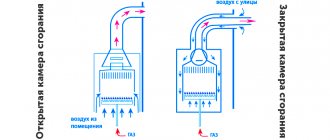

The chimney removes hazardous combustion products from the boiler and provides a supply of oxygen for combustion of gas fuel. The correct operation of the chimney system largely depends on draft - the movement of flue gases in the pipe from an area of high pressure to an area of low pressure. For safe operation of gas equipment, the consumer must know how to check the draft in a gas boiler and how to restore it if it is absent or reduced.

What is the danger of poor traction or lack thereof?

The draft is created due to the difference in pressure at the upper and lower points of the chimney. When it is sufficient, the required volume of air for combustion of the fuel enters the boiler, and the combustion products are immediately discharged outside. The absence or weak movement of air flows in the chimney is fraught with dangerous consequences:

- Penetration of toxic carbon monoxide into the premises, which creates a risk of poisoning people. Of particular danger is a slight increase in carbon monoxide concentrations at night. Depending on the degree and time of exposure to CO on a person, the consequences vary: from a slight deterioration in health to very severe, even death.

- A lack of oxygen to support combustion in the absence of automatic equipment on the equipment will cause the flame to die out, gas will fill the room, and this threatens not only poisoning, but also an explosion.

- Increased soot formation leads to rapid clogging of the chimney pipe and boiler chambers, which reduces the draft force.

Why is there no normal draft in the chimney?

Sometimes backdraft appears in the chimney, when the air flow does not go up, but returns back into the room. The reasons that influence the presence of cravings can be easily eliminated and more serious:

- the project was implemented with violations that will reveal themselves over time. For example, incorrect calculation of the cross-sectional area or height of the pipe, violation of the dimensions of the channel or firebox, etc.;

- high-rise buildings, mountains or tall trees near the house can form a wind surge;

- the low position of the pipe creates too small a pressure difference;

- poor draft may be due to errors in the ventilation system;

- the tightness of the chimney is broken;

- changes in weather in the form of low atmospheric pressure and high humidity reduce the rate of replacement of hot air with cold;

- a lot of soot in the chimney, reducing the useful diameter of the pipe.

Let's sum it up

If you have a question: why is there no draft in the chimney, then first of all you should check the following. If problems with the removal of waste substances arose when using the stove or fireplace for the first time, then pay all your attention to the design documentation. Check that the calculations and dimensions of the chimney pipe are correct.

If you have used the stove until now and everything was in order, then you should first check for a blockage in the pipe. It is quite possible that after a long period of stagnation, the chimney became clogged with various dirt. Birds can sometimes make a nest in the pipe.

It is possible that the chimney pipe has collapsed over time. In this regard, the normal sealing disappeared, and the exhaust flow of exhaust gases became not so strong. First of all, you should check the chimney, part of which is located above the roof. A pipe that is constantly exposed to precipitation can easily collapse. This can happen if a mortar with a low cement content was used for laying bricks.

Another reason that very often leads to the problem of poor draft is a large amount of draft accumulated in the chimney pipe. In this case, the chimney must be cleaned. After cleaning the soot, be sure to check the return draft in the chimney. If your chimney has not been cleaned of soot for many years, then after cleaning it, be sure to use products that prevent excessive soot from settling on the chimney walls.

Helpful advice. If you have not used the stove or fireplace for a long time, and the weather was heavy with precipitation, then before firing it is recommended to check the efficiency of the chimney. Otherwise, it may turn out that all the smoke goes directly into the room and not into the chimney.

If you find that there is a chimney backdraft, what should you do to eliminate it? Try to remove any excess moisture that has accumulated in the pipe. To do this, before lighting the stove or fireplace with wood or peat, be sure to burn a couple of newspapers. Such actions will somewhat dry out the walls of the pipe and eliminate high humidity, so the stove will melt easier and faster, and smoke from the burning fuel will begin to escape into the pipe.

