An excellent option for organizing an autonomous heating system in a private house or bathhouse is a stationary stove with a water heating boiler.

Such a device is practical and economical, has high heat transfer and efficiency, which allows you to effectively heat rooms of various sizes in a short period of time.

It is quite easy to organize such a system yourself, without involving expensive specialists.

Design features of a furnace with a circuit

A stove with a heating circuit ensures uniform and rapid heating of the room thanks to the coolant (water or other liquid) located inside the system. The thermal energy released during the fire is used to heat the room and heat the water in the system.

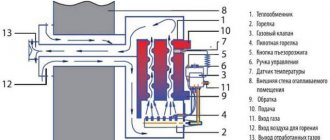

Heating equipment of this type is equipped with a metal heating circuit. It is a tank with fittings and pipes connected to them.

Modern stoves with a heating circuit are made of metal or refractory brick, with different placement of the heater, as well as with a water tank.

Structurally, the furnace boiler is presented in two types:

- Boiler in the chimney. This device is characterized by high performance characteristics, long service life and ease of use. The only drawback of the design is the inability to heat large rooms.

- Boiler in the firebox. It is intended for heating large areas, is accessible and durable. The disadvantages include close contact with open fire, which leads to severe overheating and destruction of metal structural elements. In addition, a high temperature of the heating circuit leads to the rapid formation of soot and a decrease in the efficiency of the device.

Types of heat exchangers for furnaces

When creating an autonomous heating system, two types of heat exchangers are used: flat and tubular.

Flat type heat exchanger

Stove boilers with a flat configuration heat exchanger are a practical option for country houses, private cottages and baths. They are easy to manufacture, install and maintain.

Such devices are mounted vertically and horizontally and have a high efficiency. The flat design of the boiler is characterized by a large chamber volume, which ensures rapid heating of the water necessary for heating and water procedures.

A significant drawback of the equipment is the reduction in thermal output from the furnace wall structures. The heat exchanger is presented in a U-shape and is mounted around the entire perimeter of the firebox. This leads to a decrease in the heating temperature of the external walls of the furnace and an increase in the time for heating the room. This is only problematic in cases where the heating stove is installed inside residential premises, where the combustion process is carried out constantly.

You can increase the heating rate of a flat boiler in several ways: lengthen the heater and place it above the firebox, or use a metal chimney, first increasing its length.

Tube type heat exchanger

A tubular boiler for a stove differs in the type and size of the structure and installation method. If repairs or replacement are necessary, the heat exchanger can be easily removed from the furnace.

Seamless water pipes are used to make a tubular register for a brick stove, so it is considered the most reliable, safe and durable.

When choosing or manufacturing a heat exchanger, you need to remember that its design and dimensions must fully correspond to the shape of the firebox, which will allow heating the maximum amount of water. A high-quality register provides a large heat exchange area.

Advantages

A boiler made of brick is considered a simple and effective heating structure, which is advisable to use for heating private houses. The advantage of such a structure is the possibility of making it yourself, which allows you to save a lot, as well as be confident in the quality of the materials used and the finished boiler. The manufacturing process itself consists of a minimum number of steps that do not require a large amount of welding work. Having purchased a ready-made heat exchanger, do not use welding. A brick boiler is multifunctional, as it can be used as a heating device for rooms. Additionally, as a hob for cooking.

In addition, such a boiler has the ability to maintain the required coolant temperature for a long time, allowing you to maintain a healthy and comfortable atmosphere in the room. A brick kiln allows you to burn even plastic or rubber waste. However, it is important to know that the firebox should not contain more than 1/3 of the total amount of fuel.

Main operational characteristics of furnaces

A do-it-yourself stove with a water heating boiler is designed to perform two important functions: heating rooms and heating water. In addition, it can be equipped with a hob and oven, which will allow you to use it for cooking.

