When traction is not enough

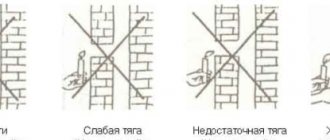

Methods for determining thrust

If you do not have an anemometer, use one of the popular methods for determining chimney draft:

- Smoke. The most obvious sign of a lack of draft is the presence of a small amount of smoke indoors; a large amount of smoke indicates a high risk of fire and the risk of food poisoning.

- Flame color. By the color of the flame, you can understand the level of draft. If the flame inside the stove has a white tint and cracks when burning, then the draft is very powerful. An orange-red color indicates a lack of traction. If the chimney is made correctly, the flame should have an even golden color fading to yellow.

- With a match. You need to bring a lit match to the heater. If the flame deviates towards the stove, then there is draft. If it remains level, then you can be sure that there is traction, but of average magnitude. When the flame deviates in the opposite direction from the stove, a backdraft occurs in the chimney.

- With a mirror. Another way to check the draft force in the chimney is to place a small mirror against the stove. The occurrence of condensation on the surface of the mirror indicates that smoke removal is difficult.

Attention!

The difference in pressure outside and indoors is the basis for creating draft inside the chimney duct. The temperature in a heated room is higher than outside, and, consequently, the pressure it creates inside the room is greater. Hot air, supported by colder air from below, is squeezed into a zone with lower pressure, that is, into the atmosphere. When measurements are taken in summer, the temperature difference is least striking, therefore the draft will be worse and the measurement results may be low relative to the winter period.

Causes of malfunctions

Once you are sure that there is not enough draft inside the chimney, it is necessary to identify and correct the possible cause. Professionals say the most common causes of smoke duct failures are.

Error in design

To make a choice of chimney pipe, you need to focus on the volume of the firebox. If the size is smaller than the calculated parameter, then a weak chimney will not allow smoke to escape from the room.

Short pipe length

A pipe length of less than 5 m does not make a significant difference between indoor and outdoor pressure, which creates weak draft.

Incorrect placement of the chimney pipe

A master stove maker advises laying the chimney vertically, as tight corners keep smoke inside the chimney, reducing draft.

Long horizontal sections

If when laying the chimney it is not possible to avoid horizontal sections, make sure that their length does not exceed 100 cm, otherwise an amplifier will be needed for this.

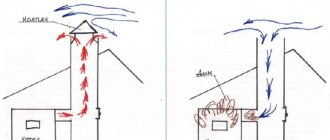

Getting into the wind support zone

If there is a tall building near the house, it blocks the chimney from the wind, preventing the normal functioning of the chimney system.

Weather conditions

Often, a decrease in draft occurs due to a decrease in atmospheric pressure, moisture entering the chimney due to rain, fog or snow. But this is not critical, because all these are temporary phenomena.

Recommendations for the operation of gas boilers

An autonomous home heating system is becoming one of the most common methods of heating a home.

Among the many options, preference is given to gas boilers as the most efficient and economical units.

European companies are recognized leaders in the production of gas units, but their products are not always able to work effectively in Russian conditions.

Domestic manufacturers, having analyzed the experience of their foreign colleagues, decided to use a completely different approach to the design and functionality of boilers.

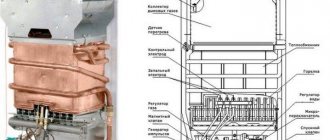

Let's consider one of the models of the Russian gas boiler - Zhukovsky AOGV 23.

What functions does the Zhukovsky gas boiler AOGV 23 have?

The abbreviation AOGV 23 stands for Domestic Gas Heating Apparatus with a power of 23 kW. This is a single-circuit floor-standing unit capable of efficiently heating a room up to 200 m2 .

Such possibilities are optimal for use in a private house, cottage or other premises. The boiler is designed to perform only one function, which allowed the manufacturer to eliminate all unnecessary parts and unused design elements.

This increased reliability and reduced the number of failures and breakdowns. In addition, a feature of AOGV 23 boilers is energy independence.

In the event of a sudden power outage, the boiler will continue to operate as usual, which is important in the Russian winter . This feature significantly increases the reliability of the home heating system.

At the same time, the lack of power supply requires a specific location of the radiator system, since the coolant will circulate naturally.