Source

Methods for controlling draft in a chimney

With a noticeable decrease in the efficiency of a gas boiler, consumers are interested in how to check the draft in the chimney. There are different verification methods.

Anemometer

A special device measures the speed of gas movement. It is placed in the pipe and the presence of draft and its indicators are checked. Normal values are in the range of 10 Pa - 20 Pa; with other readings, the reasons for the incorrect operation of the equipment are determined and eliminated.

The minimum gas flow velocity that an anemometer measures is 1 m/s. The device is expensive, and it is not used very often, so it is advisable to rent it for a while.

Visual method

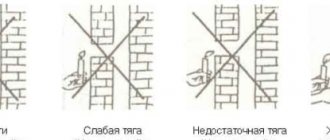

It is not highly accurate, but it is the simplest and fastest. The front panel of the boiler is equipped with a technical window through which you can observe the burning of the flame. If there is a lack of oxygen, the fire will take on a red hue.

A constant change in the shape and direction of the flame, accompanied by the sounds of a draft, indicates reverse draft (air moves backward).

A burning match or a light sheet of paper

Checking the draft in the chimney with a match is carried out as follows: it is lit and brought to the technical window on the front panel of the boiler. Next, observe the behavior of the match flame: a clear drawing of the fire into the window means the presence of air flow movement, even burning without hesitation indicates the absence of draft, turning the flame in the opposite direction from the inspection hole indicates the presence of reverse draft. A light sheet of paper can be checked in the same way - the degree of its deviation indicates the presence of traction. The smoke exhaust system must be tested before igniting the boiler.

Checking for chimney blockage

The most common problem that owners face. The chimney system is equipped with special inspection hatches through which blockages can be detected. If it doesn’t work, then you need to lower a heavy ball on a rope into the pipe from above to the very bottom. The unobstructed descent of the object indicates the cleanliness of the chimney.

Gas equipment sensor

Modern gas boilers are equipped with sensors to control and automate their operation. If the flue gas movement is insufficient, the device sends a signal to the automatic system to shut down. Checking a special gas boiler draft sensor will show the efficiency of the unit and allow you to control the quality of gas combustion, the presence of flame, and combustion intensity.

Solution

Taking into account the fact that the reasons for the occurrence of poor traction are different, it is necessary to select a solution that is appropriate to the problem and capable of preventing it.

If the outlet overpasses are clogged with debris and soot, they should be cleaned. If the chimney is not designed correctly, the structure must be dismantled and reinstalled.

Increasing draft in the chimney with your own hands

There are several effective ways to improve chimney draft.

Cleaning the chimney from blockages

Contamination of the chimney system is the most common problem, which occurs due to soot settling on the walls or dust and debris entering the chimney. To clear the blockage, you will need a metal brush on a steel cable. With its help, the walls are thoroughly cleaned with progressive movements along the entire length of the pipe. The procedure is carried out regularly, even during normal operation of the boiler.

Improved thermal insulation

If the chimney is insufficiently insulated, most of it quickly cools down, and temperature changes negatively affect the creation of a normal vacuum zone. You just need to insulate the pipe with heat-insulating material or replace it with a new one.

Chimney sealing

It is necessary to check the chimney for cracks and holes, and if necessary, eliminate them to completely restore the seal.

Eliminating a cold air lock in a chimney

The normal movement of air flow in the chimney can be disrupted by a cold plug, making it difficult to ignite the burner. You need to burn paper or straw to heat the chimney; for greater effect, you can direct the fire inside the chimney using a flat object.

Installation of aerodynamic devices

Umbrellas, deflectors and other aerodynamic devices are mounted to provide strong draft in the smoke channel.

Warming up the room

If the house is not heated for a long time in cold weather, the pressure at the bottom and top of the chimney will be the same, so the air will not move. To eliminate the problem, you need to warm up the room with an electric heating device to create a temperature difference, after which the burner is ignited.

