The task of the circulation pump is to drive the coolant along the entire line of pipes through the boiler with the most efficiently configured operating parameters. An incorrectly selected device will reduce the efficiency of the system, the water circulation will be less efficient, and the heating will be weak and slow. If the device is too powerful, excessive consumption of electricity is possible. It is necessary to pay attention to noise level, acceptable level of complexity of maintenance and repair. The pump must be installed and adjusted correctly. Let's look at how circulation pumps are selected, characteristics, stages and installation requirements, and how to install them.

Is it necessary, and in what cases?

Many owners of country real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then it will be necessary to remove air plugs or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

An additional pump in the heating system may not be needed if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the radiators and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Electrical connection options

An electric pump for heating has the only drawback: in the event of an emergency power outage, the circulation will stop, so it is necessary to design the system with the expectation of additional use of the natural flow of coolant.

The pump box is equipped with three contacts, marked as phase, ground, zero, which are connected to the socket with a cable and plug, or the cable line from the meter runs directly to the device. Manually starting the device increases energy consumption, wear of the mechanism and parts, so it is better to make the connection to electricity automatic - through a thermostat.

The advantage of using a thermostat is the regulation of the switching time: the pump of the Wilo heating system starts working only when the water is heated, and does not allow cold water to run idle.

Operating principle: the thermostat is attached to the pipe, measures the temperature of the heat pipe, and starts the mechanism of the unit.

If it was not possible to buy a device special for pipes, you can connect the circulation pump to electricity using a room household thermostat, which has an external temperature measurement sensor attached to the pipe.

In the absence of electricity, use a backup UPS source that provides uninterrupted power to the heating pump: car batteries, or a set of batteries in a compact cabinet.

The connection follows the following diagram: the home electricity line is connected to the UPS, then connected to the pump and boiler. Connection conditions:

- Do not allow the power cable to come into contact with hot parts of the device - motor, housing, pipe;

- Avoid wetting the terminal box;

- if the box is on the side, connection is allowed from below;

- the cable must be heat-resistant;

- be sure to ground.

If you equip the pipe with a thermostat, energy losses during pump operation will be reduced.

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

Operating principle of hydraulic separator

Such devices are recommended for use in heating systems where the coolant is heated using long-burning boilers. The fact is that the heating devices in question can operate in several phases (fuel ignition, combustion process and attenuation), and for each of these phases it is necessary to maintain a certain combustion mode.

Installing a hydraulic needle in the heating system allows you to create a certain balance in the operation of heat and warming up the system. The anuloid itself is made in the form of a pipe with four outlet pipes. The main functions of such a device include:

- Automatic removal of accumulated air;

- Collecting sludge particles (works as a dirt trap).

Heating in a private house performs many functions that must be implemented regardless of coolant flow and possible pressure drops in the pipelines. It is quite difficult to achieve efficient operation of the system, because the liquid enters the pipeline circuits from one source of thermal energy - the boiler, which will ultimately lead to unbalanced heating. To prevent such situations, the hydraulic separator serves; it performs the function of decoupling.

Do-it-yourself pumping equipment installation diagrams and standards

Circulation pumps are installed in two ways. The first connection diagram for the unit is two-pipe. This connection method is described by a high temperature difference in the system and variable coolant flow. The second scheme is one-pipe. In this case, the temperature difference in the heating system will be insignificant, and the media consumption will be constant.

Installed circulation pump

Connect the pump yourself according to the instructions that come with the unit. It also indicates the installation procedure for the functional reinforcement chain. Before installing the pump, be sure to drain all water from the system. Often there is a need to clean it. During the operation of the heating boiler, a lot of debris accumulates on the internal surfaces of the pipes, which worsens the technical performance of the system.

Experts advise placing the circulation unit in front of the boiler - on the return line. This is done in order to eliminate the risk of boiling of an open type heating system due to the vacuum that is created when installing the supply pump. In addition, if you install a circulation unit on the return line, its trouble-free operation will be significantly increased due to the fact that it will operate at lower temperatures.

