An open heating system is the simplest and most energy-independent system with natural circulation. This system is based on the laws of thermodynamics. At the outlet of the boiler, increased pressure is created, then the hot water passes through the pipes to an area with lower pressure, losing temperature as it passes. Next, the cooled coolant is returned back to the heating boiler, where it is heated again. Natural coolant circulation occurs. The system operates exclusively on water, since the use of antifreeze for heating leads to their rapid evaporation.

Features of open and closed systems

Open heating system

To heat a house, a closed type of coolant flow structure is used, including a boiler, radiators and pipes. The system works on the principle of heating water to a certain temperature in special equipment, moving through a pipeline to radiators and further releasing heat to warm up the rooms. After cooling, the liquid is returned back to the heating device, forming a repeating cycle.

Open system

To understand what an open heating system is, it is worth using the multi-apartment building type as an example. This type of heating involves the use of a special storage tank, which is actively functioning in most multi-story buildings. On the roof of the high-rise building there is an expansion tank to collect excess water. The tank is not sealed, which allows vapors to escape into the external environment.

The open version is installed without a circulation pump. The coolant is directed through the pipes naturally. After heating the boiler to a certain temperature, the pressure increases, and the hot water, rising to the top, pushes out the cold water. The volume of water also increases when heated, so the excess goes into the expansion tank. The cooled coolant is again sent to the system.

Closed type of communications

Closed system

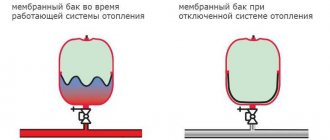

A closed heat supply scheme involves a pump that provokes the movement of water through the pipes. Forced circulation is also realized using pipes, a boiler, radiators, and an expansion tank. The metal tank is sealed, consists of two rolled parts, and has the following contents:

- internal rubber diaphragm – heat-resistant membrane;

- gas in a small volume - factory nitrogen or air accumulated in the line.

The membrane divides the container into two compartments - for collecting excess heated water and for storing air.

The coolant moves through the system, but when it heats up, the reservoir valve takes away the excess. They enter the expansion tank, penetrate the membrane and are pushed back with the help of gas. After cooling, the circulation pump pumps water back into the system, while simultaneously monitoring pressure levels. In this way, the coolant is deaerated.

Main differences

The difference between an open and closed heating system is as follows:

- Location of the expansion tank. In the open - the top floor of a private house or the roof of a high-rise building. The closed tank can be placed anywhere.

- Isolation from air access. Unlike an open one, a closed highway is protected from air currents. Additional pressure at the top points prevents airing of the batteries.

- Complexity of arrangement. An open system will differ from a closed system in the type of pipeline. Products of large diameter are mounted taking into account the location of radiators, air slope, the presence of turns and rises.

- Organization costs. Closed heat and water supply requires financial costs for the purchase of thick-walled pipes. You can save on an open system by using small-diameter lines.

- Noise level. The forced type of circulation in a closed line involves the use of a pump. When installed correctly, the equipment will not make noise.

Creating heating for a closed house will save from 10 to 40% of energy resources per year.

Autonomous heat supply of a residential building

In old-type buildings, the design provides for a centralized system. Individual schemes allow you to choose the types of heat supply systems in terms of reducing energy costs. There is the possibility of turning them off mobile if there is no need.

Autonomous systems are designed taking into account heating standards. Without this, it is impossible to put the house into operation. Following the standards guarantees comfortable living conditions for the residents of the house.

The source of water heating is usually a gas or electric boiler. It is necessary to choose a method for flushing the system. In centralized systems, the hydrodynamic method is used. For autonomous use, you can use a chemical one. In this case, it is necessary to take into account the safety of the influence of reagents on radiators and pipes.

System connection options

The laying of communications is carried out in a dependent and independent way. The first option is characterized by simplicity and minimal costs for components. The second method is used in new buildings.

Dependent method

The specificity of the scheme is an in-house heating unit with an elevator. The heat station mixer mixes hot water from the external main with the return one. The coolant receives a temperature of up to 100 degrees. The advantages of dependent systems include:

- supply of water for heating and supply directly from the heating main;

- simplicity and inexpensive price of input equipment for one subscriber;

- withstand large temperature fluctuations;

- small pipe diameter;

- reduction of coolant consumption.

Disadvantages of central heating include high water consumption, difficulties with temperature control and excessive energy consumption.

The internal line is dependent on external heat supply.

