Fireplace glass is not only a beautiful accessory, but also a very convenient device that makes it possible to expand the capabilities of the fireplace. But equipping an old fireplace with such glass is often quite difficult - on the one hand, not every glass is suitable for installation, and on the other hand, not every glazier can boast of the ability to work with such material. But, as you know, there are no hopeless situations, and if the desire to make a glass door for your fireplace is so great, you can find a way out of this situation.

Should I put a door on the fireplace? Benefits of an open fireplace

To be specific, an open fireplace is a very practical thing. Whether it is a house with or without stove heating. Yes, let’s say right away that stove heating does not exclude the presence of an additional fireplace. It perfectly complements life in a house with stove heating. With a fireplace, it is much easier to choose the furnace firing mode for heating the house; we’ll talk about this in more detail later.

A familiar picture: a family gathers and two or three generations are sitting in front of their smartphones... believe me, a fireplace can turn the familiar picture around a little. It acts as a gathering place. He participates in life - as a reason for his brothers, as a small holiday. A little fireworks, if you want analogies. Living fire carries something magical... Be that as it may, it fascinates and encourages communication. Distracts attention from the smartphone. Living fire in our lives is something unusual, oddly enough.

You can even hold business meetings, not just family ones, behind an open fireplace. It would seem, why install a fireplace door with glass?

Criterias of choice

The basic rule when choosing glass for a fireplace door is the very purpose of the heating structure. If it is planned to be used as a heating source, then it is recommended to choose laminated glass, since this is the material that can withstand high temperatures. For a fireplace that primarily performs decorative functions, one layer of glass will be sufficient.

In addition, when choosing glass you should take into account a number of other features:

- the glass must withstand the maximum temperature that will be created inside the firebox;

- the maximum service life should be selected;

- the glass should muffle the noise created inside the firebox;

- the material must be sufficiently reliable.

Installing a manufactured door in a fireplace or stove with a brick body

The placement of the stove depends entirely on what exactly the owners expect from it. If it is installed in a small house and will be used as a fireplace for friendly gatherings, you can use the first scheme. This stove is a good option for cooking barbecue on the grill or kebabs.

Brick kiln placement options

The second scheme is for a house of solid square footage. In this case, the front side of the fireplace stove opens into the living room, the stove walls heat both bedrooms, and the heat in the remaining rooms is maintained using heat exchange.

The third scheme with a stove for heating and cooking is a budget housing option for a bachelor or a small family. Pros: a warm bed and the ability to place a dryer in the hallway.

Important: you should take care of the external insulation of the house in advance, because it greatly increases the efficiency of stove heating

- if the door is glass, then the glass is first removed from the frame;

- then the door is applied to the edge of the fireplace in such a way as to cover the entire surface of the firebox;

- a cutting line is drawn on the surface of the brickwork;

- grooves are cut out in the masonry using a grinder;

- a second cut is made from inside the furnace so that part of the masonry can be removed;

- unevenness of the chip is leveled with a chisel;

- the door is fitted into the slot;

- the door is removed and the fastening tape is screwed to it;

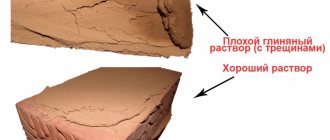

- a small volume of oven mixture is mixed (for half an hour of work);

- an asbestos cord is dipped into the stove mixture solution, which is then wrapped around the perimeter of the firebox;

- the combustion door is wrapped with a cord several turns;

- the door is installed back into the hole and secured with dowels;

- noticeable seams must be filled.

The structure is ready.

When installing fireplace doors without brickwork, you will need to drill 4 holes with a diameter of 4 mm. To do this, the attachment points are marked with a marker. The remaining stages of work are similar to those described above.

Features of oven glass

As already mentioned, only heat-resistant glass is used to make the oven door, which can withstand oven heating up to 1000 degrees. This possibility is achieved due to the fact that the glass contains no impurities and it undergoes special processing, that is, tempering, impregnation with chemical reagents and polishing.

We recommend: Why is an electric gas heating boiler popular and what are its features?