The pump installation procedure itself looks like this:

- Make a bypass (in professional slang - bypass) in the area where the pump will be located. The bypass diameter is always taken to be slightly smaller compared to the cross-section of the main pipe.

- Mount (strictly horizontally) the shaft of the pumping device, and place the terminal box on top.

- Place valves (ball valves) on both sides of the pump.

- Install the filter. It is not recommended to operate the equipment without this device.

- Place an automatic (or manual) release valve above the bypass line. This device will allow you to clean air pockets that regularly form in the system.

Next, valves (shut-off) are installed at the inlet-outlet section of the circulation unit. For an open heating system, an expansion tank is additionally required (not installed in closed complexes). The final stage of installation work is the treatment of all connection points of various elements of the system with a good sealant.

Where to put

In the autonomous heating system of a private house, it is recommended to install circulation pumps with a wet rotor, which rotate without the use of special lubricants. The coolant and lubricating element here are the coolant. When installing such a device, the following rules must be taken into account:

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

Selection, calculation

Let's look briefly and clearly at how to choose a circulation pump for a heating system in specific situations.

What characteristics to pay attention to:

- pressure Must cover hydraulic losses on the line;

- productivity - max. pumped mass of resource per unit. time;

- working t°. Most modern models are designed for a range of +2...+110° C, which is enough for most circuits;

- power. Mechanical power, taking into account hydraulic losses, should prevail over useful power;

- The diameter of the pipes should be selected to match the existing pipes (25, 32 mm), however, adapters can also be used.

Circuit type

For open systems, wet devices are not desirable, since the coolant in them usually contains abrasive particles (sand, oxidized iron, lime, etc.): if they get between the rotor and stator, impeller, they will quickly damage the device. But in closed systems where the water is filtered, distilled, or another clean special coolant (propylene glycol) is used, such products will last for years without special maintenance. For units with a dry rotor, the quality of the working resource and the type of circuit do not matter.

Open circuit bypass pump:

Examples of schemes for one- and two-pipe circuits:

Another typical example:

Power calculation

There is a standard formula for calculating pump performance based on equipment characteristics: for every 10 meters of line there is 0.6 m of device pressure. For a small house with a contour of 80 m, we take a pump with a head of 4.8 m. It is advisable to add 15–20% of the reserve to the obtained result, especially if there are rises to the upper floors.

More complex equation:

R is taken as standard for the European region 100 W/m² for properties with 1 or 2 apartments and 70 W/m² for multi-apartment buildings.

Speed, noise

Modern average units are equipped with three speeds as standard. The selected unit must have adjustment; the wider its range, the better. The setting will allow you to quickly heat your home when it gets cold, and when it warms up, you can reduce heating and electricity consumption.

A dry pump cooler makes noise; if it is not possible to provide sound insulation and extraneous sounds are undesirable, then choose a wet version of the product.

Example of a circulation pump, manufacturers

Examples of popular brands with a good reputation:

As an example for a heating circuit for a house of 100 m², you can take the Grundfos UPS model, its characteristics are as follows:

- for pipe connection Ø32 mm;

- for productivity - 62 l/sec.;

- weight 3.65 kg;

- cast iron;

- The power is enough to raise the resource to the 2nd floor.

Central heating unit Wilo STAR-RS 25/6 180 (wet) can be considered as an average sample of a product for a not too demanding system:

There are electronically controlled devices that allow you to quickly, automatically switch the equipment to the desired mode depending on changes in pressure and temperature. Such devices are equipped with digital displays that display data on temperature, pressure, and resistance.

Dry or wet rotor

Wet pumps have the following features:

- if the pressure (meaning provided by the device, the calculation we described above) is more than 15–17 m, then for this parameter the products in question are rare on the market, they are expensive;

- used only for closed systems, where there is less need for high pressure, clean coolant;

- in terms of price, if the pressure is more than 10–14 m, it is often more expensive than a dry pump, and in addition, they have increased motor sizes;

- It is not recommended to place it on an open system where there may be dirt, sand and other abrasive particles. The pump will fail in a year or two, since water here acts as a lubricant, washes the internal parts, there is a constant circulation and friction of the abrasive, the gap between the rotor and stator quickly becomes clogged, and the graphite bearings wear out.