Independent way

The scheme provides for the presence of a main and additional circulation circuits, which are separated by a heat exchanger. In the main circuit, water is supplied from the boiler house or thermal power plant to the central heating station, and is directed from it to the heat exchanger. An additional circuit will be home heating, receiving heat from the network.

The system operates on the principle of heating water in two isolated circuits. The mechanism of the external heating main works on a closed internal network without further mixing of the liquid. The advantages of an independent scheme include:

- the ability to connect any number of heat exchangers;

- use of water for heating and household purposes;

- no pressure fluctuations in the home circuit;

- adjusting the temperature in the rooms using a thermostat;

- availability of drinking water in the domestic hot water supply system;

- filtration of coolant from salts in a small circuit.

Disadvantages of communications are the need for periodic flushing of the heat exchanger, the cost of purchasing equipment and control elements.

Ratings

Which scheme is better for the consumer?

If the main criterion is water quality, there is no doubt. Heating with a boiler or water heater is much more practical than supplying hot water from an elevator unit. The fact is that network water is positioned as technical water and is intended only for household needs, but the cold water supply system is supplied with drinking water that complies with SanPiN 2.1.4.1074-01.

Hot water from the tap is not always clean.

Another evaluation criterion is the price of a cubic meter of water. Let's do a simple calculation with our own hands - calculate the cost of a cubic meter of cold water heated by an electric boiler and compare it with the cost of a cubic meter of hot water.

As a starting point, I will take the tariffs current at the beginning of 2022 for Moscow:

- A cubic meter of cold water without drainage costs 30 rubles;

- A cube of hot water costs 160 rubles;

- A kilowatt-hour of electricity at a single-rate tariff is 5 rubles.

A few additional conditions:

- The average cold water temperature at the entrance to the house is approximately 15 degrees;

- Target DHW temperature is 70 degrees;

- To simplify the calculations, I will neglect the heat loss of the boiler through the thermal insulation, taking its efficiency equal to 100%;

An electric boiler loses at least 2 kWh of heat per day through the thermal insulation of the tank.

To heat a cubic meter of water by 1C, 1.1631 kilowatt-hours of heat is required.

Next is a simple calculation:

- It will take 1.1631 * (70 - 15) = 64 (rounded) kilowatt-hours of electricity to heat a cube of cold water to the target temperature;

- Taking into account the cost of cold water and electricity tariffs, they will cost 64 * 5 + 30 = 350 rubles, which is more than two times the cost of a cubic meter of hot water.

The instructions are obvious: if you want to save on utilities, using your own electric boiler is definitely not worth it.

Centralized hot water supply will be cheaper.

https://youtube.com/watch?v=vVEj7wcr1ik

Features of pipe routing

Layout of elements in a one-pipe and two-pipe system

Depending on the location of the main pipe, the technology for connecting batteries, and supply risers, the wiring technology is selected.

One-pipe method

When single-pipe wiring is used, a horizontal and vertical diagram is used. Laying pipes horizontally eliminates the possibility of adjusting the amount of water, so bypasses are additionally used. The vertical location of the highway is typical for high-rise buildings.

Two-pipe method

The two-pipe wiring method provides for the supply of two lines to one radiator - for supplying warm water and discharging cold water. The following schemes can be implemented in an apartment or house:

- gravity - circulation of warm water occurs naturally;

- classical – dead-end type system;

- annular - the coolant moves along the same path;

- radiant - heat is supplied from the distribution manifold to the radiators individually.

The two-pipe system is suitable for heated floors, where the heating circuits play the role of radiators, and the pipes and comb with mixer act as highways.

What is the brand of cable

The wire grade is a letter designation that characterizes the material of the current-carrying conductors, insulation, degree of flexibility and design of protective covers. The following designations are used in the labeling of domestic goods:

- The first letter indicates the material of the conductor (say, A - aluminum). The absence of a letter in the brand means that the conductor is made of copper.

- The second letter represents the wire.

- The third is the insulation material (for example, R - rubber, B - polyvinyl chloride, P - polyethylene).

Marks of wires and cords may also contain letters characterizing other structural elements:

- O - braid.

- T - for installation in pipes.

- P - flat.

- F - metal folded shell.

- G— flexible, etc.

Types of wire

Types of communications by type of circulation

Types of water circulation in a heating system

In open and closed lines, the coolant can move in two ways.

