Despite the general gasification, there are still many places where you cannot do without a good wood stove. In addition, rising gas prices sometimes pose insurmountable financial challenges to homeowners. Finding alternative heating methods and upgrading existing ones often solve problems that arise in the most unexpected way. Thus, a water stove can save up to 50% of fuel and makes you look at classic home heating in a new way.

A water stove will help reduce fuel consumption and save a lot of money

Wood burning stove

Solid fuel stoves can handle any volume of heated water in the pool, they are easy to operate and economical.

You can choose the right stove for heating a pool by determining the task that the equipment faces:

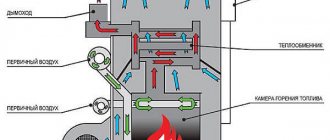

Heating year-round pools with a large volume of water, maintaining a constant temperature. To solve this problem, massive brick furnaces with a heat exchanger, long-burning boilers of the Stropuva type, and pyrolysis boilers with a shaft structure are ideal.

The advantages of such stoves are the ability to maintain the same temperature in the heat exchanger for a long time and regulate the heating rate, long battery life without loading, and the ability to heat a pool using indirect heating. The downside is the relative high cost of the equipment and complex plumbing.

Quickly heat up a seasonal indoor pool and maintain the required temperature. The main requirement for equipment is high power. It can be calculated by knowing the volume of the pool, the difference in water temperatures, and heat loss. To heat 1 liter of water by one degree in 1 hour you need 0.001 kW. Heating 1 thousand liters in 1 hour will require a power of 1 kW.

Taking into account heat loss, you need to multiply this figure by 1.2-1.3. Thus, a 25 kW boiler will heat 1 cubic meter of water by 1 degree in 15-20 minutes. The water heater must be permanently installed; it is better to use a flow-through heating circuit.

Quickly heats up a small outdoor pool at low ambient temperatures. The main requirement for a boiler for this mode of operation is high power and mobility. The light weight and compactness of the stove will be a pleasant addition.

Operating principle

It’s not for nothing that they say that everything new is well forgotten old. The ancient Bible echoes this proverb: “What has been is what will be; and what has been done will be done, and there is nothing new under the sun” (Ecclesiastes 1:9). Indeed, all physical and chemical laws were invented and put into practice long before we were born, so a person can only use them for his own purposes.

Thus, few people know that to enhance combustion in steam locomotives and other similar units actively used in past centuries, water was used as a combustion catalyst. Remembering this feature of a commonly available liquid, some modern Kulibins came up with a simple design for a furnace, where water as fuel helps to increase the heat transfer efficiency by tens of percent.

Thanks to a water stove, you can provide unprecedented warmth in your home.

The fact is that when water vapor is heated to temperatures above 600 degrees, a flammable mixture of hydrogen and carbon monoxide is formed . In combination with oxygen, it burns remarkably well and contributes to an even greater rise in temperature.

This is why severe fires and fires with high temperatures cannot be extinguished with water or snow. On the contrary, this method promotes even greater flare-up. This is interesting: a version of a waste oil boiler with a water circuit.

However, if you take control of this feature of the most common liquid, you can achieve an amazing effect that helps improve the combustion process.

Here are the main advantages of this method:

- More complete combustion of fuel and less combustion waste.

- The absence of black smoke means less soot – a cleaner chimney.

- Higher combustion temperature, greater heat transfer.

- Excellent combustion of raw wood, no smoke.

- The combustion time of the same amount of fuel almost doubles.

In this video, learn more about the water stove:

It turns out that using a water-based stove design is much more effective than the conventional option.

Building a boiler with your own hands

When working with metal, it is important to follow simple safety rules.

Project selection

For a home craftsman, a real challenge will be to independently manufacture a “Buleryan” type heater, but with patience and metal welding skills, this task is doable.

To create a device for heating water, you will need a square profile pipe with a wall thickness of 4 mm. During work, a welding machine, grinder, clamps and other metalworking equipment are used.

In addition to the square pipe, you will need several sheets of iron for the second chamber and doors, a valve, a pipe for the expansion tank, plumbing threads for the outlet and input of coolant.

The procedure for welding a hot water stove using wood

First of all, the collectors are welded: lower and upper. The lower one has the shape of a “box”, the entire structure will stand on it, the upper one is of any shape and serves as an expansion tank.

The heat exchanger consists of L-shaped square or round pipes bent in the form of a clamp. Their bottom is connected to the manifold, the top to the expansion tank. The gaps between the pipes are welded tightly with sheet metal.

A secondary combustion chamber is installed at 2-3 heights of the resulting tunnel. Hot gases rise along the hot shelf. It is better to make it from metal 5-7 mm thick; air ducts are connected to the beginning of the shelf.

A grate is installed at the bottom of the firebox.