Up to 7–10 m of head for a productivity of 25–30 m³/hour, wet products are cheaper than dry ones. But the noise of the latter is much greater.

Tips on what to choose:

- at working requirements 1–10 m of water. Art., flow rate 1–25 m³/h, it is advisable to take wet products;

- at 12 m water. Art. and we select dry pumps for any performance. They are for particularly high consumption;

- in any case, if it is possible to make noise insulation, then a dry pump is a good choice;

- if less noise is required, then only wet types. You can use 2-3 such devices: they will cope with the increased requirements of the system, and at the same time there will be no noise, although the price of such a scheme may be somewhat more expensive. You can also install one powerful wet blower for heating, but such models, as we have already noted, are rare on the market and expensive.

With warm floor

When filling the system with coolant, it is not always possible to get rid of the air present here. Accumulated gases often block the movement of fluid, and not every manifold can be used as a relief valve. To solve this problem, the circulation pump has a special outlet valve made in the form of a disk.

To release accumulated gases, you need to turn this part with a screwdriver counterclockwise. After supplying water from the slot, the disk is tightened and the pump is started again. A similar procedure is repeated several times in a row.

Cost of different types of pumps

There are many companies on the market specializing in the production of circulation units. Consumers are advised to buy models from reputable European manufacturers. The products of some Russian enterprises are also in demand.

| Model | Manufacturer country | price, rub. |

| Prima UPS 25/60 180 | Russia | 1570 |

| Wester WCP 25-40G | Russia | 2127 |

| LRP 32-50/180 | China | 2598 |

| Hoffmann UPC 25-40 180 | Germany | 5256 |

| Yonos PICO 15/1-4 | Germany | 6051 |

| A 56/180 XM | Italy | 10953 |

You can find both budget and expensive models on sale. Which pump to buy for a heating boiler is an individual decision for the home owner. When choosing, some are guided by the level of popularity of the manufacturer, others - by cost, and still others - by the availability of the service. Learn how to choose a heating radiator by following the link.

The need to install an additional circulation pump

The thought of installing a second device arises when the coolant is heated unevenly. This is due to insufficient boiler power.

To detect the problem, measure the temperature of the water in the boiler and pipes. If the difference is 20 °C or more , the system should be cleared of air pockets.

If the malfunction continues, install an additional circulation pump. The latter is also necessary if a second heating circuit is installed, especially in situations where the length of the piping is 80 meters or more.

Reference! Invite specialists to clarify the calculations. If they are incorrect, installing an additional device will result in poor performance. In rare cases, nothing will change, but the purchase and placement costs will be wasted.

A second pump is also not needed if the heating system is balanced with special valves. Clear the pipes of air, replenish the amount of water and carry out a test run. If the devices interact normally, then there is no need to install new equipment.

Hydraulic separator

Used when installation of an additional pump is required. The device is also called an anuloid .

Photo 1. Hydraulic separator model SHE156-OC, power 156 kW, Poland.

Such devices are used in heating if water is heated using long-burning boilers. The devices under consideration support several modes of heater operation, from ignition to fuel extinction. In each of them, it is advisable to maintain the required level, which is what the hydraulic gun does.

Installing a hydraulic separator in the piping creates a balance during the operation of the coolant. Anuloid is a tube with 4 outgoing elements . His main tasks:

- independent air removal from heating;

- catching part of the sludge to protect pipes;

- filtering dirt that gets into the harness.

Attention! You need to carefully select the characteristics. Choosing a quality device will help protect the system from problems. Because of this, installing a pump becomes mandatory.

Functionality

A connection with a circulation pump performs many tasks. They must be allowed regardless of the flow of working water and possible pressure surges in the pipes. Efficiency is difficult to achieve because the fluid is supplied internally from a common source.