The combustion chamber of the boiler is atmospheric type, with air intake directly from the room and natural smoke removal using stove-type draft.

Household antifreeze is used as a coolant, which increases the reliability of the heating system in severe frosts.

Malfunctions of the AOGV-23 ZhMZ boiler

___________________________________________________________________________

- Repair and adjustment of AOGV boilers

- AOGV-11.6-3 Economy

- AOGV-17.4 Borinsky

- AOGV-17.4 – Installation and installation

- AOGV-23 — Design and maintenance

- AOGV-23 ZhMZ – Operation

Malfunctions of the Zhukovsky boiler AOGV-23 and their elimination

By pressing the start button it is not possible to ignite the igniter, the flame on the igniter goes out, comes off - The gas valve in front of the device is closed - Open the gas valve. — The hole in the igniter nozzle is clogged — Clean the hole with Ø 0.3 mm wire. — Gas pressure is below 635 Pa (65 mm water column) — Notify the gas department.

— The presence of strong drafts in the room, leading to the flame breaking off on the igniter — Eliminate or reduce drafts. There is no spark between the spark plug electrode and the igniter - There is a large gap between the electrode and the igniter - Adjust the gap. — Piezo ignition does not work — Replace piezo ignition.

When the start button is released (after holding it for at least a minute with the igniter burning), the igniter flame goes out - Oxidation of the solder on the contacts at the junction of the electromagnet with the contact wire, weak pressing of the pins in the sockets - Unscrew the contact wire fitting from the gas magnetic valve body, clean the contact with a file until shiny (remove oxide film).

Screw the fitting back into the housing. Remove the sockets from the pins and lightly crimp the sockets with pliers. Install the sockets onto the pins.

To avoid breaking the soldering of the electromagnet contacts and the contact wire, do not overtighten the wire fitting when screwing it into the gas magnetic valve body. — The traction sensor microswitch does not work. — Replace the microswitch. — The thermocouple does not produce an EMF, the end of the thermocouple has burned out (the value of the EMF of the thermocouple must be at least 20 mV) — Replace the thermocouple.

— The igniter flame does not touch the thermocouple — Install (bend) the thermocouple so that the flame washes the end of the thermocouple (see Fig. 3). — The safety thermostat is faulty — Replace the safety thermostat. The flame of the burner and igniter goes out. Automatic shutdown of the gas supply when the gas boiler AOGV-23 ZhMZ is operating.

The draft sensor is triggered - Complete or partial blockage of the chimney - Clean the chimney. — The presence of strong drafts in the room, leading to the flame failure on the igniter — Eliminate or reduce drafts. — The pressure has dropped below 635 Pa (65 mm of water column) — Notify the gas department.

— To measure the gas pressure in the network, disconnect the igniter tube from the fitting of the valve body. Connect a measuring device to the fitting.

— Turn the adjustment knob, setting it to 50 - 60 °C. Press the start button all the way, then release it 2 - 3 mm and after 8 - 12 seconds. take readings from the device. The response time of the automatic operation of the gas Zhukovsky boiler AOGV-23 for draft is less than 10 seconds. in the absence of draft in the chimney.

The automatic response time for traction is more than 60 seconds. in the absence of draft in the chimney. — The traction sensor is not adjusted — Adjust the sensor, for this purpose: unlock it, unscrew (or tighten) the adjusting screw by 1-2 mm and lock it again. Check the response time. Repeat the operation if necessary.

— The response time depends on the size of the gap between the adjusting screw and the microswitch button. As the gap increases, the response time increases and vice versa.

The main burner does not turn off - The "thermal bellows" is depressurized - Replace the "thermal bellows" - The thermostat is out of adjustment - Adjust the thermostat in the response ranges within 50-90 °C. After switching off, the burner does not turn on for a long time.

The water in the tank is hot, the radiators are cold - There is no circulation in the heating system - Eliminate reverse slopes in the heating system. Eliminate air pockets in the heating system.

Presence of flame at the combustion holes of the main burner when the thermostat is turned off - Leakage of the thermostat valve due to the presence of dirt - Remove the front cover of the thermostat. Clean the valve plug and apply sealing lubricant. The draft breaker door does not rotate or rotates slowly - There is dirt on the door axle - Remove dirt from the door axle and the socket for installing the axle in the draft breaker body.