Functionality check

If problems are observed in the operation of the boiler, the sensor may need to be replaced. For example, if the burner is regularly turned off, but no problems are observed in the combustion gas exhaust system. You also need to check the operation of the device when it periodically turns off after 20-30 minutes.

To check the serviceability of the boiler sensor, you need to consider 3 methods:

- Attach a regular mirror near the device. If the sensor is operating normally, then the surface of the mirror should not be covered with condensation.

- A simple way to check by partially blocking the chimney. A working sensor will promptly give a signal and the equipment will turn off.

- If a double-circuit boiler is used as heating equipment, then to check the device you can switch it to DHW mode, without heat supply. Then open the tap to a powerful stream of water. Here the situation is the opposite - turning off the sensor will be a sign of its problematic operation.

There are many manufacturers of traction sensors. Among them are such market leaders as Junkers, KAPE, Sitgroup, Eurosit. Some boiler manufacturers (Baxi, Danko) produce devices for their heating equipment. It is necessary to select the correct sensors for the equipment that is used (gas water heaters, wall-mounted or floor-standing boilers). It is important to periodically check the serviceability of the boiler draft sensor.

Design and installation errors

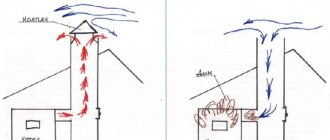

The functionality of the smoke exhaust system may be impaired due to errors in the design or installation of equipment. Errors when designing a chimney system - small pipe height (less than 5 m), small pipe diameter, large number of elbows. When drawing up a project, standards for the size of the roof ridge are also taken into account.

When solving the problem of how to increase draft in a chimney, errors may also be discovered in the design of the chimney, which you can eliminate yourself:

- if the pipe cross-section is small, they can be replaced with a larger analogue, maintaining the correct proportion: their diameter should be equal to the diameter of the gas heating boiler pipes;

- It is better to replace long horizontal sections of the chimney with inclined sections at 30°, and it is also better to convert 90° turns into 2 elbows with an angle of 45°;

- the height of the chimney pipe can be easily increased, but you need to focus on the correct parameters: the chimney should rise 0.5 m above the roof, in the case of a complex roof shape or when the house is surrounded by tall buildings (trees) - the height is at least 1.5 m;

- a cap (wind vane, umbrella) over the chimney will increase draft and protect the internal areas of the pipe from precipitation, dust and debris.

For the safe operation of gas equipment, checking the draft in the chimney system plays an important role. The reasons that influence the deterioration and complete absence of traction are different, but many can be eliminated with your own hands.

A timely solution to the problem will eliminate the risk of carbon monoxide poisoning, fire and smoke in the room. Gas equipment and the chimney system will function correctly if the design and installation are carried out in accordance with current building codes and regulations.

How to fix the situation

If checking the draft in the chimney shows its complete absence or poor quality, you will have to make a certain decision so as not to be left without heat in bad weather.

In general, ideally, a special device is installed in the chimney pipe - a chimney draft regulator. It helps maintain the pressure required by building codes in the flue gas system. This in turn eliminates the incorrect operation of the system as a whole. If necessary, the regulator can either reduce or increase the exhaust gas exhaust force in the pipe.

So, such a device is useful for prevention, and what to do when the chimney pipe can no longer cope with the load or, as it turns out, was designed incorrectly. Then all that remains is to correct the errors and do it as soon as possible.

Therefore, using a fireplace or stove if the chimney is not working correctly is simply prohibited. Carbon monoxide may not be noticed at all. Sometimes a headache just starts and drowsiness appears; a person can lie down for a while and inhale toxic substances.

If we talk about the height of the pipe, then in accordance with established standards, its size directly depends on the slope of the roof. If the height of the pipe does not correspond to the given parameters, it will have to be increased. According to established standards, it is allowed to arrange the height of the pipe a little more, but not less than the established standards.