For residents of the private sector, issues related to the operation of an autonomous heating system are not particularly difficult. At first glance, everything is very simple. There is a boiler, there is fuel for it, so you just need to put wood in the firebox and set it on fire. It may work, but most often in such situations you will have to simultaneously solve several problems at once, each of which threatens to negatively affect the quality of heating. The many years of practical experience that old-timers have will tell you how to properly heat, how to fill a solid fuel boiler with wood correctly in order to achieve a better combustion effect.

Let's try to figure it out ourselves. How to heat heating units using solid fuel from a scientific and technical point of view, how important it is for the operation of the boiler to be used to heat it and how it is fired.

Main article: heating a house with wood.

Fuel

What is the advantage of a solid fuel boiler? Such a boiler can be heated not only with wood, but also with fuel briquettes (pressed sawdust, bark, shavings, peat), fuel pellets and coal.

Since firewood is the most common and cheapest type of fuel, owners of private houses and cottages often prefer it. When choosing firewood, you should take into account the calorie content of the wood species. The higher the calorie content, the less firewood will be needed to warm the room to the desired temperature.

Recycling construction wasteCeramic chimney: advantages of use

- Dry stream: perfect for any garden style

High demands are placed on the physical condition of firewood. First of all, they must have low humidity, since damp wood not only burns poorly and slowly, but also reduces the life of the boiler, which is not operating at full capacity. A room heated with raw wood warms up slowly and cools down quickly.

Features of the operation of modern solid fuel boilers

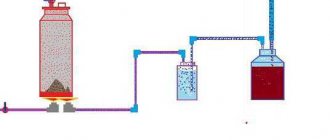

Solid fuel boilers of the modern generation are equipped with a pressurization system and an automatic control unit. Electronics controls the temperature of the coolant using a sensor installed in the heat exchanger. Depending on the temperature conditions, the automation gives commands to turn on and off the blower, which supplies air to the combustion chamber and facilitates the effective removal of combustion products through the chimney. This regulates the intensity of the fuel combustion process depending on the temperature of the coolant.

Thus, the user takes the minimum necessary participation in the operation of the equipment. His concern about how to fire a TT boiler comes down to adding fuel at a certain frequency. After this, the boiler switches to intensive combustion mode. As the temperature rises, the combustion intensity weakens, and when the temperature reaches its maximum, the boiler goes into smoldering mode. After the coolant temperature drops below the set value, the boost is turned on again.

Timely loading of fuel into the TT boiler is the main task of the user, which cannot be automated. The number and frequency of fillings is determined based on the boiler power and the required temperature conditions. If you miss the start date, the boiler will only be able to operate in smoldering mode for a limited time, after which it stops.

It is of great importance how to heat a solid fuel boiler. Today the following types of fuel can be used for this purpose:

- firewood;

- coal;

- fuel briquettes;

- pellets.

To achieve maximum efficiency, you need to know how to effectively heat a solid fuel boiler with different types of fuel.

Heating a country house

If you use firewood as fuel, you should carefully study the operating features of a solid fuel boiler kazancompressor.ru. Maximum efficiency is achieved only with proper placement of logs.

There are a number of developments where combustible raw materials are supplied to the core automatically. But the popularity of such devices is quite low, since they cost significantly more than conventional models. TT boilers, where firewood is supplied manually, are more accessible and easier to use. This type of technology can be divided into three categories:

- Long burning boilers;

- Pyrolysis;

- Classic.

Features of briquette firing

Now let’s take a closer look at how to properly heat a solid fuel boiler with briquettes. Kindling is performed using the same method as when using coal. It is important to consider what kind of briquettes you burn with. When using “Euro firewood”, kindling is done with wood chips and special small briquettes for ignition. If they are missing, then you can simply grind ordinary briquettes. If peat briquettes are used, kindling is done with wood chips and small firewood.

The first placement of briquettes is carried out after the formation of a stable flame and sufficient heating of the boiler. Wood briquettes (“Euro firewood”) are first laid in a layer of 10-15 cm. When it flares up well enough, a layer of briquettes 15-20 cm thick is laid. The first layer of peat briquettes should be smaller - about 5-6 cm. In the future, they are also laid in thickness 15-20 cm. The blower must be closed with each new addition of fuel. It is opened only after loading of briquettes has been completed and the combustion door has been locked. In this case, you need to install the blower in the correct position to create optimal traction.

During the combustion process, it may be necessary to stir the briquettes in the firebox. You should not do this too often, so as not to cool the firebox. Mixing must be done carefully, avoiding sudden movements, to prevent briquette dust from rising into the air and entering the room.