How to make a traction stabilizer with your own hands

To make a traction stabilizer with your own hands, you will need to prepare tools for working with stainless metal and material for making the regulator itself.

To work you will need:

- Welding machine for working with stainless steel. This can be a gas welding machine or an inverter device operating on direct current.

- Stainless steel electrodes diameter 4 or argon for gas welding.

- Grinder, cutting and grinding wheel.

Materials for the manufacture of traction stabilizer:

- Metal sheet made of steel grade AISI 304 (analogue 08Х18Н10) or AISI 321 (analogue 08Х18Н10Т). Metal thickness 10 mm.

- Bolts, nuts, metal rod with a diameter of 10 mm - all made of stainless, heat-resistant steel.

The installation diagram is as follows:

- It is necessary to weld a pipe from a sheet of metal - the regulator body. Calculate the diameter based on the diameter of your chimney. You will need to put the stabilizer on a tee or pipe extending from the main pipe. Therefore, the inner diameter of the stabilizer must match the outer diameter of the tee. Usually it is 115 mm, but it can be more.

- The metal for the body should be cut with the calculation of overlapping welding with a seam width of 1 cm.

- The cut sheet is rolled and welded. The seam is cleaned until smooth on the outside and inside.

- Roll a restrictive barrier at the end of the housing at a distance of 40 mm from the edge. It will serve as a stopper when installing the device on a pipe.

- At the other end of the body, weld stops in the lower part to prevent the damper from tipping inward. At the top or in the middle (depending on the shape of the damper), fastenings for the rotary axis are welded.

- A damper is cut out of metal. Its size is equal to the internal diameter of the outlet of your case, or matches the contours of the outlet if you decide to make it smaller.

- A hole is drilled at the bottom of the damper for the adjusting bolt.

- A rotating axis is welded in the middle (for a symmetrical damper) or in the upper part (for an expanding form).

- Install the damper on the body.

- Install the draft stabilizer on the pipe.

When installing the stabilizer on a pipe, coat the contact points of the pipes with heat-resistant sealant. This will make the connection stronger and more airtight.

The principle of operation of the stabilizer

If the draft force in the system begins to exceed its optimal values, then a valve opens in the regulator, which reduces the pressure and thermal lift force due to the air coming from the room and mixing with the flue gases. The valve will remain open until the temperature drops and reaches the optimal level. Next, the valve will automatically close and the chimney system will continue to function properly.

This method of maintaining normal traction is simple and effective. Fuel in a stove or boiler will be burned evenly and consumed economically.

Installing a chimney draft stabilizer provides the following advantages:

- increasing the operational safety of the chimney system;

- reducing the amount of harmful substances released into the atmosphere;

- better air circulation when the valve is kept slightly open;

- the ability to operate on both forced and natural draft;

- uniform combustion of fuel in the boiler, which makes it impossible for the chimney to overheat;

- protection from strong gusts of wind;

- no burning smell in the room;

- increasing the service life of the smoke exhaust channel;

- preventing heat loss;

- possibility of installation in modern low-temperature boilers;

- ensuring fuel savings of 15-20%.

Main purpose

For each specific case, its own system of channels is made through which smoke escapes from a boiler or other heating device. Its effectiveness depends not only on the build quality, but also on some external factors. For example, traction force can be influenced by atmospheric pressure. The lower it is, the worse the traction will be. Also, the draft is better when the smoke moves from hot to cold, which means it will be stronger in winter. The draft stabilizer is designed to moderate the impact of such changes on the heating system. If necessary, it will independently raise or lower the pressure. Thanks to the stabilizer, you can achieve fuel savings of at least 10%, which is a very good indicator.

Ways to increase chimney draft

There are several ways to increase draft in a pipe:

- The first thing to do is clean the pipe. To do this, you can resort to the services of a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- Everyone knows about the dependence of thrust on the height and diameter of the pipe. In this regard, the power of the chimney can be increased by increasing the height of the chimney above the roof surface, adding several additional segments to it. In the same way, the chimney is removed from the area of wind support from the ridge and a higher building.

- Exhaust pipe attachment to improve draft. This is a special device designed for automatic traction control. It is made in the form of an umbrella with a temperature sensor, which is mounted on the chimney pipe. The temperature sensor monitors the temperature of the exhaust gases and operates independently. The nozzle on the pipe to increase draft is responsible for maintaining the pressure in the chimney within 10-35 Pa, thereby optimizing the functioning of the heating device and the amount of fuel consumed.