In terms of its heat resistance, glass is in no way inferior to metal. There is no possibility of chips, cracks or scratches on it. Often, a small area of the flooring is covered with the same material to prevent the surface from igniting if coal accidentally falls out.

Among the main characteristics of glass it is necessary to highlight:

- Single-layer glass can withstand temperatures up to 550 degrees, and multilayer glass up to 1000 degrees. The choice of one type of glass or another depends entirely on what fuel the stove will run on;

- The optimal insert thickness is 3.5-4 mm. The strength of the glass will depend on this parameter;

- Multilayer glass inserts are quite strong and durable, but for a home stove, a single layer will be sufficient;

- The glass surface is capable of self-cleaning. All soot that gets on the glass will burn and there will be too little soot left;

- If the stove is used regularly, it will be quite noisy.

Why do they even put doors on the fireplace?

It is believed that a glass door is a necessity for a modern fireplace. Everyone sees something different in this. The advantages of a fireplace door seem to be undisputed. So why?

With a fireplace door, you don't have to be afraid to step away from the fireplace. After all, at any moment a coal can jump out and burn through the flooring. Children may get burned. Smoke may come out, after all... There is an opinion that in general “there are no fireplaces that don’t smoke”... and so on.

A fireplace door prevents the biggest disadvantage of open fireplaces. They keep you warm while they burn. But as soon as active combustion ends. All the heat is “blown out” quite quickly into the pipe. A very large volume of air is “pumped” through an open fireplace, which does not allow it to be used as a full-fledged heating device.

With the installation of the door this problem goes away. At any time, you can cover/close the ash pit and the coals will burn out without sacrificing all the heat that the burning wood provided.

It is generally accepted that a fireplace door with glass prevents possible smoke in the fireplace. The fireplace spits less when there are pressure changes and problems with the flow of combustion air. Dark marks of soot do not appear on the arch/covering of the fireplace.

By the way, here is one of these doors on our stove, masonry and finishing - autumn 2022.

The nuances of caring for fireplace glass

If you have installed a fireplace or stove with a glass door, then you are most likely familiar with the problems of how to clean soot from glass.

Quite often, the fireplace is considered the center of attention in the house, and it should always look neat. To do this, you will have to take into account some of the nuances associated with caring for it.

The process is simplified if the door has an automatic glass cleaning system. In this case, you will not have to wash it often, but it is still not recommended to forget about water procedures.

You shouldn’t put off cleaning until later; it’s better to do everything in a timely manner to save time and effort. The right solution is to periodically wipe the glass with a special compound.

Fireplace glass needs to be cleaned regularly.

The correct fuel must be used to fire the fireplace. Coniferous varieties produce the most soot due to the high level of resin content. In addition, the firewood must be thoroughly dried before use to minimize the percentage of soot generated.

To clean the glass surface, you must use liquid compositions or solutions with the addition of ammonia, prepared independently.

By following these simple rules, you can keep your fireplace glass clean at the highest level.

Types of fireplace doors

There are several most popular materials from which doors are made to prevent it from getting too hot near the fireplace. Forged - presented in the form of a lattice with various patterns and ornaments made of steel. A fence of this type does not fully fulfill its function, since sparks can fall through the holes and smoke can leak out.

Such fencing is used for Art Nouveau style, irreplaceable classics, and modern design.

Depending on the stylist’s idea, you can also create interesting combinations of different materials with each other. Ceramic ones are produced by firing clay at a high temperature, this contributes to the material’s sufficient resistance to open fire. Doors of this kind are often installed in ovens if provided for by the designer. This style adds appeal and coziness, and will create harmony in a home that has a rustic feel.

Metal blinds have a fairly attractive design and provide complete safety. Such doors are made of cast iron; it has increased resistance to high temperatures, but for greater reliability, additional coating is also carried out using fire-resistant enamel. These types of doors are used quite rarely; they need to be handled very carefully so as not to end up with a rough room.

Installing a firebox door for a brick stove: 3 different methods Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable fireplace door yourself - - Heating Market Do-it-yourself fireplace door with glass, manufacturing algorithm Do-it-yourself stove door: Door for DIY ovens: step-by-step instructions with photos – DIY oven door | All about heating - Mini hotel "Hotel A" Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable door for a fireplace yourself - - Heating Market Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable door yourself for fireplace — — Heating market

There are options from different types of glass:

- Tempered;

- Borosilicate;

- Kvartsev.