It is important to decide which briquettes are best to heat a solid fuel boiler. “Eurofirewood” is made from plant materials. The basis of these briquettes is dry sawdust. They may also contain husks of cereals and seeds. This type of fuel differs little in its properties from ordinary firewood, but it provides higher efficiency and burns out more slowly. During combustion, a large amount of soot is not formed. These features make wood briquettes the best option for heating a home or bathhouse.

When burning, peat briquettes emit a lot of ash, which leads to rapid contamination of the grate and ash pan, and also pollutes the room in which the boiler is installed. Therefore, this type of solid fuel is not recommended for use for heating residential buildings. The advantage of fuel briquettes is their lower price. In addition, they burn out more slowly than wood ones.

Pyrolysis boiler

Connoisseurs of high technology may be interested in pyrolysis boilers, the cost of which, although higher than usual, is not comparable in productivity to traditional systems. The owner of such a boiler saves significant amounts on firewood, since the process includes the stage of burning gas released from solid fuel. With one stack of firewood, such a boiler can operate for more than a day.

To properly heat a pyrolysis boiler, you should put a portion of wood chips and a large piece of dry paper into the scorching door, and firewood and a small amount of coal on top into the loading door. You should light a piece of paper, from which the combustion process will spread further. The door can be closed as soon as the wood chips ignite.

conclusions

There is nothing complicated about how to heat autonomous solid fuel heating boilers with wood. The design of most products is simple and straightforward. Having certain skills and following safety measures will allow you to operate a solid fuel boiler in normal mode.

Firewood in the firebox can be stacked in different ways, in a row and in the form of a well. Such layout methods are usually used in traditional boilers, fireplaces and conventional stoves. For pyrolysis boilers and long-burning units, the stacking of firewood must be done as tightly as possible so that there are no air gaps between the logs. A working boiler must burn almost all the fuel contained in it.

Before lighting a fire in the firebox, check for draft. If your match or paper flares up with a white flame, there is excessive draft in the chimney. If, on the contrary, the flame turns red, the draft is insufficient. The most optimal option for working draft, when the flame has a yellow tint. All nuances and subtleties should be taken into account when working with wood-burning boilers. Not only your comfort and coziness, but also the duration of uninterrupted operation of the heating device depends on how you handle heating equipment.

Long burning boiler

Maintenance of such equipment does not take much time: loading of fuel components is carried out once every 6 hours:

- Fill the fuel chamber completely with firewood;

- Use kindling from wood chips and a piece of paper;

- When the wood chips ignite, you can close the door and turn on the control unit.

A heavy press is placed on top of the firewood to prevent strong burning.

Principles of kindling

Understand what fuel supply scheme is used and what the operating principle of the boiler is in general. The installation usually has 2 doors - lacing and loading. Wood chips and paper are loaded into the lacing box, and firewood is placed in the second. Then they close the door.

In many ways, the quality of operation of the installation will depend on the serviceability of the chimney system. Make sure it is warmed up and cleaned.

Hot water boiler maintenance

Check the tightness of the boiler lining once a week.

At least once a shift, check the operation of the safety valve by manually lifting the levers until water appears from the flow line.

When stopping the boiler at the end of the season, you should drain the water from the boiler, rinse, clean the boiler of dirt and scale, the flues of ash and soot, then fill the boiler and system with water, removing remaining air through the air valve. Completely clearing the combustion chamber, rotary box and grate from slag and ash.

The water heating boiler must be subject to technical inspection by the administration before being put into operation, periodically during operation (according to the established deadlines) and, if necessary, ahead of schedule.

Technical inspection of boilers must be carried out by a person responsible for the good condition and safe operation of the boiler.

External and internal inspections are aimed at:

- during the initial inspection, establish that the boiler was manufactured, installed and equipped in accordance with the “Rules for the design and safe operation of steam boilers with a steam pressure of not more than 0.07 MPa (0.7 kgf/cm2), water heating boilers and water heaters with a water heating temperature not above 388 K (115 °C)” approved by the Ministry of Construction of Russia on August 28, 1992 and the documents submitted during registration, and also that it and its elements are in good condition;

- during periodic and extraordinary inspections, establish the serviceability of the boiler and its elements and the reliability of its further safe operation.

