Among gas heating boilers, products from European manufacturers are considered leaders in quality and reliability.

However, their approach to the creation of heating equipment does not always fit well into the Russian technological framework.

The products of domestic companies often confidently outperform them in various positions, the main one of which is cost.

Siberia heating boilers are a striking example of such superiority, demonstrating a completely different approach to creating autonomous heating systems.

Let's consider one of the most popular models of boilers from this company.

Model of gas boilers Siberia 23

The Siberia trademark belongs to CJSC Rostovgazoapparat. The company offers floor-standing boilers with an atmospheric burner and a stainless steel heat exchanger.

The Siberia 23 model under consideration is a gas single-circuit unit designed only to power the heating circuit.

There is also a double-circuit option, Siberia 23 K (combined), capable of supplying hot water for household needs in addition to heating the coolant. The numbers “23” in the name mean the thermal power of the model is 23 kW.

Based on the power value, you can roughly determine how much area the boiler can heat by multiplying it by 10.

For example, Siberia 23 is designed to serve premises of 230 m2.

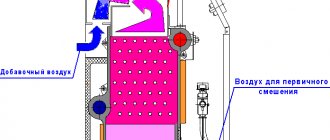

Smoke removal is carried out naturally, using a stove-type draft (atmospheric burner).

Coolant circulation is also based on the process of rising heated layers of liquid upward, which introduces special requirements into the configuration of the heating circuit.

What functions does it have?

The main function that the boiler performs is heating the coolant and supplying it to the heating circuit.

In addition, the boiler has the following capabilities:

- Determining the temperature of a liquid using a thermometer.

- Pressure control using a capillary action pressure gauge.

- Piezo ignition.

- Availability of mechanical sensors for controlling traction, gas pressure, flame.

The list of boiler functions is not as wide as that of imported models, but this does not prevent the device from performing its task efficiently.

IMPORTANT!

The list of functions of the Siberia 23 boiler is quite modest, but this does not indicate the primitiveness of its design, but indicates the absence of unnecessary components and parts that complicate the work.

History of creation

The game was announced on December 14, 2001.

In January 2002, the first details appeared, in particular, the plot of the plot. The release date was set for May of the same year.

Benoit Sokal said the following about working on the game script:

| Almost everything, from my family history to the news on TV and newspaper articles I read, served as a source of inspiration for me. For example, I was watching a TV show about mammoths and how they disappeared thousands of years ago, and I started researching... I actually did some research that lasted about a year to create the plot and characters for Syberia... |

Colleagues confirmed the history of the development of the diology concept:

Specifications

Let's consider the technical parameters of the unit:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems |

| Efficiency | 90 % |

| Serviced area (maximum) | 230 m2 |

| Boiler power | 23 kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 65 kg |

| Dimensions | 850×380×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

Advantages and disadvantages

The advantages of the Siberia 23 model include:

- Reliability, stability of the operating mode, unpretentiousness.

- Economical, low gas consumption.

- Non-volatility, no need to connect to power grids or voltage stabilization.

- The price of boilers of this brand is almost half that of other similar devices.

- The boilers are created taking into account Russian technological operating conditions and are maximally adapted to them.

- Service support available.

The disadvantages of Siberia 23 gas boilers can be considered:

- Ignition of the burner is done manually, which requires some skill.

- Atmospheric thrust is unstable and is often subject to external influences that can change the thrust vector to the opposite.

- The coolant circulation mode is quite weak; it often has to be strengthened using an external circulation pump.

The disadvantages of boilers are due to design features, in particular, energy independence.

However, most users treat the presence of these limitations with understanding, considering the guarantee of stable operation of the unit even during a power outage more important.

NOTE!

If necessary, the draft and circulation of the coolant can be enhanced by installing external devices - a turbo nozzle and a circulation pump. In this case, the system configuration should in any case be calculated so that the boiler can operate independently if the power supply suddenly turns off.

Peculiarities

The Siberia 23 model has the following overall dimensions - 380x850x560 mm (WxHxD), while the weight is 65 kg. Installed on the floor in compliance with all necessary distances from the nearest walls.

Principle and main operating parameters. The convection type of device involves the generation of heat from gas combustion, while the boiler operates on natural gas (methane, consumption 2.3 cubic meters per hour).

The non-volatile operating principle does not require connection to the electrical network and this is a plus, but usually, with this scheme, ignition must be started manually, and the coolant must circulate naturally, without a pump. The downside is the lack of electronic fuel saving algorithms.

Primary heat exchanger. In the case of Siberia 23, steel is used, its advantages are budget cost, lightness and tolerance to shocks and deformations, disadvantages are a little more susceptible to corrosion, less durable, an approximate service life of 5-20 years, depending on the intensity of use.

Management and control

The Siberia 23 gas boiler is mechanically controlled, which means that the main parameters are adjusted only manually and, as a rule, there are few of them; there is no way to save fuel. The advantage is greater reliability than that of an electronic panel and less expensive repairs in case of breakdown.

A thermometer is necessary to monitor the temperature of the coolant in the boiler.

Protection systems

Gas control - a useful and necessary function of the burner automatically stops the gas supply if the flame goes out for any reason.

Connection

- The connecting size for the gas pipe is 3/4″.

- To connect the heating circuit - 2″.

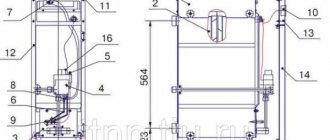

Device

The main design elements of the Siberia 23 boiler are a steel heat exchanger and an open type gas burner. They are combined to obtain maximum effect when working.