Tempered glass is produced by first heating it to a high temperature, then rapidly cooling it. After such procedures, the glass becomes sufficiently resistant to both high temperatures and various damages that often occur in everyday life. Quartz doors are made of quartz or sand, there are practically no foreign impurities observed. Such a material has a very painstaking and complex manufacturing procedure, but is highly resistant to various temperature changes, therefore it has an acceptable cost, but for many it is too high.

Borosilicate glass is made from substances such as silica and boron oxide. Due to their low melting point, they are not only resistant to very high temperatures and various mechanical damages, but are also quite plastic when compared to ordinary glass. Doors of this kind can decorate and transform almost any interior, adding attractiveness, comfort and color to it, and in combination with forged elements, they will look elegant and stylish.

Types of doors

Several door structures can be installed in the furnace at once, including:

Firebox. This type of door is necessary for loading coal, firewood and other fuel materials. They must be as airtight as possible, because if even one small ember falls out of the stove, this will be enough to start a fire. You can also use the combustion chamber to change the flow of oxygen to the fire.

Blower. Just like the furnace room, it must be completely sealed. Its main task is to provide air flow and clean the stove from ash.

For cleaning. This type of door is not required for installation; instead, you can leave one movable brick, which can be removed if necessary.

Furnace portal. It contains two structures at once: a combustion chamber and a blower. It also serves as an additional decoration and makes it possible to clean the stove from contamination or, if necessary, carry out repairs.

Each of the listed doors can be made of different materials, the main thing is that they are fireproof. According to the type of opening, it can be either swing or guillotine. This is at the owner's request.

The oven door can have a different design, for example, a metal frame with glass. Fastening to the stove occurs using pins or brackets. The glass is mounted in such a way that it can withstand high temperatures. Its mount is removable so that in case of damage it can be easily replaced with a new one.

The glass in the oven is highly impact-resistant and it is almost impossible to break it with logs or a poker. The door is equipped with a locking handle and several hinges. For greater sealing of the product, a heat-resistant cord is laid between the glass and the metal frame. When burning wood in a stove, you can safely touch the metal frame without fear of burning, because it has low thermal conductivity.

It is very important to keep the stove completely sealed to avoid carbon monoxide, which is very dangerous to human health, from entering the room.

DIY Methods

When a user plans to make a device on his own, he will need certain knowledge of furnace equipment, its structure and principle of operation. Of course, it will not always be possible to make a high-quality glass product, but it is permissible to try the metal option. Preparations:

- First of all, you need to choose the material for making the product.

- Next, the type and size of the future product are determined. The user's financial budget must be taken into account.

If you don’t have any imagination about the shape and model of the door, you can go online and look for a ready-made solution there. As a result, the user will be able to receive an exclusive product.

Important! To have confidence in the advisability of creating a device yourself, you need to familiarize yourself with all the advantages

Recommendations

There are certain recommendations that make it possible to make the right choice of a specific product, regardless of the material of manufacture. The most useful of them:

- When the user wants to look at the fire, he will need a product made of glass or metal, but with inserts. The higher the price of the device, the greater the attractiveness.

- When the thickness of the fireproof glass is less than 0.5 cm, it is installed in the damper using a sealant and making a small gap. This is required to compensate for thermal expansion under the influence of fire (otherwise the material may crack).

- To protect children or pets from burns during sudden contact with a hot coating, it is recommended to install metal doors with a special shield. It prevents the surface from heating above 40 degrees.

- When the heating device operates on mixed fuel, the stove doors must be made of cast iron. When wood is used as fuel, it is possible to install glass doors.

- Regarding the parameters, it is recommended to entrust the choice to a qualified specialist who will install the device. In this matter, you need to take into account certain details that an uninformed person does not know.

Important! It must be taken into account that every brick stove is a fireproof device. In view of this, the construction should be approached with the required knowledge of the matter. It should also be noted that it is advisable to choose 2-leaf products.