Heating equipment has a number of advantages:

- A traditional stove emits up to 7 thousand kcal of thermal energy in 1 hour of operation, which is enough to heat a country house. The heating boiler has a higher efficiency, which makes it possible to heat a large residential building and a bathhouse. At the same time, low fuel consumption leads to significant savings.

- A combined heating system consisting of a furnace and boiler provides maximum performance at minimum costs.

- The main fuel is charcoal, firewood or pellets. Such materials are affordable, convenient to transport and store.

- Furnaces equipped with a water circuit do not require continuous combustion. One addition of fuel material per day is enough to ensure rapid heating of the premises and hot water supply.

- The efficiency of combined devices compared to traditional furnaces reaches 85%.

- Any homeowner can organize an autonomous heating system, combined with a water circuit, by preparing the necessary tools and materials.

Recommendations for carrying out construction activities

When constructing a stove with a hob and a water circuit, the following standards must be adhered to:

- The stove and nearby surfaces must be separated by a safe distance. For these purposes, a metal sheet is additionally installed in front of the firebox to protect the floor and partitions.

- To make the masonry as strong as possible, every 4th row of bricks is reinforced with metal pins.

- A clay mortar of medium plasticity is used as a mounting mixture. A small ball rolled from it should not crack or crumble when it hits the floor.

- The chimney must have a height of at least 5 m: the presence of a head is a prerequisite. This element is designed to protect the chimney from climatic precipitation and blockages. In addition, it helps to increase traction and decorate the building.

Building a home stove with a boiler with your own hands usually does not cause any particular difficulties. Quite often you can find metal structures that are not inferior to brick ones in terms of external aesthetics. Such a product can greatly decorate a home interior. For the construction of brick kilns, a special building material is selected. The best option is fired ceramic red bricks. They are distinguished by their uniform color and metallic sound when tapped.

Safety rules for operating furnaces with a water circuit

To ensure proper operation of the stove and boiler, it is recommended to follow important safety rules, as well as recommendations for caring for the equipment:

- Water heating devices must be operated under human supervision. This applies to adding fuel and regularly cleaning the chamber from soot and ash.

- Safe operation of the stove requires control of the smoke exhaust ducts. Before starting the fire, it is necessary to check the technical condition of the channels and the position of the valves. When starting a fire, the valves must be completely open.

- Such a system is recommended for use in winter, when it is necessary to provide rapid heating of rooms and hot water supply. Using a stove with a water circuit in the summer only for cooking and heating water is irrational. In this case, it is recommended to choose more economical heat sources.

- An open fire leads to excessive heating of the stove structure, which can be the main cause of heat exchanger failure.

- When using a homemade heating system, you can install a pumping unit to inject liquid and devices to control pressure levels.

Construction of a brick oven with a heating boiler

Construction work begins after preparing a standard design and manufacturing a heat exchanger, the dimensions of which are used to lay the brickwork of the furnace.

A furnace with a water circuit can be placed in a place convenient for operation and maintenance.

After the construction of the foundation, the arrangement of the furnace is prepared, taking into account the water circuit - a plan for the location of the ash and fuel chamber, the smoke exhaust and the hob (if present).

To build a furnace with a boiler, heat-resistant bricks without chips, cracks or damage are used.

The construction of the furnace is carried out in stages:

- Preparing a kiln solution from clay, sand and water. You can purchase a ready-made mixture, but experienced craftsmen mix the brickwork mortar with their own hands.

- A layer of waterproofing made of roofing material or film is laid on the foundation.

- The oven mortar is evenly applied to the waterproofing and the initial brick row is laid. Next, according to the diagram, subsequent rows are completed, and a heat exchanger is mounted in the firebox.

- An ash pit and a combustion chamber are being built. The correctness of the masonry is checked by the building level.

- The door to the combustion chamber is fixed, the stove vault and chimney are laid out. Rounded bricks are used to line the internal walls of the firebox and chimney.

- After the masonry is completed, the water circuit is installed. Water pipes connected to a heating radiator are supplied to the heat exchanger. An expansion tank is installed, and the finished system is filled with water or other liquid.