- During external and internal inspections of the boiler and its elements, attention should be paid to identifying possible cracks, tears, bulges, bulges and corrosion on the internal and external surfaces of the walls, violations of the density and strength of welded joints, as well as damage to the lining, which can cause overheating of the metal elements boiler

Hydraulic testing of boilers is aimed at checking the strength of the boiler elements and the tightness of their connections and is carried out in the manner established by paragraphs. 3.16 and 3.17 “Rules for the design and safe operation of steam boilers with a steam pressure of no more than 0.07 MPa (0.7 kgf/cm2), hot water boilers and water heaters with a water heating temperature not higher than 388 K (115 °C)” approved by the Ministry of Construction of Russia 08/28/92

The administration is obliged to carry out inspections of boilers within the following periods:

- external and internal inspections - after each cleaning of internal surfaces or repair of boiler elements, but not less than after 12 months;

- hydraulic test with working pressure - every time after cleaning internal surfaces or repairing boiler elements;

- hydraulic test with test pressure - at least once every two years.

Early (extraordinary) technical inspection of the boiler must be carried out in cases where:

- the boiler was inactive for more than a year;

- the boiler was dismantled and installed in another place;

- bulges or dents were straightened, as well as repairs using welding of the main elements of the boiler;

- more than 50% of the total number of screen pipes were replaced at the same time;

such inspection is necessary at the discretion of the person responsible for the good condition and safe operation of the boiler.

Before hydraulic testing, external and internal inspections must be carried out.

Before internal inspection and hydraulic testing, the boiler must be cooled and thoroughly cleaned of scale, soot and ash. If there is any doubt about the good condition of the walls or seams, the person responsible for the safe operation of hot water boilers must open the lining or remove the insulation in whole or in part.

If during the technical examination of the boiler no defects are found that reduce its strength, operation of the water heating boiler is allowed under operating parameters.

If, during a technical examination of the boiler, it turns out that it has defects that cast doubt on its strength, further operation of such a boiler should be prohibited until these defects are eliminated.

The results of the inspection and the conclusion on the possibility of operating the boiler, indicating the permitted parameters (pressure, temperature) and the timing of the next inspection, must be recorded in the boiler passport by the person performing the inspection.

During an early inspection of the boiler, the reason that necessitated such an inspection is indicated.

Technical inspection of the boiler consists of external, internal inspections and hydraulic testing.

How to heat a solid fuel boiler as efficiently as possible?

Firewood, coal, briquettes or pellets are used to fire a solid fuel boiler. Depending on the specific model of the unit, the highest efficiency of the heating system can be achieved by using a certain type of fuel. Also, the efficiency of the boiler is directly affected by the quality of the combustible material and the method of its placement. A competent answer to the question “How to properly heat a solid fuel boiler?” will save a significant amount of money on the purchase of fuel, and at the same time will have a positive effect on the ease of operation of the heating unit.

What is the best way to heat a boiler?

The optimal fuel for a boiler is the type for which it was originally designed based on its design. Thus, solid fuel (SF) long-burning units are focused on the use of coal as the main fuel. Conventional cast iron boilers such as Buderus, KChM-5, Viadrus or Prometheus can equally successfully process briquettes, pellets or firewood, as well as coal.

Many nuances arise when considering the convenience of the combustion process itself. The most important question in this matter is how often should you add fuel to the boiler? And here, in addition to restrictions on the volume of the firebox of a particular model, you should focus on the combustion rate of a certain combustible material. Let us consider from this point of view the four most common types of fuel.

- Dry wood burns out faster. There are even a number of techniques for them that allow you to prolong the combustion process of this material in the firebox. These techniques will be discussed in more detail later, but they make it possible to increase the intervals between approaches to the boiler by only a few tens of percent. A much more noticeable increase in the duration of fuel combustion is provided by the use of sawdust briquettes or “Eurowood”.

- Eurofirewood is dried sawdust compressed into small briquettes. They burn 1.5-2 times longer than dry wood. Peat briquettes are also produced in a similar way, which show higher heat transfer. But here it is important to consider that peat-based fuel contains a significant amount of ash, comparable to coal. Therefore, the use of peat briquettes is only appropriate for water heating boilers with grates.

- Coal takes longer to burn than other combustible materials. Some automatic coal boilers, so-called “coal automatics,” allow you to maintain a stable temperature in the house even in severe frosts for up to two days. This effect can only be achieved by using high-quality coal - anthracite, as well as installing an additional heat accumulator.

- As for pellets, by burning them you can achieve the highest efficiency of the heating system. However, this type of fuel is also the most expensive combustible material. Even the highest quality anthracite coal will ultimately cost 10-15% less than heating with good pellets. Good pellets burn much longer than sawdust briquettes and are only slightly inferior to coal.

Wood burning technology

First you need to light the boiler.