- Use of a special deflector. Models of deflectors are produced that are made in a special aerodynamic shape. Due to the ability of air to reduce pressure, during the fall effect while passing an obstacle, a rarefaction area is formed in the deflector, which stimulates smoke to exit the pipe. However, such devices are effective only in windy weather.

Ready-made options

In cases where there is no time or opportunity to tinker with making a traction stabilizer yourself, you can purchase ready-made options. One of the good solutions that is on the market is Darco products. Its RCO model stabilizers are designed for round chimney pipes. They are attached to them using clamps. This draft stabilizer is mounted on the very edge of the chimney. Anyone can cope with this task. RCR series models will require installation during installation of the entire system or some modification. Such stabilizers are also attached with clamps, but directly at the boiler outlet.

Solutions have also been developed for chimneys with rectangular or square cross-sections. These are RCP series models. They will require making an additional hole in the chimney and sealing the stabilizer. If necessary, it automatically opens the air intake valve. Adjustment is allowed within the range from 10 to 35 Pa. Another representative for surface mounting are models of the RCW series. They are also suitable for brick or other rectangular chimneys.

Principle of operation

There are two types of traction control - automatic and manually controlled.

Reducing draft in the pipe

An automatic draft stabilizer is a kind of membrane that reacts to changes in the density of smoke in the chimney. As the draft increases, the damper opens and admits an additional flow of cold air into the pipe. This helps to cool the combustion products, the gases become heavier and rise upward more slowly, and the draft decreases.

The mechanical smoke regulator is adjusted manually. To do this, there is a weight on the bottom of the regulator damper. When making a device with your own hands, it is convenient to use a regular bolt as a weight. The stabilizer is adjusted during the period of maximum fuel combustion. By tightening the bolt, the center of gravity of the damper is shifted in the desired direction so that it remains closed at the required gas pressure in the chimney, and opens when it increases.

We recommend that you read: How to make a spark arrestor for a chimney with your own hands?

Backdraft Prevention

The throwing of smoke into the room (backdraft) occurs when there is a sharp and significant decrease in the smoke pressure in the chimney. This happens in windy weather, when the furnace is opened, or when the outside temperature changes. The traction stabilizer reacts sensitively to these changes and blocks the flow of cold air (the damper closes completely) as soon as this happens. When the pressure rises above the desired value, the valve opens again.

Function of regulators

The temperature regulator performs a very important function in solid fuel boilers. All units using wood or coal must have a water jacket. If the water temperature is not regulated, it will simply boil, so mechanical or automatic regulators are a very important and necessary element of a solid fuel boiler.

Automatic temperature sensors protect the boiler from overheating and breakdowns, thereby preventing the boiler from exploding.

If water boils, pressure rises and an explosion occurs. Therefore, if a solid fuel boiler has only a manual damper for temperature regulation, it represents a high-risk device. An alternative is to install an additional container where excess heat will go, but this option is not ideal and may malfunction, although it will somehow protect the boiler from overheating.

An automatic draft regulator for solid fuel boilers will do all the work for a person without his direct participation. At the right time, it will close the damper to the required level and prevent water from boiling in the jacket of the device. It is also necessary to take into account that the temperature will continue to increase for some time, but the process of increasing degrees will stop.

In addition to the main advantages of the draft regulator, there are others:

- Using the regulator you can set the maximum temperature. This is especially convenient in autumn or early spring, when the temperature does not necessarily have to stay within +80...+90°C. You can set it to +60°C, and that will be enough.

- When the damper is closed, the combustion rate decreases, which helps save on fuel. But such actions slightly reduce the efficiency of the device.

Sometimes, as an alternative, a safety valve is installed that opens at high pressure. But this method is not a panacea, since after 2-3 operations the valve often begins to leak due to overload, so the ideal option would be to install a draft regulator on the boiler.