The ends of the tunnel are welded, a chimney is mounted on the back wall, and doors and an ash pan are hung on the front side.

It is convenient to make the ash pan in the form of a removable scoop: this makes it easier to clean the stove.

The legs are welded, handles and wheels are attached - the stove can be transported like a wheelbarrow.

The stove is ready, now you can connect the chimney, fill the system with water and do a test run.

Device design

Having decided to equip an economical water stove with their own hands, many are faced with the problem of where to get the drawings for the device of this design. In our age of technology, obtaining such information is a mere trifle. Moreover, having understood the operating principle of such a furnace, many try to create their own version, and sometimes such attempts lead to the appearance of very effective samples.

Details may vary, but the main components of such a device remain unchanged.

If you try, you can easily make such a stove in your dacha

Here is a list of these parts:

- Steam generator. A device that supplies water and converts it into steam. The principle of operation is well known to those familiar with moonshine brewing.

- Superheater. This device is used to superheat steam above a temperature of 500°C.

- Auxiliary nodes. They may vary depending on the design, but connecting hoses and tubes are mandatory elements of any such device.

- Expansion tank or other container for storing water.

- Bake. The shape and materials from which such stoves are made are so diverse that there is no point in listing them. In fact, any stove that burns wood, peat or coal can be converted into a steam stove.

Whatever design is chosen, it is so simple that any craftsman can make a water stove with his own hands.

Material of manufacture

Copper. Due to its ductility, copper is most optimal for the manufacture of a heat exchanger. A copper tube is easy to bend and give any shape. It has a high thermal conductivity coefficient - more than 380. But copper is also not a heat-resistant material and is expensive. Stainless steel. Also quite flexible and responsive material. Although it has a lower thermal conductivity coefficient. But it is resistant to temperature changes. You can weld any configuration from it

IMPORTANT: Galvanized steel cannot be used; when heated, it releases toxic zinc compounds into the air. Metal-plastic. Easily available practical material

Easily found, but it has a low thermal conductivity! Almost two orders of magnitude lower than that of copper. But this material is durable and resistant to temperature changes.

Fuel from water! - the cheapest…

Inventors of all stripes, from home craftsmen to academic consolidations, are trying to create something new. The priority is energy conservation and savings, new boilers and new, cheapest types of fuel.

The idea of creating fuel for the home from water, or with an admixture of water to make it cheaper, is not new. She still occupies a leading position among home inventors.

Is it possible to literally heat your house with water?, what were the results?, - more...

What's the idea

It is known that water consists of hydrogen and oxygen, H2O. Hydrogen itself (H2) burns, releasing energy 3 times more than ordinary natural gas. Oxygen (O2) is an oxidizing agent during combustion, a very active substance, it reacts with the same hydrogen, carbon (C) forming water and carbon dioxide CO2 or carbon dioxide CO gases with a large release of heat.

If you somehow split water into its components, you can get the most needed fuel cells.

The question arises: what will happen, for example, if water vapor is supplied to the plasma, mixed with burning wood or coal...

Amazing experiments more...

Experiments with eternal logs

An everlasting log is a small metal tank with small holes to allow water vapor to escape. This container is filled with water, the neck is screwed on, and placed on the bottom of the oven. The container heats up to a high temperature, water vapor comes out of it, going directly onto the burning coals.

As a result, according to the experimenters, black soot disappears in the smoke. Those. supposedly the carbon particles normally carried away into the pipe now all react with oxygen. The flame becomes saturated with long tongues, etc.

But it’s true that measurements of the actual heat received were not carried out, it is impossible to measure it at home, but all the signs of high energy output are present...

Adding water to regular fuel

By analogy, another experiment from people who call themselves “home inventors.”

What happens if you add water to diesel fuel? It turns out that the mixture is burning! There is also less soot, some roughness of combustion occurs, and a crackling sound is heard.

Add a little diesel fuel to a bottle of water, mix it well, let it sit for about five minutes, then dip a piece of paper into the top of the mixture, set it on fire, and it burns.

Another experiment. We mix diesel fuel with water in some proportions, pour it into the diesel engine of the tractor, start the unit, the tractor works. those. rumbles, standing still...

And you can come up with many more similar experiments with adding water to any fuel (flammable substance) - gasoline, gas, oil, diesel fuel. And if done carefully, it is likely to get burned...

Similar videos from “inventors” can be easily found on the Internet. And we can conclude that water can be used to heat a house, for example...

What can be questioned

In such experiments, the main thing is not agreed upon - the amount of heat received, energy released and work done.

This applies to both eternal logs and burning diesel fuel with water. But it is not known whether the “tractor on water” will be able to move, let alone work for months and years.