In order for the process of active combustion of firewood to start in the firebox, you need to put a small amount of wood chips about 5 cm thick at the very bottom. Thicker firewood is laid out on them - up to 15 cm in diameter in an amount of 3-4 pieces. The space between the wood chips can be filled with paper if there are no long matches available and the wood does not light up immediately. When the preparatory fire is lit, you can begin filling the firebox with large logs. If there is a need to save firewood and you need to get the maximum amount of heat from each log, then you should add them every 30-40 minutes. 1-2 large logs are thrown into the firebox, which leads to the most efficient combustion of wood.

An ordinary household TT boiler is capable of maintaining active combustion of wood for 3-4 hours. This is achieved by completely filling the firebox with large logs on top of burning wood chips laid out in the manner described above.

If we are talking about long-burning boilers, such as Stropuva or Bubafonya, then small firewood is not suitable for them. The use of logs of small diameter causes a decrease in the efficiency of such structures. During the combustion process in such units, small firewood produces a large amount of gases, and the combustion of wood does not occur completely.

Stropuva type boilers are ignited using small chips. And laying the firebox requires the use of logs with a diameter ranging from 15 to 30 cm. It is not recommended to lay larger firewood, since operating the boiler at low power will lead to a decrease in the efficiency of the unit. The temperature in the furnace will not be enough to burn pyro-gases, which may cause the flame to completely extinguish.

As for the choice of firewood, solid fuel boilers are very sensitive to the degree of moisture in the wood. This figure should not exceed 20%. If more humid fuel is used, the boiler's operating efficiency decreases. There is a way to extend the burning time of the boiler by adding raw firewood, but the use of this method causes active formation of tar inside the boiler and chimney. Cleaning the heating unit after such experiments will require a lot of time and effort.

The optimal moisture content of firewood is achieved by drying fresh logs under a canopy for 1.5-2 years. Wetter wood does not burn longer, it just takes longer to flare up and during the combustion process it produces a large amount of smoke, soot and tar. You can increase the duration of fuel combustion by choosing the optimal position of the thermostat and slide valve. For different boiler models, these provisions will be different and are determined exclusively experimentally.

Instructions for putting coal into the boiler

Primary kindling is carried out by igniting a small amount of wood chips. To do this, small chips, about 5 cm thick, are laid out on paper, and 3-4 small logs with a diameter of 10-15 cm are placed on top of them. The paper is set on fire and the fire door is closed. The blower needs to be opened enough so that there is enough draft to flare up. If there is a gate valve, it only needs to be opened a little during the kindling process. If there is an air supply regulator, it is set to 70-80 °C.

After 15-20 minutes of active burning of wood in the firebox, the boiler and chimney warm up enough to allow coal to be thrown in. At this point, the slide valve can be fully opened, and the thermostat can be set to a lower temperature. The process of lining the coal begins with closing the ash pit. Only after this can you open the firebox door and first add a small portion of coal in a layer of 5-6 cm. When the first batch burns out, you can add the next portion, adding up to 15-20 cm of fuel.

Each subsequent addition of coal is carried out according to the same scheme as the last addition. The ash pan closes, after which you can open the combustion door and add the required amount of fuel.

If the coal contains a certain amount of dust and fine particles up to 5 cm, then it needs to be wetted. Adding water to fuel occurs at the rate of 1 liter per bucket of coal. This technique allows you to avoid small particles spilling into the ash pan and clogging the grate. The only type of coal that does not require wetting is coarse anthracite of 60 mm or more. Moistening it is simply useless, since its effectiveness is approximately the same as using wet firewood. The only exception is the need to protect the boiler from overheating.

How to heat with briquettes?

Briquettes or “eurofirewood” are made from dried sawdust, seed and cereal husks, and also based on peat. The technology for firing a boiler with this material is similar to the technique for firing coal. First you need to warm up the firebox with a small amount of briquettes or wood chips. Large briquettes are not used for kindling. Either special small briquettes are taken for ignition, or standard briquettes are crushed.

Briquettes or wood chips mixed with paper are placed on the bottom of the firebox and set on fire. After the formation of a stable flame, the first batch of briquettes is laid out on top of the kindling layer in a layer of 10-15 cm. Then, when this portion flares up, you can add the next one, already 15-20 cm high. Each new cast is accompanied by preliminary locking of the ash pit. After adding the required number of briquettes, the firebox door closes, and the ash pan opens and is installed in the desired position.

