In what cases is it compiled?

The act is required when:

- Commissioning of new equipment. The certificate will confirm that each element is in its place, the installation was carried out responsibly, and the system is working.

- The heating season is approaching. After a summer break in work, the pipes could fail. After checking their capacity, a report is drawn up.

- Already carried out repair work.

- The occurrence of contained emergency situations on the pipeline. In this way, specialists identify the amount of work required and the weak points of the existing heating network.

For the uninterrupted operation of the heating system, preventative control checks and reliable information about the quality functioning of the system upon startup are necessary.

Chemical flushing of heating systems

In the process of chemical cleaning of elements of heating structures, the circuit is filled with reagents (an acid or alkali solution with inhibitors to prevent corrosion processes in pipelines) and their long-term circulation in the system is ensured (for more details: “Flushing a heating system in a private house - instructions and rules for flushing”).

Used compounds are disposed of, but since they are not allowed to be drained into the sewer (reagents can significantly shorten its service life), neutralization is first carried out by adding an alkaline solution to the acidic reagents and vice versa.

Chemical washing is effective in cleaning steel pipes from rust, as well as magnetic and calcium salts. As for siltation, then it is useless (about

The essence and types of crimping

Nowadays heating is most often carried out by a “water circuit” system. In this case, heated water circulates through the pipes, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then there is a level of risk and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels inside.

- Documentation of work performed, generation of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly and does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping from the very beginning. Only a heating system that has passed the test is allowed into the heating season.

Important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

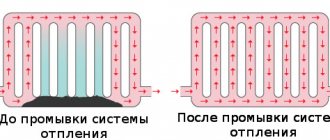

If there are deposits of about 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a special report is also drawn up.

The procedure for flushing the heating system and its design

The sequence of work performed by organizations that specialize in flushing heating structures is as follows:

- The equipment is being inspected. An assessment of its technical condition is made. Primary pressure testing is carried out, and the pressure must exceed the operating indicators by 1.25 times (minimum value - 2 atmospheres). This is necessary so that during operation, leaks do not cause a conflict with the customer of the work. Any deficiencies found should be corrected before flushing begins.

Hydropneumatic flushing

As mentioned earlier, hydropneumatic flushing of the pipeline heating system is carried out using a special pulp. This method of descaling pipes involves using a large amount of water. Houses connected to central heating or water supply use hot water circulating in pipes. If the heating system is located in a private house, then purification is carried out using cold water supply.

Hydropneumatic cleaning

When flushing the heating with hydropneumatic pressure cleaning, perform the following algorithm of actions:

- the water is forced to circulate in the opposite direction to the heating, then it is started again;

- together with the incoming liquid, compressed air is blown in using a compressor;

The resulting flow copes well with sludge, but does not sufficiently wash away salt deposits and rust formed on the walls of the pipeline and radiators. When risers are used in heating, during the process they are blocked in groups and washed. The fewer risers are included in the group, the better the radiators will be cleaned.

When cleaning the heating yourself, it is very important to carry it out until the waste liquid is as clean as possible and no longer contains rust particles or sediment.

Acceptance

In the first section of our material, we touched upon the acceptance of casual washing. Let's give it more attention.

Formally, the acceptance of flushing must be reduced to measuring the amount of suspended matter in samples taken in the elevator unit and several sections of the circuit.

In practice, a simpler method is used:

- The lower blind plugs of several radiators are unscrewed.

- Client representatives visually evaluate the contents of the end sections.

The survey results are activated. If you are thirsty, an example of the act of flushing the heating system is easy to find on the websites of specialized organizations.

It is recommended to include the following items:

- Washing technology.

- When using the hydropneumatic method, it is worth mentioning what kind of water was used - cold or warm.

- Water consumption and (in the case of warm water) its temperature are also indicated.

- Finally, an assessment of the quality of washing (satisfactory or unsatisfactory) is included in the report. In the second case, the procedure and timing for re-execution of work can be agreed upon.

Pipeline (pipeline network) flushing/purge act

Capital construction project_________________________________________________

(Name,

__________________________________________________________________________

postal or construction address of the capital construction project)

Developer or customer__________________________________________________________

(name, number and date of issue

__________________________________________________________________________

certificate of state registration, OGRN, TIN,

__________________________________________________________________________

postal details, telephone, fax - for legal entities;

__________________________________________________________________________

last name, first name, patronymic, passport details,

__________________________________________________________________________

place of residence, telephone, fax - for individuals)

The person carrying out the construction_______________________________________________

(name, number and

__________________________________________________________________________

date of issue of the state registration certificate, OGRN,

__________________________________________________________________________

TIN, postal details, telephone, fax - for legal entities;

__________________________________________________________________________

last name, first name, patronymic, passport details,

__________________________________________________________________________

place of residence, telephone, fax - for individuals)

Person carrying out construction, performing technical supervision of installation work_________________________________________________

(name, number and

__________________________________________________________________________

date of issue of the state registration certificate, OGRN,

__________________________________________________________________________

TIN, postal details, telephone, fax - for legal entities;

__________________________________________________________________________

last name, first name, patronymic, passport details,

__________________________________________________________________________

place of residence, telephone, fax - for individuals)

The person preparing the design documentation_____________________

__________________________________________________________________________

(name, number and date of issue of the certificate of

__________________________________________________________________________

state registration, OGRN, TIN, postal details,

__________________________________________________________________________

telephone, fax - for legal entities;

__________________________________________________________________________

last name, first name, patronymic, passport details, place

__________________________________________________________________________

residence, telephone, fax - for individuals)

The person carrying out the construction who carried out the flushing/purging of the pipeline (pipeline network)__________________________________________

(name, number and date of issue of the certificate

What is crimping?