The final stage is the decorative finishing of the stove with plaster or tiles, as well as a test firebox to identify and eliminate design flaws.

You can build an economical stove with a heating circuit yourself. This design is safe, practical and durable, with high efficiency, and is also independent of centralized energy sources.

DIY brick cauldron

A solid fuel boiler is an excellent option for solving the heating problem in private homes. If you wish and have all the necessary knowledge and materials, you can build such a thermogenerator yourself, without any help.

Homemade solid fuel boilers can be assembled from pieces of pipes, sheets of steel or brick. However, when building such a heat exchanger, the most popular option is to use brick and metal, since entirely metal structures are often too heavy and expensive.

In addition, a brick boiler can be used not only as a heating device for a private home, but also as a stove for cooking. In this material we will talk about building a brick solid fuel boiler with your own hands.

The process of making a solid fuel boiler from brick with your own hands

What materials and tools are needed for construction?

To build a solid fuel boiler with your own hands, you need to have the slightest knowledge of welding, mason skills and be able to use a gas cutter. It is advisable to understand the marking and cutting of working material, as well as have an understanding of working with power tools. With such a wealth of knowledge, you will be able to quickly build a high-quality solid fuel boiler at a minimal price. To do this you will need the following materials:

- clay, brick;

- grate;

- pipes;

- gravel;

- water;

- sheet metal;

- doors;

- water pump and water heating device.

It is necessary to prepare the following tools:

- welding machine;

- Bulgarian;

- cutting torch;

- a marker that is clearly visible on metal;

- spatula for putty;

- level;

- pliers;

- roulette;

- electric drill.

To protect yourself, it is important to prepare personal protective equipment (goggles and mask) and only then begin making a brick cauldron.

Stages of work

Vertical solid fuel heating devices are popular, which you can design yourself as follows:

- Prepare the heat exchanger and take dimensions from it for the manufacture of the combustion chamber.

- Build a foundation of brickwork or rubble stone.

- Lay the base of the boiler with a waterproof roofing felt pad.

- Line the bottom of the chamber and the ash pan with the door with stove bricks and separate them from each other with a cast iron grate.

- Install the TO and lay the walls out of brick, leaving a gap of 1.5-2 cm.

- A door is attached in front to cover the stored fuel, and a hole is left for the chimney at the back.

- A cast-iron hob or a thick metal sheet covered with a layer of brick is laid on top of the chamber walls if you do not plan to use the boiler for cooking.

- The smoke exit channel is located on the side or on top of the combustion chamber, made from a metal pipe or building material.

- When the masonry has dried well, the heat exchanger pipes are attached to the pipeline using couplings or welded.

- Finally, a test fire is carried out and the operation of the heating device is checked.

Return to contents

Principle of operation

The peculiarity of the operation of horizontal and vertical structures is that when fuel is burned, air is heated, which rises and is discharged through the chimney. At the same time, in the process of transferring heat from heated air, cold water is heated in the heat exchanger.

There is also another type of heat generator, in the form of a mine boiler. This design differs from others in the vertical location of the large loading chamber. At the same time, the fuel burns at the bottom of the shaft, and hot air and smoke exit through the second chamber, where the heat exchanger is located.

What is needed

First, you should decide on the dimensions of the future solid fuel boiler and select the most suitable design. Of course, knowing all the aspects of building brick heat generators, you can design and build everything yourself.

However, in the absence of proper knowledge, it is better to carefully read and choose an option from those presented on the Internet.

It is immediately worth noting the fact that when building a solid fuel boiler from brick with your own hands, you will have to deal with welding work, since the heat exchanger is made of pipes or sheet metal.

If you wish, you can buy a ready-made heat exchanger in a specialized store, then you can do without welding work.

Materials

So, from the materials for building a solid fuel boiler made of brick you will need:

- Cement and reinforcement for the foundation. If a brick foundation is planned, then additional amounts of broken bricks and pebbles will be required.

