The question of how to insulate a frame house is usually not raised in those countries where this technology came to us - it is believed that it is sufficiently insulated at the structural level. Our winters are very harsh - in the central part of the country the frosts are much stronger than at the same latitude in Europe or North America, so we have to insulate even frame houses, the design of which initially includes a layer of insulation.

Another layer of insulation for our climate will not be “superfluous” Source fasad-exp.ru

Choosing insulation for a frame house

Before insulating a frame house from the outside, you need to find out what thermal insulation materials were used inside the walls. And, focusing on their properties, choose an insulation scheme. This dependence is determined at the level of standards, which directly state that the materials and external insulation scheme should not create conditions for the wall itself to get wet. What does this mean?

It is estimated that per day, during the life of one person, up to 4 liters of water evaporate in a room: cooking, washing, hygiene, wet cleaning, pets and indoor plants. The main part should be ventilated due to ventilation, but the other part of the moisture will penetrate into the enclosing structures.

The standard wall design is a frame sheathed with thin-sheet materials on both sides, between which the insulation is located. And so that it does not get wet, it is protected from the inside with a vapor-proof membrane, and from the outside - with a windproof and waterproofing film that can “pass” water vapor.

Standard diagram of the facade of a frame house Source stroyfora.ru

If you use thermal insulation outside with a vapor permeability lower than that of the main insulation, the process of diffusion (removal) of water vapor to the street will be disrupted.

Three types of materials are used in the construction of the wall of a frame house:

- expanded polystyrene;

- polyurethane foam (mainly in SIP panels);

- mineral wool.

Polymer insulation has approximately the same vapor permeability, and it is low.

Note : The exception is PVC foam, but this is an expensive insulation material that is used to insulate the hulls of yachts and other small elite class vessels.

If a frame house is insulated with mineral wool, the scheme must take into account the fact that this is a “breathable” material, but hygroscopic. The latter property is compensated by the fact that the fibrous structure (as opposed to the cellular structure) gives off moisture as easily as it absorbs it. Provided it is freely weathered.

Conclusion:

- If polystyrene foam or polyurethane foam is placed inside the wall, then the outside of the frame house can be insulated with any material.

- If there is mineral wool inside, then only it can stand outside. As an alternative, ecowool or open-cell sprayed polyurethane foam, which have approximately the same vapor permeability coefficient.

It is advisable to insulate a frame house outside and inside Source k-dom74.ru

Stage two. Preparatory activities

First, you should understand a number of important points, without which thermal insulation of a frame building can easily turn into a waste of money. First, we note that you need to think not only about the walls, since both the ceiling and the floor can also let in cold air! In addition, the insulating material should be properly protected from moisture using internal/external waterproofing. Finally, when performing installation work, you need to leave small ventilation gaps between the walls and the insulation itself.

Before starting installation work, thoroughly clean all working surfaces from dirt and dust. If protruding screws or nails are found, remove them. And if there are gaps between the frame elements of the building, then fill them with polyurethane foam. Dry all damp areas (if any) using a hair dryer.

Note! If previously the outer surface of the walls was thermally insulated using waterproofing material, then its re-installation inside the building is no longer required, otherwise an excess amount of moisture will accumulate in the structure and, as a result, it will quickly collapse. Below are instructions for internal insulation only.

Properties, advantages and disadvantages of insulation materials

Each type of insulation has a certain “set” of properties that influence the choice. Vapor permeability was mentioned above. It is worth focusing on other qualities and differences.

Density

What density of insulation for the walls of a frame house, in addition to direct thermal insulation, also affects the method of fastening. When using insulation with fastening sheets or mats inside the frame (sheathing), there are no strict requirements for strength.

Stone wool . If we are talking about stone wool, then it should not be too loose so that it does not slip or wrinkle in a vertical structure. In ventilated facades, its density can start from 50 kg/m³.

When choosing a “wet” façade technology with a thin layer of light plaster, mineral wool must have a density of at least 85 kg/m³. For heavy plaster - from 125 kg/m³.

Note : The division of plaster is quite arbitrary. Light weights are considered to be up to 1500 kg/m³, heavy - above.

If we consider that the density of cement is 1100-1300 kg/m³, and acrylic polymers are about 1200 kg/m³, then the main factor influencing the “heaviness” is fillers. For decorative facade plaster, coarse quartz sand, screenings and stone chips are usually used, which provide higher mechanical strength but increase specific gravity. Therefore, most of its types are classified as severe.