In such devices, the outer doors (solid) are equipped with a slot, thanks to which the air flow can be adjusted. It is necessary for burning fuel (such a detail is important for wood-burning devices that are not equipped with ash pans). The doors inside (lattice) will catch coals and sparks, preventing them from entering the 2nd door. This will minimize the likelihood of a fire.

The door is considered a mandatory component of the stove design. It won't be difficult to create it yourself. The material used is durable glass, fireproof steel or cast iron. Metal doors are considered the most versatile in production and installation. Devices made of glass favorably emphasize the design of the room, and those made of cast iron can last for a long period of time.

Step-by-step instructions with photos for laying a stove

Different stove makers have their own masonry technologies and their own secrets that come with years of experience. Here is information about a fairly simple way to create a stove-fireplace for heating a two-story house; the process will not seem extremely difficult even to novice stove makers.

Foundation laying

The base course of brickwork will serve as the foundation. It is done with any brick; some stove makers even fill this level with crushed stone.

When laying the base row, cement mortar is used.

The foundation is completely filled with mortar, the layer is leveled.

Construction of the furnace body

The first row of stoves is marked. The horizontal line from which they start when marking is the wall of the room.

A grate is placed where the fireplace is planned to be placed. From this row, the bricks are already laid on the kiln mortar.

An important stage of work is the scrupulous alignment of each new row by level.

Laying the second row. The stove wall, located closest to the wall of the room, is reinforced with additional bricks to increase fire safety.

The place where the chimney will be located in the 2nd row remains empty, the rest of the stove is laid completely. A door is installed through which the owners will clean out the ash.

The door is installed on the solution and leveled. For a more reliable fixation, it is secured with wire, which must be laid between the bricks.

Next, the next 3 rows are placed. Then a brick stop for the grate is installed - 2 rows of 1/4 bricks are placed on the sides.

The grate is laid not on a simple brick, but on a refractory brick. To ensure that it lies at the same level as the bricks, holes are cut in the fireclay bricks.

The size of the brick can be easily adjusted - the excess is measured and carefully cut off.

The large door is mounted next to the installed grille.

The large oven door is similarly secured using wire fasteners.

The first row of fireboxes is placed exactly above the fireplace, it is reinforced with metal corners and a strip or thick tin. So that the masonry can lie on them, it is cut using a grinder, then the slots are adjusted manually to the desired size.

The next brick row is laid.

A fireplace grate is laid on the fire-resistant brick along with the brick row.

The door is fixed, the brick is strictly adjusted to it.

The firebox of the new stove and fireplace is ready.

Fire-resistant fireclay bricks are placed above the stove firebox.

The stove body is built.

Creating a chimney

The space left for the chimney is divided into wells. The design requires reinforcement with metal plates.

Brick chimney wells are laid.

Soot cleaners are mounted above the firebox roof.

The wells are divided again, the first rows of walls should be reinforced with strips of metal.

After strengthening, the ceiling of the furnace body is erected. The space associated with the chimney remains empty.

The body cornice is laid out, then the chimneys are laid.

The final stage of work on the first floor. The stove is located at the bottom left, the smoke inside the chimneys moves in a spiral and comes out at the top left. The final separation of the wells is covered with a tin sheet. In order to compensate for the pressure inside the fireplace stove, 2 brick rows are laid on the tin.

There are two chimneys stretching to the second floor of the house - from the fireplace and the stove itself, they are separated from each other. Each chimney requires the installation of a separate damper.

Floor level of the second floor. Waterproofing is installed here, the chimney is again reinforced with metal corners. To save money and avoid building a heating stove on the second floor, the chimney of the stove under construction is again divided. The smoke will snake through it, managing to warm up the room. In order for the chimney to warm up much faster, it is laid in the area of the second floor with a thickness of 1/4 or 1/2 brick.

A hole for the stove chimney is carefully cut out in the roof.

Before placing the chimney on the roof, it is reinforced with metal corners.

If the chimney is located in close proximity to the roof ridge, it must be laid out at least 0.5 meters above the ridge. If further, then the height of the chimney is allowed equal to the height of the ridge, but not lower. In this case, the wind increases the stove draft, lifting the smoke upward.