- Fireclay bricks and mortar for laying a furnace.

- Pipes and sheet metal for heat exchanger.

- Doors and grate.

- Water pump.

- Device for heating water.

You will also need tools such as:

- Welding machine.

- Grinder, gas cutter, electric drill.

- A marker that will be used to mark sheet metal.

- Level, pliers and tape measure.

In addition, do not forget about personal protective equipment in the form of gloves, goggles and a mask to protect yourself while working.

Preparing the heat exchanger

To build a brick boiler with your own hands, you first need to prepare a heat exchanger so that you can take dimensions from it for the combustion chamber. That is, you will have to either buy a ready-made heat exchanger or design it yourself.

For example, if you decide to make a horizontal type heat exchanger from pipes, you will need:

- First, prepare pipe sections of the required size.

- Next, holes are cut out of the rectangular pipe in the corner posts, with the help of which the transverse pipes will be joined. Holes are made with a diameter of 50 mm on a face of 60 mm. In total, each rack has 4 holes. 2 more holes are made in the front wall. One is done from below and is required for the return. The second one from the top is for hot water drainage.

- After this, you need to weld the racks to the transverse pipes at an angle of 90 degrees.

- The underwater and outlet pipes are also welded, and then the ends of the rectangular pipes are welded.

Also, a horizontal heat exchanger can be made of steel and pipes. The principle of performing all the work is similar to the option described above, except that in this case the corner posts, as well as the longitudinal pipes, will be replaced with hollow walls.

A vertical type heat exchanger not only provides the ability to transfer heat to the room, but it can also be used to install a stove with one burner. The location of the chimney will depend on its presence or absence.

Do-it-yourself solid fuel boiler for ultra-long burning

A homemade heater will have the following design:

- The firebox is a “box” 460 mm deep, 360 mm wide and 750 mm high with a total volume of 112 liters. The fuel load volume for such a combustion chamber is 83 liters (the entire volume of the firebox cannot be filled), which will allow the boiler to develop power up to 22 - 24 kW.

- The bottom of the firebox is a corner grate on which the firewood will be placed (air will flow into the chamber through it).

- There should be a 150 mm high compartment under the grate to collect ash.

- The 50 liter heat exchanger is mostly located above the firebox, but its lower part covers it on 3 sides in the form of a 20 mm thick water jacket.

- A vertical flue pipe connected to the top of the firebox and horizontal flame pipes are located inside the heat exchanger.

- The firebox and ash pan are closed with sealed doors, and air is taken in through a pipe in which a fan and gravity damper are installed. As soon as the fan turns off, the damper lowers under its own weight and completely blocks the air intake. As soon as the temperature sensor detects a decrease in the temperature of the coolant to a user-specified level, the controller will turn on the fan, the air flow will open the damper and a fire will break out in the firebox. Periodic “shutdown” of the boiler in combination with an increased volume of the firebox allows you to extend operation on one load of fuel up to 10 - 12 hours with wood and up to 24 hours with coal. The automation of the Polish company KG Elektronik has proven itself well: a controller with a temperature sensor - model SP-05, a fan - model DP-02.

do-it-yourself solid fuel boiler with extra long burning time

The firebox and heat exchanger are wrapped in basalt wool (thermal insulation) and placed in the housing.

The process of making a boiler with your own hands.

First of all, you need to prepare all the necessary preparations:

- Steel sheets 4 - 5 mm thick for making a firebox. Alloy steel of heat-resistant grades 12Х1МФ or 12ХМ (with additions of chromium and molybdenum) is best suited, but it needs to be welded in an argon environment, so the services of a professional welder will be needed. If you decide to make a firebox from structural steel (without alloying additives), then you should use low-carbon grades, for example, Steel 20, since high-carbon grades may lose their ductility due to exposure to high temperatures (they are hardened).

- Thin sheet steel 0.3 - 0.5 mm thick, painted with a polymer composition (decorative cladding).