Reputable manufacturers already indicate on the packaging the purpose and methods of fastening stone wool Source obustroeno.com

Expanded polystyrene . Choosing the density of polystyrene foam is a little easier. For external insulation, it is used either according to the “wet” facade scheme, or as part of thermal panels. And here we are usually talking about PSB-S-25 or PSB-S-35. The second option is preferable - stronger, with almost the same thermal conductivity.

How to choose a filler

The best insulation for floors is considered to be mineral wool, polyester, steel shavings, etc. They are easy to install, use, environmentally friendly and fireproof. However, they have increased requirements for vapor barrier and waterproofing.

You can also use materials such as:

- Polystyrene is lightweight, resistant to adverse influences and has a long service life. It can be regular (less durable, fireproof) and extruded - it has low thermal conductivity and moisture absorption.

Installing this type of insulation is simple: the sheets are placed end to end, and an edge strip is installed along the entire perimeter of the floor.

- Expanded clay and slag - has low thermal conductivity and is light in weight.

- Penofol is an insulating foil that is rarely used as an independent insulation material.

- Edge tape - This is used to edge the entire perimeter of the house before the insulation is installed.

Video description

We will dwell in more detail on insulating a house with polystyrene foam.

Find out how safe polystyrene foam is in our video: Extruded polystyrene foam , used for facade insulation, has a density of 35 kg/m³. But thanks to its cellular structure with a monolithic “skeleton” (and not glued together from individual microcapsules), its strength is much higher than that of conventional PSP-S-35 foam.

Extruded polystyrene foam is not susceptible to water Source remontik.org

PPU (polyurethane foam) . There are two types of sprayed polyurethane foam: open cell and closed cell.

Open-cell polyurethane foam is a lightweight insulation material (9–11 kg/m³). Its properties are similar to mineral wool: high vapor permeability and almost the same thermal conductivity coefficient. It can only be used when spraying between frame or sheathing elements followed by paneling. But it is more expensive than mineral wool.

Closed-cell sprayed polyurethane foam for insulating facades has a density of 28–32 kg/m³. It is already able to withstand a layer of finishing plaster and has the lowest thermal conductivity coefficient among all types of insulation.

See also: Catalog of companies that specialize in home insulation.

Thermal conductivity

The lower the thermal conductivity, the better the thermal insulation properties of the material. For calculations, coefficients fixed at the standard level are used. Although manufacturers often indicate the characteristics that were obtained during laboratory tests, and they always differ for the better. However, when calculating according to standard indicators, you can be sure that things will not get worse.

Comparison of thermal conductivity of various materials Source realsroier.ru

Both two-component and one-component polyurethane foam are considered the best thermal insulation materials. Their thermal conductivity, according to some sources, is not higher, and sometimes lower, than that of dry air - 0.02–0.023 W/m*deg. Expanded polystyrene insulation has the same coefficient in the range of 0.031–0.38, and mineral wool – 0.048–0.07.

Other characteristics influencing the choice

Water absorption indicates the tendency of a material to become wet. The best indicators here are for extruded polystyrene foam and closed-cell sprayed polyurethane foam - about 2%.

Next on the list is expanded polystyrene - up to 4%.

Mineral wool (including stone) - up to 70%. When wet, ecowool can increase its weight several times. But after drying, they restore their thermal insulation properties.

Stage three. Waterproofing layer

Let’s immediately make a reservation that the installation technology for all materials is approximately the same. First, measure all the walls of the frame, then, in accordance with the calculations, cut strips of the material that was chosen for waterproofing. Attach the material to the posts using a stapler so that the frame is completely covered.

Self-adhesive penofol

We advise you to learn more about the technology of insulation using penofol, more details about which can be found here

Video description

Which thermal insulation is better: based on stone wool or fiberglass, is discussed in the video:

If we talk about the cost of insulation, the most expensive technologies are spraying ecowool and polyurethane foam. “In the middle” are suspended facades with stone wool. Then - insulation using EPS. And the most affordable type is the “wet facade” with polystyrene foam.

It would seem that insulating a frame house with foam plastic outside and inside the walls should be the most popular technology - low cost and water absorption with high thermal insulation properties.

For brick and monolithic houses, this is indeed the most common material. And the scheme for insulating the walls of a frame house, like a wooden one, must first of all take into account the fire safety of materials and their environmental properties.