Even a small stove in the house means coziness and comfort. Larger stoves require increased skill and additional materials, but the principle of their construction is similar to the method described above.

19.02.17

Preparation, list of tools

Before starting work, you need to determine and mark the place that the new stove will occupy.

The chimney pipe should be no closer than 15 cm from the roof rafters.

If you are doing masonry for the first time, professional stove makers advise you to practice in advance by making a model of the future stove from prepared bricks. Naturally, without a solution. This minimizes possible risks during real masonry, allowing you to learn from your mistakes, which can still be corrected in the layout.

The stove foundation requires preliminary waterproofing; its area must exceed the area of the stove.

When laying a new row, you need to control the absolute verticality of the walls.

To build a brick kiln, the following tools are needed:

- plumb line;

- trowel;

- roulette;

- putty knife;

- Bulgarian;

- knitting wire;

- building level;

- metal strips, corners;

- containers for cement and clay mortar.

Glass doors

Cast iron doors with glass inserts are aesthetically beautiful and allow you to easily admire the fire. The sight of a living flame has a fascinating effect on a person, apparently awakening in the soul the memories of ancient ancestors about gatherings in the forest in front of a fire. There is no functional need for glass doors for stoves and fireplaces. There is only a person’s subconscious craving for the eternal beauty of fire, respect for its elemental power, enclosed in a small hearth behind a glass door. Therefore, despite the fact that in some respects glass is inferior to cast iron, almost everyone strives to have stoves with glass doors in their home or bathhouse, rather than solid ones made of cast iron.

What types of glass doors are there?

Just like solid cast iron doors, products with glass are available in one or two door versions. There is no functional difference between them. It's a matter of taste here. One door, as a rule, has a larger window for viewing the fire. For two-door stoves, the design is closer to ancient forms. The fire can be admired either through one large glass or through two smaller glasses. Here a lot depends on the taste of the owners and the design of the room.

Minuses

:

- The production of doors with glass inserts is a much more complex process than the production of solid doors. To avoid cracks during operation, leave a small space with the seal during installation. The doors trap fiery sparks, preventing them from entering the room. Glass inserts must be designed in such a way that hot air streams blow across the glass, preventing soot from lingering on it. Otherwise, the glass will always be smoked. As a rule, branded products are free of design flaws.

- The cost of doors with glass inserts is more expensive than the cost of solid doors.

- The fragility of tempered glass. Tempered fireproof glass can crack even with a small impact.

- The efficiency of fireboxes with glass doors is much lower than with cast iron doors, since part of the heat is dissipated through the glass. The larger the glass, the lower the efficiency of the stove in heating the room.

pros

:

- Glass can withstand high temperatures for a long time - this is why it compares favorably with steel structures. In terms of fire resistance, glass is even superior to cast iron.

- Special heat-resistant glass for stoves and fireplaces is about 4 mm thick and can withstand temperatures up to 2000 degrees.

- Compact and light weight products.

- The main advantage of glass firebox doors is the opportunity to admire the play of fire in the firebox. This feature far outweighs any disadvantages, forcing stove owners to purchase glass doors, despite the reduced durability and increased cost compared to solid or solid cast iron doors.

Door specifics

If you intend to make a door with glass inserts, you should first of all decide on its style

It is important that it matches the overall decoration of the room and the specifics in your particular case. So, for example, in small rooms it makes sense to make a double-leaf insert or a rising one to save space.

Both of these options are ideal for a corner fireplace.

The main point that should not be forgotten is the selection of glass. It must have a heat resistance of at least 800 degrees - it is to this temperature that the flame usually flares up.

The prepared glass is inserted into the metal frame of the door itself, and that, in turn, is attached with hinges to the outer frame, which is fixedly fixed in the opening of the firebox. Wherein:

- a seal is installed on the inside to prevent smoke from entering the room;

- At the bottom of the outer frame, holes are made with adjustable plugs for air access to the firebox;

- Keep in mind that metal tends to expand greatly when heated, so the gap between the transparent insert and the frame is not made too large;

- When starting production, remember that the glass cannot be fixed tightly, because during installation it will need to be removed from the door;

- strips of fiberglass are inserted into the frame to seal it.