Natural circulation

The system is organized without a pump and operates on the difference in liquid density during heating and cooling. The coolant is heated in the boiler, becomes less dense and light, and as a result is directed upward. In a cold state, water moves through the outlet riser - a pipe with a large diameter. Along the wiring and to the heating devices, the coolant moves from top to bottom, cooling as heat is released.

When cold, the density of water increases and it is directed to the heating tank. The pipeline is installed at an angle. The system is characterized by energy independence - it can be used in a private home or in a country house. Among the disadvantages of natural circulation:

- complexity of installation due to large diameter pipes;

- unaesthetic appearance;

- the need to periodically top up the coolant;

- small area of heated rooms.

The system uses a leaky open container.

Forced circulation

A circulation pump is used for communications, activating the movement of water. The system is characterized by simplicity of arrangement, advanced capabilities and small pipe diameter. The user regulates the temperature himself or sets it automatically. The disadvantage of forced circulation is energy dependence.

Autonomous heat supply of a residential building

In old-type buildings, the design provides for a centralized system. Individual schemes allow you to choose the types of heat supply systems in terms of reducing energy costs. There is the possibility of turning them off mobile if there is no need.

Autonomous systems are designed taking into account heating standards. Without this, it is impossible to put the house into operation. Following the standards guarantees comfortable living conditions for the residents of the house.

The source of water heating is usually a gas or electric boiler. It is necessary to choose a method for flushing the system. In centralized systems, the hydrodynamic method is used. For autonomous use, you can use a chemical one. In this case, it is necessary to take into account the safety of the influence of reagents on radiators and pipes.

Installation rules

Open expansion tank

The rules for connecting equipment and creating a system depend on its type.

Requirements for installation of an open system

When setting up you should:

- Select the lowest point for the heat source and the highest point for the tank.

- Use pipes with a large diameter for the movement of coolant.

- A narrow pipeline is necessary to normalize pressure.

- Install a high riser that will distribute the water evenly.

- Avoid a large number of turns, forks and connections.

- Install the system in a limited space - up to 159 square meters.

- In private households it is better to install a good circulation system.

The open system is suitable for a small country house or cottage.

Installation procedure for a closed system

Closed expansion tank

If a closed heating system with a pump and expansion tank is installed, you must:

- Place the boiler in the basement and the expansion tank in the attic.

- Ensure high-quality thermal insulation of rooms with a container and riser.

- Do not use a large number of shaped elements.

- Avoid overheating the water.

- Drain the coolant if the system does not start in winter.

- Form a pipe slope of 2-3 mm per 1 m of contour.

The principles for calculating the cross-section and slope of a closed heating pipeline are prescribed in SNiP 2.04.01-85.

Pump insertion into the heating circuit

It is recommended to install the circulation pump on the return pipe, in which case the already cooled liquid will pass through the device. However, when using more modern models, which are made of heat-resistant materials, tapping into the supply line is not excluded. In any case, the installed equipment should not interfere with the circulation of the coolant.

There are several options for changing the gravitational scheme to a forced version:

- Installing the expansion tank at a higher level. This option can be called the simplest, but this will require a high attic space.

- The expansion tank is moved to the far riser. If you use this method to reconstruct an old system, it will require a lot of effort and time. If a new system is developed according to this scheme, it will not justify itself.

- Placing the riser of the expansion tank in close proximity to the elbow on which the pump is located. In this case, the pipe with the reservoir is cut out from the supply line and embedded in the return pipe behind the pump.

- Pump insertion into the supply line. This method is considered the most optimal option for reconstructing the heating circuit. However, it should be remembered that not every device can withstand high temperatures.

In order for a heating system with an open expansion tank and pump to work efficiently, it is important to choose the right circuit, calculate the parameters of all component elements, select the appropriate equipment and consistently carry out installation work.

Independent organization of the heating system

Arrangement of a boiler room

A good and high-quality heating option can be done with your own hands, if you take into account the costs of design, purchase of equipment and the complexity of the organization. The best option for a private home would be a closed type of communications with a circulation pump and tanks. Its creation is carried out like this:

- Communication calculations. Ordered from a design company or produced using an online calculator.

- Coordination of the project, obtaining permits and technical conditions.

- Purchase of equipment. You will need a heating boiler, a pump, pipes, an expansion tank, radiators (circuits if you plan to have a heated floor), air vents, shut-off devices, and automatic controllers.

- Boiler installation and boiler room equipment. High-quality ventilation is organized in the room and a chimney is installed. The walls, floor and ceiling surfaces are sheathed with fire-resistant materials.