Thus, the coolant leaving the boiler unbalances the system.

Because of this, a hydraulic separator is placed: its main purpose is to create a decoupling that will solve the problem described above.

The following functions are also important:

- contour matching , if several are used;

- support of the calculated flow rate in the primary piping, regardless of the secondary ones;

- constant operation of circulation pumps;

- facilitating the operation of branched systems;

- cleaning pipes from air;

- sludge fishing ;

- ease of installation when using modules.

Where to put the second device in the house

In autonomous heating, it is recommended to install a device with a wet rotor, which is self-lubricated with the working fluid. Therefore, consider the following points:

- the shaft is positioned horizontally , parallel to the floor;

- the water flow is directed in one direction with the arrow installed on the device;

- the box is placed on any side except the bottom , which protects the terminal from water ingress.

The device is mounted on the return line, where the coolant temperature is minimal.

This increases the service life, although some experts disagree with this phrase. The latter is related to the operating rules: the device must withstand heating of the working fluid to 100-110 °C.

Important! Placement is possible not only on the return pipe, but also on the straight pipe. The main thing is to install it between the boiler and radiators, since the opposite is prohibited. This also makes the device easier to maintain.

Recommendations for pump installation procedure

This work should be done in the so-called “off-season”. But if there is a need to carry out the installation during the heating season, the boiler needs to be “turned off” and wait until the temperature of the coolant drops - these are basic things that do not need additional comments.

- If it is necessary to install a bypass, it is better to assemble it separately, installing all the fittings and the circulation pump. All that remains is to make an insert into the pipe.

- The next stage is bleeding the air while simultaneously monitoring the system to detect leaks.

After this, you can safely switch the circuit to work with a pump.

Useful tips

Circulation pumps are divided into 2 groups, according to the specific location of the rotor - “wet” and “dry”. What is the difference? Without going into the specifics of engineering solutions, it is enough to just note the pros and cons of each modification.

With a “dry” rotor. Higher efficiency. But there are also disadvantages - increased “noise”, the need for regular maintenance (primarily lubrication of seals) and special requirements for operating conditions. Such circulation pumps must be installed in separate, absolutely clean rooms. The explanation is simple - the slightest dust leads to a decrease in their efficiency or breakdown.

Recommendation - it is advisable to purchase a “dry” pump if there is no analogue in the boiler itself, and the product is the only device that ensures water circulation through the pipes of the heating system.

With a “wet” rotor. As a rule, these pumps are installed more often. The fact is that all modern household heating boilers are initially equipped with such a device (located under the casing of the unit), and the newly installed one serves only as an additional element that ensures better coolant circulation. For example, when choosing the wrong heat generator model, when increasing the length of the heating circuit, when installing radiators not provided for in the primary circuit.

The disadvantage of such a pump is low efficiency. But taking into account that it is not the only one in the system, this drawback is leveled out, since it does not particularly affect the heating efficiency. An additional advantage is that no maintenance is required. Such pumps function properly until their service life is completely exhausted, provided that the rules for their installation are followed.

Recommendation - if your household boiler already has its own pump, then you can safely choose a product with a “wet” rotor.

Is an additional pump needed for a double-circuit boiler?

After installing a double-circuit condensing boiler, many users consider installing an additional pump in the heating system of a country house. The need to use an additional pumping device is explained by the uneven heating of the living spaces of a two-story house with sufficient power of the boiler equipment.

Advice! If the temperature differences of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air pockets.

Installing another pump is necessary in the following cases:

- When installing heating in a private house with an additional circuit, or in cases where the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced using special valves. Therefore, before purchasing pumping equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If after such procedures the autonomous heating of a private house works normally, then another pump will not be needed.

Installation rules

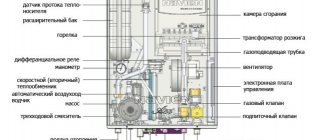

The main components of the heating system: boiler, membrane expansion tank, circulation pump, radiators, coupling valve, gas valve, alarm devices. It is necessary to have a mesh filter, a water supply branch, controls, temperature and emergency sensors.