Comparative characteristics and prices

The table below shows popular models of fireplace doors, their characteristics, as well as the average market cost.

| DK 555-1K “Ruslanovo-masonry” 53x55.4 cm Steel, heat-resistant glass From 10,000 to 11,000 rubles | SVT 450 SVT 34.5x29 cm Cast iron 5400 rubles |

| DT-4(B) “Rubtsovo” 27x25 cm Cast iron, ornament, gray color From 700 to 850 rubles | “Lyon” “Meta” 47x44 cm Steel, cast iron 11,200 rubles |

| DP 3081S “Meta” 26.8x30.8 cm Heat-resistant glass, steel 2800 rubles | “Promo-700” (glass) 69.5x52 cm Cast iron, heat-resistant glass 14,900 rubles |

| DTK-2S “Rubtsovo” 43.5x32 Cast iron, heat-resistant glass 4400 rubles |

As you can see, even among popular models there are representatives of different price ranges. But, as you know, you always have to pay more for quality.

What should such doors be like?

There are certain requirements for stove doors. Let's get to know them.

- In the manufacture of doors, only those materials that are characterized by increased fire resistance should be used.

- Also, they should not interfere with the penetration of oxygen into the combustion chamber. The best option would be the ability to regulate the air supply, which will affect both the quality and quantity of firewood combustion.

- Finally, the doors must be fireproof to ensure that the room is reliably protected from fire.

Video – Fireplace doors

Installation

The complexity of installing a product is directly related to its design and model. To install the door yourself, you need a set of special devices and tools.

You will need:

- angle grinder;

- cutting disc;

- sealing cord;

- impact drill or hammer drill;

- set of drills;

- screwdriver;

- self-tapping screws;

- permanent marker;

- heat-resistant oven mixture.

To perform installation, you need to perform a number of sequential actions:

- Attach the door to the fireplace opening. It is necessary to ensure that the body of the product matches the design of the fireplace. Using a permanent marker, make marks on the surface of the firebox through the mounting holes in the body. Carefully remove the product.

- To make grooves in brickwork, you will need a grinder with a diamond wheel. This job requires a lot of attention and additional equipment. You will need special glasses to protect your eyes and a respirator to protect your respiratory system. After cutting out the grooves, you need to use a chisel and a hammer to break off pieces of brick.

- Using a hammer drill or impact drill, you need to make holes along the marked marks for mounting the product body. Try the frame on and make sure the holes in the frame and the brickwork line up.

- Heat-resistant oven solution must be diluted according to the manufacturer's instructions. Soak the asbestos sealing cord in the oven mixture. Wrap it tightly around the frame frame. Insert the prepared product into the structure by tapping it with a rubber hammer. If any gaps remain, it is necessary to fill them with asbestos cord and level them with a heat-resistant oven mixture.

- Screw the frame to the fireplace.

- After the solution has dried, insert the glass into the door.

- The control fire can be carried out after 3-4 days.

If the door is matched to the fireplace under construction, problems with selection and installation can usually be avoided. It is much more difficult to add a door to an already finished fireplace. In such cases

Fireplaces are becoming increasingly popular again. People install them if there is a technical and financial opportunity. The fireplace has a number of advantages over other heating systems:

- Efficiency.

- Aesthetic appearance. Looking at a blazing fire through a glass door never gets old.

- Making a fireplace with your own hands with the appropriate construction skills is a very real thing.

The topic of today's material is not about arranging a fireplace as such, but about how to make heat-resistant glass with your own hands in order to equip a door in it.

Material

Metal (often stainless steel or cast iron) is used as the basis for the fire door for a stove with glass. According to the characteristics of experienced craftsmen, cast iron is more preferable: it is distinguished by durability, it is not afraid of high temperatures, it is easy to clean, and it is quite durable. Stainless steel will become very hot when the stove is fired; it is not intended for open fire and will soon warp.