- 4mm structural steel sheets for the body.

- Pipe DN50 (fire pipes inside the heat exchanger and pipes for connecting the heating system).

- Pipe DN150 (pipe for connecting the chimney).

- Rectangular pipe 60x40 (air intake).

- Steel strip 20x3 mm.

- Basalt wool 20 mm thick (density - 100 kg/cubic m).

- Asbestos cord for sealing openings.

- Factory made door handles.

Welding of parts should be performed with MP-3S or ANO-21 electrodes.

How the system works

The simplest water circuit is with natural circulation of water flow. Its basis is a simple physical phenomenon: the expansion of liquids when they are heated. The unit that creates pressure is an expansion tank (a container for collecting water), installed in the attic or attic.

The water circuit is a closed system. The boiler heats the water in it and, expanding, it is directed through a pipe into a storage tank. The movement is carried out under pressure created by the cooled water constantly entering the boiler and passing through the entire system. Boiling water from the expansion tank is directed by gravity down through the pipes leading to the batteries. Having given off the heat, it returns to the tank and heats up again.

Installing a pump will help to significantly increase the pressure in the system and speed up the circulation of the coolant. At average outdoor temperatures, it can be turned off and the circuit will function on the natural movement of water. This will save you on your energy bills. Water enters the pump with the check valve closed. By turning it off (leaving it open), the entire volume of coolant is directed to bypass the pump.

Such a stove can be loaded not only with wood or coal. When using alternative fuels, it is possible to complicate the structure of the system by adding:

- granule storage tank;

- a mechanism that feeds pallets into the firebox (pneumatic or auger).

You can make the operation of the stove easier by installing an automatic system for regulating its operation and forced ventilation.

Creating a heating wiring diagram

You can combine a stove with a water heating boiler and connect the circuit to the heating system using two schemes.

Open system

With an open system, the expansion tank is located at the highest point - in the attic; you can include a pump in the circuit

The coolant moves by gravity, so the installation of a circulation pump is required. It is placed on the bypass, reduces the temperature difference between the return and supply, increases the speed of water movement and the quality of heat transfer. Without electricity, the line will operate on the principle of gravity.

To organize it, you will need to increase the line and horizontal slopes in diameter. The open system is equipped with a 32 mm distribution manifold with a slope of 3 to 5 mm per linear meter. The expansion tank is located at the top; air enters it from the communications.

Closed system

The radiator network provides for forced movement of water. The thrust in this case is created by a pump. It also pumps up pressure from 1 bar for cold coolant. The membrane-type reservoir is located at the bottom. A shut-off valve is used to connect it to the main line. Safety devices (air vent, pressure gauge, drain valve) are required.

Installing a water circuit in the chimney

The water circuit heat exchanger has a complex design. One of the options for its placement is to be built into the chimney. The furnace can be initially built with a coil, or it can be built into a ready-made structure.

Peculiarities

This method allows you to use heat, which quickly and practically uselessly flies into the pipe. Wherein:

- The decision to install this type of circuit is made at the furnace design stage. It is virtually impossible to integrate a heat exchanger into the chimney of a stove that has already been put into operation.

- Heat is not taken away from the stove; the firebox heats up to the maximum.

- The degree of heating of the coolant is regulated by the length of the coil. For a large house - a large coil.

- The service life of the coil built into the smoke duct is much longer, since there is no contact with fire.

- Requires a stove with a rather large and complex chimney, which leads to an increase in the size of the stove.

Installing a heat exchanger in the firebox

Boilers installed in the firebox have a variety of designs and do not require a large firebox volume. The spider model heat exchanger shown in the photo has a symmetrical two-sided structure and can consist of a different number of fins. It is quite compact. Through its openings, an open fire perfectly heats the walls of the oven.

Peculiarities

- possibility of heating large areas;

- several options for the structure of the boiler (in the form of a wide tank or flat container);

- flat boilers and tanks have a larger volume than pipe structures and allow some of the water to be used for sanitary needs;

- difficult, but nevertheless a real possibility of embedding into an already folded stove.

