to the room for several days, without human intervention.

Solid fuel units with an automatic control system, in addition to the above devices, are also equipped with safety devices, in particular, a safety valve.

It is necessary to discharge water from the boiler tank in case of overheating, to stabilize pressure, and also provides reliable protection of the casing from destruction. The boiler can be equipped with an overheating sensor, which signals if the temperature is exceeded at the initial stage.

So, boilers can be equipped with:

- Traction control sensor.

- Water level sensors in the jacket.

- Fan - smoke exhauster.

- Pressure recorders.

- Circulation pump.

- Fuel and water consumption sensor for domestic hot water.

- Sensors for the level of pellets or coal in the container.

All these devices are interconnected with a controller that performs control and signals emergency situations. The most sophisticated devices have a remote control function, where you can control automation via the Internet and mobile applications.

Chimney for solid fuel installation

Speaking about the dependence of the operation of a solid fuel boiler on draft, one cannot help but touch upon the topic of arranging a chimney, thanks to which the combustion products are released into the atmosphere in a timely manner. Modern boiler units with a closed combustion chamber are equipped with a coaxial smoke exhaust, which has many advantages and does not require it to be installed above the roof. Most models of boiler equipment with an open combustion chamber require a stationary chimney, which must be in accordance with fire safety rules and have the necessary design to ensure unhindered removal of combustion products.

https://www.youtube.com/watch?v=ZUXWDzWeXk4 The following materials are used to construct the chimney:

- Brick. Traditional brick pipes do their job quite well, but they are heavy, have a complex masonry pattern and require a solid foundation.

- Stainless steel sandwiches. An excellent design, which consists of sections of double pipes, between which there is insulation. This material allows you to do without a foundation and can be assembled by one person, like a constructor. But this design also has a disadvantage - high cost.

- A ceramic chimney is an excellent alternative to steel sandwiches. It is easy to assemble, has good fire resistance and a perfectly smooth inner surface, and can withstand temperatures up to 900°C.

It’s easy to install a ceramic chimney for a solid fuel boiler with your own hands, because it is assembled from chimney blocks, like a children’s construction set. A ceramic pipe insulated with mineral wool is inserted into the assembled chimney.

Advice: when choosing a chimney for a solid fuel boiler, be guided by the installation data sheet, which gives the recommended cross-section of the smoke exhaust channel. In addition, when choosing, focus on the temperature and pressure of the exhaust gases when operating in natural draft and boost modes. Don't forget about condensate drains and collectors!

Features, Pros and Cons

The main functions of the automatic control unit include:

- Dosed supply of combustion air.

- Control over the performance of the heat generator.

- Indirect regulation of thermal power depending on the temperature of the coolant.

- Direct control of power relative to the air temperature in the house or weather conditions.

- Ensuring the operation of the water heating installation in a safe mode.

- Automatic fuel supply.

- Ignition and extinguishing of the furnace of the unit.

Positive aspects of using automation:

- indicator has increased .

- There is no need to constantly monitor the combustion process.

- Economical fuel consumption.

- Maintaining a constant temperature in the heating system.

- during operation of the unit increases

- The interval between scheduled inspections is increasing.

- If a part fails , special sensors send a signal to the control unit, and the heating system automatically turns off (stops its operation).

Flaws:

- High price. The presence of additional options for automation significantly affects the price of the device.

- Considering the volatility of the control unit , there is a need to purchase an uninterruptible power supply, or you can use a mechanical traction regulator.

Connecting the chronothermostat

A special case of using automation in the form of a normally open contact thermostat is the use of a chronothermostat. On the thermostat itself, time periods are set and two or three heating levels are set: the lowering temperature is “night” and the temperature is “day”. But in any case, the coolant temperature will be the one set from the control panel.

+ The boiler heating differential is set based on the user's needs.

— The temperature set from the control panel is adjusted manually.

Types and selection criteria

The automatic control unit is available in both mechanical and electronic versions.

Advantages of a mechanical control system:

- Does not require connection to an electrical outlet.

- Convenience and ease of use.

- Regarding electronic automation , its price is several times lower.

- It is reliable.

- There is no need to call a specialist for installation.

Mechanical automation ensures both the opening and closing of the air duct into the combustion chamber, which affects the rate of combustion of the coolant, its burnout, and the presence of heat in this compartment.

The electronic type of automation is the most efficient, but is a volatile device.

When choosing automation for a heating system, it is recommended to familiarize yourself with its parameters:

- Thermal operating mode.