Immediately before testing, it is necessary to check all elements of the system: valves, filling fittings, etc. If necessary, a gland seal is added in some places to increase tightness. Using plugs, the system to be tested is isolated from the main water supply. Also, according to SNIP 3.05.01-85 clause 4.6, the expansion vessel and boiler should be turned off, and after that the pressure testing procedure itself is carried out.

To carry out crimping, special equipment is required. Typically this is a pneumatic or hydraulic pump. The choice of equipment depends on how the tests will be carried out with water or air.

Checking the tightness of the system itself involves pumping water or air into the system under very high pressure. For cottages this is about 2 atmospheres; in apartment buildings this value is higher and depends on the operating pressure of the system. Typically, the critical pressure is 20–30% higher than the operating pressure.

If during the pressure testing process “weak” places are discovered, that is, places where the injected water or air escapes out, thereby indicating a violation of the tightness, then they must be replaced. This allows you to identify problems in a timely manner and eliminate them in a timely manner.

At the end of the procedure, a pressure test report for the heating system is drawn up.

Certificate of testing of external and internal sewerage for spillage

A test report for internal and external sewerage is drawn up as a result of checking the operability of the system. It confirms the position of the commission that the system has withstood the test of a spill of water, and the design complies with the design documentation, GOSTs and standards.

Diagnostics of the normal functionality of the sewer system is necessary when installing a new facility or after carrying out repair work on an existing system. Information about the performance check is entered into the report. The form is drawn up in the form specified in Appendix “D” to the Code of Rules 73.13330.2012.

The act specifies:

- name of the system and the facility in which it is installed;

- information about the members of the commission. Representatives of three organizations are needed: the general contractor, the customer and the installation company;

- information about the name of the project is written down;

- the results are entered: the number of simultaneously connected devices, as well as the connection time or filling of water on the floor (unnecessary ones are crossed out);

- the third paragraph states that no leaks were detected at the joints and through the walls. This means the system is suitable for use.

The decision is signed by the members of the commission.

Concentrates

DIXIS LUX

The drug is diluted with water (preferably soft or rain) in a ratio of 1 to 9. The product is suitable for heat transfer surfaces made of ferrous metal, stainless steel, and copper alloys.

Price: from 1530 rub./10 l.

DIXIS LUX

pros

- low price;

- neutralizing solution included;

- You can drain the used product into the sewer;

- quick rinse (2.5 hours);

- Contains only organic acids, acid corrosion inhibitor.

Minuses

the required temperature of the working environment is 60...70 °C.

DIXIS LUX

ARGUS SUPER POWER

Before use, the concentrate should be diluted with 10-15 liters of water, depending on the degree of contamination. Contains a corrosion inhibitor. Operating temperature for effective cleaning is 20...40 °C.

Price: from 1200 rub./4 l.

ARGUS SUPER POWER

pros

- low cost;

- color indicators;

- corrosion inhibitors;

- low operating temperature.

Minuses

- has a characteristic odor;

- there is no information about the possibility of draining liquid into the sewer.

ARGUS SUPER POWER

Heat Guardex Cleaner 824R

The product is intended for cleaning the circuit in a heating system running on antifreeze. The product is diluted in a ratio of 1 to 30.

Price: 6400 rub./l.

Heat Guardex Cleaner 824R

pros

- highly concentrated substance;

- Effectively removes sludge and glycol residues.

Minuses

high price.

Heat Guardex Cleaner 824R

TELAKKA HEAT

1 liter of concentrate is diluted in 3–5 liters of water. The product is suitable for flushing systems with plastic and rubber tubes. The product is safe for sealants. The working temperature of the solution is 20...35 °C.

Price: from 1600 rub./5 l.

TELAKKA HEAT

pros

- operates at relatively low temperatures;

- contains anti-corrosion components;

- safe for rubber seals;

- without smell;

- does not contain mercury, chlorine, heavy metals and other harmful components;

- When combined with waste water, it does not form toxic or explosive compounds.

Minuses

- not suitable for products made of aluminum, non-ferrous metals and stainless steel;

- quite high cost.

Telakka HEAT heating system cleaner

SYNTILOR Watesup

This professional product is suitable for washing pipes made of plastic, metal alloys, and rubber. Requires prior testing when used in stainless steel equipment. Requires dilution in 5–15 liters of water. The solution does not destroy seals.

Price: from 450 rub./l.

SYNTILOR Watesup

pros

- operates at low temperatures 20...35 °C;

- does not destroy rubber, plastic;

- does not affect the structure of metals;

- provide protection of metals from oxidation;

- has no pungent odor;

- without mercury, heavy metals, chlorine.

Minuses

- not suitable for cleaning aluminum and aluminum-based alloys;

- relatively high cost.

SYNTILOR Watesup

SYNTILOR Watesup All

The product is intended for flushing heating systems made of aluminum. The product does not destroy seals. Before use, it is recommended to dilute in 5–15 parts of water.

Price: from 480 rub./l.

SYNTILOR Watesup All

pros

- the preparation can also be used for different types of steels, including stainless steel (after a preliminary test);

- the solution is compatible with plastic and rubber pipes;

- does not contain mercury, heavy metals, or other harmful impurities;

- without smell;

- effective at temperatures 20...35 °C.

Minuses

not noticed.

SYNTILOR Watesup All