Operating principle

If draft increases in the chimney system, pressure rises. As soon as it reaches a certain level, the valve is activated. It opens the damper and draws more air from the room. It lowers the temperature inside the chimney, thereby reducing the pressure. As soon as the temperature and pressure drop to the required minimum, the valve closes and the air intake stops. This process allows the flame temperature to be kept within the required range so that the fuel burns at the required rate. There are several positive points that speak in favor of installing a traction stabilizer:

- greater system security;

- increase in service life;

- reduction of harmful emissions;

- less soot settling in the chimney;

- no sudden pressure changes.

Thanks to the traction stabilizer, there is better air circulation. This means that less combustion waste will settle on the walls of the chimney, which will reduce waste on cleaning it. With a stabilizer, you don’t have to worry that in windy weather there may be a sharp drop that will cause the flame to go in the opposite direction. There will no longer be a burning smell in the room where the heating boiler is installed. The temperature inside the chimney will be maintained within acceptable limits

This is important to prevent soot from igniting, which leads to severe fires. That is, the traction stabilizer guarantees additional safety of the entire system.

Operating principle

The boiler automatically changes the temperature thanks, first of all, to a thermostat placed in a cylindrical body. Using a handle and chain, the body, in turn, is mechanically attached to the ash pan door. The thermostatic element itself looks like a flask filled with liquid, which expands significantly when heated. The thermostat is located at the bottom of the cylindrical body, directly in the part that is connected to the water circuit of the boiler, so the element is in contact with the coolant.

Technologically, the operation of the regulator is as follows:

- when the temperature increases, the sensor (thermostat) reacts to it and weakens the spring located inside the cylindrical body, which, in turn, is connected to the lever and chain;

- the lever lowers and the damper closes accordingly, and the thrust decreases;

- due to the fact that there is less air, combustion slows down;

- the process is repeated.

A temperature adjustment handle is installed on the cylindrical body. If you set a certain limit, the lever will not fall below this norm, and therefore the temperature will not decrease.

Principle of operation

There are two types of traction control - automatic and manually controlled.

Reducing draft in the pipe

An automatic draft stabilizer is a kind of membrane that reacts to changes in the density of smoke in the chimney. As the draft increases, the damper opens and admits an additional flow of cold air into the pipe. This helps to cool the combustion products, the gases become heavier and rise upward more slowly, and the draft decreases.

The mechanical smoke regulator is adjusted manually. To do this, there is a weight on the bottom of the regulator damper. When making a device with your own hands, it is convenient to use a regular bolt as a weight. The stabilizer is adjusted during the period of maximum fuel combustion. By tightening the bolt, the center of gravity of the damper is shifted in the desired direction so that it remains closed at the required gas pressure in the chimney, and opens when it increases.

We recommend that you read: Do-it-yourself installation of various types of plastic pipes for water supply lines

Backdraft Prevention

The throwing of smoke into the room (backdraft) occurs when there is a sharp and significant decrease in the smoke pressure in the chimney. This happens in windy weather, when the furnace is opened, or when the outside temperature changes. The traction stabilizer reacts sensitively to these changes and blocks the flow of cold air (the damper closes completely) as soon as this happens. When the pressure rises above the desired value, the valve opens again.

Installation nuances

There are two main ways to install a traction stabilizer. One of them involves placing a stabilizer at the level where the boiler and chimney are connected. It is worth remembering that it must be at least 40 cm above the ground. In the second case, the stabilizer is placed 50 above the place where the boiler is connected to the chimney. There is another option for a traction breaker. It is made in the form of a fungus and can be mounted on gas boilers. The drawings can be viewed below. It is also mounted in the chimney pipe. Part of it has a slight expansion in the form of a fungus. It is under it that there are channels for the flow of air from the room. It performs the same functions as described for the stabilizer above.

Since the factory stabilizer operates in automatic mode, it requires a special sensor that will monitor changes in parameters. It records the temperature of the emitted gases. If it rises and gases accumulate, the sensor transmits a signal to the boiler automation, which automatically stops the gas supply and combustion stops. The principle of its operation is shown in the illustration below.

Preventing the condition of the chimney

To avoid the need to use means of forced exhaust of a chimney made of heat-resistant material, it is necessary to use preventive means to maintain it in working condition.

Since the main reason for reducing the intensity of flue gas extraction is the reduction in the passage of the pipe by soot accumulated on the walls, we will consider means of combating this phenomenon.