From glass

Glass doors are available in single or double door versions. One oven door usually has a large window to view the fire. There is no difference in functionality. A lot depends on taste here. In two-door ovens, the design is close to ancient forms. It is possible to look at the fire through 1 large glass or 2 small ones. Much will depend on the preferences of buyers and the interior of the room. Advantages of a stove door with glass:

- Glass can withstand the influence of elevated temperatures for a long period of time - this positively distinguishes it from devices made of steel. It is superior in fire resistance to cast iron.

- Fireproof special glass for stoves and fireplaces is approximately 0.4 cm thick and can withstand temperatures up to 2000 degrees.

- Compact dimensions and low weight.

- The main advantage of a glass oven door is the ability to look at the flame. Such an option will outweigh any disadvantages, forcing stove users to purchase stove doors made of a similar material, despite the short period of use and high price compared to solid metal doors.

Flaws:

- The creation of glass doors for a furnace is considered to be a more labor-intensive process than production from a solid sheet. To avoid cracks during use, a little space is left when installing with a seal. The doors will trap sparks from the fire, preventing them from entering the room. Glass inserts are designed so that air blows over the material, preventing soot from lingering on it. Otherwise, the glass will be smoked.

- Fragility of the material. Fire-resistant glass sometimes cracks with minor impacts.

- The price of a device with glass inserts is higher than one made of solid material.

- Glass door ovens are much less efficient than cast iron ovens because heat dissipates through the glass. The larger the material, the less efficient the stove is at heating the room.

Important! Often a stove door with glass is combined with a metal device. In such situations, the frame is made of steel and the door is made of glass.

We suggest you familiarize yourself with How to properly make a blind area around the house

This category involves doors made entirely of metal. The installation process is quite simple and does not have any complications. The products retain heat well and are distinguished by increased fire safety. When the need arises, it is possible to make them yourself with minimal expense. Key advantages of metal products:

- Reasonable price. Compared to a stage on a glass device, it is much smaller, which is why it has a certain prevalence.

- Durability and reliability of such devices. With proper care (regular anti-corrosion treatment using paints that are classified as fire-resistant), they will last a long period of time without causing discomfort to the user.

Important! Despite the fact that such doors have their own consumer, the market demand is quite low, since they do not provide the opportunity to look into the flame.

Cast iron door

Cast iron doors, which are heat resistant, are considered the best for brick stoves. When parts made of steel deform over time due to temperature, those made of cast iron can last for decades. In the place of combustion, the temperature will reach 800 degrees, and for steel the working temperature will be 600.

Main advantages:

- Excellent interaction with elevated temperatures.

- Durability and reliability. The cast iron fireplace vent door can withstand any load.

- Beautiful models can be easily created from cast iron.

All this optimally finds its own application in this area; many firebox doors are made directly from cast iron.

Borosilicate glass

This glass is made from a large amount of silica with the obligatory addition of boron oxide. This chemical element is famous for its ability to provide a low melting point, which means that the glass will have plasticity. The finished product can have a high degree of heat resistance (about 800 degrees). In addition, it will be endowed with special mechanical strength, 5 times greater than that of ordinary glass. That is why fireplace doors are so often made from it.

How to make a door with your own hands

The first step is to measure the dimensions of the door - the height and width of the stove opening in which it will be installed. To do this, use a tape measure and a marker. If you want to make an arched door, determine the height in the center and two side dimensions. It is necessary to make a drawing on paper to make it easier to manufacture the product.

First, a metal frame is made from corners to fit the size of the stove opening. The door may have a fireproof glass insert, or it may be closed with a sheet of metal. The glass is attached to the frame with bolts; they are not clamped too tightly so as not to interfere with expansion when heated.

Stages of work

The first thing to do is cut out the corner. And then give the desired shape to the structure. In order to carry out this operation, you need to lay the corner on a flat surface, check the correctness of all connections, and then weld all the necessary parts. After finishing the work, you need to inspect the door again for correctness and compliance with the form.

Then you need to mark the inner contour of the frame on a sheet of metal. After finishing the markings and receiving all the measurements, you need to increase them slightly and leave a small allowance on each side. Taking these marks into account, it is necessary to cut out the part using a metal grinder. Since the door is planned with glass, it is necessary to have a piece of heat-resistant material that will be mounted.