When determining the location of the structure, the main condition is to ensure free access to the unit and electrical network devices, as well as to connect the grounding. Other Important Pump Installation Conditions

- “Wet” models should be positioned only horizontally, so that the rotor is completely immersed in water.

- Versatile equipment of the device with ball shut-off valves for maintenance, repair, dismantling.

- Installing a protective filter in front of it.

- The bypass is equipped with a built-in valve to remove air plugs.

- Hermetic serial connection of threaded elements of the system.

The instructions included with each device contain the basic rules for installation and operation. Exact fulfillment of all conditions will extend the life of the structure and ensure uninterrupted supply of coolant.

Why do you need a hydraulic arrow?

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or hydraulic arrow must be included in the circuit. This device can be used together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Catching dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail if there are several booster units.

Types of devices for boilers

Pumps embedded in the heating circuit increase the circulation of coolant in the pipes. Depending on the area of application, they differ in design and technical parameters.

The devices are divided into two types: circulation pumps for a gas boiler and feeders for steam units. The main thing is to choose the right device for a specific pipeline and boiler characteristics.

Circulating

Many models of single- and double-circuit gas boilers are equipped with circulation pumps that are installed next to the hydraulic unit. For domestic needs, the ideal option is single-phase pumps with a power of up to 100 W, providing a liquid pumping speed of up to 2 m/s. These models are easily installed on plastic pipes and can last for a long time without repair, as they are assembled from stainless components.

Pumps in single-circuit gas boilers, as well as in electric ones, are “wet” and “dry”. They are necessary in cases where there is low gas pressure in the system. The unit helps such a boiler develop power up to 80%.

Nutritious

Industrial installations designed to supply coolant to steam boilers of power plants or oil refineries are called feed pumps. The units, depending on the type of model, pump water with temperatures from 80 °C to 165 °C. The amount of impurities in the liquid should not exceed 0.2%.

Feeding units are produced in several types and in various designs. They are used in difficult conditions, so many are equipped with an automatic shut-off device. Each unit has a check valve - this is a protective measure to prevent reverse rotation of the rotor or overheating of the water.

The working part of the devices is made of steel, cast iron alloys or non-ferrous metals.

Installation nuances

When installing turnkey heating, a master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise; its rotor rotates without lubrication. Coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure-injecting device is positioned horizontally relative to the floor plane.

- Carry out installation in such a way that the direction of water coincides with the arrow on the device body.

- Install the device with the terminal box facing up, which will prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipeline of the heating system of a single-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend its service life.

Installation of the unit is carried out only after draining the water from the system. If there is a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, and a mesh filter is installed in front of the inlet pipe to prevent scale and debris from getting onto the impeller. In addition, shut-off valves are provided at the input and output of the device for possible replacement and repair of the device.

As we can see, installing a circulation pump requires certain skills, so the installation of this equipment must be carried out by a professional. To order a service, you can leave a request on the website or call the number

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

Additional pump in the heating system

The Vaillant boiler installed in the house has a built-in circulation pump. The heating circuits are quite extensive, and it seems that the power of this pump is not enough. Two-pipe system. The question is: is it possible to install an additional circulation pump that will work constantly. What’s confusing is that the built-in pump turns off during each operating cycle, although only for a very short time.

It is possible, but you need to install a hydraulic separator and turn on the pump from it. If you simply turn on the pump in series with the boiler, then when the water is heated, it will work “at a standstill,” which is harmful for it. Or, as an option, you can install a bypass valve. We implemented this solution once and it worked fine. But I like the hydraulic separator better, because I don’t need to configure anything.

