Home / Solid fuel boilers

Back

Published: 05/25/2019

Reading time: 2 min

0

6262

In the recent past, the rate of fuel combustion in solid fuel heating units could only be adjusted manually. For this purpose, there was a ash door, by opening or closing which the air flow to the firebox increased or decreased.

Today, an automatic device called a draft regulator for a solid fuel boiler is successfully used for this purpose. To set the required temperature. When using it, it is enough to determine the required coolant temperature. The presented characteristics will help demonstrate the capabilities of a useful invention for the home.

- 1 Why do we need draft regulators?

- 2 Operating principle

- 3 Types of regulators, and which ones are better

- 4 How to install and configure the regulator

Installation of the draft regulator:

The draft regulator can be installed in three ways: vertically and horizontally (from the side or front of the boiler).

1 Install the draft regulator in a vertical or horizontal position in a special 3/4 hole in the boiler body. Use special products to seal threaded connections.

2 If it is necessary to align the draft regulator relative to the boiler body, loosen screw 3 and bring the draft regulator to the required position. Fix screw 3.

3 Use the screw (2) to secure the lever (1) in the draft control body so that the hole for the chain is above the damper.

Advantages

Installing a chimney draft stabilizer provides a number of positive aspects:

- the safety of operation of the chimney system increases due to the stabilization of the flow of fuel gases;

- the service life of the chimney increases due to a decrease in peak loads from hot combustion products;

- the amount of harmful substances released into the atmosphere is reduced;

- Thanks to the constantly slightly open damper, air circulation increases;

- the regulator is capable of operating on forced and natural draft;

- stabilization of fuel combustion;

- maintaining a constant temperature of combustion products in the chimney, as a result of which it does not overheat;

- protection from strong gusts of wind;

- exhaust gases do not enter the room;

- it becomes possible to operate low-temperature heating devices with old chimney systems;

- external heat loss is reduced.

Traction control calibration:

1 Flood the solid fuel boiler.

2 Bring to a temperature of 60 degrees.

3 We set the temperature on the regulator to 60 degrees and connect the lever and the damper with a chain, so that the damper is slightly open by 1-2 mm.

4 Use the appropriate draft control scale depending on the installation method, horizontal is the upper scale, vertical is the lower scale.

An example of a completed draft regulator installation on a Cooper boiler:

An example of a completed installation of a draft regulator on a ZOTA MIX boiler:

Regulus draft control installation:

Installing a Honeywell draft control:

Installing the Esbe draft regulator:

Temperature regulator Boilers

Previously, the combustion intensity of solid fuel boilers was regulated manually by opening or closing the ash pan door, from where air is supplied to the firebox due to the natural draft of the chimney. Now this is done by a special device - an automatic draft regulator for the boiler. The owner of the house only needs to set the desired coolant temperature. The question is how well the thermostat copes with its functions and whether it is needed at all.

Self-assembly of the stabilizer

To make a stabilizer you will need:

- semi-automatic argon welding machine;

- argon gas cylinder;

- grinding discs;

- stainless steel AISI 304 or 321 with a thickness of 8-10 mm;

- steel rod with a diameter of 8-10 mm for the axle, screws, nuts and washers.

The pipe joint is fastened by welding so that the internal diameter is 115 mm. The welds must be thoroughly cleaned outside and inside, and a cutout made for the valve is 15% of the cross-section of the chimney pipe.

A latch is installed in the damper area, and the rotary axis, which is equipped with a rotary valve handle, protrudes from the pipe by 120-150 mm. From the top and bottom edges at a distance of 25-30 mm, roll the sides to connect with adjacent pipes.

It is best to install the stabilizer into a gap in the chimney pipe. To fix the device at the top and bottom, clamps 50-60 mm wide are used.

We offer you to watch a video of a homemade traction stabilizer.

How does the draft control work?

The main part of the air regulator is a mechanical thermoelement placed in a cylindrical housing. Through a lever and a chain, it regulates the rise of the air damper on the ash pan door.

The device is a sealed flask filled with a heat-sensitive liquid that expands greatly when heated. The flask stands inside the housing, which is screwed into the sleeve of the boiler's water jacket and is in contact with the coolant. How a thermostat with a chain drive works is shown in the diagram:

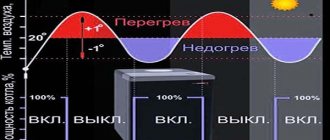

The operating principle of the automatic draft regulator is based on controlling the flow of air flowing into the firebox under the influence of chimney draft. The algorithm looks like this:

- When solid fuel burns and the coolant heats up, the liquid inside the element expands and acts on the actuator and lever, overcoming the elastic force of the spring.

- The lever weakens the chain, the valve begins to close and reduce the flow area. Less air enters the firebox, and the combustion process slows down.