- The required degree of adjustment of the temperature regime of the coolant.

- Real economic effect.

- Compatibility of the device and the specific boiler model.

Which automation is better?

Today, the boiler equipment market is oversaturated with proposals for boiler automation coming from both imported and domestic manufacturers.

The first ones are very expensive and capricious, they do not tolerate the operating conditions of Russian engineering networks, the second ones are less functional. The best automation for a boiler is always its own, that is, produced in a single configuration by the manufacturer.

It is there at the stands that it receives the correct settings with the operating modes of the unit. An equally important factor in boiler room automation is the manufacturer’s warranty, which must guarantee its operation free of charge for at least a year and replace the unit if it fails.

German

German automation for boilers Vaillant, Honeywell, AEG, Bosch is quite popular on the Russian market, which is explained by its excellent consumer quality, durability and reliability. High level of automation and protection. Recently, German manufacturers have established automation of condensing boilers, ensuring efficiency. almost 100%.

Italian automatics

EuroSIT 630 is considered the best Italian automatic system for gas boilers in the world. It is produced in full compliance with EU standards, but at the same time has a lower price than German systems.

The EuroSIT 630 boiler automation covers all parameters of the boiler operation, but is very sensitive to the operating parameters of the gas line and electrical network. For this system, it is mandatory to install input voltage stabilizers.

Russian

Recently, more and more boilers are being purchased with Russian automation systems, since they provide a good protection system and reliable boiler control at the lowest prices.

The experience gained with automation of processes in industrial boiler houses has been successfully integrated into the operation of household boilers using the latest technologies and developments from European manufacturers. Among the large number of Russian companies, especially the most popular are Neva-Transit and Lemax.

Installation and configuration

The installation process of an automatic control system includes:

- Connection of the blower fan. As a rule, the turbine is located on the lowest door of the boiler, where the damper is located. But there are models of units where it is installed on the side wall, or in a special place on the top of the boiler, it all depends on the design features. Everything is simple here: the damper is removed, and a fan is put in its place; four bolts are used for fastening. If there are no holes for mounting, they need to be drilled. For fans with a damper, installation is carried out in such a way that the damper is closed when the fan is off.

- Installation of the controller. First of all, you need to decide on the place where the device will be installed. The main requirement is that it should not heat up. On models without a hob, the automation is mounted on top. If the design of the unit allows, you can install the unit on the side wall. Don't forget about the length of the cables.

- Connecting the temperature sensor. A correctly installed temperature sensor will ensure the normal functioning of the entire control unit. If the model does not have a special place for the sensor (hole parameters: diameter 10 mm, depth 60 mm), then it can be mounted on the output metal pipe. A clamp is used as a fastening material; it can be supplied with the device.

- Connecting connectors. To do this, you need to connect the turbine connector to the control unit connector. Finally, you need to connect the device’s network cable. The automation is ready to perform its functions.

Types of boiler automation systems

Boiler automation is available in 2 types:

- Volatile, which operates only from the mains.

- Non-volatile, capable of operating in autonomous mode without supplying voltage to its actuators.

Advanced energy-dependent systems have the widest range of functions, from the boiler safety system to weather-dependent control, using the latest technological solutions and integration into the Smart Home system.

Non-volatile automation is more simplified and does not have a developed control system; it is used in places with an unstable power supply, as well as on coal-fired units. The main parameters that such a system controls are: water overheating, vacuum level in the firebox and the presence of a torch in the firebox.

Price and reviews

The cost of an automated system is influenced by the technical indicators and functionality of the device. Thus, the price of the simplest mechanical model varies within 1.5 thousand rubles.

The price range of more progressive options is from 25,000 rubles to 100,000 rubles. The more expensive the model, the higher the ergonomics of the heating system will be, and the resource consumption will be correspondingly lower. Therefore, it is more advisable to give preference to more expensive options.

Reviews:

Nikolai Viktorovich. “The control unit from the Krypton company is one of the best devices today. It is distinguished by the quality of its components; the kit includes a sensor, cords for connecting to the fan and pump, a clamp, and adapters. A reliable device from a Polish manufacturer.”

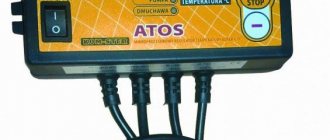

Fedor. “On the recommendation of a friend, I installed the ATOS automatic, its performance characteristics are excellent.”