These methods could be:

- Burning about half a tablespoon of naphthalene in the furnace firebox. Naphthalene vapor decomposes soot into loose components, large ones fall inside the firebox and are subsequently removed with the ash, and small ones fly out through the pipe along with the furnace gases. This product cannot be used for smoke removal from a fireplace and for pipes of open hearths - it leaves a characteristic suffocating smell in the rooms.

- From time to time, burn potato peelings in the firebox. They are pre-dried. Starch vapors loosen the soot deposit and it will fall into the firebox. Pure starch acts similarly, which is fed into a well-lit firebox in the amount of one tablespoon.

- A good way to remove soot from pipes is walnut shells. It burns at a high temperature, burning off soot deposits on the inner walls. A single dose of shells should be no more than three liters. Frequency of application - as accumulation occurs.

- Aspen firewood has a similar effect on soot. One or two logs are burned at the end of the last stack of firewood. They burn at high temperatures.

The frequency of use of high-temperature products should be regular, at least twice a week, so that soot does not have time to accumulate. Otherwise, you can cause a serious fire, since the soot burns and releases a very large amount of heat.

In addition to those listed, there are many anti-soot agents on the market for both chemical and thermal decomposition of soot. The use of preventive measures can eliminate the need for forced measures to improve the exhaust hood on the chimney.

chimney draft stabilizer.

| Does your chimney need a draft stabilizer? Traction regulator Are they snorting? Heat Without Gas - 10 years of experience. |

| Click to view | Order (096)640-50-01, (066) 682-04-76, (063)437-67-61 (044) 338-58-89 Heat Without Gas - 10 years of experience... |

| Tags: |

| Chimney draft stabilizer FOR SOLID FUEL BOILER |

| In this video, you will learn what a chimney draft stabilizer is, how it affects the operation of solid fuel... |

| Tags: |

| Briefly, about a useful thing: about the chimney draft regulator |

| For those who are tormented by a furnace with a roaring flame with a furious draft and for those who need to increase the duration of... |

| Tags: |

| Testing a chimney draft stabilizer! The numbers don't lie! |

| , Moldova, Chisinau, str. 5, tel: (022) 83-53-53 We measure the draft in the chimney of a solid fuel boiler with ... |

| Tags: |

| Chimney draft stabilizer |

| Click to view | A useful device for the boiler. Do-it-yourself traction stabilizer, homemade. On the Kholmov boiler, the mine cat... |

| Tags: |

| Part 1 Chimney draft regulator. Purchase, installation, configuration |

| Draft stabilizer, stainless steel chimneys, sandwich pipes, stainless steel with insulation... |

| Tags: |

| Chimney draft stabilizer for solid fuel heating boilers |

| Regulator overview and principle of operation. |

| Tags: |

| DIY chimney draft regulator |

| Made of stainless steel 1 mm thick. Mail - [email protected] Viber - 0506264205 WhatsApp ... |

| Tags: |

| New chimney draft stabilizer. |

| Click to view | The big draw is money on the street. You can make a draft stabilizer yourself from a ventilation check valve... |

| Tags: |

| Draft stabilizer from check valve. |

| Buy a chimney draft stabilizer for a solid fuel boiler... |

| Tags: |

| Chimney draft stabilizer - video review |

| Click to view | You can purchase draft stabilizer for a chimney at (044) 495-1839 Or draft stabilizer… |

| Tags: |

| Comparison of the Polish Darco traction stabilizer and Ukrainian-made traction stabilizer |

| Click to view | FAQ on 99% of questions and answers to them that arise from people who have never installed a chimney: ... |

| Tags: |

| What is the best way to install the chimney: in a straight line, through the roof or on brackets, along the wall? Advantages and disadvantages |

| If there is a chimney, then there must be draft. The lack of draft only means that the chimney... |

| Tags: |

| Chimney draft |

| Click to view | In this video I will talk about how to calculate the minimum required chimney height or the basic principles... |

| Tags: |

| How to calculate the height of the chimney! |

| Each boiler manufacturer develops its own rules for connecting to the chimney,… |

| Tags: |

| Chimney diagrams for a boiler |

| You can purchase a chimney draft stabilizer at (044) 495-1839 A regulator of this type... |

| Tags: |

| How does a chimney draft stabilizer work? |

| Is the boiler blowing out? Problem solved. Support the channel: 5368 2900 0136 8523 (VTB) Yandex cat... |