- The temperature of the water in the boiler tank decreases, the liquid is compressed and the return spring forces the lever to open the damper again through a chain.

- The cycle is repeated until the wood in the firebox is completely burned out, then the spring opens the door as wide as possible.

The draft limiter works on the opposite principle - the higher the water temperature in the boiler tank, the stronger the damper closes

The adjustment knob at the end of the thermostat serves to limit the stroke of the lever and, accordingly, the air damper. This sets the maximum coolant temperature.

Reference. In addition to mechanical regulators that do not depend on electricity, there is automation for solid fuel boilers with a controller and a blower fan (or smoke exhauster). The latter supplies air to the firebox at the command of the electronic unit, which is guided by the signals from the temperature sensor. Similar automation kits are installed on all pyrolysis and pellet boilers.

Principle of operation

The mechanical draft regulator is installed so that its lower part is in contact with the coolant.

The main components of the device include:

- cylindrical body;

- thermostatic element;

- lever arm;

- chain connecting the ash pan door to the lever.

The device operates as follows:

- the liquid in the thermostatic element heats up in contact with the heating coolant;

- due to the expansion of the working medium in the thermostatic element, the actuator moves the lever;

- when the lever moves, the chain loosens and the flap begins to close the hole;

- by reducing the air flow into the firebox, the intensity of fuel combustion is reduced;

- the coolant cools down and at the same time the working medium in the thermostatic element contracts;

- the lever moves, slightly opening the damper;

- the adjustment is performed cyclically until the fuel burns out completely; when the coolant cools down, the lever raises the damper to the upper position.

There is a setting knob at the end of the device. It limits the stroke of the lever, determining the extreme position of the air damper. This makes it possible to set a certain coolant temperature, which will be maintained automatically.

Why are regulators needed?

Unlike any wood-burning stove, a hot-water solid fuel boiler is equipped with a water jacket and cannot heat up to too high a temperature, otherwise the water in it will simply boil. In such cases, the resulting steam sharply increases the pressure in the system, causing an explosion. That is, a solid fuel boiler, whose power is manually regulated by the ash pan door, is a source of increased danger.

Note. At the very least, the boiler, without any automation, can work together with a buffer tank - a heat accumulator, whose volume is correctly calculated. Excess heat will go there if you did not close the door in time and did not limit the flow of air into the firebox.

An automatic chimney draft regulator, which you can install on any solid fuel boiler yourself, will supply air for you and much better than you. It will react in time to an increase in the temperature of the water in the boiler jacket and shut off the air supply to the chamber if the firewood gets very hot. Although, by inertia, the temperature will rise for some time, but in general the heating process will stop. In addition to ensuring safety, a mechanical boiler draft regulator helps solve the following issues:

Purpose of the stabilizer

The design of the smoke exhaust system largely depends on the type of heating device with which it is intended to be used. Natural temperature changes caused by weather or time of year have a noticeable impact on efficiency. Significant temperature changes during the cold season can cause the formation of high air draft in the chimney, which will cause a decrease in the efficiency of the entire system and increased fuel consumption. The draft stabilizer allows you to regulate the created pressure to the optimal value, thereby increasing the efficiency of the heating device.

Also, the draft in the smoke exhaust system is affected by atmospheric air pressure, which can be determined by the location of the house, weather conditions, time of year and day. For example, the difference in atmospheric pressure in March on cloudy weather and September on a clear day can be up to 90 Pa.

The presented video shows the principle of operation and operation of a traction stabilizer in a chimney.

Recommendations for choosing a device

Oddly enough, you can still find budget models of wood-burning heaters on sale that are not equipped with any automation. Most of them have in the basic configuration only a sleeve mounted inside the water jacket. To automate such a boiler, you will have to buy and install a draft regulator yourself.

Hence the first recommendation: when choosing a heat generator, pay attention to the presence of such a sleeve and an ash pan door that rises upward.

To choose the right mechanical regulator, you must adhere to the following recommendations:

- the force developed by the drive (indicated in the product data sheet) must be enough to lift the door;

- select the temperature control range from 60 to 90 °C;

- make sure that the operating stroke of the drive is sufficient to fully open and close the sash;

- The threaded connection on the body must match the mating part in the boiler, usually ¾”.

You should also pay attention to the location of the liner in the boiler body. It can be on top, front or on the side panel. For the first option, you need to select a device that can work in a vertical position, for the other two - in a horizontal position. There are traction regulators, for example, Regulus rt3, which work in any position and have 2 adjustment scales.

Instead of a preface

Today, high technologies make it possible to create various automation tools; thanks to them, boiler equipment works independently, and there is almost no need to pay attention to it. But most of them use electricity, which is not very convenient. Along with power outages, the house is filled with cold, this situation cannot be called rare

The reason is that the heating device is turned off automatically

Along with power outages, the house is filled with cold; this situation cannot be called rare. The reason is the automatic shutdown of the heating device.