In addition, the elements of the unit include:

- A three-way valve in which a colder return flow is mixed into the heated coolant to obtain the desired temperature in the heating circuit.

- Gas equipment, including a magnetic valve, supply system and control unit.

- External chimney (not included in delivery and must be purchased separately).

The operation of the unit consists of the coolant entering the primary steel heat exchanger, heating it to the maximum temperature and passing into a three-way valve. Having reached the operating temperature, the coolant is removed from the boiler and re-entered the heating circuit.

Smoke removal occurs under the influence of natural draft, as does the movement of the coolant.

All work is based on mechanical effects and occurs without the use of electricity.

Main faults of Siberia

The simple design of these boilers does not cause serious malfunctions, especially when users carry out systematic maintenance of the main modules. For this reason, there is practically no interest in spare parts for Siberia gas floor equipment.

The most common operational failures are:

- The piezo igniter or the main burner device does not light well. The most common cause of this failure is poor traction. A possible reason for the lack of combustion is a clogged wick or base burner.

- The pilot burner goes out after 5-15 seconds. This failure indicates reverse draft in the chimney. The reason for this is often an incorrectly designed gas duct: it is too short or too long and there is no deflector.

- The boiler unit does not raise the temperature of the heating water above 60 C. Most often, this occurs due to a clogged gas valve.

- Software failure E01, it indicates the absence of a torch. This can happen when the gas tap is turned off, there is a significant pressure drop in the gas network or surges in the electrical network.

- Failure E04 - pressure drop in the water system is less than 0.7 bar. As a rule, this is due to air locks, leaks, breakage of the expansion tank or safety relief valve.

For which rooms is it best suited?

Siberia 23 boilers are designed for heating residential or public premises with an area of about 230 m2.

This is the most common size for a private home, office, shopping pavilion, etc.

In general, boilers of this model can be used in any premises where there are no strong drafts, multidirectional air flows and constantly opening doors. This is important to ensure stable traction.

How to install correctly

The boiler must be installed in a well-ventilated room with a ceiling height of at least 2 m.

It is placed near a fireproof wall at a distance of at least 15 cm, and there must be a free space of at least 1 m in front of the unit to ensure normal maintenance conditions . If the floor is wooden, a sheet of asbestos is first laid, on top of which a sheet of metal is placed.

They must protrude beyond the boiler body on all sides by at least 10 cm.

Rules for using the equipment

In order for your boiler to last as long as possible, you should handle the equipment without violating the operating rules:

Do not turn on a boiler with a broken burner or a clogged chimney; the case requires grounding; if you use antifreeze as a coolant, then you need to buy a product that has a certificate; It is important that there is no ethylene glycol in the antifreeze. You can read about antifreeze for heating systems here. The water temperature should not exceed 95°C; if you install the device near a wall that is covered with a fire-hazardous material, then the gasket should be made of steel or asbestos; You can turn on the device only after the system is filled with water/antifreeze; Every year it is necessary to clean the chimney and filters. https://youtube.com/watch?v=PZbu_IE6RM8

https://youtube.com/watch?v=PZbu_IE6RM8

Start-up and operating instructions

The boiler is started only after all communications are connected and the system is filled with water.

Needs to be attached:

- Heating circuit forward and return pipelines.

- Water make-up pipeline.

- Gas pipeline.

After this, check the tightness of the connections, paying special attention to the gas pipe. The system is filled by opening the feed tap. When water flows from the signal pipe, the process is completed.

The boiler is turned on by pressing the control knob all the way while simultaneously pressing the ignition button.

They must be held in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

After this, the control knob is set to the desired value, which will cause a flame to appear on the main burner and start the boiler.

Operation of the unit does not require any special actions from the user and consists only of maintaining the cleanliness of the housing.

Once a year, you need to call a technician to clean the internal components, check traction and other important elements.

Also, a technician should be called immediately if problems or unusual behavior of the installation occurs during operation.

Connection and first start-up must be performed by technicians from the service center.

Download instructions

Download instructions for gas boilers Siberia 23.

Price range

The average price for a gas floor-standing boiler Siberia 23 is in the range of 26-28 thousand rubles. Please note that this is only the cost of the boiler itself in the basic configuration . The chimney and other additional devices (if needed) will have to be purchased separately.

IMPORTANT!

The guarantee agreement will also cost some money, but it should not be ignored. In the event of a breakdown or other problem, the ability to quickly have a qualified repair will be invaluable.

Competitors

Table. Comparison with competitors and analogues Photo ModelRatingPrice

| sample in the Siberia 23 review | 4,5 | RUB 27,600 |

| Bosch Gaz 6000 W WBN 6000-18 N | 6,5 | RUB 30,589 |

| Navien DELUXE PLUS 16K | 6,8 | RUB 30,325 |

| BaltGaz NEVA 18 Turbo | 6,9 | RUB 28,500 |

| Borinskoe AKGV-23.2 Eurosit | 4,6 | RUB 26,050 |

| Lemax Premium-16B | 5,1 | RUB 28,400 |

| Conord KSts-GV-16S | 4,6 | 26,500 rub. |

| Conord KSts-GV-20S | 4,6 | RUB 26,337 |

| Conord KSts-GV-20N | 4,6 | RUB 26,750 |

| MORA-TOP Meteor PK24ST | 6 | RUB 26,200 |

Sources

- https://expert-dacha.pro/otoplenie/kotly-ot/gazovye-k/proizvoditeli-gaz-k/gk-siberiya/sib-23.html

- https://ExpertKotel.ru/cat/siberia/siberia-23

[collapse]