Foam insulation is incredibly popular Source lineyka.net

When polymer insulation is “surrounded” on all sides by non-flammable materials (brick, concrete, building blocks, plaster), and it itself is low-flammable and self-extinguishing, then such insulation is safe for residents. But if the supporting structure of the house is made of wood, polystyrene foam poses a danger - in the event of a fire, it begins to melt and release life-threatening suffocating gases.

Therefore, non-flammable mineral wool is often chosen for internal insulation of frame walls, and as a result of the requirements for vapor permeability of materials, it is also used externally.

Complete solution

One of the effective methods of insulation is the use of ready-made thermal panels. The heat-insulating layer of the panels is formed by polystyrene foam or polyurethane foam, and panels of smaller thickness are made from polyurethane foam, the insulating layer does not exceed 40 mm.

There are many product options, but to complement the finished house design you need to select:

- The smallest thickness;

- The most inexpensive option for the substrate, the back side of the panel;

- The easiest and most acceptable option for outdoor decoration of products;

- Favorable price.

Insulation of a frame house from the outside with mineral wool

Of the three types of mineral wool, stone (basalt) wool is used for insulation of residential buildings. When working with glass, quite a lot of microscopic fragments of fiberglass are formed, which are dangerous for the respiratory organs of workers during the installation of insulation and residents during the first time after moving into the house. Slag wool is not recommended for use due to its low environmental qualities.

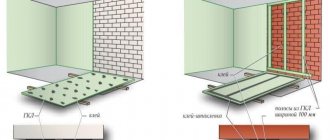

Scheme for insulating the walls of a frame house with an additional outer layer Source stroyfora.ru

With external insulation with mineral wool, the technology of a ventilated facade is somewhat different from the usual scheme. For a house made of brick, building blocks, logs or timber, the sheathing is attached to the wall. A frame house does not have a wall as such in the usual sense. What's the point of covering the frame on the outside with OSB board, and attaching the sheathing on top for the next layer of insulation, if it can be immediately mounted on the load-bearing racks.

This is also justified by the fact that “fresh” OSB boards have lower vapor permeability than stone wool. Therefore, ideally, the “pie” of proper insulation of a frame house with mineral wool looks like this:

- interior finishing (with lathing for panels);

- vapor-tight membrane;

- frame with insulation;

- lathing for the outer layer of mineral wool;

- windproof, vapor-permeable membrane:

- counter-lattice to create a ventilated gap;

- façade cladding and finishing.

Fire prevention technology

To reduce the possibility of fire of foam plastic and some other types of board insulation, it is recommended to use them together with mineral glass and basalt wool.

In the insulated surface, around window and door openings, instead of foam plastic, strips of non-combustible mineral wool are installed, eliminating the issue of spreading a separate outbreak to the surface.

The same narrow but effective delimiters of foam plastic boards are mounted at their joints - an excellent solution that makes it possible to use all the positive properties of combustible insulation.

External insulation with polymer materials

With the technology of constructing frame houses from SIP panels, foam plastic - polystyrene foam or rigid polyurethane foam - is used as internal insulation at the factory production stage.

This is what a factory-made sandwich panel looks like Source superdom.ua

Reasons for heat loss

The main problem of low thermal efficiency of houses is most often not the poor quality of wall insulation materials, but design and construction flaws:

- Insufficient thickness of the insulating layer; for the middle zone it should be at least 15 cm;

- The frame racks, which became a source of cold entering the house when they freeze, are not insulated;

- The insulation boards are loosely laid among themselves or in the frame cells, which allowed the formation of cold bridges;

- There is no moisture-protective layer or vapor barrier, which led to a decrease in the quality of the insulation;

- There are no ventilation ducts.

Spray insulation

To some extent, this technology is reminiscent of applying plaster on beacons - vertical slats are placed on the walls at a level, between which polyurethane foam or ecowool is sprayed.

A frame house, insulated on the outside with polyurethane foam, is ready for façade finishing Source mirstrojka.ru

After the polyurethane foam “hardens”, its excess is cut off with a special hand-held electric cutter or electric saw. You can either install façade panels on top or apply a layer of decorative plaster.

Is it worth disassembling the facade decoration?

Dismantling the existing facade finishing, its substructure, inspection and unpredictable repairs of thermal insulation in the frame are expensive and time-consuming processes. The removed facade materials are not suitable for reuse, which means significant losses.

But the choice of additional insulation method must be justified technically. If the house design with load calculations has been preserved, you should study it and understand how much weight the added layer will make the structure.

If there is no data, it is necessary to re-calculate the load capacity of the structure. Only based on these calculations can you choose insulation options.