A tubular heat exchanger is the most popular solution for installation in a firebox. He can :

- have various simple and complex shapes and dimensions;

- installed on the outside of the firebox or on two or three sides;

- easy to remove from the oven for routine inspection and repair.

Choose seamless patterns. Their distinguishing feature is the absence of a longitudinal weld line. Seamless pipes often crack when heated.

Installation

The heat exchanger is placed on the bottom row of bricks in the firebox and lined with fireclay stone. The size of the structure is selected taking into account the parameters of the firebox. There should be enough space left for storing firewood. The registers should not touch the walls of the combustion chamber, but too much distance will not do any good. A hole is left in the firebox for the inlet pipe and then the roof is laid out.

Installing a coil on a pipe

This is an excellent and fairly simple way to increase the efficiency of the stove. Flue gases heat the pipe to extremely high temperatures. The outer coil, like the inner one, helps reduce the temperature and somewhat cool the outer surfaces of the chimney. An external water heat exchanger is especially often installed on metal chimneys. This is an excellent auxiliary device for heating small spaces.

This heat exchanger has two pipes. The top one is connected to a pipe going to the storage tank, the bottom one is connected to the heating circuit. It is easy to make such a structure, as well as attach it to a pipe.

Use copper pipe or ready-made modules.

Materials for assembling a shaft-type boiler

To make a mine-type pyrolysis unit with your own hands, you need to prepare:

- Steel sheets with lining 3 -5 mm thick. You should not use another type of steel, since pyrolysis takes place at high temperatures and a regular alloy will quickly burn out.

- Sheet steel having a thickness of 1-2 millimeters.

- Fireclay brick.

- Pipes with a diameter of 25 and 135 millimeters.

- Corners 4x4 centimeters or a profile pipe of a similar size.

- Double ash door, preferably with an asbestos gasket.

- A valve designed to regulate air supply.

- Door for cleaning the heat exchanger chamber.

- Valves - 3 pieces: one is needed for the chimney, the second is placed between the chambers on the partition, and the third is required to regulate the flow of air into the combustion chamber.

- Basalt wool.

- Galvanized sheet.

But, before you go shopping for building materials, you should calculate the minimum power of the unit. Then they begin to develop drawings of this device.

You can use ready-made calculations and boiler diagrams. When choosing a drawing, special attention should be paid to the volume of the combustion chamber. The larger this value, the longer the combustion will be.

Important points in the construction of a furnace

In order for the water circuit to function with maximum efficiency, not only the heating water system must be properly designed, but also the furnace itself. Mere observance of order is not enough. Full compliance with furnace construction technology is important.

Foundation

Its type and thickness depend on the size of the stove. It is recommended to install a massive classic Russian stove on a solid strip foundation. For smaller modern heating structures, a concrete pad one and a half ten centimeters thick, sometimes on a frame made of reinforcement, is sufficient.

Brick

For external walls, ceramic refractory bricks are used. For the base - his own, possibly second-hand. Experts recommend that you always line the inner surface of the firebox with fireclay stone. For a more presentable appearance of the facade, it can be laid with facing bricks right away or this finishing can be done later.

Solution

The mortar for masonry is prepared traditionally: sand is mixed with clay, diluted with water and a little cement is added for strength. You can purchase a ready-made cement-based masonry composition with special additives.

Masonry

The main condition for a strong structure is the presence of high-quality ligation of seams. They must not coincide under any circumstances. It is ideal when the seams of the bottom brick row fall under the middle of the bricks lying in the next row. To do this, starting the rows, alternate whole bricks and their halves.

Stoves with a water heating body have a fairly simple and understandable design. They are popular due to their low cost and ease of use. And if you don’t like using natural gas to heat your home or don’t have access to a gas network, this heating option should be considered first. Built by a good craftsman, such a stove never disappoints its owners.