Using the same tool, glass is cut to the required dimensions. Next, you need to weld the curtains to the frame. After this, you need to grab them to the common door frame. When this operation is completed, you need to make sure that nothing interferes with the opening and closing of the door. If this condition is met, then final welding can begin. The door handle is attached last.

Making a glass oven door with your own hands, tools and materials

To work with such a specific material as heat-resistant glass, it is recommended to use the traditional scheme for creating a metal frame.

To work you will need the following tools:

- Welding machine;

- Hammer;

- Vices and bench clamps;

- Metal brush;

- Bulgarian;

- Locksmith corner;

- Roulette, marker;

- Bulgarian;

- Gloves, protective mask;

The following materials will be used in the work:

- Steel corner 25x25 mm;

- Corner 15x15 mm or 20x20 mm;

- Mineral wool 2-3 mm thick;

- Metal drills;

- Miniature garage curtains;

- Shutter or locking device;

- Taps;

- Cleaning and cutting discs;

In addition, ready-made or assembled forged elements can be used for decoration.

The main method of connecting parts will be electric welding.

“Deaf” made of metal

Another type is a blank metal door. It acquired this name because of its completely closed surface. This model will be the most universal option: it does not require special skills in manufacturing and installation.

A do-it-yourself metal stove door should be made of heat-resistant material. The most common is steel. The steel door is strong and durable and does not require much effort in manufacturing and installation. To make it, a simple set of metalworking tools, welding and a grinder are enough. The material will be 4 corners, a steel sheet, bolts, nuts.

Making a door from metal occurs in several stages:

- Paint all metal parts of the required size with heat-resistant paint.

- Weld a frame from a corner.

- Make a rectangle smaller than the frame from a sheet of metal

- Place hinges between the frame structure and the iron sheet (so it can be opened).

- Weld the handle and latch to the door.

- Attach the structure using metal anchors or any other method convenient for you.

Classification of furnace units

Most often, homemade stoves are made with cooking surfaces.

According to the characteristics of the device they are made:

- chamber;

- duct;

- bell-shaped

In chamber stoves, flue gases enter a special chamber and are completely burned there due to natural circulation. Their design creates a similarity to the burning of an ordinary fire in a confined space. In domestic models, the combustion compartment is connected to the afterburning compartment into a single module called the crucible. Its vaulted shape ensures complete combustion of fuel. An example of such a design is the classic Russian stove.

In a ducted unit, the flue gases first burn out, then gradually cool down and move through the channels located between the partitions. When moving, they give off heat to the furnace body. There is no afterburning inside until the temperature in the combustion chamber reaches 400 degrees. The efficiency of these devices does not exceed 60%.

In a bell-type furnace, combustion products move to the roof of a special bell and linger there, burning out completely. Then the gases sink to the bottom and give off heat to the body. To kindle such a unit, it is enough to warm up only a small area of the hood. Its efficiency can be 75%.

Oven

The oven is usually made of strong steel. The gaps are determined using a level; the frame is wrapped in sheet asbestos, half a brick wide. The plane of the frame at the top must coincide with the masonry surface of the last row of bricks, therefore, if necessary, the asbestos layer must be increased.

The grate must be installed 25-30 cm below the combustion opening with a slope towards the combustion door. The bottom of the firebox is shaped like a trough, and the slots located between the grates should be along the firebox.

To prevent the grate from destroying the masonry when heated, it is necessary to leave 5 mm gaps, which are then covered with sand. The grate cannot be secured using the solution!

The blower door and, together with it, the cleaning door are installed in the same way as the firebox door. The blower door is practically not exposed to high temperatures, so it must be tightly and firmly walled into the stove masonry, treating the seams with clay mortar. The horizontal of the frame is also determined using a level.

What you need to prepare

The tools we will need are:

- electric drill or hammer drill;

- angle grinder;

- a hammer weighing up to a kilogram;

- welding machine and electrodes;

- roulette.

The following materials are needed:

- steel corner of the width that suits you;

- metal strip;

- hinges (turned eccentric);

- bolt;

- handle for opening.

You will determine the exact dimensions yourself and adjust the above drawing to fit them.