Usually, in wall-mounted boilers, the pump can be switched to constant operation quite simply, this will also improve the hydraulics of the heating system. Just in case, check what speed the pump switch is set to. By what sensations did you determine that the pump power is not enough? If the temperature difference on the boiler is less than 20 or so and no circuit is being pressed through, it is necessary to balance the heating circuits. If the boiler cannot reach the temperature, there is not enough boiler power. Without a bypass valve and a hydraulic separator, an additional pump of increased power and pressure against the boiler can be installed as follows: between the supply and return of the boiler, install a full-bore jumper L = 300-400mm directly at the boiler (the smaller the better), install the additional pump on the supply line behind boiler and the jumper connection point at any distance from them. Those. you will get two circulation rings - a large one for the heating circuit and a small one for the boiler circuit, with minimal mutual influence of the pumps. This is how Pindos connect their hydronic boilers. politically incorrect, American-Canadians. It is clear that when the boiler is operating on DHW, circulation in the large circuit is maintained. As usual, a filter in front of the additional pump and taps.

Standards for installing gas mounted boilers

There are regulations that specify construction rules for installation.

When installing, be sure to follow the standards. Photo source: strmnt.com

First you will have to fulfill all the conditions specified in these documents:

- Call the gas workers so that the specialists check the existing conditions and, if the rules are followed, allow the connection of the unit to the central main line of the house.

- Draw up the project correctly to avoid a fine. An exception is that the heat generator has already been installed in the house and you only need to replace it with an identical model.

As soon as the project is completed, it is necessary to contact the state supervision authorities with papers. After checking, they issue permission to install a wall-mounted boiler.

Then you need to fulfill a few more mandatory conditions - choose the right height and comply with the requirements. security.

Height

When installing the boiler on the wall, you must follow the rules for selecting the optimal height specified in the SP. It says that from the floor to the bottom of the purchased boiler the distance should be 0.9 meters (minimum), but not more than 1.2 meters

It is important to note that these parameters are used for boilers, but gas manufacturers often make these requirements for boilers as well

It is important to comply with the minimum height established by gas workers, which is calculated by the distance from the chimney pipe. Official regulations indicate that a wall-mounted device will have to be lowered by 2 diameters (minimum value) of the chimney

The permissible limits for installing a heat generator are 0.8-1.8 from ground level.

Fire safety standards for installation

Equipped boiler room.

Photo source: th360.ru When installing a wall-mounted gas boiler in an apartment, it is necessary to comply with industrial safety standards.

Therefore, it is necessary to set fire breaks (minimum indicators that should be adhered to are indicated):

- The distance from the equipment to the wall is at least 10 cm.

- From the opposite wall - at least 40 cm.

The fire safety rules clearly state that a thermal insulation shield must be installed on the equipment, attaching it to the wall. It must be located immediately under the gas boiler. If you have to install a chimney through the roof, then it is also necessary to install fire breaks.

It is necessary to install a protective non-combustible partition between the room with a single-circuit wall-mounted boiler and the residential part. It must have an increased degree of fire resistance for the safety of household members. When connecting equipment, it is necessary to use a corrugated metal pipe. It is strictly forbidden to purchase rubber hoses for boiler installation.

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.

Safety precautions when connecting to the electrical network

Automatic adjustment of pressure and temperature is carried out by sensors powered by electricity. The circulation unit itself also operates from the mains. Therefore, safe operation in residential or domestic premises should be ensured.

- Mandatory grounding of outlets. They should be located away from stopcocks, safety valves and other elements that may leak.

- The wires are secured to prevent sagging on a wet floor or hot pipes or radiators.

- The insulation corresponds to that specified in the instructions for the unit.

General information about positive displacement pumps.

A hydraulic machine is called a volumetric hydraulic machine, the working process of which is based on alternately filling the working chamber with liquid and displacing it from the working chamber. The working chamber of a volumetric hydraulic machine is understood as a limited space inside the machine, periodically changing its volume and alternately communicating with the places of entry and exit of the liquid. A volumetric hydraulic machine may have one or more working chambers. Depending on whether hydraulic machines create or use fluid flow, they are divided into positive displacement pumps and hydraulic motors. In a positive displacement pump, liquid is moved by displacing it from the working chambers using displacers. Displacer - the working part of the pump that performs the work of displacement (pistons, plungers, gears, screws, plates, etc.). According to the operating principle (the nature of the fluid displacement process), volumetric pumps are divided into piston (plunger)

and

rotary

.