- Installation of a circulation pump, distribution manifold and measuring instruments.

- Pipeline connections to battery locations.

- Installation of radiators.

- Pressure testing of the system. The first launch is carried out in the presence of specialists.

The collector circuit is difficult to install and is expensive, but by adjusting the circuits, the living conditions in the room will be comfortable.

There are several differences between open and closed heat supply communications. It is worth choosing a heating system depending on the conditions and installation location. It is easy to organize an open highway yourself. Specialists must create a closed system.

Drawing up a heat supply diagram

The heat supply scheme is a pre-design document that reflects legal relations, conditions for the functioning and development of the heat supply system for an urban district or settlement. In relation to it, federal law includes certain norms.

- Heat supply schemes for settlements are approved by executive authorities or local governments, depending on the population size.

- For the corresponding territory there must be a single heat supply organization.

- The diagram indicates energy sources, indicating their main parameters (load, work schedules, etc.) and range.

- Measures are indicated to develop the heat supply system, conserve excess capacity, and create conditions for its uninterrupted operation.

Heat supply facilities are located within the boundaries of the settlement according to the approved scheme.

The main disadvantages of water as a coolant[edit]

The main disadvantages of water as a coolant:

- greater energy consumption for pumping network water compared to its consumption for pumping condensate in steam systems;

- greater “sensitivity” to accidents, since coolant leaks from steam networks due to significant specific volumes of steam are many (about 20-40) times less than in water systems (with minor damage, steam networks can remain in operation for a long time, while water systems require shutdown);

- high coolant density and rigid hydraulic connection between all points of the system.

According to the conditions for satisfying the thermal conditions of subscriber installations, determined by the average temperature of the coolant in the subscriber heat exchangers, water and steam can be considered equivalent coolants. Only in special cases, when steam is used directly for the technological process (blowing, steaming, etc.), can it not be replaced with water.

When supplying heat from boiler steam, it is also used for heat loads of low potential. The correct choice of coolant parameters is of great importance. When supplying heat from boiler houses, it is, as a rule, rational to choose high coolant parameters that are permissible under the conditions of the technology for transporting heat through the network and using it in subscriber installations. Increasing the parameters of the coolant leads to a decrease in the diameters of the heating network and a reduction in pumping costs (with water). When heating, it is necessary to take into account the influence of coolant parameters on the economics of the thermal power plant. The choice of a closed or open water heating system depends mainly on the water supply conditions of the thermal power plant, the quality of tap water (hardness, corrosiveness, oxidation) and the available sources of low-grade heat for hot water supply.

A prerequisite for both open and closed heat supply systems is to ensure stable quality of hot water for subscribers in accordance with GOST 2974-82* “Drinking water”. In most cases, the quality of the source tap water determines the choice of heating system. The primary use of each of the heat supply systems under consideration is determined by the following indicators of the source tap water. With a closed system: saturation index J > - 0.5; carbonate hardness FA≤7 mg-eq/l; (Cl + 3O4) ≤ 200 mg/l; permanganate oxidation is not regulated. With an open system: permanganate oxidation O < 4 mg/l; saturation index, carbonate hardness, chloride and sulfate concentrations are not regulated.

With increased oxidation (O > 4 mg/l) in stagnant zones of open heating systems (radiators of heating installations, etc.), microbiological processes develop, the consequence of which is sulfide pollution of water. Thus, water taken from heating installations for hot water supply has an unpleasant hydrogen sulfide odor.

In terms of energy indicators and initial costs, modern two-pipe closed and open heat supply systems are on average equivalent. In terms of initial costs, open systems have some economic advantages if the thermal power plant has sources of soft water that does not require water treatment and meets sanitary requirements for drinking water. When using open systems, water for hot water supply is taken from the heating network, which, on the one hand, relieves the cold water supply network and creates in some cases additional economic benefits, and on the other hand, it often forces main water pipelines to be connected to the thermal power plant, which increases capital costs.

In terms of operating costs, open systems are somewhat inferior to closed ones due to additional costs for water treatment. In operation, open systems are more difficult than closed ones due to the instability of the hydraulic regime of the heating network and the complexity of sanitary control of the system density.

For long-distance transportation of heat in areas with a relatively large load of hot water supply, if there are water sources near a thermal power plant or boiler house that meet sanitary requirements, it is economically justified to use an open heat supply system with a single-pipe (unidirectional) transit and a two-pipe distribution network.