Anatoly Yurievich. “The Proton automation surprised me with the presence of additional components in the package (a clamp for attaching the sensor, a stand for the unit, self-tapping screws). The device is efficient, reliable and easy to use. ”

Features of electric boilers

A special feature of the electric boiler is a heat exchanger with a heating element for heating water. A pump is used to organize forced circulation. There is an inlet for cold and an outlet for hot coolant.

Design

The operating mechanism of the heating unit is simple. Cold water is supplied to the heat exchanger. The heating element is heated by electric current. Thanks to the circulation pump, the liquid is distributed into the heating radiators.

DIY making

The thermostat, as an automatic device for regulating the operation of the heating system, can be purchased at the electrical goods retail chain.

At the back of this device there is a heat removal plate; it will need to be pressed against the exposed part of the unit. The thermostat has three contacts inside: common, normally open and normally closed. By rotating the adjusting knob, you can change the positions of the contacts.

So you need to set the handle to the minimum mark and connect to the open contacts:

- to the general one .

- We connect one wire from the turbine to the open one

- to the second wire from the turbine .

An automated control system is rightfully considered not only convenient, but also an effective device. With its help, you can significantly simplify the process of operating the heating system.

Connecting an analogue modulating controller

Another possibility for operating boilers is to use, together with the boiler, not a disconnecting thermostat, but an analogue smooth-action regulator. This allows you to control not only the room temperature, but also adjust the burner power due to feedback. Communication with the gas boiler automation is carried out via a wired or wireless line. It becomes possible to track various parameters that depend on a specific model.

Since this will already be an electronic device, it often immediately becomes possible to control the chronoprofile, that is, heating periods and waiting periods for the boiler are set. You can set several different temperature levels.

What in the end...

Automation for a solid fuel boiler is a set of devices for adjusting and controlling the entire heating system. These include traction control sensors, pellet or coal level sensors in the tank, pressure recorders, water level sensors in the jacket, a circular pump, a remote control system, photo sensors, temperature sensors and others. It is not difficult to make the simplest automation for a solid fuel boiler; for this you will need to buy and connect a thermostat to the boiler.

Question

Write in the comments whether you think the price for the most modern models of solid fuel boilers is justified?

Automation of cascade boiler houses

The role of automation in such boiler houses is enormous to ensure their reliable and efficient operation. It is she who is responsible for obtaining the greatest efficiency from the units operating in a cascade, while ensuring the sensitivity of the boilers to consumer demands.

In these systems, cascade logic is integrated into the basic automatic circuit and configured for a specific fleet of boiler equipment. Basic functions of automation of cascade heat supply schemes:

- Collecting user data for thermal energy production and finding priority between load types.

- Calculation of the rational mode of operation of each individual unit to guarantee the requested power.

- Guarantee of uniform distribution of thermal conditions of boilers.

- Monitoring the performance of equipment, diagnosing emergency situations and signaling them.

A similar regulatory policy is used in a modern cascade boiler house. In this case, each single device must operate at a minimum modulation that guarantees the thermal load.

Only under such conditions is it possible to obtain high efficiency of a cascade installation with uniform use of the operating life of the boiler units.

Minimum pressure switch (gas) ↑

Honeywell brand gas valve for low-power boiler equipment

Gas burners are designed to be used at rated gas pressure - that's what they are designed for. It is with these indicators that the declared useful power of the boiler will be ensured. With a decrease in gas pressure, a drop in power is also observed. Boilers equipped with atmospheric gas burners are sensitive to a decrease in gas pressure - the pipes may burn out. The falling gas pressure leads to the “settling” of the flame so that the metal part of the burner appears in the zone of the torch itself. And this can lead to breakdowns.

To protect the boiler and burner, a minimum gas pressure switch is used. The relay turns off the boiler when the pressure drops below the set value. The limit value can be changed when setting up the boiler. The gas pressure switch is structurally a kind of membrane that acts on a group of contacts. When the pressure decreases, the membrane moves under the influence of a spring and the electrical contacts switch. Switching the contacts breaks the electrical circuit, which precisely controls the operation of the boiler. The power supply to the gas valve stops and the boiler stops working. When the gas pressure is restored, the membrane will return to its original position, the contacts will switch again - and the boiler will be ready to start again. But other processes are subsequently determined by the logic of the actual control automation, and they may vary. Minimum pressure switches are mounted at the gas inlet into the boiler directly in front of the multiblock. Or in front of the front gas valve.

Dungs brand gas valve for floor-standing heating boilers