After all, everyone knows that water is used to extinguish, not to light... Because water has a high heat capacity, it cools the burning object, enveloping it, preventing oxygen from the air from accessing the carbon (usually) in the fuel. Therefore, putting out a fire with water from a bottle is no problem.

Why can't you drown with water?

The following is known. To decompose water into oxygen and hydrogen, you need to spend more energy than will be released during their reverse reaction. The ratio is something like this:

- for water splitting - 100% energy;

- When the components are burned, only 75% of the energy will be released.

That’s why nothing rides on water, doesn’t fly, doesn’t spin...

A car that runs on clean water has long been created. The splitting of water is achieved through electrolysis - H2 is released at one electrode, and O2 at the other. They are then burned in an internal combustion engine. But such a car turned out to be the least economical of all existing ones...

Pure deception

All experiments with adding water to ordinary fuel (to “burn water”) are pure deception. No energy is added. On the contrary, the benefit decreases, since most of the energy is spent on evaporation of water.

When heated by normal combustion, water does not enter into any reactions; it simply evaporates. And for this process it is necessary to select the lion's share of the heat, which could be used usefully.

For example, when burning dry wood with a humidity of no more than 20%, about 3.9 kW will be released per kilogram of fuel. When burning wet wood, 50% humidity - only up to 2.2 kW per kilogram.

What's Really Happening

- When a piece of paper dipped in a solar-water mixture burns, a cracking sound is heard - the evaporation of water. Before this, a drop of diesel fuel is mixed in a bottle of water, shaken, but then it is allowed to settle, and the diesel fuel again collects at the top of the bottle. Diesel fuel, oil, gasoline do not mix with water, do not create homogeneous mixtures, they are lighter and gradually accumulate on the surface.

- A tractor running on a water-solar mixture will not do anything - the diesel energy will not be enough for work. All you have to do is chatter while standing still. And the engine will quickly fail...

- The eternal log greatly cools the oven, taking energy to evaporate water. It's like heating with wet wood.

- The following schematic drawing of a burner with water supply to the natural gas combustion zone is a common deception.

We always drown with water

Water vapor is always present in the air. In residential premises, the average air humidity is 50%, in rainy weather outside the humidity is 90%. So water is already present during the combustion of any fuel; it is found in large quantities directly on the hot surface of the substance that reacts with oxygen from the air, whether we like it or not. It turns out that there is no need to carry out such experiments, water is always present in the flame anyway...

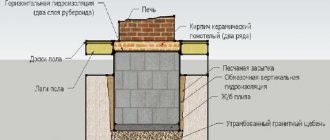

Foundation for the building

Before building a stove, you need to lay the foundation for the future structure. The work is carried out in stages:

- First you need to dig a pit. Depth 45-50 cm.

- Sand is poured onto the bottom and compacted thoroughly. The layer thickness is 8-10 cm. A layer of crushed stone is placed on top.

- Next, you should install the reinforcing grid and fill it with cement mortar. The mixture contains crushed stone, sand and cement in a ratio of 1:2:1. The pit is filled to one third.

- Then the second layer is poured. The solution is represented by sand and cement (3:1). It should be filled in such a way that 5 cm remains to the top of the pit. A second mesh with a cell size of 7x8 cm is also placed here.

- Pour the last third layer of cement mortar and level it with the rule. The structure is covered with a polyethylene film.

The concrete will cure within 30 days. To make it stronger, experts recommend moistening it every day. At the end, the foundation is lined with strips of roofing felt.

Electric and liquid fuel

Electric heating is considered the most efficient. Only it can provide 99% efficiency. In addition, it does not require ventilation or chimneys; maintenance as such is not provided, unless there is a need to clean the device every 2-3 years.

Installation, like the cost of the equipment itself, is cheap. Of course, all these properties of an electric boiler make it attractive in the eyes of the buyer, but it is still not cheap. Financial costs are due to the need to pay for electricity. You can install a multi-tariff meter, although this will not allow you to bypass a wood-burning heat generator in terms of functional characteristics.

Liquid fuel boilers operate on diesel fuel and waste oil. This type of heating is considered the dirtiest. After visiting the boiler room, you will certainly have to wash your hands of diesel fuel. Also, the clothes will emit a corresponding smell. The unit will need to be cleaned once a year. This is a separate event, after which you will have to wash off the soot from almost your entire body. The use of diesel fuel is not the most profitable solution. Its cost can cancel out all the obvious advantages. Used oil has now risen in price and can only be beneficial to those who have a cheap source.

https://youtube.com/watch?v=d0idwQchW3s

Modern heating boilers contain many important elements. Among them is a heat exchanger for a brick kiln with welded plates. It is inside it that heat is transferred to the carrier from the generator. Today there is a large assortment of different heating boilers, but this does not prevent owners of private households from making such devices on their own.