In a piston type,

liquid is displaced from fixed chambers as a result of the reciprocating movement of displacers (pistons, plungers, diaphragms).

In rotary

- liquid is displaced from moving working chambers as a result of rotational or rotational-translational movement of displacers (gears, screws, plates, pistons).

According to the nature of the movement of the input link, volumetric pumps are divided into rotary (with rotational movement of the input link) and direct-acting (with reciprocating movement of the input link). The general properties of positive displacement pumps include the following: 1. Cyclicity

of the working process and the associated batching and unevenness of supply.

The supply of a volumetric pump is not carried out in a uniform flow, but in portions, each of which corresponds to the supply of one working chamber. 2. Tightness

of the pump, i.e. constant separation of the pressure pipeline from the suction pipeline (vane pumps are not hermetically sealed, but are flow-through).

3. Self-priming

, i.e. the ability of a positive displacement pump to create a vacuum in a suction pipeline filled with air, sufficient to lift the liquid in the suction pipeline to the level of the pump.

In this case, the liquid suction height cannot be greater than the maximum permissible. Vane pumps without special devices are not self-priming. 4. Rigidity

of the characteristic (its steepness in the coordinate system (or) according to), which means a small dependence of the pump supply on the pressure it develops.

The ideal flow does not depend at all on the pump pressure (the characteristics of vane pumps are usually flat). 5. Independence of the pressure

created by the positive displacement pump from the speed of movement of the pump working body and the speed of the liquid. When operating on an incompressible fluid, a positive displacement pump with an ideal seal is capable of creating an arbitrarily high pressure due to the load at an arbitrarily low speed of movement of the displacers. To obtain high pressures with a vane pump, high wheel speeds and high fluid velocities are required.

Parallel and series connection of pumps

Designations

\(L_{E}\quad\) Equivalent or total flow \(L_{1}\quad\) Flow of the conditional first pump \(L_{2}\quad\) Flow of the conditional second pump \(P_{E}\quad \) Equivalent pressure \(P_{1}\quad\) Pressure of the conditional first pump \(P_{2}\quad\) Pressure of the conditional second pump

About the joint operation of pumps in heating and cooling networks

In hydraulic circuits, you can often find parallel connection of pumps and very rarely - sequential connection. However, sometimes the pumps still operate in series - although such a scenario may not have been considered when creating the circuit.

Basically, the joint operation of pumps is found in redundant schemes - where one pump is the main one, the other is the backup one. Although more than two pumps can work together, for simplicity we will consider only two - the first and second. More precisely, in such schemes, each pump is both the main and the backup, and the load can be distributed by 50% to each pump. If one pump fails, the second provides at least half the load.

Pump characteristics

The pump characteristic is a curve of flow versus developed pressure. This curve depends on the design of the pump and is determined during its production and testing. In general, it looks something like the picture

Figure 1 General view of the pump characteristics

Parallel connection of pumps

If you connect two pumps in parallel - for example, as shown in the figure, then what will their overall characteristics look like? The general characteristics will be based on the following rule:

When pumps are connected in parallel, their flow rates are added up at the same pressure value

The equivalent characteristic will look like shown in the figure

Figure 2 Parallel connection diagram

Figure 3 Equivalent characteristic for parallel connection

Serial connection

As already mentioned, it is the intentional sequential connection of us that is very rare; let’s say now this is not a common practice. Although sequential operation of pumps can be found, for example, in multi-circuit circuits. If the pumps are connected in series, then their equivalent characteristic is constructed as shown in the figure based on the rule:

When pumps are connected in series, their pressures are added at the same flow rate

Figure 4 Serial connection diagram

Figure 5 Equivalent characteristic for series connection

Tips and tricks

Is it necessary to construct an equivalent pump characteristic? If you take the design of hydraulic circuits seriously, and hydraulic circuits definitely deserve such an attitude, then a characteristic must be built, otherwise how will you know how the network will behave under different operating modes