However, on sale today you can find fairly simple automation equipment that does not require electricity to operate; this includes a draft regulator, which is used in conjunction with mechanically driven boilers.

Brief conclusions

We can conclude about the need for draft regulators for solid fuel boilers: such primitive automation is better than its complete absence. Yes, mechanical regulators cannot boast of high accuracy, but they will save you from manual control “by eye” and will allow you to save wood and coal. The devices have an undeniable advantage over controllers and fans - energy independence.

In the recent past, the rate of fuel combustion in solid fuel heating units could only be adjusted manually. For this purpose, there was a ash door, by opening or closing which the air flow to the firebox increased or decreased.

Today, an automatic device called a draft regulator for a solid fuel boiler is successfully used for this purpose. To set the required temperature. When using it, it is enough to determine the required coolant temperature. The presented characteristics will help demonstrate the capabilities of a useful invention for the home.

Useful tips

The main recommendation from manufacturers is that the draft regulator must be tested at all possible temperature conditions before active use.

Don't worry if something goes wrong the first time. After closing or opening the damper, several minutes will pass until the coolant cools down/heats up.

Watch videos about the Kupper line on our company’s website, as well as a free course on installing and configuring the regulator. Teplodar specialists are always happy to answer any questions you may have.

Why do you need draft regulators?

First of all, a hot water boiler operating on solid fuel differs from conventional stoves in the presence of a water jacket. For this reason, the heating temperature of its circuit has its own limit, limited by the possibility of boiling of the coolant.

If it comes to this, steam will enter the system, which will quickly increase the pressure and cause an emergency. In other words, an uncontrolled manually operated boiler is a dangerous unit.

The draft regulator installed on the boiler controls the fuel combustion process in automatic mode, allowing you to avoid critical temperature values. It is designed to control the heating of the coolant and is able to reduce the air flow to the firebox if necessary to reduce the combustion intensity.

In addition to ensuring safety, the device is designed to perform the following functions:

- Regulates the set temperature of the coolant, the heating of which does not always need to be kept at 90 degrees.

- By closing the valve that limits the air flow, the period of fuel combustion from one fill increases, which significantly increases the efficiency of the unit.

To ensure the safety of the heating circuit, a safety valve is used that can release excess pressure. However, this device is not able to control the heating temperature of the coolant, which, if it reaches a critical point, can lead to serious consequences, resulting in the need for repairs.

Physical phenomena in the chimney system

The stable operation of a heat source (boiler, stove, etc.) largely depends on the correct setting and adjustment of the combustion mode. One of the factors is sustainable traction. Combustion products (gases, water vapor, mechanical particles) from the combustion space exit through the chimney. The latter is a channel made of fireproof material (brick, stainless steel, ceramics).

The chimney system can have different sizes, both in height and internal cross-section. It is quite difficult to make a high chimney (10-15 m) with the correct parameters. As a result, phenomena such as unstable mode or “reverse” thrust arise. In the latter case, the direction of movement of combustion products changes in the other direction, into the room. Reasons may include:

- narrowing of the internal channel due to soot, soot, and trapped debris;

- an increase in pressure at the outlet of the chimney during strong gusts of wind (the chimney “blows out”);

- seasonality of the climate, in which there are differences in atmospheric pressure and temperature in cold or warm times;

- the chimney was built in the “wind” shadow of another tall building or nearby trees.

This causes a change in the vacuum of the flue gases. On the other hand, the opposite phenomenon may be observed—increased emission. In this case, the sound in the pipe resembles the roar of a jet engine. By regulating the pressure inside the chimney, a uniform exit of combustion products from the boiler is achieved. For this purpose, a special device is used - a chimney draft stabilizer.

Types of regulators and which ones are better

On the modern market there are samples capable of performing both automatic and mechanical draft control for boilers operating on solid fuel. An automatic regulator can provide a wider range of adjustments, but is more expensive. In addition, the device requires an uninterrupted connection to the electrical network, and such a draft regulator for solid fuel boilers is difficult to install with your own hands.

For this reason, for solid fuel boilers, mechanical draft regulators are more often chosen, capable of providing control regardless of energy sources. The most popular are sectional units made of cast iron. The regulator provided by the design allows the device to be used to control the temperature in a selected range, which allows the use of a long-burning boiler in an economical mode without direct participation. It is best if the adjustable temperature range is from 60 to 90 degrees.

Among imported manufacturers, the most popular is the Czech one, which produces draft regulators for solid fuel boilers of the “Regulus” series, which are suitable for equipping not only branded products, but also other units.