It is advisable not to stir the briquettes in the firebox very often to prevent the firebox from cooling. During the rustling process, briquette dust will tend to rise into the air and may enter the room. This should not be allowed, because the process of mixing the fuel is carried out extremely carefully and without sudden movements.

Firing with peat briquettes

Peat briquettes are not recommended for use in private homes, bathhouses or other residential premises. The fact is that this material, when burned, forms a large amount of ash, which causes rapid clogging of the ash pan and grate. In addition, this feature makes peat briquettes approximately comparable to coal in terms of the amount of dirt and dust that is formed in the boiler room.

However, peat also has its advantages - these briquettes burn longer than wood briquettes, and their cost is noticeably lower. The process of firing the boiler will be similar to technology using coal. Before throwing briquettes, the firebox and chimney are heated with a small amount of small firewood. After that, the first batch is placed in the combustion chamber in a layer of 5-6 cm. When the fuel flares up, the second batch is added - 15-20 cm.

How to extend the operation of the boiler from one load?

The efficiency of the boiler depends not only on the quality of the firewood and the correct use of the boiler. The cleanliness of the heating unit is also of great importance. Its design is designed to ensure the highest combustion efficiency. If soot or soot accumulates inside some channels or other structural elements of the boiler, its efficiency begins to decrease noticeably.

In addition to the cleanliness of the boiler itself, the efficiency of its operation depends on the operating mode. We are talking about the load level at which the unit operates. The fact is that maximum performance is only possible when the boiler is operating at full capacity. But this also leads to rapid combustion of fuel, which requires constant refilling.

To avoid the need to visit the boiler room too often, a heat accumulator (TA) should be installed in the heating system. This device allows you to accumulate the heat produced by the boiler. As a result, in a short period of time the boiler heats not only the radiators inside the heating system, but also the water supply of the heat accumulator. This will heat the water in the system for several hours after the fuel in the boiler has completely burned out.

Proper combustion of a TT boiler always requires the unit to operate at full power. Regardless of the type of fuel used, its efficient combustion is only possible if the boiler is operated correctly. The use of the techniques described above for working with coal, firewood and briquettes will ensure high-quality gradual heating of the combustion chamber and chimney. A well-heated boiler operating at peak power in conjunction with a heat accumulator will show the highest efficiency and will significantly reduce fuel consumption during the heating season.

KUBAN 20L

- The presence of a steam gun effect

- No cooking surface

- The oven is designed for a steam room with a volume of up to 20 cubic meters.

- Works in wet steaming mode, Russian bath effect

- The firebox is made of stainless steel

- Steam is achieved by stones + steam gun

- Remote type fuel channel

- Has an additional function - water heating

- The Kuban sauna stove is equipped with a blind door

- Purpose of the device – household

- Loading stones up to 40kg

- Operational service life up to 10 years

- Possibility to use firewood and briquettes

- The chimney of the sauna stove has a diameter of 115 mm

- Oven parameters – 865x500x700

- Weighs 49kg

- Provides a two-year warranty

- The manufacturer is Teplodar

- Price from 22000 rubles

Tips for more efficient heating

If before refueling the boiler has recently been operating, and the chimney has excellent draft and has not yet lost its high temperature, it is enough to close the doors and, after turning on the control, record the desired temperature. After some time, you can remove the control unit and check whether the previously added part of the coal has ignited. If so, then it’s time to add additional combustion material. In this case, there is no need to close the slots in the front part of the grille.

Rice. 2 Automatic coal boiler

If the chimney is not preheated, after setting the paper on fire, the bottom door of the ash pan must be opened. Next, without turning on the fan, it is important to give the device some time to warm up using natural draft. After the combustion intensifies, its thrust will increase significantly; noticing this, you can close the door tightly and activate the control unit by turning it on.

When the chimney has not been used for a very long time, or it is new, it is worth warming it up well before lighting it. To do this, it is enough to set fire to the paper while inspecting the chimney until the draft in the boiler increases.

Energy options

You can heat solid fuel boilers:

- Coal is an economical and practical option, the price is cheap, there will be a lot of heat, and the burning will be long. The downside of coal is that after its combustion, dark traces remain; over time, they become embedded in the surface and virtually cannot be removed. Environmental friendliness is below average.

- Firewood is a cheap option, which also has many disadvantages. Observe the storage conditions for logs, otherwise they will become damp and spoiled, and this will negatively affect combustion. Wood burns out quickly too.

- Briquettes - or Euro-firewood, that is, pressed wood shavings. The solution is not the most democratic, but it is easy to use and “clean” (there will be no ash after combustion). Dense briquettes produced using a powerful press perform best.