| Tags: |

| Boiler valve |

| Now the device looks like this - Order. Ukraine. Kramatorsk. 0506264205. 0970052898. |

| Tags: |

| Chimney draft stabilizer from Metalblesk. Chimney workshop. |

| You can buy it here: stabilizator-tiagi-d ymohoda Normal store, tested it on myself. |

| Tags: |

| Preparing for winter, beginning. Chimney draft stabilizer |

| The work of stabilizing the chimney draft. It is located in the lower (end) part of the chimney. |

| Tags: |

| Chimney draft stabilizer |

| Cold chimney draft. Immediately after the boiler, I installed a draft stabilizer on the chimney. It was made... |

| Tags: |

| Cold chimney draft. |

| Click to view | The chimney draft stabilizer reduces the fuel consumption of the pellet burner. |

| Tags: |

| Chimney draft stabilizer Bege Mott |

| Subscribe to the channel! Give it a like! Write your comments on the video too! Consultation/order - tel. mob... |

| Tags: |

| How to set the chimney draft regulator of a solid fuel boiler to burn wood economically?” rel=»spf-prefetch |

Regulator location

The stabilizer is installed in the same room where the boiler is located. The draft breaker is mounted on a vertical pipe in two ways:

Installation is carried out at a distance of 400–600 mm from the junction of the exhaust pipe from the firebox and the main chimney.

The chimney draft regulator is mounted at the level of the stove, at a distance of at least 400 mm from the base. In other words, they are attached at the beginning of the main part of the chimney pipe.

Possible gaps are filled with high-temperature sealant. Compaction with asbestos, previously soaked in water, is allowed.

What is it and what is it for?

There are several standard options for placing the gate. The valve is placed in the firebox of a stove or fireplace. This arrangement is often used because it is convenient for adjusting the position of the plate in the pipe. The device is inserted into the pipe at a height of no more than 1 m from the top of the heating compartment in an area that is not insulated.

The damper is installed according to the principle of one pipe in another. This is what they do when making a chimney from metal. As a standard in factory systems, the gate valve comes complete with pipes; its installation does not require additional fasteners. The product is installed in accordance with the manufacturer's instructions.

To simplify the heating operation, obstacles to the warm flow are installed, which requires a damper in the chimney. It performs the functions:

- Partially or completely obscures the passage in the pipe, which makes it possible to open the exit for smoke from the firebox or stop its movement outward. When the oven is not burning, the scraper is in the closed position.

- The valve regulates the draft in the pipe. The open plate increases traction, and the closed position reduces the intensity of air output, which saves firewood and coal. The impact on the air flow occurs as a result of a decrease or increase in the cross-section of the chimney.

- Using the part, the intensity of combustion in the firebox changes - the degree of heating of the room is regulated.

You can answer the question of what a gate is by considering its positive aspects. The damper retains heat in the fireplace or stove; when the correct position is selected, the fuel energy is used to heat the interior of the room and does not escape outside. Fuel economy is an important factor for home owners. The valve regulates the draft and prevents the fire in the hearth from going out.

The use of a damper in the design of a smoke duct has several disadvantages:

- After installing the device, it becomes difficult to clean the internal space of the pipe from carbon deposits and soot, since the damper prevents the passage of the brush.

- The gate quickly becomes dirty and requires periodic maintenance. Its upper surface is cooled by the supplied outside air, and the lower plane is heated by hot flows from the furnace mouth. Contact of 2 different temperatures leads to the appearance of condensation drops, which contributes to the rapid destruction of the damper.

- An incorrectly mounted damper causes a lot of trouble during use: it jams, and unaccounted heat flows escape through the gaps left behind.

- To install the damper yourself, a minimal understanding of how the gate operates is required.

The valve serves for different periods of time under changing operating conditions. The period of use without failure is affected by the type of material used for the body and plate. Stainless steel up to 3 mm thick will last 7-9 years without replacement, cast iron will last 12-14 years.

The smooth stainless steel valve, polished during manufacture, collects little soot, but a layer will build up over time. Periodic cleaning of the device is required to prevent the moving part from jamming. Anti-corrosion lubricants are used to treat the rubbing parts of the gate.

Stainless steel gate (Photo: Instagram / ventilyciy.dumoxod.kondicioner)

Operating principle of the gate mechanism

The mechanism includes:

- frame,

- gate,

- stand,

- sealing elements,

- stuffing box seal assembly.