Mechanical automation for TT boilers

The mechanical draft regulator for solid fuel boilers has a simple design. The operating principle is as follows:

- The thermostat is installed in a special mounting hole leading to the water jacket of the boiler, which allows the device to be in direct contact with the coolant medium.

- The actuator has a chain drive connected to the ash pan flap. The chain regulator, when heated, tightens or releases the chain, opening and closing the door.

- The temperature-sensitive element is filled with liquid or gas. When heated, the substance expands, which sets the device in motion.

- Settings are made using the controller located on the head of the mechanical temperature controller.

The mechanical temperature controller device has the following advantages:

- Reliability.

- Energy independence.

- Low cost.

The disadvantage of the thermostat is the error in setting, which is several degrees. The efficiency of the device is affected by the weight of the ash pan door and the correctly selected chain length.

How does a mechanical traction control work?

The operating principle of the mechanical regulator and air supply is as follows:

- As the coolant heats up, it affects the temperature-sensitive element, thereby driving the chain drive.

- The ash pan damper closes, the fire begins to die out, and the coolant cools.

- After the temperature in the water circuit drops, the temperature-sensitive element begins to work in the opposite direction. The ash pan door opens slightly. The fire flares up with renewed vigor.

Installation of the draft regulator for a solid fuel boiler is carried out in a special mounting hole located on the front or side panel.

The operation of the regulator is based on the principle of thermal expansion of the substance surrounding the temperature-sensitive element.

How to install and configure the regulator

To install the draft thermostat, it is necessary to free the boiler jacket from the coolant; for this purpose, as a rule, special taps are provided in the unit piping that cut off the circuit with the heating element. Otherwise, you will have to drain the entire volume of the system.

The next step is to remove the plug from the sleeve on the boiler, and install the prepared device in its place. After this, the system is filled with water again. To set up the draft regulator, you need to start the boiler for heat and perform a series of sequential actions.

- Open the damper to fully supply air to the firebox. In this case, the chain should not be connected yet.

- It is necessary to loosen the fixing screw on the adjustment handle.

- Select the position corresponding to the required temperature, for example, 70°.

- Noting the heating with a thermometer, connect the chain to the damper when the coolant reaches a temperature of 70°. The damper, in this position, should leave the hole open by only 2 mm.

- Finally, the fixing screw is tightened again.

After the structure is assembled, the draft regulator is checked in different operating modes from maximum to minimum. You should pause for the difference between reaching the set temperature and the moment the lever is activated, because firewood is not a gas and extinguishes smoothly. For this reason, you should not rush to set up the device again without pausing. After passing all checks, the installation of the draft regulator is considered completed.

Installation rules

Standard sleeve and adjuster threads are typically 3/4 inch. The accessory does not screw in immediately; first, sealing agents are applied to the threads. FUM tape (fluoroplastic sealing material for sealing pipelines) is often used. You will also need an adjustable wrench and a regular Phillips screwdriver for installation.

Before starting work, the liquid (coolant) is drained from the water circuit. Then the shut-off valves are closed and the plug is removed from the boiler sleeve. FUM tape is applied to the external thread of the traction regulator.

The device twists clockwise quite tightly, but without excessive effort. This completes the installation of the regulator. All that remains is to prepare it for work and launch it correctly.

Connection diagrams

All methods of connecting a thermostat to a heating system are divided into three connection options:

- Directly to the boiler.

- To the circulation pump.

- On the pipe supplying coolant to the radiator.

The first two schemes eliminate the deterioration in the throughput of the heating pipeline. No additional locks are placed in it, and the hydraulic resistance of the entire system does not change. The thermostat here only controls the operation of the pump or boiler; it “does not come into contact” with water.

When installing a thermostat on a battery or a common pipe with several radiators, the hydraulic resistance, on the contrary, increases. Even when fully open, the thermostat valve slightly slows down the flow of coolant.

Ideally, the boiler piping project should be carried out immediately, taking into account all thermostatic and other devices.

If the water heating system in the house is made according to a single-pipe scheme, then it is better to immediately abandon the third option. When the temperature sensor is triggered, the valve will immediately shut off the entire radiator line in several rooms, and then you can immediately forget about comfort in rooms far from the boiler.

The thermostat should be connected to the radiator input via a bypass. So, when triggered, it will redirect the coolant flow bypassing the battery. In this case, the water will return uncooled back to the boiler. The latter will stop heating it, thereby reducing the consumption of gas fuel or electricity.

The temperature sensor must be mounted:

- in a place where there is no direct sunlight;

- away from cold bridges, drafts and rising heat flows from radiators;

- so that it is not covered by decorative screens or curtains;

- at a height from the floor within 1.2–1.5 meters.

If the sensor is installed incorrectly, the thermostat will produce false signals. This can lead to overheating not only of the air in the room, but also of the coolant in the system. And in the second case, it won’t be long before there are problems with the boiler.