The force by which the movement of the gate is regulated is transmitted through the rod.

Tightness is ensured by strong pressing of the gate element to the seals by the pressure of the moving medium. The design of the gates may include a retractable or non-retractable stem. Fixed stem is widely used when installing gate valves in confined spaces.

Frame

Gate valve bodies can be cylindrical or rectangular. They can be all-metal or prefabricated (for example, welded). The housings can be equipped with a removable bottom cover and a through gate. The housings are made of high-strength cast iron, non-ferrous metal or alloy steel.

The material from which the valve is made has a direct impact on its resistance to aggressive environments. Thus, cast iron elements are less resistant to the effects of:

- diesel fuel,

- motor oil,

- gasoline,

- industrial oil.

In order to reduce the cost of the valve and increase its resistance to aggressive environments, combined valves are used - the body is made of cast iron, and the gate is made of alloy steel. If cast iron is exposed to an aggressive environment, it is coated with epoxy resin for preservation purposes. In some cases, in aggressive environments, gate valves with bodies made of high-strength PVC are used.

Knife

It can be made from a thick rolled plate having sealing

parallel elements. The knife element has a through hole obtained by drilling. The diameter of the hole should be equal to the diameter of the pipe to which the gate is attached.

The gate element may have a pointed edge, which may be at an angle to the hole being closed or close it directly. This allows you to separate the elements of the gates:

- for knife

- and guillotine.

The sharpened element of the knife allows you to easily close holes through which a viscous or solid medium passes. The possibility of closing the pipeline opening as quickly as possible depends on the size of the sharpening.

High-strength alloy steel is used to make knives. The knife is polished, ensuring the easiest possible sliding along the sealing elements and the tightest possible connection to the edge of the seal or pipeline. High-quality polishing helps prevent braking or jamming when blocking flows of media containing a large number of solid inclusions.

Seals

Two types of seals can be used: metal, synthetic components.

- In the petrochemical industry, nitrile rubber is used as a sealing material.

- When working with oils and fuels at low temperatures, a sealant based on a rubber mixture and SKN is well suited.

- Silicone-based sealants are widely used in the pharmaceutical and food industries.

The seal ensures a tight seal on the top of the device. Its padding consists of cotton fiber, synthetic polymaterials, and graphite-containing material.

Types of connection to pipelines

The devices are attached to pipelines by:

- flanged,

- wafer,

- welding connection.

Strengthening the tightness of the gate with a wafer or flange connection is enhanced by means of special gaskets.

Advantages of a traction stabilizer

The chimney draft stabilizer is universal, i.e. can be used with any heat generating unit. Including in heating systems with condensation-type devices, in which the temperature of the burned gases is below the “dew point”. Due to the fact that the stabilizers are made of stainless steel, they can operate at operating temperatures up to 500˚C. They are quite easy to install in a minimal area and adjust. In addition, the following advantages of installing a draft regulator can be noted:

- Effective reduction of heat loss;

- Economical use of fuel;

- Increased safety and service life of the chimney system;

- Increasing the level of air flow circulation;

- The ability to operate the chimney in different conditions (forced and natural draft);

- Alignment of the fuel combustion process inside the chamber;

- No burning smell and no release of harmful compounds both indoors and outdoors;

- Installation is allowed even on an old chimney for connection with new boilers.

Probably many owners of solid fuel appliances, having heard about a chimney draft stabilizer, thought about a damper. A damper is a small damper that covers the chimney to contain heat inside the firebox. As sad as it is to say this, this solution is ineffective. Since when the damper is closed, the speed of gas movement in this section of the chimney simply increases. However, the volume of exhaust gases per unit time remains practically unchanged.

Afterword

The safe operation and high efficiency of furnaces and boilers largely depends on the presence of adequate draft in the chimney. If even minor problems arise with the smoke exhaust system, you should definitely inspect the chimney for permeability and begin to normalize the draft. The presence of carbon monoxide indoors is very dangerous to human life. It is quite possible to carry out repair work and install the stabilizer with your own hands.

The uneven flow of gases through the chimney is a consequence of errors in its manufacture or a manifestation of “reverse” draft. A chimney draft stabilizer helps eliminate these phenomena.